Академический Документы

Профессиональный Документы

Культура Документы

zn409 Datasheet

Загружено:

ian_new0 оценок0% нашли этот документ полезным (0 голосов)

129 просмотров6 страницServo data sheet

Оригинальное название

zn409 datasheet

Авторское право

© © All Rights Reserved

Доступные форматы

PDF, TXT или читайте онлайн в Scribd

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документServo data sheet

Авторское право:

© All Rights Reserved

Доступные форматы

Скачайте в формате PDF, TXT или читайте онлайн в Scribd

0 оценок0% нашли этот документ полезным (0 голосов)

129 просмотров6 страницzn409 Datasheet

Загружено:

ian_newServo data sheet

Авторское право:

© All Rights Reserved

Доступные форматы

Скачайте в формате PDF, TXT или читайте онлайн в Scribd

Вы находитесь на странице: 1из 6

Servo control IC RS ZN409

Issued November 1984

RS stock number 304-813

The RS ZN409 is a precision monolithic integrated

circuit designed particularly for pulse-width posi-

tion servo mechanisms used in many types of

control applications. The low number of compo-

nents required with the device, together with its

reduced length and low power consumption, make

this integrated circuit ideal for use in compact

servo applications where space, weight and battery

life are at a premium. The amplifier will operate

over a wide range of repetition rates and pulse

widths and is therefore suitable for the majority of

systems. The RS ZN409 can also be used in motor

speed control circuits.

Absolute maximum ratings

Supply voltage __________________________6.5 Volts

Package dissipation__________________300 Milliwatts

Operating temperature range_________-20C to 65C

Storage temperature range __________-65C to 150C

Features

G Low external component count

G Low quiescent current (7mA typical at 4.8V)

G Excellent voltage and temperature stability

G High output drive capability

G Consistent and repeatable performance

G Precision internal voltage stabilisation

G Time shared error pulse expansion

G Balanced deadband control

G Schmitt trigger input shaping

G Reversing relay output

(dc motor speed control)

Characteristics V

CC

= 5V At 25C ambient temperature unless otherwise stated.

Parameter Min. Typ. Max. Unit Conditions

Input threshold (lower) 1.15 1.25 1.35 V Pin 14

Input threshold (upper) 1.4 1.5 1.6 V Pin 14

Ratio upper/lower threshold 1.1 1.2 1.3 10 to + 65C

Input resistance 20 27 35 k V

in

2V (Pin 14)

Input current 350 500 650 A V

in

2V (Pin 14)

Regulator voltage 2.1 2.2 2.3 V 10 to + 65C, 1.3mA load current

Regulator supply voltage rejection ratio 200 300 V

CC

= 3.5 to 6.5V

RSRR

=

dV

in

dV

out

Monostable linearity for 45 pot rotation 3.5 4.0 % R

p

= 1.5k, R

1

= 12k

Monostable period temperature 0.01 %/C Excluding R

T

, C

T

.

coefficient R

p

= 1.5k, R

1

=12k

(potentiometer slider set

mid-way)

Output Schmitt deadband 1 1.5 3 S C

E

= 0.47F

Minimum output pulse 2.5 3.5 4.5 mS C

E

= 0.47F, R

E

= 180k

Error pulse for drive 70 100 130 S 15 ms repetition rate

C

E

= 0.47F, RE = 180k

Total deadband 3.5 5 6.5 S C

D

= 1000pF

P.N.P. drive 40 55 70 mA T = 25C

35 50 65 mA T = 10C

Output saturation voltage 300 400 mV I

L

= 400mA

Direction bistable output 2 2.8 3.6 mA V

CC

= 5V max.

Supply voltage range 3.5 5 6.5 V

Supply current 4.6 6.7 10 mA Quiescent

Total external current from regulator 1.3 mA V

CC

= 3.5V

Peak voltage V

C EXT

(with respect 0.7 V T = 25C

to 2V regulated voltage) 0.5 V T = 10C

004-204

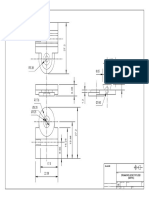

PIN CONNECTIONS

TOP VIEW

Data Pack J

Dat a Sheet

004-204

2

Circuit operation

Figure 1 System diagram

Component function

Circuit

reference Value

Monostable timing components R

T

100k

C

T

0.1F

Potentiometer and timing reference

components R

p

2k

R

1

6.2k

Pulse expansion C

E

0.47F

R

E

180k

Deadband C

D

2200pF

Dynamic feedback R

F

300k

R

B

300k

R

2

1.2k

Input coupling C

C

2.2F

Motor decoupling C

2

0.1F

C

3

0.1F

R.F. decoupling (see text) C

1

0.1F

Drive transistors T

1

, T

2

BC461

Input circuit

The RS ZN409 operates with positive going input

pulses which can be coupled either directly or via a

capacitor to pin 14. the advantage of ac coupling

is that should a fault occur which causes the input

signal to become a continuous positive level, the

servo will remain in its last quiescent position,

whereas with direct coupling the servo output arm

will rotate continuously. A nominal 27k on-chip

resistor is shunted across the input to provide dc

restoration of the input signal when ac coupling is used.

The active input circuit is a Schmitt trigger

which allows the servo to operate consistently with

slow input edges and supplies the fast edge required

by the trigger monostable independent of input edge

speed.

Figure 3

The system diagram in Fig. 1 illustrates the internal

structure of the RSZN409 servo control IC

In the standard servo application the displacement

of a potentiometer control varies the pulse width of

a timing circuit. The signal produced provides the

control input for the servo IC The servo shown in

Fig. 2 consists of the RS ZN409 integrated circuit,

several external components, a power amplifier

consisting of two external PNP transistors and two

on-chip NPN transistors which form a bridge circuit

to drive the dc motor. The motor drives a reduc-

tion gear box which has a potentiometer attached

to the output shaft. The RS precision dc servo

system components are ideally suited for this ap-

plication and the 6V motor should be used. This

potentiometer in association with R

1

and the timing

components C

T

and R

T

controls the pulse width of

the timing monostable. The input pulse is com-

pared with the monostable pulse in a comparison

circuit and one output is used to enable the correct

phase of an on-chip power amplifier. The other

output from the pulse comparison circuit drives the

pulse expansion circuit (C

E

, R

E

) via the deadband

circuit (C

D

). Thus any difference between the input and

monostable pulses is expanded and used to

drive the motor in such a direction as to reduce this

difference so that the servo takes up a position

which corresponds to the position of the control

potentiometer.

Figure 2 Servo system using theRS ZN409

Input circuit Input characteristics

004-204

3

The input circuit and its V/1 characteristic are

shown above. D

1

and D

1

are the parasitic substrate

and isolation diodes associated with the input

resistors. It is advisable that the pulse input ampli-

tude should not fall below 0V nor exceed the

supply voltage Vcc in order to prevent these diodes

from conducting, although a small amount of con-

duction will not cause the circuit to malfunction.

When ac coupling is used the value of C

C

should

be chosen to give a pulse droop not exceeding 0.3

volts.

Assuming that the input signal swings between 0V

and V

CC

and taking the input chord resistance R

IN

of

13k the droop for a pulse of duration msec will

be:

V

d

=

V

CC

t

p

volts

t

p

(msec)

C

C

. R

IN

C

C

(F)

R

IN

(k)

For a nominal pulse width of 1.5 msec and V

d

equal

to 0.3 volts the required minimum value of C

C

can

be found to be 1.85F and a nominal value of 2.2F

is chosen. (Nearest preferred value).

4.8 1.5

C

C

=

0.3 13

= 1.85F

If it is required to operate the servo with reduced

input pulse amplitude the input pulse should ex-

ceed the upper Schmitt threshold voltage of 1.5

volts by a reasonable margin and a minimum input

pulse amplitude of 2.4 volts is recommended.

Deadband circuit

The function of the deadband circuit is to provide a

small range of output shaft positions about the

quiescent position where the difference pulse does

not drive the motor. This is necessary to eliminate

hunting around the quiescent position caused by

servo inertia and overshoot. The minimum dead-

band required is also a function of the pulse expan-

sion characteristics and dynamic feedback compo-

nent values.

When the difference pulse is applied T

1

turns off

and the base of T

2

rises on an exponential wave-

form with a time constant of 4.7 k C

D

. If the

difference pulse is small the potential reached on

the base of T

2

is insufficient to turn T

2

on and no

output results.

The pulse expansion circuit has a built in deadband

of 1.5 sec with C

E

= 0.47 F and this must be

added to the deadband caused by C

D

to obtain the

total T

d

.

T

d

= 1.5 + t

d

sec

and t

d

= 3.3C

D

sec(C

D

in nF)

(Taking V

1

= 1.5 volts and V

be

= 0.75 volts)

Thus with C

D

equal to 2200pF(2n2)

t

d

= 7.26sec and T

d

= 8.76sec.

The mechanical deadband d depends on the

chosen sensitivity S

1

of the servo and in a typical

application at 500sec input pulse variation

causes 50 rotation, ie. S

1

= 10sec per degree.

Thus d = 2.T

d

degrees (T

d

in sec. S

1

in sec per

S

1

degree).

Thus a value for T

d

of 8.76sec provides a mechan-

ical deadband d of 1.8.

And generally:

3 + 6.6 C

D

d = degrees

S

1

Pulse expansion

Figure 4 Input waveforms

Figure 5 Deadband circuit and waveforms

Figure 6

Pulse expansion circuit and characteristics

{

C

D

in nF.

S

1

in sec per

degree.

004-204

4

A schematic of the pulse expansion circuit is shown

in Fig. 6. In the quiescent state with no drive the

Schmitt trigger input is biased via R

E

and takes up a

level just above the lower threshold V

L

.

A drive pulse causes a current I

E

to be switched on

for the duration of the pulse and this discharges C

E

linearly with time. Thus, at the end of the pulse the

voltage on C

E

depends on the duration of the pulse.

If the pulse is narrow and just causes the potential

on C

E

to fall to V

L

the Schmitt trigger will switch to

the upper threshold V

H

and at the end of the drive

pulse C

E

will start to charge to V

H

with a time

constant C

E

R

E

. When the potential on C

E

reaches

V

H

the Schmitt will switch to V

L

and C

E

will dis-

charge to the quiescent level. The output drive is

taken from the Schmitt output.

(shown dotted in Fig. 6) and if this is excessive it

can lead to the servo exhibiting an underdamped

characteristic causing jittering or hunting. Thus for

full pulse expansion the voltage on C

E

should

discharge from its quiescent value of 1.5V to 0.75

volts. Thus with I

E

= 3mA for the current source:

1.5 - 0.75

I

E

=

t

e

C

E

C

E

= 4.t

e

F(t

e

in msec)

For t

e

= 0.1 msec, a value of 0.47F was chosen for

C

E

.

If t

p

is the maximum motor drive pulse length

required, ie. equal to the input pulse repetition

period for full pulse expansion, and the mean value

of the potential on C

E

is taken as 1.2 volts, then:

(t

p

- t

min

)

dv = (V

CC

- 1.2)

C

E

R

E

And for the discharge period t

e

:

I

E

t

e

dv =

C

E

R

E

= (t

p

- t

min

) (V

CC

- 1.2)

I

E

t

e

For nominal values of V

CC

= 4.8V and I

E

= 3mA

(t

p

- t

min

) k

R

E

= 1.2

t

e

and for t

p

= 20msec, t

min

= 3.5msec, t

e

=0.1msec,

R

E

= 180k. (Nearest preferred value).

Monostable timing

dc motors need a certain amount of drive to

overcome static friction and the minimum output

pulse obtained from this form of pulse expansion

characteristic is chosen to ensure that the motor

will rotate when driven.

The value of t

min

is determined by the Schmitt

trigger hysteresis and the exponential waveform

on C

E

because V

H

is small the following linear

relationship is sufficiently accurate.

(V

CC

- V

L

)

V

H

= t

min

C

E

R

E

For nominal operation V

CC

= 4.8V; V

L

= 1.5V; V

H

=

0.12V and:

C

E

R

E

C

E

in F

t

min

msec

30

R

E

in k

and for C

E

= 0.47F and R

E

= 180k, t

min

=

3.5msec.

It can be seen from the simple equation that t

min

is

dependent on V

CC

, and t

min

will increase with

reducing V

CC

. This variation is put to good use to

maintain the initial motor drive, V

CC

t

min

reason-

ably constant over the operating voltage range of

3.5 to 6.5 volts.

When the pulse expansion drive is increased above

the minimum value the output pulse increases

from t

min

almost linearly until full pulse expansion

is reached, ie. when the ouput pulse width equals

the input pulse repetition rate. The pulse expansion

will be almost linear provided that the current

source I

E

does not saturate, ie. provided that C

E

is

not discharged to almost zero volts. Ideally the

current source should saturate when full motor

drive is obtained but due to component tolerances

it is usual to allow some margin to ensure that full

motor drive can be obtained. If a margin is allowed, an

extended pulse expansion characteristic results

Figure 7 Pulse expansion timing diagram

{

Figure 8 Pulse expansion waveform

Figure 9

Monostable timing circuit and waveform

The leading edge of the input waveform triggers

the timing monostable by opening switch S1. CT

then charges until the differential amplifier detects

that the timing waveform potential has fallen to Vp,

the potential on the potentiometer wiper and

switch S1 is closed to terminate the timing pulse. Thus

the monostable period is determined by the

setting of the potentiometer wiper. In the standard

004-204

5

application the servo centre position pulse width is

1.5 msec with a range of 50 rotation at 10 sec

per degree. Thus the 2.0 msec maximum monost-

able period t

mono

(max) corresponds to a potentio-

meter setting of 200 (for a linear relationship) and

since the potentiometer has a total rotation of

approximately 270 and the maximum allowable

swing on pin 3 is specified as 0.5 volt, the value of

C

T

R

T

can be calculated as follows:

0.5 2

t

mono (MAX)

C

T

R

T

C

T

R

T

= 4t

mono (max)

Thus if t

mono (max)

= 2 msec, C

T

R

T

= 8msec.

The optimum value of R

T

is 100k due to the

design of the on-chip monostable circuit giving C

T

= 0.1F (nearest preferred value).

R

T

= 100k C

T

= 0.1F

The value of R

1

can now be calculated from the

actual voltage swing with a potentiometer setting

of p = 200 and max = 270.

V

m

= 2.0. t

mono(max)

C

T

R

T

since C

T

= 0.1F (nearest preferred value) was

chosen with R

T

= 100k, V

m

= 0.4V and hence: R

1

= 3.1 R

p

. If R

p

= 2kthen R

1

= 6.2k.

Dynamic feedback

Without dynamic feedback in the standard applica-

tion the inertia of the motor and gearbox causes

the servo output shaft to overshoot the set position

which results in the servo 'hunting'. If the dead-

band was widened to stop this effect an unaccept-

ably large deadband would result and the servo

would still be underdamped. The dynamic feed-

back circuit utilises the motor back emf (which is

proportional to motor speed) and feeds back a

proportion of this signal to the wiper of the poten-

tiometer. The phase of the feedback signal is

chosen to modify the potential on the wiper so that

the monostable period is dynamically varied to

reduce the motor drive as the servo output shaft

approaches the set position and the values of the

feedback resistors are chosen to achieve optimum

setting characteristics.

The value for R

F

and R

B

of 330k will suit the

normal type of servo mechanism, however if the

servo is fairly fast this can be decreased to 300k

to minimise any tendency to overshoot. Where the

servo is slow R

F

and R

B

can be increased to 360k

or 390k.

RF Decoupling

C

1

(typical value 0.1F) is only necessary where

strong RF fields may affect the operation of the circuit.

Transistors T1 and T2

The external PNP transistors are usually selected

for a low V

CE

(sat) to obtain maximum output drive.

The recommended type is BC461.

Motor speed control

Introduction

In the motor speed control application the

Figure 11

Proportional motor speed control circuit

Figure 10

Potentiometer set at 200C

Equivalent circuit

Thus from the equivalent circuit:

Vm

=

(V

CC

- V

m

)

200 70

270

R

p

R

1

+

270

R

p

where V

m

is calculated from the actual values of C

T

and R

T

chosen using the relationship:

004-204

RS ZN409 is used as a linear pulse width amplifier.

The dc motor is driven via a power amplifier with

a train of pulses whose mark/space ratio can vary

between zero and one to control the motor speed

from zero to maximum. The device operates with

fixed timing components and a fixed resistor re-

places the position feedback potentiometer. The

nominal monostable period represents zero motor

speed and input pulses less than or greater than

nominal drive the motor in the forward and reverse

direction respectively. The motor direction is usual-

ly controlled by a relay operated from pin 4, the

direction output. Pulse expansion components C

E

and R

E

are chosen to obtain the required relation

between control potentiometer and motor speed

and it is usual to operate with a much larger

deadband than that used in the servo application.

The outputs from pins 9 and 5 of the RS ZN409

integrated circuit are combined using two ZTX500

PNP transistors to provide a pulsed output whose

mark/space ratio varies from 0 to 1 depending on

the deflection of the control potentiometer.

This signal is then used to drive the motor via the

power amplifier.

The RS ZN409 has additional circuitry which per-

forms the motor reversing function by taking the

output from the direction bistable and provides

either zero current or approximately 3mA sink

current at pin 4, depending on the state of the

direction bistable. This current is amplified and

used to drive the relay coil (100mA) via the 2N3053

transistor thus controlling the motor direction via

the relay changeover contacts.

It is usual to have a relatively wide deadband and

C

D

= 22nF provides a deadband of about 14% (7

degrees).

A 1k potentiometer (R

p

) can be used to set up the

zero output condition with the control pot in its

central position.

Pulse width generator

A pulse width generator circuit is shown in Figure

12 suitable for driving the RS ZN409 in servo or

motor speed applications.

the frame rate is generated by the first timer and

the frequency is adjusted by VR1 so that the time

between pulses is 18mS. VR2 is then used to

control the ouput pulse width over the range

1-2mS. VR3 is set so that the midpoint of VR2

corresponds to an output pulse of 1.5mS.

VR4 can be included should an output amplitude

control be required.

Figure 12 Pulse width generator

RSComponents Ltd. PO Box 99, Corby, Northants, NN17 9RS

An Electrocomponents Company

Telephone: 01536 201234

RS Components Ltd. 1995

The information provided in RS data sheets is believed to be accurate and reliable; however, RS Components Ltd. assumes no responsibility for inaccuracies or

omissions, or for the use of this information, and all use of such information shall be entirely at the users own risk.

No responsibility is assumed by RSComponents Ltd. for any infringements of patents or other rights of third parties which may result from its use.

Specifications shown in RSComponents Ltd. data sheets is subject to change without notice.

Вам также может понравиться

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeОт EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeРейтинг: 4 из 5 звезд4/5 (5794)

- ICL8038 Linear Sweep Function Generator CCTДокумент2 страницыICL8038 Linear Sweep Function Generator CCTian_new100% (1)

- 1-4 Scale Topslide 2 (Imperial)Документ1 страница1-4 Scale Topslide 2 (Imperial)ian_newОценок пока нет

- Drummond Flat Bed 1-4 Scale Cross Slide 1 (Imperial)Документ1 страницаDrummond Flat Bed 1-4 Scale Cross Slide 1 (Imperial)ian_newОценок пока нет

- Drummond 1-4 Scale Saddle 1 (Imperial)Документ1 страницаDrummond 1-4 Scale Saddle 1 (Imperial)ian_newОценок пока нет

- Plotting B-H Curves - in - 2Документ14 страницPlotting B-H Curves - in - 2ian_new100% (2)

- 1-4 Scale Topslide 1 (Imperial)Документ1 страница1-4 Scale Topslide 1 (Imperial)ian_newОценок пока нет

- Engineering Vol 56 1893-12-29Документ31 страницаEngineering Vol 56 1893-12-29ian_newОценок пока нет

- 1-4 Scale Cross Slide 1 (MetricДокумент1 страница1-4 Scale Cross Slide 1 (Metrician_newОценок пока нет

- ICL8038 - An-013 Everything You Wanted To Know About The ICL8038Документ4 страницыICL8038 - An-013 Everything You Wanted To Know About The ICL8038ian_newОценок пока нет

- 1-4 Scale Topslide 1 (Metric)Документ1 страница1-4 Scale Topslide 1 (Metric)ian_newОценок пока нет

- 1-4 Scale Topslide 2 (Metric)Документ1 страница1-4 Scale Topslide 2 (Metric)ian_newОценок пока нет

- Engineering Vol 56 1893-10-13Документ33 страницыEngineering Vol 56 1893-10-13ian_newОценок пока нет

- 1-4 Scale Saddle 1 (Metric)Документ1 страница1-4 Scale Saddle 1 (Metric)ian_newОценок пока нет

- Engineering Vol 56 IndexДокумент33 страницыEngineering Vol 56 Indexian_newОценок пока нет

- Engineering Vol 56 1893-11-10Документ35 страницEngineering Vol 56 1893-11-10ian_newОценок пока нет

- Engineering Vol 56 1893-12-15Документ33 страницыEngineering Vol 56 1893-12-15ian_newОценок пока нет

- Engineering Vol 56 1893-12-22Документ29 страницEngineering Vol 56 1893-12-22ian_newОценок пока нет

- Engineering Vol 56 1893-11-24Документ29 страницEngineering Vol 56 1893-11-24ian_newОценок пока нет

- Engineering Vol 56 1893-12-01Документ31 страницаEngineering Vol 56 1893-12-01ian_newОценок пока нет

- Engineering Vol 56 1893-12-08Документ33 страницыEngineering Vol 56 1893-12-08ian_newОценок пока нет

- Engineering Vol 56 1893-11-03Документ33 страницыEngineering Vol 56 1893-11-03ian_newОценок пока нет

- Engineering Vol 56 1893-10-27Документ29 страницEngineering Vol 56 1893-10-27ian_newОценок пока нет

- Engineering Vol 56 1893-10-20Документ29 страницEngineering Vol 56 1893-10-20ian_newОценок пока нет

- Engineering Vol 56 1893-12-15Документ33 страницыEngineering Vol 56 1893-12-15ian_newОценок пока нет

- Engineering Vol 56 1893-11-17Документ35 страницEngineering Vol 56 1893-11-17ian_newОценок пока нет

- Engineering Vol 56 1893-09-29Документ29 страницEngineering Vol 56 1893-09-29ian_newОценок пока нет

- Engineering Vol 56 1893-10-06Документ33 страницыEngineering Vol 56 1893-10-06ian_newОценок пока нет

- Engineering Vol 56 1893-09-22Документ29 страницEngineering Vol 56 1893-09-22ian_newОценок пока нет

- Engineering Vol 56 1893-09-15Документ33 страницыEngineering Vol 56 1893-09-15ian_newОценок пока нет

- The Yellow House: A Memoir (2019 National Book Award Winner)От EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Рейтинг: 4 из 5 звезд4/5 (98)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceОт EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceРейтинг: 4 из 5 звезд4/5 (895)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersОт EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersРейтинг: 4.5 из 5 звезд4.5/5 (344)

- The Little Book of Hygge: Danish Secrets to Happy LivingОт EverandThe Little Book of Hygge: Danish Secrets to Happy LivingРейтинг: 3.5 из 5 звезд3.5/5 (399)

- The Emperor of All Maladies: A Biography of CancerОт EverandThe Emperor of All Maladies: A Biography of CancerРейтинг: 4.5 из 5 звезд4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaОт EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaРейтинг: 4.5 из 5 звезд4.5/5 (266)

- Never Split the Difference: Negotiating As If Your Life Depended On ItОт EverandNever Split the Difference: Negotiating As If Your Life Depended On ItРейтинг: 4.5 из 5 звезд4.5/5 (838)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryОт EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryРейтинг: 3.5 из 5 звезд3.5/5 (231)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureОт EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureРейтинг: 4.5 из 5 звезд4.5/5 (474)

- Team of Rivals: The Political Genius of Abraham LincolnОт EverandTeam of Rivals: The Political Genius of Abraham LincolnРейтинг: 4.5 из 5 звезд4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyОт EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyРейтинг: 3.5 из 5 звезд3.5/5 (2259)

- The Unwinding: An Inner History of the New AmericaОт EverandThe Unwinding: An Inner History of the New AmericaРейтинг: 4 из 5 звезд4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreОт EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreРейтинг: 4 из 5 звезд4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)От EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Рейтинг: 4.5 из 5 звезд4.5/5 (120)

- Trafoindo Catalogue Oil Immersed Transformers PDFДокумент2 страницыTrafoindo Catalogue Oil Immersed Transformers PDFarie611Оценок пока нет

- Pain in TransformerДокумент4 страницыPain in TransformeradauОценок пока нет

- Addressable Loop Modules: Introduction FC410MIMДокумент8 страницAddressable Loop Modules: Introduction FC410MIMLORIUNEAОценок пока нет

- Manual Hioki 3454-11Документ2 страницыManual Hioki 3454-11Mauricio Cárdenas Roa100% (1)

- Mirage b2530g ManualДокумент5 страницMirage b2530g ManualWilliam C. AdamsОценок пока нет

- Electronic Products & Components in PUNEДокумент4 страницыElectronic Products & Components in PUNESenthil Kumar MuraliОценок пока нет

- EETДокумент15 страницEETAzirul SambasОценок пока нет

- A Report On Switchyard Equipment Testing (132Документ11 страницA Report On Switchyard Equipment Testing (132harsh_biharОценок пока нет

- Indracontrol S20 Analog Input Module 8 Inputs: FeaturesДокумент20 страницIndracontrol S20 Analog Input Module 8 Inputs: FeaturesDaniel LimaОценок пока нет

- Leroy Somer AVR R220 en PDFДокумент8 страницLeroy Somer AVR R220 en PDFJORGE ARMANDO CARRASCO TICLLEОценок пока нет

- Datasheet Solis - (100-110) K-5G GBR V2.1 2022 10Документ2 страницыDatasheet Solis - (100-110) K-5G GBR V2.1 2022 10Pawrij SuriyaaroonrojОценок пока нет

- Autostart Control Panels - Analog Control System - Product Training Department - OLYMPIAN PDFДокумент22 страницыAutostart Control Panels - Analog Control System - Product Training Department - OLYMPIAN PDFpevare100% (18)

- Diode Characteristics and ApplicationsДокумент12 страницDiode Characteristics and ApplicationsZuopan YapОценок пока нет

- Olympus CH - Brochure - OKДокумент8 страницOlympus CH - Brochure - OKYasuda ReiОценок пока нет

- Booklet On Domestic WiringДокумент113 страницBooklet On Domestic Wiringpubuduclk93% (42)

- 6 - 7 Lmu 5000Документ4 страницы6 - 7 Lmu 5000Anonymous CuRRTsRОценок пока нет

- Types of Transmission Structures: Fact Sheet Fact SheetДокумент2 страницыTypes of Transmission Structures: Fact Sheet Fact Sheetpinku_thakkarОценок пока нет

- NEON LampДокумент14 страницNEON LampVijay GajjalaОценок пока нет

- bdv65 Bdv65a bdv65b bdv65cДокумент3 страницыbdv65 Bdv65a bdv65b bdv65cMaurice LugusaОценок пока нет

- MXL9000 ManualДокумент2 страницыMXL9000 ManualbhsoulОценок пока нет

- Growatt 18000TL3-HE/20000TL3-HE: Leading - Edge TechnologyДокумент2 страницыGrowatt 18000TL3-HE/20000TL3-HE: Leading - Edge TechnologyTu Nguyen Thi CamОценок пока нет

- CAN Data Link Circuit - Test (RENR5096)Документ3 страницыCAN Data Link Circuit - Test (RENR5096)Josip MiškovićОценок пока нет

- Question Bank: Unit-IДокумент8 страницQuestion Bank: Unit-Iollata kalanoОценок пока нет

- Any Grid - PSW H - EN Manual - 2022 02 21 1Документ58 страницAny Grid - PSW H - EN Manual - 2022 02 21 1mahmoud ElmasryОценок пока нет

- Ficha Tecnica SOL GT PolyДокумент2 страницыFicha Tecnica SOL GT Polylic_palominoОценок пока нет

- RET615 - Brochure - Transformer ProtectionДокумент8 страницRET615 - Brochure - Transformer Protectionfiatraj1Оценок пока нет

- MR-J4 Servo Amplifier Cables and Connectors: For 3.5 KW or SmallerДокумент5 страницMR-J4 Servo Amplifier Cables and Connectors: For 3.5 KW or SmallerJesus PonceОценок пока нет

- MODEL PC-414R Transformer Temperature Indicator: 1. ApplicationДокумент4 страницыMODEL PC-414R Transformer Temperature Indicator: 1. ApplicationMKОценок пока нет

- Ntu Ee2002Документ198 страницNtu Ee2002Aaron Bourne Lee100% (1)

- E18 D80NKДокумент5 страницE18 D80NKIlham AhiiemОценок пока нет