Академический Документы

Профессиональный Документы

Культура Документы

D-AAA-TRAFO-ATR-EXP-11 - 200 (Rev.0-2011)

Загружено:

virasamirИсходное описание:

Оригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

D-AAA-TRAFO-ATR-EXP-11 - 200 (Rev.0-2011)

Загружено:

virasamirАвторское право:

Доступные форматы

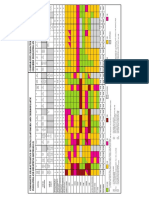

Standard Technical Specifications for Electrical Works

TRANSFORMERS / REACTORS / RESISTORS

( Data Sheets )

Auxiliary/Distribution Transformers (Epoxy-Resin Dry-Type,

Indoor Installation), 200 kVA, 11 5%/0.415 kV

ADWEA/ADDC/AADC STANDARD : D-AAA-TRAFO-ATR-11_200

(Rev.0-2011)

________________________________________________________________________________________

225664272.xls.ms_office

Page 1 of 7

TRANSFORMERS / REACTORS / RESISTORS

Auxiliary/Distribution Transformers (Epoxy-Resin Dry-Type,

Indoor Installation), 200 kVA, 11 5%/0.415 kV

Table of Content

Page

1.00

GENERAL

2.00

RATINGS

3.00

INSULATION LEVEL

3.01

Primary

3.02

Secondary

4.00

PROTECTIVE HOUSING

5.00

TESTS

6.00

OPERATING DETAILS

7.00

DESIGN DETAILS AND FEATURES

8.00

MASSES, MEASURES AND DRAWINGS

_____________________________________________________________________________________________________________

225664272.xls.ms_office

Page 2 of 7

TRANSFORMERS / REACTORS / RESISTORS

Auxiliary/Distribution Transformers (Epoxy-Resin Dry-Type, Indoor Installation), 200 kVA, 11 5%/0.415 kV

Sl. No.

REQUIRED

1.00

GENERAL

1.01

Manufacturer

1.01.1

name

1.01.2

country of manufacturing

TENDERED

1.02

Place of testing

1.03

Kind of installation

1.04

Applicable standards

1.05

Type of core

1.06

Number of windings

two

1.07

Material of windings

Aluminium

1.08

Conductor of windings

2.00

RATINGS

2.01

Rated power

2.02

Service conditions

indoor

IEC

60076, 60726

core type

multi-layer foil

kVA

200

2.02.1

maximum ambient temperature

50

2.02.2

maximum service altitude

1000

2.03

Temperature rise limits

2.03.1

windings average

90

2.03.2

windings hot spot

110

2.04

Thermal class of windings

2.05

Fire behaviour class of transformer

2.06

Rated voltages

class F

class F1

2.06.1

primary

kV

11

2.06.2

secondary at no-load on principle tap

kV

0.415

2.07

Number of phases

2.08

Rated current

2.08.1

primary (at principal tap)

2.08.2

secondary

TENDERER`s STAMP SIGNATURE

___________________________________________________________________________________________________________________

225664272.xls.ms_office

Page 3 of 7

TRANSFORMERS / REACTORS / RESISTORS

Auxiliary/Distribution Transformers (Epoxy-Resin Dry-Type, Indoor Installation), 200 kVA, 11 5%/0.415 kV

Sl. No.

REQUIRED

%

TENDERED

2.09

Permissible load of neutral point

2.10

Vector group symbol

2.11

Rated frequency

Hz

50

2.12

Impedance voltage (120 0C) at full rated power

4.0

2.13

Magnetic flux density

Dyn11

2.13.1

at nominal voltage and frequency

Tesla

2.13.2

at maximum system voltage

Tesla

2.13.3

saturation

Tesla

2.14

100

1.72

Maximum permitted Losses at 1200C, rated voltage,

frequency, full site rated load and main tap

2.14.1

load losses

kW

max. 6.325

2.14.2

no-load losses

kW

max. 1.0

2.15

Tolerance for penality application

2.15.1

.for total losses

2.15.2

.for component losses

2.16

No-load current (Io/In)

2.17

Core losses (W17/50)

W/kg

2.18

Tapping range

2.19

Number of steps

No.

2.20

Tapped winding

2.21

Principal tapping at

3.00

INSULATION LEVEL

3.01

Primary

3.01.1

2 x 2.5

2

HV

kV

11

Power frequency withstand voltage

kV

28

3.01.2

Lightning impulse level

kV

75

3.02

Secondary

3.02.1

Power frequency withstand voltage

kV

4.00

PROTECTIVE HOUSING

TENDERER`s STAMP SIGNATURE

___________________________________________________________________________________________________________________

225664272.xls.ms_office

Page 4 of 7

TRANSFORMERS / REACTORS / RESISTORS

Auxiliary/Distribution Transformers (Epoxy-Resin Dry-Type, Indoor Installation), 200 kVA, 11 5%/0.415 kV

Sl. No.

REQUIRED

IP

TENDERED

4.01

Protection class

min. 21

4.02

Housing prod-proof

5.00

TESTS

5.01

Routine tests according to IEC 60076

and specifications

on each unit

5.02

Separate source AC voltage withstand test

on each unit

yes

5.02.1

test voltage / primary

kV

28

5.02.2

test voltage / secondary

kV

5.03

on each unit

Induced AC voltage withstand test

5.03.1

test voltage / primary

kV

23.1

5.03.2

test voltage / secondary

kV

0.83

5.03.3

test duration

60

5.04

Heat-run test (for pre-qualifucation only)

on one unit

5.05

Full-wave lightning impulse tests (for pre-qualifucation only)

on one unit

5.05.1

test voltage / primary

5.05.2

polarity

5.06

kV

75

positive

Short circuit test (for pre-qualifucation only)

5.06.1

name of independent testing laboratory

who carried out the short circuit test on

similar transformer

5.06.2

test certificates attached

5.06.3

validity of quality control certificate

5.06.4

name of issuing authority

yes

6.00

OPERATING DETAILS

6.01

Cooling method

AN

6.02

Constant power at all taps

yes

6.03

Noise level (LpA) at measuring

distance of 1.0 m

dB(A)

max. 56

TENDERER`s STAMP SIGNATURE

___________________________________________________________________________________________________________________

225664272.xls.ms_office

Page 5 of 7

TRANSFORMERS / REACTORS / RESISTORS

Auxiliary/Distribution Transformers (Epoxy-Resin Dry-Type, Indoor Installation), 200 kVA, 11 5%/0.415 kV

Sl. No.

REQUIRED

6.04

Auxiliary supply voltage

6.05

Permissible over-load and duration (in minutes)

6.05.1

Vac

at 30 0C

min.

6.05.1.2

at 40 0C

min.

6.05.1.3

at 50 0C

min.

6.05.2

30 % over-load

6.05.2.1

at 30 0C

min.

6.05.2.2

at 40 0C

min.

6.05.2.3

at 50 0C

min.

6.05.3

40 % over-load

6.05.3.1

at 30 0C

min.

6.05.3.2

at 40 0C

min.

6.05.3.3

at 50 0C

min.

6.05.4

50 % over-load

6.05.4.1

at 30 0C

min.

6.05.4.2

at 40 0C

min.

6.05.4.3

at 50 0C

min.

7.00

DESIGN DETAILS AND FEATURES

7.01

Current densities at rated power

7.01.1

primary

A/mm2

7.01.2

secondary

A/mm2

Winding resistances at 75 0C

7.02.1

primary

/ Phase

7.02.2

secondary

/ Phase

7.03

400/230

20 % over-load

6.05.1.1

7.02

TENDERED

Insulation material

7.03.1

primary

7.03.2

secondary

7.03.3

tapping leads

TENDERER`s STAMP SIGNATURE

___________________________________________________________________________________________________________________

225664272.xls.ms_office

Page 6 of 7

TRANSFORMERS / REACTORS / RESISTORS

Auxiliary/Distribution Transformers (Epoxy-Resin Dry-Type, Indoor Installation), 200 kVA, 11 5%/0.415 kV

Sl. No.

REQUIRED

7.03.4

7.04

core lamination

Efficiencies

7.04.1

at 25 % of rated power

7.04.2

at 50 % of rated power

7.04.3

at 75 % of rated power

7.04.4

at 100 % of rated power

7.04.5

at 125 % of rated power

7.04.6

at 150 % of rated power

7.05

Voltage regulation at 75 0C and rated power

7.05.1

at power factor 0.80

7.05.2

at power factor 0.85

7.05.3

at power factor 0.90

7.05.4

at power factor 0.95

8.00

MASSES, MEASURES AND DRAWINGS

8.01

Overall dimensions

8.01.1

height

mm

8.01.2

depth

mm

8.01.3

width

mm

8.02

TENDERED

Shipping dimensions

8.02.1

height

mm

8.02.2

depth

mm

8.02.3

width

mm

8.03

Total mass

kg

8.04

Transportation mass

kg

TENDERER`s STAMP SIGNATURE

___________________________________________________________________________________________________________________

225664272.xls.ms_office

Page 7 of 7

Вам также может понравиться

- S Aaa SWG MV Dist 11 Fixed 0.4 Ac (Rev.0 2011)Документ23 страницыS Aaa SWG MV Dist 11 Fixed 0.4 Ac (Rev.0 2011)mahmoudОценок пока нет

- Types of Power Factor CorrectionДокумент52 страницыTypes of Power Factor CorrectionAurobindo Mandal100% (1)

- EmiratesGBC Energy and Water Benchmarking For UAE Hotels 2016 ReportДокумент27 страницEmiratesGBC Energy and Water Benchmarking For UAE Hotels 2016 ReportdharmaОценок пока нет

- Review of Dimming Techniques For Solid-State LED LightsДокумент7 страницReview of Dimming Techniques For Solid-State LED LightsijaertОценок пока нет

- 26 32 13.13 Diesel Engine GeneratorДокумент36 страниц26 32 13.13 Diesel Engine GeneratorDavid Rowland Droyce100% (1)

- EnergyCalculator AspxДокумент2 страницыEnergyCalculator AspxWael AlmassriОценок пока нет

- RM6 Production Plant SFCME-EnДокумент10 страницRM6 Production Plant SFCME-EnNguyen Nga-VietОценок пока нет

- UKPN G81 Design Planning Appendix v1.0 KK 040711Документ20 страницUKPN G81 Design Planning Appendix v1.0 KK 040711Sandeep LallОценок пока нет

- The Electricity Wiring Regulations (Third EditionДокумент139 страницThe Electricity Wiring Regulations (Third EditionAllen AnyayahanОценок пока нет

- Qcs 2010 Section 21 Part 4 Motor StartersДокумент6 страницQcs 2010 Section 21 Part 4 Motor Startersbryanpastor106100% (1)

- 7.short Circuit CalculationsДокумент14 страниц7.short Circuit Calculationskvramanan_1Оценок пока нет

- Cum - Voltage Drop-BASEMENTДокумент12 страницCum - Voltage Drop-BASEMENTprkshshrОценок пока нет

- 628E - Generator Options ReportДокумент19 страниц628E - Generator Options ReportRachel BushОценок пока нет

- 3000kva Transformer DimensionДокумент20 страниц3000kva Transformer DimensionPopoola O. AdedotunОценок пока нет

- Street Lighting Technology ComparisonДокумент7 страницStreet Lighting Technology ComparisonManoj KavediaОценок пока нет

- QuestionsДокумент9 страницQuestionsI Gede Darma Susila100% (1)

- iBusway DC Solution Provides 1.6x Power AvailabilityДокумент25 страницiBusway DC Solution Provides 1.6x Power AvailabilitySargurusivaОценок пока нет

- Qcs 2010 Section 21 Part 5 Variable Speed Controllers PDFДокумент8 страницQcs 2010 Section 21 Part 5 Variable Speed Controllers PDFbryanpastor106Оценок пока нет

- Amtech Quick Guide 2015Документ16 страницAmtech Quick Guide 2015Mohammad SamourОценок пока нет

- LV SWBD Design ProblemДокумент15 страницLV SWBD Design ProblemkggganiОценок пока нет

- Abb - KNX Product Range Overview 2cdc500007b0206Документ70 страницAbb - KNX Product Range Overview 2cdc500007b0206Logain SunОценок пока нет

- Power 2 Slides 2016Документ395 страницPower 2 Slides 2016Ali BabaОценок пока нет

- Electrical Specs KsaДокумент75 страницElectrical Specs KsaMEP299 MAPUAОценок пока нет

- S-AAA-CAB-GEN (Rev.0-2011)Документ35 страницS-AAA-CAB-GEN (Rev.0-2011)Karuppu SamyОценок пока нет

- Current carrying capacity of cablesДокумент3 страницыCurrent carrying capacity of cablesStefanita100% (1)

- The Panama Canal: Third Set of Locks ProjectДокумент33 страницыThe Panama Canal: Third Set of Locks Projectomar_cohen_1Оценок пока нет

- 2012Ch1 Supple NotesДокумент12 страниц2012Ch1 Supple Notesskywalker_handsomeОценок пока нет

- ATC Aluminum ConduitsДокумент4 страницыATC Aluminum Conduitsomh129Оценок пока нет

- Electrical Requirements SummaryДокумент10 страницElectrical Requirements Summaryfarooq929Оценок пока нет

- Networking Working BOQ PDFДокумент9 страницNetworking Working BOQ PDFMuneeb Ur rehmanОценок пока нет

- Brochure SIMARIS Software ToolsДокумент8 страницBrochure SIMARIS Software ToolsDavid LovatoОценок пока нет

- Comparing Characteristics of Elastomeric and Thermoplastic Insulation MaterialsДокумент1 страницаComparing Characteristics of Elastomeric and Thermoplastic Insulation MaterialskapilОценок пока нет

- International Telecommunication Union: RecommendationДокумент25 страницInternational Telecommunication Union: Recommendationghosh_souvikОценок пока нет

- Alumoweld Overhead Ground Wire CharacteristicsДокумент2 страницыAlumoweld Overhead Ground Wire Characteristicsdowner52Оценок пока нет

- Ear Thing and Lightning Protection ProjectДокумент26 страницEar Thing and Lightning Protection ProjectNishrachОценок пока нет

- Protection Study SOWДокумент1 страницаProtection Study SOWnknfiveОценок пока нет

- How To Find The Suitable Size of CableДокумент9 страницHow To Find The Suitable Size of CableMajid GhaffarОценок пока нет

- Wire Basics of Ampacity or Copper Wire Current Carrying Capacity Carrying CapacitiesДокумент3 страницыWire Basics of Ampacity or Copper Wire Current Carrying Capacity Carrying CapacitiesarifardentОценок пока нет

- Calculate Cable Size and Voltage Drop Electrical Notes Articles PDFДокумент10 страницCalculate Cable Size and Voltage Drop Electrical Notes Articles PDFRavi SharmaОценок пока нет

- Operation of Circuit BreakerДокумент21 страницаOperation of Circuit BreakerBossОценок пока нет

- 0 Introduction To Electrical System Design (Lec)Документ12 страниц0 Introduction To Electrical System Design (Lec)EdryanPoОценок пока нет

- List of IEC StandardsДокумент17 страницList of IEC StandardsRagesh JoshiОценок пока нет

- Street LightingДокумент28 страницStreet Lightinganon_688386444Оценок пока нет

- Rowan University Design Guide - PanelboardsДокумент1 страницаRowan University Design Guide - PanelboardszeliteОценок пока нет

- S-AAA-CAB-ACC-LV-S&I (Rev.0-2019)Документ10 страницS-AAA-CAB-ACC-LV-S&I (Rev.0-2019)Wael AlmassriОценок пока нет

- 000 EE 153 CAD For EEE PDFДокумент35 страниц000 EE 153 CAD For EEE PDFStampinusStephanoОценок пока нет

- ITU RecommendationsДокумент25 страницITU Recommendationscoolbuddy_2k4Оценок пока нет

- Electrical Thumb Rules (Part 1)Документ3 страницыElectrical Thumb Rules (Part 1)Manish Tiwari100% (1)

- EDS 08-0136 LV Network Design Standard PDFДокумент21 страницаEDS 08-0136 LV Network Design Standard PDFRajendra Prasad ShuklaОценок пока нет

- Basics of Solar Energy SystemsДокумент41 страницаBasics of Solar Energy SystemsestebanОценок пока нет

- UNI 11248 - EN 13201 TABLESДокумент5 страницUNI 11248 - EN 13201 TABLESelshoubryОценок пока нет

- DIALux Evo ManualДокумент101 страницаDIALux Evo ManualHerby Beiter Jiménez PeredoОценок пока нет

- ELECTRICAL INSTALLATIONSДокумент10 страницELECTRICAL INSTALLATIONSyoga rajОценок пока нет

- SRMU Training at META Co. RiyadhДокумент46 страницSRMU Training at META Co. RiyadhTanveer Ahmad100% (1)

- Electrician's Guide To The Building Regulations (3rd Edition)Документ2 страницыElectrician's Guide To The Building Regulations (3rd Edition)Ahmed Ben Alaya100% (1)

- Practical Guide to International Standardization for Electrical Engineers: Impact on Smart Grid and e-Mobility MarketsОт EverandPractical Guide to International Standardization for Electrical Engineers: Impact on Smart Grid and e-Mobility MarketsОценок пока нет

- Paving The Way For Project Efficiency: Mammoet Enviro-MatДокумент7 страницPaving The Way For Project Efficiency: Mammoet Enviro-MatvirasamirОценок пока нет

- Isin Y A.Practical Bollard-Pu - Jul.1987.MT PDFДокумент6 страницIsin Y A.Practical Bollard-Pu - Jul.1987.MT PDFvirasamirОценок пока нет

- 'Ballasting CalculationДокумент2 страницы'Ballasting CalculationvirasamirОценок пока нет

- Syllabus For HAADДокумент7 страницSyllabus For HAADvirasamir100% (2)

- Supply of Cast Resin Distribution Transformers TenderДокумент178 страницSupply of Cast Resin Distribution Transformers Tendervirasamir0% (5)

- Costing SubstationДокумент20 страницCosting SubstationvirasamirОценок пока нет

- Dust Collection System Explosion Hazards and ProtectionДокумент8 страницDust Collection System Explosion Hazards and ProtectionsguariniОценок пока нет

- Linear System Theory and Desing PDFДокумент688 страницLinear System Theory and Desing PDFJose David MartinezОценок пока нет

- PSC Unit 4 PPT - Part 3Документ35 страницPSC Unit 4 PPT - Part 3Rino VidОценок пока нет

- Management GurusДокумент44 страницыManagement GurusRouben ParmanumОценок пока нет

- High-Temperature Quad 2-Inputs OR Gate DatasheetДокумент6 страницHigh-Temperature Quad 2-Inputs OR Gate DatasheetSalim Abdul Rahman Sa'dyОценок пока нет

- Datasheet CONTI SILENTSYNC ENДокумент1 страницаDatasheet CONTI SILENTSYNC ENViniciusОценок пока нет

- D Screenplay DialoguesДокумент75 страницD Screenplay DialoguesReza GhalibОценок пока нет

- Catalogue 12V Ilss For Polis Bantuan Vehicles (Petronas)Документ7 страницCatalogue 12V Ilss For Polis Bantuan Vehicles (Petronas)Afiq Muizz SallehhoudinОценок пока нет

- 2755 22 (G78A) Milwaukee PBДокумент2 страницы2755 22 (G78A) Milwaukee PBZeckОценок пока нет

- PHD Thesis BentzДокумент320 страницPHD Thesis Bentzcrusanu50% (2)

- PDF 256372311 Pec QC With Answerpdf DDДокумент6 страницPDF 256372311 Pec QC With Answerpdf DDLee Robert OlivarОценок пока нет

- Diagnostic Trouble Code ChartДокумент5 страницDiagnostic Trouble Code ChartGregory AshleyОценок пока нет

- Quiz 12Документ3 страницыQuiz 12mwende faiyuuОценок пока нет

- ABC Vs Acb Phase Seq t60 Get-8431bДокумент3 страницыABC Vs Acb Phase Seq t60 Get-8431bkcirrenwodОценок пока нет

- Stability Data BookletДокумент18 страницStability Data BookletPaul Ashton25% (4)

- MP3 - Equations of StateДокумент8 страницMP3 - Equations of StatePatrick ValdezОценок пока нет

- Kitchen DetailsДокумент12 страницKitchen DetailsAJ PAJEОценок пока нет

- 1724 Albany, Ferndale, MI - Updated, Spacious BungalowДокумент8 страниц1724 Albany, Ferndale, MI - Updated, Spacious BungalowTodd Waller Real EstateОценок пока нет

- 20 Things To Know About The Jeepney Modernization ProgramДокумент2 страницы20 Things To Know About The Jeepney Modernization ProgramMark Julius MaravilloОценок пока нет

- PackagesДокумент2 страницыPackagesSteven MirandaОценок пока нет

- Preliminary: SPCA702AДокумент60 страницPreliminary: SPCA702Avetchboy0% (1)

- En 818-6 PDFДокумент5 страницEn 818-6 PDFlub007Оценок пока нет

- ASSAM - Uniform Zoning Regulation 2000Документ35 страницASSAM - Uniform Zoning Regulation 2000rajatesh1Оценок пока нет

- Aranya Housing Final To Be Submitted PDFДокумент37 страницAranya Housing Final To Be Submitted PDFsucheta100% (4)

- Fls Brochure Usa v2 PDFДокумент4 страницыFls Brochure Usa v2 PDFXa ViОценок пока нет

- CalibrationДокумент7 страницCalibrationstolen mechieducОценок пока нет

- PDFДокумент156 страницPDFVasilescu Corina100% (1)

- Chainsaw SparesДокумент2 страницыChainsaw SpareswanttobeanmacccОценок пока нет

- Design-Rcc Over Head TankДокумент82 страницыDesign-Rcc Over Head Tankjay_p_shah60% (5)

- OEM Industrial Air Handling Products CatalogДокумент31 страницаOEM Industrial Air Handling Products CatalogalexОценок пока нет