Академический Документы

Профессиональный Документы

Культура Документы

TD Tip Tinner PDF

Загружено:

behzadИсходное описание:

Оригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

TD Tip Tinner PDF

Загружено:

behzadАвторское право:

Доступные форматы

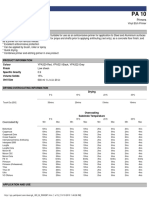

TIP TINNER

INTERFLUX ELECTRONICS N.V.

Technical data Tip Tinner

latest version on www.interflux.com

Ver: 2.0 28-08-12

Page 1

Soldering tip tinner for hand soldering irons

Description: The Interflux TIP TINNER is designed to keep wettable soldering tips in a good condition. It cleans off carbonized flux residues and simultaneously re-tins oxidized soldering tips of hand (de)-soldering equipment. The Interflux TIP TINNER does not contain halogens or abrasive materials that can damage the surface of the soldering tip. Correct use of the TIP TINNER can increase the life time of soldering tips substantially. A clean soldering tip gives better heat transfer and will optimize the takt times in a hand soldering process. Application: After the soldering operation, the soldering tip is dipped into the TIP TINNER and moved gently around until wetting of the tip has occurred. After that, the excess solder is wiped off on a damp sponge. It is advisable not to use cleaning tools, like metallic sponges, scraping tools, abrasive tip tinners,... as they may damage the Physical and chemical properties:

Specific density Colour Odour Solubility in water Alloy : 1.704 g/ml 0.1 : grey : mild : insoluble : Sn99,3Cu0,7

N.V. INTERFLUX ELECTRONICS S.A. - Eddastraat 51BE-9042 Gent tel.: +32-9-251.49.59 fax.: +32-9-251.49.70

surface of the soldering tip. This initial damage can quickly lead to the destruction of the soldering tip, especially with lead-free alloys. To enhance the cleaning of heavily oxidised soldering tips, lower the tip temperature to about 250C-320C. It is advisable to use the Tip Tinner after the soldering operation, before putting it back into the holder. The frequency of the cleaning can be adapted towards the needs of each individual process and will depend on the soldering temperature, the type of solder wire and the frequency of use. Small emissions of smoke are inherent to the process. As for any hand soldering operation, an air extraction is advised.

More information:

Test results P.2

Packaging

P.2

Key advantages: Easy applicable Efficient cleaning action Faster soldering due to better heat transfer Increased tip life Absolutely halogen free

www.interflux.com

Page 2

Technical data Tip Tinner

Test results:

Surface Insulation Resistance test (SIR): according to J-STD-004A, IPC-TM-650 Method 2.6.3.3

For this test, the soldering tip was dipped into the Tip Tinner, excess solder was wiped off on a damp sponge and the comb patterns were soldered with a no-clean, halogen free, lead-free solder wire.

Result : Pass

Packaging:

The TIP TINNER is available in the following packages: 30 g metal can

Trade name: Interflux Tip Tinner

Because we cannot anticipate or control the many different conditions under which this information and our products may be u sed, we do not guarantee the applicability or the accuracy of this information or the suitability of our products in any given situation. Users of our products should make their own test to determine the suitability of each such product for their particular purposes. The product discussed is sold without such warranty, either expressed or implied.

Product information in other European languages can be obtained at Interflux Electronics NV, 9042 Gent.

Copyright: INTERFLUX ELECTRONICS

For the latest version of this document please consult:

www.interflux.com

N.V. INTERFLUX ELECTRONICS S.A. - Eddastraat 51BE-9042 Gent tel.: +32-9-251.49.59 fax.: +32-9-251.49.70

www.interflux.com

Вам также может понравиться

- TD If 9009ltДокумент4 страницыTD If 9009ltbehzadОценок пока нет

- 13 Depliant 1000V - LowДокумент64 страницы13 Depliant 1000V - LowChetankumar ChaudhariОценок пока нет

- Pa 10Документ3 страницыPa 10LymeParkОценок пока нет

- Solder Paste LP 5707: No-Clean, Halide Free, Lead-Free Solder PasteДокумент4 страницыSolder Paste LP 5707: No-Clean, Halide Free, Lead-Free Solder PastebehzadОценок пока нет

- Inductive Sensor Brochure UKДокумент20 страницInductive Sensor Brochure UKifm electronicОценок пока нет

- Rasheed Panther TD SbaДокумент42 страницыRasheed Panther TD Sbasheedy pantherОценок пока нет

- Weller Portasol P-1K EnglishДокумент3 страницыWeller Portasol P-1K EnglishMark RobbinsОценок пока нет

- Dry Machiningof T6061 Aluminium Alloy Using Titanium Carbonitride Ti CNcoatedtoolsДокумент6 страницDry Machiningof T6061 Aluminium Alloy Using Titanium Carbonitride Ti CNcoatedtoolsJesslyne CheniaОценок пока нет

- Toggle Valves Series Tgv01Документ6 страницToggle Valves Series Tgv01Uzair AnsariОценок пока нет

- Sentry Industrial Dry Chemical Hand Portable Extinguishers: Data/SpecificationsДокумент2 страницыSentry Industrial Dry Chemical Hand Portable Extinguishers: Data/SpecificationsjohnzepolОценок пока нет

- E 57220088Документ28 страницE 57220088Mohammed Al-shalfouhОценок пока нет

- 07 Katalog E-I Lemp Intercable EngДокумент257 страниц07 Katalog E-I Lemp Intercable EngCristian Anghel100% (1)

- Catalogue FBI GeneralДокумент10 страницCatalogue FBI Generaldanielph15Оценок пока нет

- Leaflet EasyStar - enДокумент2 страницыLeaflet EasyStar - enA JunedОценок пока нет

- Flex MasterДокумент9 страницFlex MastervanillalavenderОценок пока нет

- Catálogo de Herramientas Phoenix Contact 2Документ44 страницыCatálogo de Herramientas Phoenix Contact 2Auxiliadora LopezОценок пока нет

- Hose Technic DataДокумент28 страницHose Technic Dataerol_ay98Оценок пока нет

- Help With Nickel Alloy Welding - GA5Документ5 страницHelp With Nickel Alloy Welding - GA5chompink6900Оценок пока нет

- N1500i Literature May10Документ2 страницыN1500i Literature May10haist67100% (1)

- Yokogawa-WIKA C13WT+series Ed0Документ20 страницYokogawa-WIKA C13WT+series Ed0haisamsarwarОценок пока нет

- Folija Za StampuДокумент1 страницаFolija Za StampuIvan NikodijevicОценок пока нет

- PIC TechnicalNote P885T0001 PDFДокумент2 страницыPIC TechnicalNote P885T0001 PDFNuraidinAzisОценок пока нет

- JuradoДокумент45 страницJuradoMichelangeloОценок пока нет

- Vulcoferran 2194.20140129.en - TI.sy000152K00Документ2 страницыVulcoferran 2194.20140129.en - TI.sy000152K00domingo_carbajalОценок пока нет

- Catalog MeinhardДокумент108 страницCatalog Meinhardvarian1221Оценок пока нет

- Katunap KatunAP-0708EAMEДокумент58 страницKatunap KatunAP-0708EAMERandula SigeraОценок пока нет

- Unifire Nozzle SpecificationsДокумент16 страницUnifire Nozzle Specificationskothat82Оценок пока нет

- IT Hypalon Glove SpecДокумент2 страницыIT Hypalon Glove SpecedsonleviОценок пока нет

- HR3200C HR3210C HR3210FCT: GB Ua PL Ro de Hu SK CZДокумент56 страницHR3200C HR3210C HR3210FCT: GB Ua PL Ro de Hu SK CZMarian StoicaОценок пока нет

- Type 330 All-Welded Flush Mini Diaphragm Seal: Product FeaturesДокумент2 страницыType 330 All-Welded Flush Mini Diaphragm Seal: Product FeatureshdrОценок пока нет

- DB GB NK10Документ4 страницыDB GB NK10cadhoaОценок пока нет

- Hanstar Long Life Soldering Tip (Lead Free) : 900M Series 900L SeriesДокумент6 страницHanstar Long Life Soldering Tip (Lead Free) : 900M Series 900L SeriesFerdinand EstanislaoОценок пока нет

- Impact: Wear Resistant SteelДокумент6 страницImpact: Wear Resistant SteelmazuckОценок пока нет

- 5 Herramientas y Equipo para ServicioДокумент17 страниц5 Herramientas y Equipo para ServicioPablo TovarОценок пока нет

- Productdatasheet Rigips Fixing Screw FNДокумент2 страницыProductdatasheet Rigips Fixing Screw FNzaxaxazОценок пока нет

- Lukas KatalogДокумент31 страницаLukas KatalogJosko SpehОценок пока нет

- Installation Instructions For Platinum Resistance Thermometers.Документ4 страницыInstallation Instructions For Platinum Resistance Thermometers.username3015Оценок пока нет

- Chemical Comparison ListДокумент6 страницChemical Comparison ListMuhd Khir RazaniОценок пока нет

- Wagner SprayerДокумент12 страницWagner SprayerkenyutОценок пока нет

- 2020 1910 Embedment Tests Nail Screws 3253RPTДокумент8 страниц2020 1910 Embedment Tests Nail Screws 3253RPTMiguel SaОценок пока нет

- Caudalímetros Zona IndustrialДокумент29 страницCaudalímetros Zona IndustrialpabloОценок пока нет

- Ultrasonic Flow Meter UltraFlow 2500 Data SheetДокумент4 страницыUltrasonic Flow Meter UltraFlow 2500 Data SheetSaman Raza KhanОценок пока нет

- Application Instructions Application InstructionsДокумент5 страницApplication Instructions Application InstructionsmameeranОценок пока нет

- AI Hempe's Galvosil 15780 EnglishДокумент5 страницAI Hempe's Galvosil 15780 EnglishTamerGalhoumОценок пока нет

- Fire Fighting Hose - 12 Bar - EN 694 Typ A1: Application: Temperature RangeДокумент1 страницаFire Fighting Hose - 12 Bar - EN 694 Typ A1: Application: Temperature RangeKok WaiОценок пока нет

- Bollhoff Quicksert Expansion InsertsДокумент4 страницыBollhoff Quicksert Expansion InsertsAce Industrial SuppliesОценок пока нет

- Product Overview: Simple. Good. AffordableДокумент32 страницыProduct Overview: Simple. Good. AffordableTabure22Оценок пока нет

- Yokogawa DIN CEДокумент36 страницYokogawa DIN CEAnonymous XS9jAhY1pEОценок пока нет

- Convoluted - Bore PTFE Hose, Series C-CON (MS-02-351) R1Документ2 страницыConvoluted - Bore PTFE Hose, Series C-CON (MS-02-351) R1herysyam1980Оценок пока нет

- HEAT RESISTANT SILICONE ALUMINIUM PAINTДокумент3 страницыHEAT RESISTANT SILICONE ALUMINIUM PAINTrumi_2kОценок пока нет

- Red Line Class D Extinguishers: FeaturesДокумент2 страницыRed Line Class D Extinguishers: FeaturesEduleofОценок пока нет

- Basic Info TK-U.B.I Sleeves3Документ17 страницBasic Info TK-U.B.I Sleeves3Saradhi MedapureddyОценок пока нет

- Nesl Training ManualДокумент91 страницаNesl Training ManualSOUMYA DEEP CHATTERJEEОценок пока нет

- Elements Re51420 2010-10Документ14 страницElements Re51420 2010-10Admir TalicОценок пока нет

- Merenje ProtokaДокумент468 страницMerenje Protokasokol_poleceОценок пока нет

- SeminarДокумент17 страницSeminarRisvin RafeequeОценок пока нет

- Flame Arrestor With ThermometerДокумент9 страницFlame Arrestor With ThermometervasuОценок пока нет

- Tooling TechДокумент24 страницыTooling TechLeonel RochaОценок пока нет

- Weld Like a Pro: Beginning to Advanced TechniquesОт EverandWeld Like a Pro: Beginning to Advanced TechniquesРейтинг: 4.5 из 5 звезд4.5/5 (6)

- Miniature magnetic field sensor FLC 100Документ2 страницыMiniature magnetic field sensor FLC 100behzadОценок пока нет

- Ijarece Vol 3 Issue 3 347 350 PDFДокумент4 страницыIjarece Vol 3 Issue 3 347 350 PDFbehzadОценок пока нет

- Low ESR polymer capacitors application guideДокумент31 страницаLow ESR polymer capacitors application guidebehzadОценок пока нет

- EMRLДокумент1 страницаEMRLbehzadОценок пока нет

- FravaharДокумент11 страницFravaharbehzadОценок пока нет

- 1N5817Документ3 страницы1N5817Gallego OrtizОценок пока нет

- فرهنگ چیستДокумент15 страницفرهنگ چیستJonbeshEnghelabiОценок пока нет

- Farsi FATEk PDFДокумент147 страницFarsi FATEk PDFbehzadОценок пока нет

- Fravahar 2Документ16 страницFravahar 2behzadОценок пока нет

- Large Capacitance Aluminum Electrolytic Capacitors: S I EsДокумент2 страницыLarge Capacitance Aluminum Electrolytic Capacitors: S I EsbehzadОценок пока нет

- EXR series capacitors for switching power suppliesДокумент2 страницыEXR series capacitors for switching power suppliesbehzadОценок пока нет

- Miniature Size: 7Mml 85, Standard CДокумент1 страницаMiniature Size: 7Mml 85, Standard CbehzadОценок пока нет

- SGH13N60UFDДокумент8 страницSGH13N60UFDbehzadОценок пока нет

- Features General Description: Advanced Dual PWM and Dual Linear Power ControllerДокумент13 страницFeatures General Description: Advanced Dual PWM and Dual Linear Power ControllerbehzadОценок пока нет

- Chopper Regulator, DC DC Converter and Motor Drive ApplicationsДокумент6 страницChopper Regulator, DC DC Converter and Motor Drive ApplicationsbehzadОценок пока нет

- High Current MOSFET Polarity Switch: 126 Ridge Road - P.O. Box 187 - Lansing, NY 14882Документ1 страницаHigh Current MOSFET Polarity Switch: 126 Ridge Road - P.O. Box 187 - Lansing, NY 14882behzadОценок пока нет

- Installation Instructions SL417U Model SeriesДокумент2 страницыInstallation Instructions SL417U Model SeriesbehzadОценок пока нет

- CДокумент14 страницCbehzadОценок пока нет

- Summary - Directional Antennas Dual-Band 800/900 - 1800/2000Документ30 страницSummary - Directional Antennas Dual-Band 800/900 - 1800/2000behzadОценок пока нет

- 99812028Документ1 страница99812028behzadОценок пока нет

- High Power Resistors for Industrial ApplicationsДокумент3 страницыHigh Power Resistors for Industrial ApplicationsbehzadОценок пока нет

- Fuses & Fuseholders: 6.3x32mm ( "x1 ") Glass and Ceramic FusesДокумент1 страницаFuses & Fuseholders: 6.3x32mm ( "x1 ") Glass and Ceramic FusesbehzadОценок пока нет

- cp3505 Error Messages PDFДокумент24 страницыcp3505 Error Messages PDFbehzadОценок пока нет

- Fuses & Fuseholders: 6.3x32mm ( "x1 ") Glass and Ceramic FusesДокумент1 страницаFuses & Fuseholders: 6.3x32mm ( "x1 ") Glass and Ceramic FusesbehzadОценок пока нет

- How To Solder 0902e PDFДокумент26 страницHow To Solder 0902e PDFbehzad100% (1)

- Avr Family PDFДокумент6 страницAvr Family PDFbehzadОценок пока нет

- Tweezer Style Passive Component R/C SMD: One-Hand OperationДокумент1 страницаTweezer Style Passive Component R/C SMD: One-Hand OperationbehzadОценок пока нет

- Robot3 PDFДокумент8 страницRobot3 PDFbehzadОценок пока нет

- Remanufacturing Instructions: HP Color Laserjet 3000/3600/3800Документ9 страницRemanufacturing Instructions: HP Color Laserjet 3000/3600/3800behzadОценок пока нет

- Smart Tweezers Manual ST5 PDFДокумент16 страницSmart Tweezers Manual ST5 PDFbehzadОценок пока нет

- Chemical Cleaning Products Are Destroying The Ecosystem and Your Septic Tank - Organica BiotechДокумент14 страницChemical Cleaning Products Are Destroying The Ecosystem and Your Septic Tank - Organica BiotechKrispin FongОценок пока нет

- Raychem Price ListДокумент48 страницRaychem Price ListramshivvermaОценок пока нет

- Nature and Scope of Marketing Marketing ManagementДокумент51 страницаNature and Scope of Marketing Marketing ManagementFeker H. MariamОценок пока нет

- Ch. 7 - Audit Reports CA Study NotesДокумент3 страницыCh. 7 - Audit Reports CA Study NotesUnpredictable TalentОценок пока нет

- SIM5320 - EVB Kit - User Guide - V1.01 PDFДокумент24 страницыSIM5320 - EVB Kit - User Guide - V1.01 PDFmarkissmuzzoОценок пока нет

- Executive Education Portfolio Soft Copy-INSEADДокумент58 страницExecutive Education Portfolio Soft Copy-INSEADОля КусраеваОценок пока нет

- Where On Earth Can Go Next?: AppleДокумент100 страницWhere On Earth Can Go Next?: Applepetrushevski_designeОценок пока нет

- 3 Steel Grating Catalogue 2010 - SERIES 1 PDFДокумент6 страниц3 Steel Grating Catalogue 2010 - SERIES 1 PDFPablo MatrakaОценок пока нет

- Zhihua Yao - Dignaga and The 4 Types of Perception (JIP 04)Документ24 страницыZhihua Yao - Dignaga and The 4 Types of Perception (JIP 04)Carlos Caicedo-Russi100% (1)

- Khaton Prayer BookДокумент47 страницKhaton Prayer BookKarma TsheringОценок пока нет

- Critique On A Film Director's Approach To Managing CreativityДокумент2 страницыCritique On A Film Director's Approach To Managing CreativityDax GaffudОценок пока нет

- Manju Philip CVДокумент2 страницыManju Philip CVManju PhilipОценок пока нет

- Dell EMC VPLEX For All-FlashДокумент4 страницыDell EMC VPLEX For All-Flashghazal AshouriОценок пока нет

- Docking 1Документ12 страницDocking 1Naveen Virendra SinghОценок пока нет

- Form 1 AДокумент2 страницыForm 1 ARohit Jain100% (1)

- Analysis of VariancesДокумент40 страницAnalysis of VariancesSameer MalhotraОценок пока нет

- E PortfolioДокумент76 страницE PortfolioMAGALLON ANDREWОценок пока нет

- Electronic Harassment Strahlenfolter - A Short History of Sound Weapons Pt2 - InfrasoundДокумент10 страницElectronic Harassment Strahlenfolter - A Short History of Sound Weapons Pt2 - InfrasoundFrank-BoenischОценок пока нет

- Global 6000 SystemsДокумент157 страницGlobal 6000 SystemsJosé Rezende100% (1)

- Brooks Cole Empowerment Series Becoming An Effective Policy Advocate 7Th Edition Jansson Solutions Manual Full Chapter PDFДокумент36 страницBrooks Cole Empowerment Series Becoming An Effective Policy Advocate 7Th Edition Jansson Solutions Manual Full Chapter PDFlois.guzman538100% (12)

- STERNOL Specification ToolДокумент15 страницSTERNOL Specification ToolMahdyZargarОценок пока нет

- 2.0 - SITHKOP002 - Plan and Cost Basic Menus Student GuideДокумент92 страницы2.0 - SITHKOP002 - Plan and Cost Basic Menus Student Guidebash qwertОценок пока нет

- C11 RacloprideДокумент5 страницC11 RacloprideAvina 123Оценок пока нет

- Rakpoxy 150 HB PrimerДокумент1 страницаRakpoxy 150 HB Primernate anantathatОценок пока нет

- CHEM206 Answers 1Документ3 страницыCHEM206 Answers 1Shiro UchihaОценок пока нет

- HP OpenVMS Alpha Version 8.3 and HP OpenVMS Version 8.3-1H1 For IntegrityДокумент65 страницHP OpenVMS Alpha Version 8.3 and HP OpenVMS Version 8.3-1H1 For IntegrityAlexandru BotnariОценок пока нет

- Class 9th Chemistry Unit#4 Structure of MoleculesДокумент8 страницClass 9th Chemistry Unit#4 Structure of MoleculesIrfanullahОценок пока нет

- Drypro832 PreInstallGude 0921YH220B 070627 FixДокумент23 страницыDrypro832 PreInstallGude 0921YH220B 070627 FixRicardoОценок пока нет

- Power Bi ProjectsДокумент15 страницPower Bi ProjectssandeshОценок пока нет

- The Emperor Jones: What's Inside in ContextДокумент27 страницThe Emperor Jones: What's Inside in ContextHarshvardhan RaiОценок пока нет