Академический Документы

Профессиональный Документы

Культура Документы

BoxRipper Systems For Excavators

Загружено:

fernandojИсходное описание:

Оригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

BoxRipper Systems For Excavators

Загружено:

fernandojАвторское право:

Доступные форматы

BOX RIPPER

SYSTEMS

FOR

EXCAVATORS

HENSLEY

You can break up dense

material without removing your

excavator bucket by using this

updated Box Ripper System

from Hensley.

Hensley Box Ripper Systems

are currently available for use

on five classes of excavators.

Excavator Operating

Class

Weight

(Lbs.)

B200

B250

B300

B350

B400

20,00039,000

40,00059,000

60,00084,000

85,000109,000

110,000169,000

FEATURES INCLUDE:

High quality alloy steel

castings for both box and

ripper shank

Re-engineered tighter fit

between box and shank

New stronger, reusable box

pin to reduce shank

movement

Second box pin location to

further eliminate shank

movement on older systems

Three pin hole locations in

shank to cover greater range

of bucket profiles and ripping

depths

Uses universal Caterpillar

Style ripper teeth

S I N C E 19 47

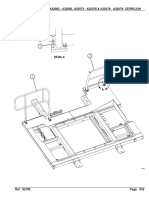

COMPLETE

BOX RIPPER SYSTEM

TYPICAL MACHINE USAGE

System

B200

B250

Machine

Make

B300

B350

B400

Machine Model

J.I. Case

9010B

9020B

9030

9040

9050

9060B

Caterpillar

311, 312

315

215, 225

320, 322

325,

330

235C

350L, 245

Daewoo

S130-3

DH170-2

DH220LC

DH280

320

DH450

Deere

490, 590

690, 790

892

992ELC

Hitachi

EX100

EX150

EX200

EX270LC

300

EX400-3

EX400LC-3

EX550

EX700

Hyundai

R130LC

R180LC

R200LC

R290LC

320

R420LC

R450LC

Kobelco

SK100

SK120

SK150

SK200, 220

SK300

SK400LC

Komatsu

PC120

PC150

PC200,

210, 220

PC250

300

PC400LC-5

PC650LC-5

Liebherr

R902, 912

922, 932

R942

R954

R964, R974

Linkbelt

Samsung

2650, 2700

LS2800, 3400

LS4300

LS-5800C

SE130

SE210LC

SE280LC, 350

SE450LC-2

INSTALLATION

Special Note: Before

installing ripper box, you

may wish to add plate

steel to back of bucket

for extra strength.

1. Assemble ripper

shank and box utilizing

the middle hole location

of the shank.

2. After determining the

pin-to-tip dimension on

the bucket, position the

ripper box on back of

bucket so that ripper

tooth is 3" greater than

pin-to-tip for extreme

ripping conditions or up

to 6" greater for less

extreme digging

conditions. Tack weld

box into position.

3. Remove box pin and

shank.

4. Inside contour of box

can be trimmed to

accommodate the bucket

shell radius.

5. Finish welding box

into position (use E7018

rod or equivalent).

PARTS NEEDED FOR SYSTEM*

HENSLEY

System

Part

200

250

300

350

350

400

Box

B200

B250

B300

B350

B350

B400

Shank

C200-12

C250-14

C300-20

C350-20

C350-22

C400-22

Box Pin

B250P

B250P

B250P

B350P

B350P

B350P

Tiger

Tooth

T9J8910

T6Y0352

T9W2452

T366503

T366503

Tooth

Fastener

9J6583P 9W2678P

6Y9459W 6Y9459W

Kit #

BK200

T9W2452

S I N C E 19 47

BOX RIPPER

SYSTEMS

FOR

EXCAVATORS

6Y3394P 6Y3394P 6Y3909P 6Y3909P

8E5559W 8E5559W 4T4707W 4T4767W

BK250

BK300

BK350-1

BK350-2

BK400

* A complete system may be ordered by Kit Number.

RIPPER BOXES

Box

Wt.

B200

6" (Typ.)

(152)

2 1/2"

(63)

14 7/8"

(378)

11 7/8"

(302)

8 9/16"

(218)

6 13/16"

(173)

10 1/2"

(267)

55.0

(25)

B250

6" (Typ.)

(152)

2 5/8"

(67)

17 1/8"

(435)

13 5/8"

(346)

9 3/4"

(248)

7 13/16"

(198)

12"

(305)

75.0

(34)

B300

6" (Typ.)

(152)

3 1/8"

(79)

19 1/8"

(486)

15 5/16"

(389)

11 3/16"

(284)

8 3/4"

(222)

13 1/2"

(343)

105.0

(48)

B350

7 1/2" (Typ.)

(191)

4"

(102)

21 1/4"

(540)

17"

(432)

12 1/4"

(311)

9 3/4"

(248)

15"

(381)

150.0

(68)

B400

7 15/16" (Typ.)

(202)

5 1/4"

(133)

25 1/2"

(648)

20 7/16"

(519)

14 3/4"

(375)

11 3/4"

(298)

18"

(457)

245.0

(111)

Ripper Box

RIPPER SHANKS

Box

Shank

Wt.

B200

C200-12

31 /16"

(792)

8"

(203)

4 /16"

(122)

3 /2"

(89)

2"

(51)

65.0

(29)

B250

C250-14

36 3/4"

(933)

10 1/8"

(257)

5 1/2"

(140)

4" (Typ.)

(102)

2 1/2"

(64)

95.0

(43)

B300

C300-20

41"

(1041)

11 1/4"

(286)

6 3/16"

(157)

4 1/2" (Typ.)

(114)

3"

(76)

113.0

(51)

C350-20

45"

(1143)

11 1/8"

(283)

6 7/8"

(175)

5" (Typ.)

(127)

3 1/8"

(79)

185.0

(84)

C350-22

46"

(1168)

12 3/4"

(324)

6 7/8"

(175)

5" (Typ.)

(127)

3 1/8"

(79)

200.0

(91)

C400-22

54"

(1372)

13 3/4"

(349)

8 1/4"

(210)

6" (Typ.)

(152)

3 3/4"

(95)

300.0

(136)

B350

B400

13

Ripper Shank

REPLACEMENT NOSES

Weld-On

Nose

For

Shank#

Wt.

C12WN

C200-12

3"

(76)

4 1/4"

(108)

5 23/32"

(145)

9.6

(4.4)

9W7488WN

C250-14

3"

(76)

5 3/8"

(137)

7 21/32"

(194)

18.5

(8.4)

C20WN

C300-20

C350-20

2 /16"

(75)

6"

(152)

8 /16"

(224)

24.5

(11)

C22WN

C350-22

C400-22

3 29/32"

(99)

7 5/8"

(194)

10 1/4"

(260)

46.9

(21)

Form0134 052599

15

13

Safety First: Hensley

recommends that you use a

soft-faced hammer and ANSIapproved (Z87.1) eye

protection while using our

products.

Hensley Industries, Inc.

Replacement Nose

2108 Joe Field Road

Dallas, Texas 75229 U.S.A.

www.hensleyind.com

Customer Service

Tel. 888.406.6262

Fax 888.241.3274

An ISO 9001:2000 Certified Company

Вам также может понравиться

- Production List SBICДокумент32 страницыProduction List SBICnemez1zОценок пока нет

- Breaker SeriesДокумент6 страницBreaker SeriesDeno Manuel LudzanОценок пока нет

- 320D Hydraulic Excavators Parts Reference GuideДокумент11 страниц320D Hydraulic Excavators Parts Reference GuidePușcă MartinОценок пока нет

- G Bushes To Suit 125mm To 200mm Dia Pins Page 33 PDFДокумент1 страницаG Bushes To Suit 125mm To 200mm Dia Pins Page 33 PDFAndrey GyrychОценок пока нет

- Catalogue Techmaflex UK USДокумент23 страницыCatalogue Techmaflex UK USAgustinus WaluyoОценок пока нет

- Part Book PC130F-7 PPC HoseДокумент1 страницаPart Book PC130F-7 PPC HoseChimanОценок пока нет

- Under Carriage PartsДокумент4 страницыUnder Carriage PartsKeith McCannОценок пока нет

- D11R Undercarriage Improvements - PEGP7031-00Документ4 страницыD11R Undercarriage Improvements - PEGP7031-00Roger MendozaОценок пока нет

- YLF Hydraulic Breaker Seal KitsДокумент5 страницYLF Hydraulic Breaker Seal KitsJaime RobОценок пока нет

- E Bushes To Suit 90mm Dia Pins Page 28 PDFДокумент1 страницаE Bushes To Suit 90mm Dia Pins Page 28 PDFAndrey GyrychОценок пока нет

- Part Eng D85e-Ss-2Документ111 страницPart Eng D85e-Ss-2Nayla AzzahraОценок пока нет

- Oem Replacement Catalogue: Wear Steel Parts For Oem Get EquipmentДокумент160 страницOem Replacement Catalogue: Wear Steel Parts For Oem Get EquipmentmazuckОценок пока нет

- WA500-3 Cylinder Head PartДокумент2 страницыWA500-3 Cylinder Head PartOecox Cah Djadoel100% (1)

- SNT Autopart Oil Seal Catalog For JCBДокумент8 страницSNT Autopart Oil Seal Catalog For JCBKudanthai SenthilkumarОценок пока нет

- Revised: SubjectДокумент9 страницRevised: SubjectRytis SiaulysОценок пока нет

- lp750 NDДокумент44 страницыlp750 NDdiabalziabОценок пока нет

- Classic Wheel Loader Parts XRef (11!15!07)Документ48 страницClassic Wheel Loader Parts XRef (11!15!07)karol1177Оценок пока нет

- Swing Bearing - KTR PDFДокумент2 страницыSwing Bearing - KTR PDFflytorahul100% (1)

- SK100-SK120LC-2 Shop ManualДокумент712 страницSK100-SK120LC-2 Shop ManualKhoa Nguyen100% (2)

- F Bushes To Suit 95mm To 120mm Dia Pins Pages 29 - 32Документ4 страницыF Bushes To Suit 95mm To 120mm Dia Pins Pages 29 - 32sashaОценок пока нет

- BucketДокумент161 страницаBucketDario OliveiraОценок пока нет

- Total Breaker BitsДокумент40 страницTotal Breaker BitsGeorge Kwamina Anaman100% (1)

- Excavator: Cummins QSB 4.5 84.3 KW (113 HP) 15,400 KG 0.6 MДокумент9 страницExcavator: Cummins QSB 4.5 84.3 KW (113 HP) 15,400 KG 0.6 MKoay B HОценок пока нет

- 2012 Duetz TractorsДокумент47 страниц2012 Duetz TractorsAgus Yulfizar100% (1)

- Deutz 1015 Marine Engine PDFДокумент6 страницDeutz 1015 Marine Engine PDFGeorge Vasiliou100% (1)

- Replacement Wear Parts For KMMP HENLEYДокумент24 страницыReplacement Wear Parts For KMMP HENLEYCyeCyeОценок пока нет

- Work Equipment PC200-7Документ4 страницыWork Equipment PC200-7Ryan Abubakar Obili PakayaОценок пока нет

- LiuGong Corporate BrochureДокумент34 страницыLiuGong Corporate BrochurebaОценок пока нет

- Arm II - LubricantsДокумент2 страницыArm II - LubricantsCarlos FernandoОценок пока нет

- Furukawa HB20GДокумент33 страницыFurukawa HB20GTaufiq AkbarОценок пока нет

- PC130-8 SEN03763-10 Structure, Function & Maintenance StandardДокумент168 страницPC130-8 SEN03763-10 Structure, Function & Maintenance StandarddatphuongОценок пока нет

- pc130 7Документ16 страницpc130 7dwahyudiyanto100% (4)

- Link Belt X4 Long Front FamilyДокумент12 страницLink Belt X4 Long Front FamilyYew LimОценок пока нет

- PC200 PC200LC: Gross: 110 KW 147 HP / 2000 Min Net: 103 KW 138 HP / 2000 MinДокумент8 страницPC200 PC200LC: Gross: 110 KW 147 HP / 2000 Min Net: 103 KW 138 HP / 2000 MinTeguhwidi YantoОценок пока нет

- JS Excavator Attachments GuideДокумент11 страницJS Excavator Attachments GuideAОценок пока нет

- Sealing List of Wys KoreaДокумент208 страницSealing List of Wys KoreaKudanthai SenthilkumarОценок пока нет

- Itr Range of Universal Joints For Heavy / Construction EquipmentsДокумент2 страницыItr Range of Universal Joints For Heavy / Construction Equipmentsاحمد عبده100% (1)

- CAT K Series Tooth System PDFДокумент4 страницыCAT K Series Tooth System PDFRyan Abubakar Obili PakayaОценок пока нет

- 3A) Brochure G.E.T.Документ20 страниц3A) Brochure G.E.T.ofm100% (1)

- SSL Comparison List/ TECH - DETAILS OF SKID STEER LOADERSДокумент80 страницSSL Comparison List/ TECH - DETAILS OF SKID STEER LOADERSHuseyin TASKINОценок пока нет

- 2E) Brochure NozzleДокумент8 страниц2E) Brochure NozzleofmОценок пока нет

- Numserie Nit Tipo Modelo NummotorДокумент42 страницыNumserie Nit Tipo Modelo NummotorDayana SernaОценок пока нет

- Def Kato Imer 12vxe enДокумент16 страницDef Kato Imer 12vxe enYew LimОценок пока нет

- SANY Excavator SY500H Specs PagesДокумент4 страницыSANY Excavator SY500H Specs PagesAzmi MaulanaОценок пока нет

- Miller 652 and 812 Owners Manualo278aj - MilДокумент44 страницыMiller 652 and 812 Owners Manualo278aj - MilrobertoarellanocastiОценок пока нет

- 120K HydДокумент4 страницы120K HydMarco OlivettoОценок пока нет

- Rapak Dalam Per 23 Juli 2019 NEWДокумент153 страницыRapak Dalam Per 23 Juli 2019 NEWsubandi pippoОценок пока нет

- CarraroДокумент59 страницCarrarorachitmail100% (1)

- M0125763en-Us 313D2LGP LKRДокумент509 страницM0125763en-Us 313D2LGP LKRDedy setiawan100% (1)

- QRF HB205+HB215Документ2 страницыQRF HB205+HB215Ralf MaurerОценок пока нет

- CWP Tooth CatalogueДокумент24 страницыCWP Tooth CatalogueLuis Panti EkОценок пока нет

- Catalogo ZapatasДокумент15 страницCatalogo ZapatasGustavo100% (1)

- Doosan EXC QuickCoupler ENДокумент2 страницыDoosan EXC QuickCoupler ENFelipe HernandezОценок пока нет

- BELTSДокумент12 страницBELTSashraf elsayed0% (1)

- BW213-4 4pgДокумент4 страницыBW213-4 4pgtokotani torajaОценок пока нет

- Komatsu SeriesДокумент22 страницыKomatsu SeriesEdU RECTIFICAОценок пока нет

- FAN Catalogue: Cosmi C Forkli FT PartsДокумент6 страницFAN Catalogue: Cosmi C Forkli FT Partsعلی چیواییОценок пока нет

- Cadenas Métricas FBДокумент15 страницCadenas Métricas FBjurgen_01Оценок пока нет

- Needle Cages and Roller Cages: ConstructionДокумент12 страницNeedle Cages and Roller Cages: ConstructionMohan Kumar MathrubaiОценок пока нет

- 930e4 Cerrejon Retarding Grid Assembly 1 3 58F-06-01590 PDFДокумент2 страницы930e4 Cerrejon Retarding Grid Assembly 1 3 58F-06-01590 PDFfernandojОценок пока нет

- 4aa7 0914eeeДокумент4 страницы4aa7 0914eeefernandojОценок пока нет

- 4aa7 0914eeeДокумент4 страницы4aa7 0914eeefernandojОценок пока нет

- Correas TransportadorasДокумент2 страницыCorreas TransportadorasfernandojОценок пока нет

- Any Rail 6 ENДокумент162 страницыAny Rail 6 ENfernandojОценок пока нет

- Haul Truck Payload Modelling Using Strut PressuresДокумент119 страницHaul Truck Payload Modelling Using Strut PressurestehnoОценок пока нет

- 930e4 Cerrejon Center Deck HandrailsДокумент2 страницы930e4 Cerrejon Center Deck HandrailsfernandojОценок пока нет

- 930e4 Cerrejon LH Steps & PlatformДокумент2 страницы930e4 Cerrejon LH Steps & PlatformfernandojОценок пока нет

- 930e4 Cerrejon RH Deck & Retarding Grid InstallationДокумент2 страницы930e4 Cerrejon RH Deck & Retarding Grid InstallationfernandojОценок пока нет

- 930e4 Cerrejon Retarding Grid Assembly 1 3 58f-06-01590Документ2 страницы930e4 Cerrejon Retarding Grid Assembly 1 3 58f-06-01590fernandojОценок пока нет

- 930e4 Cerrejon LH Deck HandrailsДокумент2 страницы930e4 Cerrejon LH Deck HandrailsfernandojОценок пока нет

- AH15849b PC Hydraulic Cylinders With Metal Guard Rings at The PistonДокумент12 страницAH15849b PC Hydraulic Cylinders With Metal Guard Rings at The PistonfernandojОценок пока нет

- Afe59-Hc 930e-4 S/N A32062 - A32065, A32073 - A32076 & A32078 - A32079 CerrejonДокумент2 страницыAfe59-Hc 930e-4 S/N A32062 - A32065, A32073 - A32076 & A32078 - A32079 CerrejonfernandojОценок пока нет

- 930e4 Cerrejon RH Deck & Retarding Grid InstallationДокумент2 страницы930e4 Cerrejon RH Deck & Retarding Grid InstallationfernandojОценок пока нет

- wm2d Tutorial PDFДокумент429 страницwm2d Tutorial PDFfernandoj100% (1)

- SCENE LT 2019.0 User Manual EN PDFДокумент253 страницыSCENE LT 2019.0 User Manual EN PDFfernandojОценок пока нет

- SCENE LT 2019.0 User Manual EN PDFДокумент253 страницыSCENE LT 2019.0 User Manual EN PDFfernandojОценок пока нет

- Working Model ManualДокумент429 страницWorking Model ManualMike Vandumurugan100% (1)

- Working Model 2DДокумент143 страницыWorking Model 2DdivyajananiОценок пока нет

- Kmax Specification Guide 201005Документ26 страницKmax Specification Guide 201005fernandoj100% (1)

- Working Model 2DДокумент143 страницыWorking Model 2DdivyajananiОценок пока нет

- Working Model Tutorial: 1. InstallationДокумент10 страницWorking Model Tutorial: 1. InstallationfernandojОценок пока нет

- Robotica Con El Boe Bot Espanol v2.2 PDFДокумент360 страницRobotica Con El Boe Bot Espanol v2.2 PDFfernandojОценок пока нет

- How To Model: Realistic Track and Trackside ScenesДокумент15 страницHow To Model: Realistic Track and Trackside Scenesfernandoj100% (1)

- Working Model Tutorial: 1. InstallationДокумент10 страницWorking Model Tutorial: 1. InstallationfernandojОценок пока нет

- Handyscan 3D Training Script - ENДокумент98 страницHandyscan 3D Training Script - ENfernandojОценок пока нет

- Handyscan 3D Training Script - ENДокумент98 страницHandyscan 3D Training Script - ENfernandojОценок пока нет

- Working Model Tutorial: 1. InstallationДокумент10 страницWorking Model Tutorial: 1. InstallationfernandojОценок пока нет

- MaxSHOT 3D Training Script - ENДокумент53 страницыMaxSHOT 3D Training Script - ENfernandojОценок пока нет

- CREO Parametric Lesson 17 PDFДокумент42 страницыCREO Parametric Lesson 17 PDFfernandojОценок пока нет

- 32 13 13 - Concrete PavingДокумент6 страниц32 13 13 - Concrete PavingKushagra AgarwalОценок пока нет

- My Future Goal Is To See The Sights of This Wonderful EnglandДокумент9 страницMy Future Goal Is To See The Sights of This Wonderful EnglandJános BakosОценок пока нет

- 1429946952876-Poc TSD EngДокумент64 страницы1429946952876-Poc TSD Engamitbehera23Оценок пока нет

- Bell ServiceДокумент19 страницBell ServiceJoshua BagtasusОценок пока нет

- Sugadev. G Mie, Chartered Engineer, 13 West Veli Street, 3Документ5 страницSugadev. G Mie, Chartered Engineer, 13 West Veli Street, 3Nithyanandhan TranzionОценок пока нет

- February 2013 Wire Rope ExchangeДокумент84 страницыFebruary 2013 Wire Rope ExchangeWire Rope ExchangeОценок пока нет

- Universiti Tun Hussein Onn Malaysia Assignment - Create Semester Ii SESSION 2018/2019Документ4 страницыUniversiti Tun Hussein Onn Malaysia Assignment - Create Semester Ii SESSION 2018/2019Nurul WanieОценок пока нет

- Peugeot 206CC 2003Документ4 страницыPeugeot 206CC 2003Kael ArialОценок пока нет

- Basic Aircraft Maintenance Training - Aircraft Maintenance Practices Course - EASA Part-66 - EASA PART-147 - FL Technics TrainingДокумент6 страницBasic Aircraft Maintenance Training - Aircraft Maintenance Practices Course - EASA Part-66 - EASA PART-147 - FL Technics TrainingPhil ZimbОценок пока нет

- Actros II III 2005 At2000st D D PDFДокумент44 страницыActros II III 2005 At2000st D D PDFMircea Gilca100% (3)

- Fuel SystemДокумент14 страницFuel SystemMORSHEDОценок пока нет

- GEOG 3 The Big DebateДокумент40 страницGEOG 3 The Big Debateplowe_10% (1)

- 5088 6088 7088 OM - CaseДокумент506 страниц5088 6088 7088 OM - CaseNicoleta Costea100% (3)

- 4.1 Manajemen Keselamatan Dan Keamanan KapalДокумент4 страницы4.1 Manajemen Keselamatan Dan Keamanan Kapaljosep juliusОценок пока нет

- Nova Full Manual 1206Документ157 страницNova Full Manual 1206martin_jaitman100% (2)

- Project GlyncoДокумент193 страницыProject GlyncoLcousins7961100% (1)

- TM55-2350-252-14 Transportability Guide Bradley M2, M3Документ68 страницTM55-2350-252-14 Transportability Guide Bradley M2, M3dieudecafe100% (2)

- ENSCO 120 Series: Ultra-Premium Harsh Environment JackupsДокумент4 страницыENSCO 120 Series: Ultra-Premium Harsh Environment JackupsDayanand Wasate100% (1)

- HSC Engineering StudiesДокумент13 страницHSC Engineering StudiesRick ThuranОценок пока нет

- Ism ChecklistДокумент16 страницIsm Checklistjonas casimeroОценок пока нет

- Indian Biogas Association Biogas Market IndiaДокумент36 страницIndian Biogas Association Biogas Market Indiasj singh100% (1)

- Kapalaran Bus Line vs. CoronadoДокумент5 страницKapalaran Bus Line vs. CoronadoaudreyОценок пока нет

- Naval Brigades: in "In The Heart of Africa"Документ4 страницыNaval Brigades: in "In The Heart of Africa"Thomas Grove100% (1)

- 5l - FORMДокумент7 страниц5l - FORMAnthony Steve LomilloОценок пока нет

- Normand SubseaДокумент2 страницыNormand SubseaarunnvОценок пока нет

- Auto. Tech - Mec.227 Theory 03Документ87 страницAuto. Tech - Mec.227 Theory 03ayariseifallah100% (5)

- Aircraft DesignДокумент19 страницAircraft Designgiganticvis100% (1)

- Engine Mountings and Vibration IsolatorsДокумент4 страницыEngine Mountings and Vibration IsolatorsShreyas Patil S100% (1)

- Cathy Batchelor PortfolioДокумент8 страницCathy Batchelor Portfolioapi-232549435Оценок пока нет

- Seam 4 QuizДокумент2 страницыSeam 4 QuizHope Earl Ropia BoronganОценок пока нет