Академический Документы

Профессиональный Документы

Культура Документы

Os Apps New Design Final

Загружено:

Pablo Valenzuela ArredondoИсходное описание:

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Os Apps New Design Final

Загружено:

Pablo Valenzuela ArredondoАвторское право:

Доступные форматы

Occupancy Sensor

Design and Application Guide

Energy saving report

SCENE

DIM

DIGITAL

O c c u p a n c y S e n s o r s

OSAPPS_1204

www.wattstopper.com

8 0 0 . 8 7 9 . 8 5 8 5

SCENE

DIM

DIGITAL

O c c u p a n c y S e n s o r s

1

Occupancy sensor design guide introduction

Now that youve determined that occupancy

sensors are the right lighting control strategy

for your facility, choosing and implementing

the ideal sensor for each application is

essential to achieving the most efficient and

reliable control. This design and application

guide aids the lighting professional in select-

ing, laying out, specifying, installing and

commissioning an occupancy-based lighting

control system.

In this guide youll find:

A flow chart that helps select the correct sensor technology for each application.

A list of dos and donts that are important rules to follow for every installation.

Detailed design steps for implementing occupancy-based control, where youll be

guided through selecting and implementing the appropriate occupancy sensor product

for each application. Design steps include:

Step 1. Evaluate space characteristics

Step 2. Match sensor technology to an application

Step 3. Layout and specify

- Select coverage patterns

- Select product features

- Choose power pack

- Integrate with other control devices

Step 4. Installation and commission

- Select optimal mounting configuration

- Sensor placement, installation, and settings

Application examples for specific building spaces

Together, these tools will help you in defining and implementing the optimal occupancy-

based control solution for every type of building space.

Watt Stopper/Legrands application experts are available for design support and assis-

tance on any lighting control question. Call our technical support at 800-879-8585.

Introduction

Is spaced used

intermittently? Are lights

left on in unoccupied

spaces?

Are there energy code

compliance requirements?

Are ceiling heights

less than 14 feet?

Would you like occupancy-

based controls?

Does space contain

partitions, large

equipment or furniture?

Is there a small or more

specific area needed for

detection?

Yes

No

No

Does space contain

partitions, large equipment

or furniture?

Is there a clear

line of sight to all areas?

Ultrasonic

PIR

No

Yes

Other control strategies

are more appropriate.

No

Yes

Yes

Are there definite space

boundaries?

Yes

Yes

No

Yes No

Is there a high volume

of air flow?

Is there moving

mechanical

equipment in

the space?

DT or Ultrasonic

DT or Ultrasonic

Yes

No

Yes

No

No

Can owner choose an

appropriate mounting

location away

from air flow?

Yes No Yes

DT or Ultrasonic

No

Yes

No

No PIR

PIR

Is space small or well

defined?

PIR

Would installation of

additional sensors justify

payback?

Yes

Yes

No

Other control strategies

are more appropriate.

Other control strategies

are more appropriate.

Occupancy sensor selection flow chart

Although there are several steps involved in implementing occupancy sensor controls

(outlined on the following pages), this flow chart offers a quick way to determine which

sensor technology is best for your application.

www.wattstopper.com

8 0 0 . 8 7 9 . 8 5 8 5

2

Energy saving report

SCENE

DIM

DIGITAL

O c c u p a n c y S e n s o r s

Following these rules helps to ensure that the sensors work effectively, providing comfort

for occupants while saving money for the facility. Be sure to review the following pages for

detailed product selection guidance.

Do

Use ultrasonic sensors in areas

screened by partitions or furni-

ture

Use PIR in enclosed spaces

Create zones controlled by dif-

ferent sensors to manage

lighting in large areas

Use dual technology sensors for

areas with very low activity levels

Install sensors on vibration-free,

stable surfaces

Position sensors above or close

to the main areas of activity in a

space

Mask the sensor lens to define

coverage of the controlled zone

even more accurately

Integrate sensor use with other

control methods (i.e. time

scheduled control, daylighting)

Educate occupants about the

new devices and what to expect

Dont

Use ultrasonic sensors in spaces

with heavy air flow

Install ultrasonic sensors in

spaces where the ceiling height

exceeds 14 feet

Use PIR sensors in spaces

where there are fixtures or furni-

ture that obstruct a clear line of

sight

Install PIR sensors so that their

line of sight continues beyond

doorways

Install sensors within 6-8 feet of

HVAC outlets or heating blowers

Position a wall switch sensor

behind an office door

Control emergency or exit light-

ing with sensors

Install PIR sensors in spaces

where there are extremely low

levels of occupant motion

Getting started Dos and Donts

www.wattstopper.com

8 0 0 . 8 7 9 . 8 5 8 5

3

Energy saving report

SCENE

DIM

DIGITAL

O c c u p a n c y S e n s o r s

Identifying the ideal occupancy sensor for a particular application involves the considera-

tion of several factors that are equally critical to an effective control solution. Because

different sensors work best under different circumstances, incorporating these factors

into the decision making process will provide optimal results:

Designing the occupancy sensor project

Design steps

Evaluate space

characteristics

Match sensor

technology to

application

Understand

coverage patterns

Select optimal

mounting

configuration

E

valuate space

characteristics

M

atch sensor

technology to

application

U

nderstand

coverage patterns

S

elect optim

al

m

ounting

configuration

Evaluate space

characteristics

Match sensor

technology to

application

Understand

coverage patterns

Select optimal

mounting

configuration

E

v

a

lu

a

te

s

p

a

c

e

c

h

a

ra

c

te

ris

tic

s

M

a

tc

h

s

e

n

s

o

r

te

c

h

n

o

lo

g

y

to

a

p

p

lic

a

tio

n

U

n

d

e

rs

ta

n

d

c

o

v

e

ra

g

e

p

a

tte

rn

s

S

e

le

c

t o

p

tim

a

l

m

o

u

n

tin

g

c

o

n

fig

u

ra

tio

n

1. Evaluate space

characteristics

2. Match sensor

technology to

application

3. Layout and

specify

4. Install and

commission

www.wattstopper.com

8 0 0 . 8 7 9 . 8 5 8 5

4

Energy saving report

SCENE

DIM

DIGITAL

O c c u p a n c y S e n s o r s

To evaluate the applications characteristics, designers should become familiar with:

Room/space size and shape

Location(s) of occupant activity and non-activity

Location of walls, doors, windows and drapes

Ceiling height

Partition height and location

Location of shelves, book cases, file cabinets, and large equipment

Large objects that would block or alter a sensors coverage

Location of HVAC ducts and fans

Areas with available sunlight for added light level sensing

Location of desk/workspace orientation with regards to walls, partitions and other

obstacles

Special attention should be paid to high levels of vibration and/or air flow,

extreme temperature conditions, and unusually low levels of activity because

these issues may help identify the best technology solution.

Step 1 - Evaluate space characteristics

Space

characteristics

www.wattstopper.com

8 0 0 . 8 7 9 . 8 5 8 5

5

Energy saving report

SCENE

DIM

DIGITAL

O c c u p a n c y S e n s o r s

Step 2 - Match technology to application

All Watt Stopper occupancy sensors use either passive infrared or ultrasonic technology,

or a combination of both.

Passive infrared (PIR) technology

Relies on line-of-sight coverage to detect occupancy by sensing the difference in heat

emitted by humans in motion from that of the background space.

Ultrasonic technology

Utilizes the Doppler principle to detect occupancy through emitting ultrasonic sound

waves throughout a space.

Dual technology (DT)

Employs both PIR and ultrasonic technologies. DT sensors will activate lights when both

sensing technologies detect occupancy, but will continue to hold lighting on as long as

only one technology detects continued occupancy.

The matrix below summarizes these technologies and the space characteristics that

would favor the use of one technology over another. Also use the flow chart on Page 3 to

help determine which technology is ideal for your application

Note

Cut off refers to the ability to clearly define or limit sensor coverage so that detection

capability will not intrude into adjacent spaces.

Match sensor

technology to

application

Coverage type

Compatible

applications

Incompatible

application

characteristics

PIR

wall switches

- line of sight

- cut off

- smaller, enclosed

spaces

- low motion levels

by occupants

- obstacles blocking

sensor view

Dual

technology

sensors

- complete

coverage

- cut off

- classroom

- spaces with low

motion levels by

occupants

- high levels of air

flow

- warehouse

Ultrasonic

ceiling sensors

- volumetric

- no clear cut off

- open spaces

- spaces with

obstacles

- bathrooms

- high ceilings

- high levels of

vibration or air flow

PIR ceiling &

wall mount

sensors

- line of sight

- cut off

- spaces where the

sensor has a view of

the activity

- low motion levels by

occupants

- obstacles blocking

sensor view

www.wattstopper.com

8 0 0 . 8 7 9 . 8 5 8 5

6

Energy saving report

SCENE

DIM

DIGITAL

O c c u p a n c y S e n s o r s

Step 3 - Specify and layout the project

Select coverage patterns

Many different coverage sizes and shapes are available for each sensor technology. While

a small application is easily covered with one sensor, larger applications benefit from

grouping controlled lighting into zones (with each zone controlled by a sensor). Familiarity

with these coverage patterns will help designers specify the right product, ensuring the

greatest sensor accuracy and occupant comfort.

Do occupants engage in major motions, such as walking, or fine motions,

such as typing or reading. Coverages change depending on motion type.

When creating zones of coverage, such as the coverage illustrated in the

example above, take care to ensure that sensor coverages overlap by 20%.

Coverage

patterns

Example (Dual technology coverage)

In a large space, such as a lecture hall,

dual technology sensors provide coverage

that suits the variable levels of motion pre-

sent. The DT-200 is mounted in the corner.

Its passive infrared portion of coverage

defines exact cutoff near the doorway. The

DT-300, with 360 coverage, fills in the rest

of the space.

Products Used

DT-200 and DT-300 dual technology sensors

Example (Ultrasonic coverage)

In an open, partitioned office, designers select ultra-

sonic sensors. To adequately cover the entire space,

multiple sensors are positioned to cover a specific zone.

Products Used

Ultrasonic occupancy sensors (UT-300)

WT-2200

www.wattstopper.com

8 0 0 . 8 7 9 . 8 5 8 5

7

Energy saving report

SCENE

DIM

DIGITAL

O c c u p a n c y S e n s o r s

50 ft.

40 ft.

Sensor

Sensor

50 ft.

40 ft.

Sensor Sensor

Manual-ON Switch

Step 3 - Specify and layout the project

Lighting designers should also consider specific features, which can add functionality

and flexibility to the control solution.

Alerts

Visual (light flash) and/or audible alerts warn occupants of impending shutoff.

Dual relays

Dual relay wall switches contain two separate relays for controlling two independent

lighting loads or circuits. This satisfies bi-level lighting control energy code require-

ments.

Hard lens

Wall switches that are placed in public spaces or schools require a lens that can stand up

to substantial contact. Up to five times the thickness of a comparable wall switch lens, a

hard lens makes the device resistant to vandalism or unintentional damage. The WN and

WA wall switches offer a hard lens.

Isolated relay

An isolated relay enables interfacing with a facilitys HVAC, BAS, or monitoring systems.

For example, people entering a building after hours trigger not only the necessary

lighting, but the heat or A/C as well. In automatic wall switches, an isolated relay can

be used to control different circuits or loads.

Light level

The light level feature holds lighting OFF when natural light levels rise above a pre-set

level. This setting is adjustable and can be overridden. It is available in several Watt

Stopper wall switches and ceiling sensors.

This light level feature is recommended for spaces that have access to abun-

dant natural light. Although multiple sensors may be used, only one sensor

should be actively utilizing the light level feature within a controlled area.

Low profile

Many applications call for lighting controls that dont take up a lot of space and that leave

the ceiling looking uncluttered. Several Watt Stopper sensors are designed to be

extremely low profile and compact.

Nightlight

Wall switch sensors with built-in nightlights provide users with a bright LED that

remains illuminated whenever overhead lights are off.

ON Mode operation

Some automatic wall switches feature a choice of either automatic or manual on

operation. For manual on operation with ceiling mount sensors, some sensors feature

the ability to work with a momentary low voltage switch for manual on/off operation.

Product

features

www.wattstopper.com

8 0 0 . 8 7 9 . 8 5 8 5

8

Energy saving report

SCENE

DIM

DIGITAL

O c c u p a n c y S e n s o r s

SmartSet

SmartSet automatically adjusts the sensors time delay and sensitivity settings for opti-

mal performance and energy efficiency. SmartSet is found in the WA, DT-300, UT-300, and

CI-300 series sensors.

Terminal wiring

Contractor friendly terminal style wiring makes installation quick and easy by eliminating

the need for wire nuts.

Voltage choice - line or low

Having a choice of line or low voltage sensors, gives the installer the flexibility to use the

type of wiring that is most appropriate for their requirements.

Walk through Mode

For extra energy savings, walk through mode switches lights off three minutes after an

area is initially occupied if no motion is detected after the first 30 seconds.

Zero crossing

Zero Crossing Circuitry ensures that a wall switch sensor or power packs switching takes

place at the beginning of the voltage wave very close to zero volts. This reduces stress on

the relay and increases sensor life.

Step 3 - Specify and layout the project

Product

features

www.wattstopper.com

8 0 0 . 8 7 9 . 8 5 8 5

9

Energy saving report

SCENE

DIM

DIGITAL

O c c u p a n c y S e n s o r s

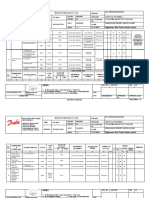

WS-200

WA-200

WA-300

WI-200

WI-300

WN-100

WD series

CN-100

CW-100

CX series

CI-200 series

CI-300 series

UT-300 series

W series

WT series

DT-200 series

DT-300 series

A

l

e

r

t

s

D

u

a

l

r

e

l

a

y

s

H

a

r

d

l

e

n

s

I

s

o

l

a

t

e

d

r

e

l

a

y

L

i

g

h

t

l

e

v

e

l

L

o

w

p

r

o

f

i

l

e

N

i

g

h

t

l

i

g

h

t

O

N

M

o

d

e

o

p

e

r

a

t

i

o

n

S

m

a

r

t

S

e

t

T

e

r

m

i

n

a

l

w

i

r

i

n

g

V

o

l

t

a

g

e

c

h

o

i

c

e

-

l

i

n

e

o

r

l

o

w

W

a

l

k

t

h

r

o

u

g

h

M

o

d

e

Z

e

r

o

c

r

o

s

s

i

n

g

*

* *

*

*

*

*

*

*

*

*

*

*

*

*

*

*

*

*

*

*

*

*

*

*

*

*

*

*

*

*

*

*

*

*

*

*

*

*

*

*

*

*

*

*

*

*

*

*

*

*

*

*

*

*

*

*

*

*

*

*

*

*

*

*

*

*

*

*

*

*

*

*

*

*

*

*

*

www.wattstopper.com

8 0 0 . 8 7 9 . 8 5 8 5

10

Energy saving report

SCENE

DIM

DIGITAL

O c c u p a n c y S e n s o r s

Step 3 - Specify and layout the project

Product

features

matrix

Power packs are a key component of low voltage sensor based lighting control systems.

Power packs provide low voltage power to sensors and other control devices and respond

to signals from those devices to switch a relay(s). However, power packs can also provide

advanced features such as switched inputs, inputs for scheduling, and dimming control.

These features and many others provide a finer degree of control over the different loads

in a building.

Single relay power packs

Provide power to control devices and switch a single load in response

to a signal from the control devices. These power packs may also

provide additional control inputs to hold on or off the relay.

Auxillary packs

Used in conjunction with a power pack to switch other loads. Do not have a transformer

so they do not provide power to a control device.

Form C power packs

Provide customizable control scenarios by including two switching options in one relay.

Dual relay power packs

Can switch two loads simultaneously from a single control device signal.

Intelligent power packs

Offer advanced features to customize applications, including dual switch inputs,

dimming capability, multiple control inputs, programmable switching scenarios.

Power supplies

Provide extra low voltage power for large applications with many control devices.

Step 3 - Specify and layout the project

Choose the

power pack

www.wattstopper.com

8 0 0 . 8 7 9 . 8 5 8 5

11

Energy saving report

SCENE

DIM

DIGITAL

O c c u p a n c y S e n s o r s

Power output needs

Matching the current consumption of all the devices connected to the power pack to the

amount of power the power pack can provide is very important. Simply sum the current

consumption ratings from all the sensors to be connected to one power pack. If this num-

ber is less than the power pack output rating, the power pack is appropriate for the

application. If the number is greater, consider decreasing the switching zones or provid-

ing an extra power pack/supply to properly power the sensors

Voltage

When selecting a power pack, consider the voltage of the electrical systems. Many power

packs are capable of accepting a range of line voltage inputs, including two phase, while

some are voltage specific. Pay attention to the input ratings of the power pack.

Relay type

The relay in the power pack is the key component that switches the load. Many power

packs provide an isolated relay so the power pack can switch a load that is different than

the line voltage supplying the power pack. Isolated relays provide better switching flexibil-

ity in different applications. Some power packs also have different types of relays so the

specifier can customize the switching of the application. While most power packs provide

a simple form A relay (normally closed) other power packs offer increased switching flexi-

bility with a form C relay (both normally open and normally closed). In addition, larger

power packs may have two or more isolated relays in the same enclosure. These power

packs can provide simultaneous or independent control of two or more loads. Smaller,

low voltage rated relays may also be present in some power packs. These relays are used

to signal other systems such as security or HVAC systems.

Relay ratings

Most power packs can switch a full 20 Amp load which is sufficient for sensor based

lighting control. An exception to this load rating is the form C power packs. Make sure the

load being switched does not exceed the load rating of the power pack.

Type of load to be switched

Power packs have specific ratings for different load types. Most common load types can

be controlled by power packs including incandescent, fluorescent and motor loads. Make

sure the power pack relay ratings match the type of load to be controlled. One load type of

concern for power packs are the newer electronic ballasts. These ballasts can cause

strain on relays due to high inrush current. To alleviate this situation, many power packs

use zero crossing technology to eliminate the potential for relay damage from high

inrush. If electronic ballasts are specified, try to choose a power pack that uses zero

crossing (such as the BZ-100 or the LC-100).

Step 3 - Specify and layout the project

Considerations

when selecting a

power pack

www.wattstopper.com

8 0 0 . 8 7 9 . 8 5 8 5

12

Energy saving report

SCENE

DIM

DIGITAL

O c c u p a n c y S e n s o r s

Power packs are generally mounted by a nipple

externally onto the knock-out of a junction box. This

places the power pack itself in the plenum space.

Make sure the power pack is plenum rated. Smaller

power packs can also be installed inside a standard

junction box. Power packs are designed so that line

voltage connections are made inside the junction box

and low voltage connections are made externally.

Make sure all low voltage wiring is plenum rated as well.

Intelligent power packs provide inputs so that multiple control devices can

be connected. This allows the installer to customize the control scenario

for different applications and end user preferences. Use intelligent power packs when

multi-device, manual switching, and dimming applications are considered.

Step 3 - Specify and layout the project

Mounting

options

Signaling from

multiple

devices

www.wattstopper.com

8 0 0 . 8 7 9 . 8 5 8 5

13

Energy saving report

SCENE

DIM

DIGITAL

O c c u p a n c y S e n s o r s

Junction

box

BLK Power

WHT Neutral

GRN Ground

RED Output 1

RED Load & Line

YLW Output 2

YLW Load & Line

LC-100

Intelligent Power Pack

Model #:

800.879.8585 972.578.1699

0-10V Ballast

Daylight

Shed

Unoccupied

24VDC

Shed Signal

Time Clock

Photocell

Occupancy

Sensor 24VDC

Designed and Manufactured in USA

Industrial Control Equipment 83AJ

01627r1

1 Blink Disable

2 ON Only when occupied

3 Automatic ON

4 Dimming

5 Daylighting Enable

6 Time Override #1

7 Time Override #2

8 100 Hour Burn In

Configuration Switches

Load Output Rating

120/277VAC, 60Hz, 1hp

20Amp Tungsten or Ballast

Auxiliary Output Rating

1Amp, 24VDC

24VDC

OFF

ON

Sensor

24VDC

Com

Gray

Violet

- + Shed

Level

- + Max

Level

Type 1 enclosure

For operation within a

Maximum Ambient of 60C

Acceptable for use in plenum

Low voltage wiring

For increased flexibility and energy savings, occupancy sensors seamlessly integrate with

many lighting controls.

Lighting control panels

Integrating occupancy sensors with lighting control panels provides convenience and sav-

ings benefits. Rather than the panels system clock signalling all lights to turn off at a

specific time, occupancy sensor control takes over during after hours. Here, lights remain

on only in spaces that are occupied, and turn off after the space is vacated.

Daylighting controls

Occupancy sensors also integrate well with daylighting controls in building spaces that

receive daylight. When used together, the occupancy sensors can keep lights off in unoc-

cupied spaces, even when the daylighting controls signal that there is not adequate

daylight.

Step 3 - Specify and layout the project

Integrating

with other

control

devices

www.wattstopper.com

8 0 0 . 8 7 9 . 8 5 8 5

14

Energy saving report

SCENE

DIM

DIGITAL

O c c u p a n c y S e n s o r s

Step 4 - Install and commission

Watt Stopper sensors are available in three basic

mounting configurations:

wall switch replacements (line voltage)

ceiling or wall mount sensors with power packs

(low voltage)

ceiling or wall mount (line voltage)

Wall switch replacements

Wall switch sensors are designed to replace existing wall

switches. Wall switch sensors utilize passive infrared tech-

nology and therefore require a clear line of sight of the

coverage area from the switch location.

Ceiling/wall mount sensors

Some sensors are recommended for ceiling mount use,

such as the CI-200, W series, WT series, DT-300 series and

WPIR. Others, such as the CX and DT-200 series, contain

built-in bracket systems that provide ceiling mounting as

well as wall mounting. This is important for applications where

the ceiling is unavailable for sensor

installation.

Many ceiling/wall mount sensors are

available in both line and low voltage

models. Although both models provide

the same function, there are situations

when one model is a better choice

than the other.

Low voltage

Low voltage occupancy sensors use a power pack. They offer

flexible wiring configurations (such as multiple sensors wired

to a single power pack) and the placement of sensors on the

ceiling or wall is easy to change upon installation and during

building renovations. However, in hard cap ceiling applications,

a line voltage sensor is recommended.

Line voltage

Line voltage occupancy sensors feature standard wiring (con-

duit and wire), and terminal wiring makes installation easy.

They are a good choice for applications where there is no

plenum or junction boxes are hard to access.

WA-200.exploded

1 2 3 4 5 6 7 8

WA sensor replaces conventional wall switches

Rear

housing

Depluggable terminal

Front

cover

Ceiling

Spring clips (2)

DT-300 ceiling mount sensor

The DT-200 sensor can be

installed on the ceiling (outlined

here in black) or on the wall

(outlined here as dotted line)

Power packs are used when low

voltage ceiling sensors are selected.

Mounting

configuration

4" Square, 2.25" Deep

*

Junction Box with

Double Gang

Mudring

Sensor

Screws

Ceiling

Front

Cover

CI-355 line voltage ceiling mount

sensor

www.wattstopper.com

8 0 0 . 8 7 9 . 8 5 8 5

15

Energy saving report

SCENE

DIM

DIGITAL

O c c u p a n c y S e n s o r s

Step 4 - Install and commission

Sensor placement

Installers should position the sensor so it

has the best view of the entire coverage

area. Care should be taken to minimize

the possibility of false ONs or OFFs due to

sensor location. For instance, an ultra-

sonic sensor should not be positioned

near an open doorway, since a passerby

could trigger lighting ON.

When installing ultrasonic sen-

sors, installers should position

the receiving side toward the area

of greatest traffic.

Installation

When installing the sensor, the contractor should wire it according to manufacturers

instructions to eliminate any functional problems or sensor damage. For instance, all

Watt Stopper wall switch sensors require grounding for proper functioning.

Settings

Following sensor installation, additional adjustments may need to be made. This is often

due to last minute changes in furniture or fixture placement. Ideally, the sensor settings

for sensitivity and time delays should match the activity levels of the monitored spaces.

For sensors that feature SmartSet technology, adjustments are typically not needed after

installation.

Placement

Installation

Settings

WS, WA or WI Automatic Wall Switch

12'

18'

This PIR wall switch has been positioned to look into

the room rather than out the door, minimizing the

possibility of false triggers. Nothing is obstructing the

sensors view and it faces the front of the worker.

www.wattstopper.com

8 0 0 . 8 7 9 . 8 5 8 5

16

Energy saving report

SCENE

DIM

DIGITAL

O c c u p a n c y S e n s o r s

Energy saving report

SCENE

DIM

DIGITAL

O c c u p a n c y S e n s o r s

Application Examples

www.wattstopper.com

8 0 0 . 8 7 9 . 8 5 8 5

Application description

Large office area with partitioned cubicles. A

majority of work is done at computers in

individual cubicles.

Control needs

A sensor that can see around obstacles such

as cubicle walls, and that has a high sensitiv-

ity to detect fine movements such as typing.

Solution

UT-300 Ultrasonic Ceiling Sensors.

Ultrasonics detect movement through obstacles so occupants working in cubicles are

detected. To ensure the entire area receives coverage, place the sensors in zones that

overlap.

Application description

Enclosed single-occupant office with a win-

dow. Primary activities are computer work,

reading and meetings.

Control needs

ON/OFF control with light level sensing. The

sensor should be able to detect small move-

ments such as typing.

Solution

WA-200 Automatic Wall Switch Sensor.

The sensor replaces a standard wall switch. It should have a direct and clear view of the

front of the occupant. Be sure not to place the sensor behind a door or other obstacle that

blocks its view. Light level sensing ensures that lights stay off if enough ambient light is

available in the room. The WAs SmartSet technology automatically adjusts the time delay

and sensitivity settings for optimal performance and savings.

Occupancy sensor applications

Partitioned office

space

Enclosed office

WS, WA or WI Automatic Wall Switch

12'

18'

42'

42'

www.wattstopper.com

8 0 0 . 8 7 9 . 8 5 8 5

18

Energy saving report

SCENE

DIM

DIGITAL

O c c u p a n c y S e n s o r s

Application description

Medium conference room that is used for meetings

and training.

Control needs

A sensor with ON/OFF control. The sensor should

have high sensitivity, as there is often little motion

in the room during meetings. Lights need to be

capable of staying off during presentations.

Solution

DT-300 360 Dual Technology Occupancy Sensor. The DT-300 uses both PIR and ultrasonic

technologies to sense occupancy, resulting in enhanced sensing capability for applications

where activity varies greatly. The sensor should be placed in the middle of the room. A

manual OFF override is useful when lights need to be off during presentations.

Application description

High school classroom.

Control needs

ON/OFF control with high sensitivity, since occupants

sit still for long periods of time.

Solution

DT-200 Dual Technology Occupancy Sensor. The sen-

sor accommodates lower levels of activity without false

triggers. The DT-200 is corner mounted behind the teachers desk for optimum coverage,

without seeing out the door.

Application description

Elementary classroom.

Control needs

Automatic ON/OFF of lights based on occupancy.

Daylight dimming of fixture row next to the windows.

Manual ON/OFF and dimming of two zones of lights

for different presentation scenes: one zone is the

middle lamps of direct/indirect fixtures, the second

zone is the outer lamps.

Solution

LC-100 Intelligent Power Pack, DT-200 Dual Technology Occupancy Sensor and LS-301

Dimming Photosensor. The occupancy and photosensors can be connected to a single

LC-100. In addition, the LC-100 facilitates dual zone switching and dimming with its dual

relay and dual 0-10V dimming outputs. A low voltage momentary switch is simply con-

nected to the dual switch inputs.

Occupancy sensor applications

Conference/

training room

Classroom

Classroom

DT-200

30'

30'

D

D

w

i

n

d

o

w

DT-300

28'

30'

www.wattstopper.com

8 0 0 . 8 7 9 . 8 5 8 5

19

Energy saving report

SCENE

DIM

DIGITAL

O c c u p a n c y S e n s o r s

Application description

Library book stacks 14 in length that

are occupied intermittently throughout

the day.

Control needs

ON/OFF control in individual book

stacks. Lights should turn when some-

one enters the aisle from either side

and lights should not turn on in adja-

cent stacks if they are not occupied.

Solution

WPIR PIR Occupancy Sensor.

The WPIR sensors are ideal for aisles under 15 in length (longer aisles should be zoned

with multiple sensors). Place the WPIR at the beginning of the aisle. The use of the LC-

100 for the power pack will provide additional features such as

Application description

Large lunch/break room occupied inter-

mittently throughout the day.

Control needs

ON/OFF control what can detect a variety

of activity levels.

Solution

UT Ultrasonic Ceiling Sensor.

The UT provides 360 of coverage and ensures lights turn on when someone enters the

room. Place the sensor above the main activity area for complete coverage.

Occupancy sensor applications

Library

Lunch/Break

Room

WT-1100 or W-1000A

20'

32'

WPIR

Book stack

Fixture

www.wattstopper.com

8 0 0 . 8 7 9 . 8 5 8 5

20

Energy saving report

SCENE

DIM

DIGITAL

O c c u p a n c y S e n s o r s

Application description

Small utility room used sporadically during the

day.

Control needs

ON/OFF sensor that ensures lights come on as

soon as the door opens.

Solution

WS-200 PIR Wall Switch Sensor.

The sensor directly replaces the wall switch. It

should not have obstacles that block coverage,

as PIR technology cannot see around objects.

Note: as an alternative to using occupancy sensors, the TS Digital Time Switch is well

suited to areas such as utility rooms where the lights remain on for a preset, user

adjustable amount of time.

Application description

Aisleways in a warehouse with high ceil-

ings. Aisles are occupied sporadically

throughout the day.

Control needs

ON/OFF control that only triggers lights in

the aisleway that is occupied.

Solution

CX-100 PIR Ceiling Sensor.

The CX can be mounted at ceiling heights

up to 50 feet. The sensors coverage zone

can be tightly defined so lights are on only where needed.

Occupancy sensor applications

Utility Room

Warehouse

CX-100-3

WS-200

15'

17'

www.wattstopper.com

8 0 0 . 8 7 9 . 8 5 8 5

21

Energy saving report

SCENE

DIM

DIGITAL

O c c u p a n c y S e n s o r s

Application description

Public restroom with six parti-

tioned stalls. Ceiling is hard-cap

or concrete.

Control needs

ON/OFF control with technology

that can see around obstacles.

Solution

The UT-355 line voltage

Ultrasonic Sensor.

Place the sensor close to the stalls, about 2 out from the stall door so the sensor has the

best opportunity to detect presence in the entire restroom. Special attention should be

given to larger stalls to ensure they are well covered. Use the UT-355 in restrooms with

hard-cap or concrete ceilings. Add a 4 square or Wiremold junction box to mount the sen-

sor on to the ceiling surface.

Application description

Lobby with high ceilings and windows.

Control needs

ON/OFF control and light level sensing. The sen-

sor should also provide accurate coverage at

greater heights and a defined cut off.

Solution

DT-200 Dual Technology Occupancy Sensor.

Place the sensor behind the reception desk so it

can see the entire space while also detecting small movements at the desk. Pay special

attention to covering the entrance, reception desk and waiting area. In addition, the DT-

200 features light level sensing, which increases energy savings by keeping lights off

when ambient light is sufficient.

Additionally, the lobby would be an ideal application for integrating daylighting controls.

Occupancy sensor applications

Restroom

Lobby

DT-200 or CX-100

STAIRS

HALLWAY

RECEPTION

Exit

24'

30'

WT-1100 or W-1000A Standard toggle switch

28'

20'

www.wattstopper.com

8 0 0 . 8 7 9 . 8 5 8 5

22

Energy saving report

SCENE

DIM

DIGITAL

O c c u p a n c y S e n s o r s

Occupancy sensor applications

Hallway

Hotel

guestrooms

Application description

Office building hallway with

walls on both sides. The hall-

way has no windows, but has

doors along each side.

Control needs

ON/OFF control that ensures lights turn on immediately when someone enters the

hallway from either side or from a doorway.

Solution

WT-2250 Ultrasonic Sensor.

Place the sensor in the middle of the hallway, halfway between entrances. The sensor

will detect when someone enters the hallway from either side or when someone

enters though a door in the middle of the hallway.

Application description

Hotel guestroom bathroom

Control needs

Lights turn off automatically based on occu-

pancy. Since guests dont always want lights

on in the bathroom, lights should not turn on

automatically when the room is occupied.

Provide users with a nightlight that is illumi-

nated when the overhead lights are off.

Solution

WN-100 Motion Sensor Nightlight Switch.

The WN directly replaces a bathroom wall switch. As a convenience to guests, the WN

provides a nightlight when lights are off. A button on the front of the switch allows

guests to turn on lighting when desired. Lights automatically turn off during times of

vacancy.

WT-2250

WN

25'

10'

www.wattstopper.com

8 0 0 . 8 7 9 . 8 5 8 5

23

Energy saving report

SCENE

DIM

DIGITAL

O c c u p a n c y S e n s o r s

Вам также может понравиться

- Switch Sensors: Design & Installation GuideДокумент16 страницSwitch Sensors: Design & Installation GuidejhedjesiОценок пока нет

- Aware Brochure tcm201-23403 PDFДокумент12 страницAware Brochure tcm201-23403 PDFsandrititosОценок пока нет

- RSR IlluminationДокумент26 страницRSR IlluminationRam RamisettiОценок пока нет

- Square D Clipsal 90° Indoor PIR Occupancy Sensor: SLC5751L For Use With Wired C-Bus™ NetworksДокумент28 страницSquare D Clipsal 90° Indoor PIR Occupancy Sensor: SLC5751L For Use With Wired C-Bus™ NetworkskahandawalaОценок пока нет

- Installersguide DGBДокумент69 страницInstallersguide DGBCaet GamingОценок пока нет

- Autroprime Guia de InstalacionДокумент68 страницAutroprime Guia de InstalacionMirko Torres PovedaОценок пока нет

- Parking Management in Shopping MallsДокумент12 страницParking Management in Shopping MallsadОценок пока нет

- 3683197Документ94 страницы3683197ArjunОценок пока нет

- 19 Aquilar TechДокумент1 страница19 Aquilar TechAyman SaberОценок пока нет

- InM Lab 9Документ10 страницInM Lab 9sufyanОценок пока нет

- Card Access WMS10 Quickstart GuideДокумент2 страницыCard Access WMS10 Quickstart Guidehban398Оценок пока нет

- Smart Sensors: Broadening The Horizon by Combining Smart Sensors With Vision TechnologyДокумент8 страницSmart Sensors: Broadening The Horizon by Combining Smart Sensors With Vision TechnologyKavin XavierОценок пока нет

- Design of Ultrasonic Alarm SystemДокумент28 страницDesign of Ultrasonic Alarm Systemmesale22222100% (2)

- Aspiration Smoke Detection Positioning Paper: BackgroundДокумент7 страницAspiration Smoke Detection Positioning Paper: BackgroundJohn simpsonОценок пока нет

- Occupancy Controls For LightingДокумент4 страницыOccupancy Controls For LightingedwardОценок пока нет

- AN447Документ20 страницAN447Maxim FrewdellОценок пока нет

- 1.1.0 General Description of VESDA Aspirating Smoke Detection SystemДокумент9 страниц1.1.0 General Description of VESDA Aspirating Smoke Detection SystemBen Lim100% (1)

- Addressable ZetaДокумент44 страницыAddressable Zetamubeen100% (2)

- Fire Alarm: 6. DetectionДокумент3 страницыFire Alarm: 6. DetectionVinay PallivalppilОценок пока нет

- Sensors, Cloud and Iot - The Trangle of Nextgen Technological InnovationsДокумент39 страницSensors, Cloud and Iot - The Trangle of Nextgen Technological InnovationsSambit Subhasish SahuОценок пока нет

- AP Sensing Power Cable MonitoringДокумент8 страницAP Sensing Power Cable MonitoringsalluahmedОценок пока нет

- Designing A Lighting Control System: LTGCONAPPS - 1204Документ15 страницDesigning A Lighting Control System: LTGCONAPPS - 1204jashfactorОценок пока нет

- Report On A Touch Sensor Alarm Circuit Using A BreadboardДокумент5 страницReport On A Touch Sensor Alarm Circuit Using A BreadboardVicks TechnologyОценок пока нет

- Content SamДокумент8 страницContent SamS SrivaniОценок пока нет

- Unit I Overview of Wireless Sensor Network: The Vision of Ambient IntelligenceДокумент19 страницUnit I Overview of Wireless Sensor Network: The Vision of Ambient Intelligencesavsen6720Оценок пока нет

- DetectorBrochure WebДокумент16 страницDetectorBrochure WebTan Kang YaoОценок пока нет

- CMBR003Документ4 страницыCMBR003Ricardo MendesОценок пока нет

- Sensor Encolador CFAH 30P32-403892Документ60 страницSensor Encolador CFAH 30P32-403892SantiagoAlpalaОценок пока нет

- Feasibility of Range FinderДокумент3 страницыFeasibility of Range FinderNecati Can ToklaçОценок пока нет

- Application of WSN in Precision Farming: Wireless Sensor Networks For Marginal Farming in India - COMMON ..Документ3 страницыApplication of WSN in Precision Farming: Wireless Sensor Networks For Marginal Farming in India - COMMON ..Nawin KumarОценок пока нет

- Unit-2 Week-1Документ37 страницUnit-2 Week-1vomyОценок пока нет

- (Ultrasonic Radar-Naman Kataria-CSB) PresentationДокумент15 страниц(Ultrasonic Radar-Naman Kataria-CSB) PresentationHimanshu VermaОценок пока нет

- VesdaДокумент6 страницVesdaBen LimОценок пока нет

- IoT Module 2 IoT Sensing and ActuationДокумент25 страницIoT Module 2 IoT Sensing and Actuationabhishek.ecОценок пока нет

- Legrand WattstopperДокумент28 страницLegrand WattstoppersulphurdioxideОценок пока нет

- Form QA-AUX01 - Auxiliary Inspection Checklist (Official)Документ3 страницыForm QA-AUX01 - Auxiliary Inspection Checklist (Official)Laurence Ann Marca100% (1)

- 89.ultrasonic Sensor in Automative Applications in Distance MeasurementДокумент4 страницы89.ultrasonic Sensor in Automative Applications in Distance Measurementvinay_2211Оценок пока нет

- Fixed Thermal Imaging Camera Systems For Process Measurement & ControlДокумент5 страницFixed Thermal Imaging Camera Systems For Process Measurement & ControlVipul GuptaОценок пока нет

- IoT Unit 3Документ50 страницIoT Unit 3lovelynani792Оценок пока нет

- ATOS Compact Scan en RevAДокумент11 страницATOS Compact Scan en RevAkoalaboiОценок пока нет

- Lab#08 IRДокумент9 страницLab#08 IRRehman ButtОценок пока нет

- Applications of Ultrasonic SensorsДокумент5 страницApplications of Ultrasonic SensorsSYED HABEEBULLAОценок пока нет

- Is 2189 2008 PDFДокумент28 страницIs 2189 2008 PDFSelva KumarОценок пока нет

- SensorДокумент2 страницыSensorguddianushaОценок пока нет

- Analog Devices - Practical Design Techniques For Sensor Signal ConditioningДокумент366 страницAnalog Devices - Practical Design Techniques For Sensor Signal ConditioningAnil Saini100% (1)

- Sensor Signal ConditioningДокумент366 страницSensor Signal Conditioningwagnalang1639100% (1)

- 5753 LДокумент7 страниц5753 LYousuf IbrahimОценок пока нет

- LEICA TPS1100 Professional Series: High-End Surveying Precise, Quick, and IntelligentДокумент14 страницLEICA TPS1100 Professional Series: High-End Surveying Precise, Quick, and IntelligentVinu PetrisorОценок пока нет

- Video SensorДокумент16 страницVideo SensorAlaa.H.MousaОценок пока нет

- I-Series GC 600G36 GB WW 1016-3Документ40 страницI-Series GC 600G36 GB WW 1016-3Erick AvОценок пока нет

- Catalogo de SensoresДокумент64 страницыCatalogo de SensoresfedtamagusОценок пока нет

- Installation Instructions Model Hfp-11 / Hfpt-11: Fireprint Detector / Fireprint Thermal DetectorДокумент4 страницыInstallation Instructions Model Hfp-11 / Hfpt-11: Fireprint Detector / Fireprint Thermal DetectorlalwinОценок пока нет

- 8A. FDAS - Presentation - IIEE-CRCSA 1st Technical Webinar - March 25, 2022Документ61 страница8A. FDAS - Presentation - IIEE-CRCSA 1st Technical Webinar - March 25, 2022Nels OdrajafОценок пока нет

- The Guideline To Motion Sensors For BeginnerДокумент10 страницThe Guideline To Motion Sensors For BeginnerjackОценок пока нет

- WatchOUT A&E Specifications - 0Документ4 страницыWatchOUT A&E Specifications - 0Francis Narváez PacahualaОценок пока нет

- LoRa Device Catalog V1 PDFДокумент54 страницыLoRa Device Catalog V1 PDFMugilan Mohan100% (1)

- NTCC PROJECTДокумент20 страницNTCC PROJECTdevpratapbthОценок пока нет

- Hochiki Smoke and Heat Detector Application Guide V1.00Документ22 страницыHochiki Smoke and Heat Detector Application Guide V1.00Nelso BedinОценок пока нет

- Bridgestone Databook 2010 - 0911Документ52 страницыBridgestone Databook 2010 - 0911jesus_pacco100% (1)

- Main - Daily Inspection Form Kalmar Ottawa CanadaДокумент1 страницаMain - Daily Inspection Form Kalmar Ottawa CanadaPablo Valenzuela ArredondoОценок пока нет

- Safety and Quality in Combined Transport (CT) - Edition 09-2019Документ32 страницыSafety and Quality in Combined Transport (CT) - Edition 09-2019Pablo Valenzuela ArredondoОценок пока нет

- Accidnt For All ForkliftДокумент14 страницAccidnt For All Forkliftjean claude BledouОценок пока нет

- Crane Accidents and Emergencies Causes, Repairs, and PreventionДокумент16 страницCrane Accidents and Emergencies Causes, Repairs, and PreventionPablo Valenzuela ArredondoОценок пока нет

- Crane Control and Automation Global Solutions - PDFДокумент21 страницаCrane Control and Automation Global Solutions - PDFPablo Valenzuela ArredondoОценок пока нет

- Forklift Training Quiz and AnswersДокумент10 страницForklift Training Quiz and AnswersPablo Valenzuela Arredondo100% (2)

- Forklift Training Quiz and AnswersДокумент10 страницForklift Training Quiz and AnswersPablo Valenzuela Arredondo100% (2)

- Escaid110 PDFДокумент1 страницаEscaid110 PDFPablo Valenzuela ArredondoОценок пока нет

- Nobles+Forklift+Jib Care+in+UseДокумент5 страницNobles+Forklift+Jib Care+in+UsePablo Valenzuela ArredondoОценок пока нет

- Operator' S Manual: Downloaded From Manuals Search EngineДокумент79 страницOperator' S Manual: Downloaded From Manuals Search EnginePablo Valenzuela ArredondoОценок пока нет

- Safety and Quality in Combined Transport (CT) - Edition 09-2019Документ32 страницыSafety and Quality in Combined Transport (CT) - Edition 09-2019Pablo Valenzuela ArredondoОценок пока нет

- Recommended Minimum Safety Features For Container Yard EquipmentДокумент19 страницRecommended Minimum Safety Features For Container Yard EquipmentPablo Valenzuela ArredondoОценок пока нет

- Forklift QuizasdasdДокумент2 страницыForklift QuizasdasdMohammad AhsanОценок пока нет

- Operator Training: Customer Training Course ProgrammeДокумент34 страницыOperator Training: Customer Training Course ProgrammePablo Valenzuela ArredondoОценок пока нет

- Field Instrumentation: Level MeasurementДокумент14 страницField Instrumentation: Level MeasurementPablo Valenzuela ArredondoОценок пока нет

- Control Valves Basics - Sizing & SelectionДокумент64 страницыControl Valves Basics - Sizing & SelectionKajer quemar100% (1)

- Fastener Handouts (Screw)Документ34 страницыFastener Handouts (Screw)cluchavezОценок пока нет

- Field Instrumentation: Level MeasurementДокумент14 страницField Instrumentation: Level MeasurementPablo Valenzuela ArredondoОценок пока нет

- Machine-Time Slide Rules: A Comparison of Scale Systems With Calculation ExamplesДокумент39 страницMachine-Time Slide Rules: A Comparison of Scale Systems With Calculation ExamplesSheldon Thomas DlimaОценок пока нет

- QuickGuide Roundtest PDFДокумент2 страницыQuickGuide Roundtest PDFArvin BabuОценок пока нет

- Machine Key Features: Function Form FITДокумент8 страницMachine Key Features: Function Form FITPablo Valenzuela ArredondoОценок пока нет

- Techcatalogue EbookДокумент87 страницTechcatalogue EbookPablo Valenzuela ArredondoОценок пока нет

- Gates PreventativeДокумент49 страницGates PreventativePablo Valenzuela ArredondoОценок пока нет

- 1936 - How To Cut Screw Threads in The Lathe - Bulletin 36AДокумент24 страницы1936 - How To Cut Screw Threads in The Lathe - Bulletin 36AJason Bowman100% (1)

- Troubleshooting: Library of Technical Reference BooksДокумент4 страницыTroubleshooting: Library of Technical Reference BooksPablo Valenzuela ArredondoОценок пока нет

- 101 Seal Face DynamicsДокумент23 страницы101 Seal Face Dynamics4familias6253Оценок пока нет

- Workshop Practice Series 35 - Milling, A Complete CourseДокумент71 страницаWorkshop Practice Series 35 - Milling, A Complete CourseCosmin Ionut100% (5)

- Leadwell t5Документ10 страницLeadwell t5Pablo Valenzuela ArredondoОценок пока нет

- All About 2n2222 Transistor and Its Circuit DiagramsДокумент5 страницAll About 2n2222 Transistor and Its Circuit DiagramsSai KiranОценок пока нет

- I 210 DatasheetДокумент8 страницI 210 DatasheetMichael WilkinОценок пока нет

- Tata Nano PresentationДокумент17 страницTata Nano Presentation01sanjubhadanaОценок пока нет

- Bangladesh Climate Change Strategy and Action Plan (BCCSAP) : How People Want To See It-BanglaДокумент16 страницBangladesh Climate Change Strategy and Action Plan (BCCSAP) : How People Want To See It-BanglaOxfam in BangladeshОценок пока нет

- Ref Compr Process 08 DatumДокумент8 страницRef Compr Process 08 DatumSugeng WahyudiОценок пока нет

- Laser Heat Treatment of Ti CoatingsДокумент48 страницLaser Heat Treatment of Ti CoatingsU19ME099 MRINAL MANOJ SVNITОценок пока нет

- Air-Handling Unit Casings: Method of Test, Rating Standard, Certification Program Why It MattersДокумент39 страницAir-Handling Unit Casings: Method of Test, Rating Standard, Certification Program Why It Mattersshant_mОценок пока нет

- Power Electronics LabДокумент4 страницыPower Electronics LabVikram RaoОценок пока нет

- Selection of Diesel GeneratorДокумент3 страницыSelection of Diesel GeneratordankorankoОценок пока нет

- 16-CONSERVATION OF LINEAR MOMENTUM - 01-TheoryДокумент15 страниц16-CONSERVATION OF LINEAR MOMENTUM - 01-TheoryRaju SinghОценок пока нет

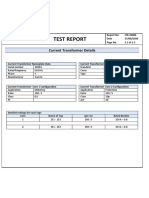

- Test Report: Current Transformer DetailsДокумент3 страницыTest Report: Current Transformer DetailsJRC TestingОценок пока нет

- Graduation ProjectДокумент97 страницGraduation Projectvenuskurd49Оценок пока нет

- Qap - NRL Rev - 1Документ6 страницQap - NRL Rev - 1Gopikrishnan ThangarajОценок пока нет

- Wire¤t Rating PDFДокумент2 страницыWire¤t Rating PDFVIKRAM DESAIОценок пока нет

- SME Management - MGT601 Spring 2009 Assignment 03Документ3 страницыSME Management - MGT601 Spring 2009 Assignment 03Rana Muhammad Arif KhanОценок пока нет

- Mock Board ReviewДокумент153 страницыMock Board ReviewLovely Rose Dungan TiongsonОценок пока нет

- N 181 enДокумент74 страницыN 181 enAbdoОценок пока нет

- FSC20 BA en 21Документ110 страницFSC20 BA en 21Daniel G. AmlakОценок пока нет

- Chemical Kinetics: The Iodine Clock Reaction: J. CortezДокумент6 страницChemical Kinetics: The Iodine Clock Reaction: J. CortezKyle CortezОценок пока нет

- Mechanics of Pole Vaulting: A Review: Sports Biomechanics June 2010Документ18 страницMechanics of Pole Vaulting: A Review: Sports Biomechanics June 2010BorypdОценок пока нет

- Electrical For BuildingДокумент198 страницElectrical For BuildingVivekKajlaОценок пока нет

- Omid Beik PHD ThesisДокумент333 страницыOmid Beik PHD ThesisMuhammad Sohaib ShahidОценок пока нет

- Pre Test and Post TestДокумент12 страницPre Test and Post TestKathleen OlaloОценок пока нет

- Assess The Performanceof Positive-DisplacementPumps, CEP, Dec-2007 PDFДокумент8 страницAssess The Performanceof Positive-DisplacementPumps, CEP, Dec-2007 PDFSanjay Gupta100% (1)

- UNIT 7 Voc - Exercises (11868)Документ6 страницUNIT 7 Voc - Exercises (11868)Аманта ЛиньковаОценок пока нет

- Concept Map of Big Bang TheoryДокумент1 страницаConcept Map of Big Bang Theorybelgacac396744% (9)

- Ficha Tecnica Sg160 - 200 Kva Data SheetДокумент6 страницFicha Tecnica Sg160 - 200 Kva Data SheetEduardoОценок пока нет

- Bicotest Model T272 - High Resistance Cable Fault LocatorДокумент2 страницыBicotest Model T272 - High Resistance Cable Fault LocatorDEEPAK KUMARОценок пока нет

- Heating Coil in The Main Air Handling UnitДокумент15 страницHeating Coil in The Main Air Handling UnitMohsinShaikh100% (2)

- BR Prepump A4 Eng 201106Документ12 страницBR Prepump A4 Eng 201106GrundfosEgyptОценок пока нет