Академический Документы

Профессиональный Документы

Культура Документы

02 - Boys Calorimeter LPG

Загружено:

Renu SekaranОригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

02 - Boys Calorimeter LPG

Загружено:

Renu SekaranАвторское право:

Доступные форматы

BKG3741 Fuel and Combustion Lab

Sem 11-2012/2013

Faculty of Chemical & Natural Resources Engineering

BKG3721

Fuel & Combustion Lab

Experiment 2

BOYS CALORIMETER-LPG

Name

Matric No.

Group

Program

Section

Date

Sem. 11 - Session 2012/2013

1.0 Objective

BKG3741 Fuel and Combustion Lab

Sem 11-2012/2013

1.

To investigate the calorific value of LPG.

2.

To use and understand techniques for accurate calorimetric

analysis

2.0 Introduction

Boys Calorimeter

The Boys Non-recording Gas Calorimeter was designed by the late Sir

Charles Boys F.R.S. as simple but accurate equipment for ascertaining

the calorific values of a large range of gaseous fuels. The gas is fed to

the two burners mounted in the base of the calorimeter where it is

burnt in air. The exhaust gases from the burners are fed through the

calorimeter over the water filled calorimeter coils and leave the

apparatus through a vent in the top of the unit. A thermometer for

measuring the exhaust gas temperature is suspended in this vent. An

outlet drain is provided for any condensate, which is formed from the

exhaust gas. Coolant water is fed through the coils of the calorimeter

from the constant head overflow funnel fixed above the unit. The

water outlet from the calorimeter is fed into a changeover funnel,

which is used for diverting the outlet water from waste into a

measuring vessel or vice-versa. This enables the flow rate of water

through the calorimeter to be determined. The temperature of both

the inlet and outlet water is monitored by mercury in glass

thermometers. When the calorimeter is not in use during short

periods during the testing, the coils of the unit are kept immersed in a

tank containing an alkaline solution. This serves to neutralize any

acidic products deposited on the coils by the combustion of the gas.

Hyde Gas Meter

The gas for the calorimeter is fed via a Hyde type gas meter, which

consists of a specially designed measuring drum housed in a gas-tight

casing and sealed with water. On entry to the-meter the gas is

introduced into a space above the water in the outer casing and the

gas must pass through the measuring drum, causing it to rotate, to

get to the outlet connection of the meter. The measuring drum is

coupled to the pointer on the front of the meter.

3.0

DESCRIPTION

BKG3741 Fuel and Combustion Lab

Sem 11-2012/2013

The Boys Gas Calorimeter Set can be used to determine the calorific

value of a selection of gaseous fuels. The Cussons Type P5615 Boys

Gas Calorimeter set consists of the following items.

1.

A Boys non-recording gas calorimeter.

2.

3.

4.

5.

6.

7.

8.

9.

10.

11.

12.

13.

14.

15.

A constant head overhead funnel with water connecting tubes,

2 thermometers engraved on stem 0-50 C for temperate

climates or 0-75 C for tropical climates, for inlet and outlet

water temperatures.

2 adjustable reading lenses, chromium plated, with spring clips

for attaching to stems of thermometers in item 3.

2 thermometers engraved on stem 0-35 C for temperate

climates or 0-50 C for tropical climates, for effluent gas and

room temperatures.

3 litre collecting vessel and 1000 ml graduated glass vessel, for

measuring outflow from calorimeter.

Graduated glass vessel, capacity 50 ml, for collecting

condensed products.

General purpose burner set comprising

Town gas and coke oven gas burner, - 14.9 - 22.35 MJ / m3

(400 - 600 BTU / ft 3.) Ref. No. 3 burner

Burner to BS3804; 22.3 - 33.5 MJ / m3 (600 - 900 BTU / ft 3.)

Ref. 5034/100

Natural gas and methane burner, 33.5 - 44.7 MJ / m3 (900 1200 BTU / ft 3.) Ref, 7443/60

Butane, propane, acetylene, ethylene & propylene burner, 44.7

- 130.4 MJ / m3 (1200 -3500 BTU / ft 3.) Ref. 7445/35

Gas control valve (quadrant cock).

A "Hyde" pattern meter of 2.0 liters per revolution capacity. The

dial is divided into 100 divisions and is enclosed by a glass

front. The casing and measuring drum are of tinned copper and

all brass fittings are lacquered. A spirit level, point setting key

and height gauge are provided for setting up the meter

together with fittings for a 0 - 35 C thermometer for

measuring the inlet temperature of the gas.

Cylindrical metal vessel to contain alkaline solution into which

the coils portion of the calorimeter is placed when not in use.

Three accessories are available for use with the calorimeter set.

These are a type P5617 reducing valve, a P5616 set of additional

burners and an automatic gas cut-off device. The reducing valve type

P5617 is intended to reduce the pressure of the incoming gas from

valves up to 30 cm H2O to 5 cm HA If gases at pressures higher than

30 cm H20 are to be used, then a primary stage of pressure reduction

should be used. The P5617 may not be required when testing high CV

bottled gases such as Butane and Propane mixtures if a suitable

pressure reducing valve and control valve are provided on the bottle.

The P5616 set of additional burners contains 3 extra burners to

extend the range of the calorimeter. The burners are suitable for

BKG3741 Fuel and Combustion Lab

Sem 11-2012/2013

Blast furnace gas and low calorific value gas 3.7 MJ / m 3 (150 - 300

BTU / ft3.) " Ref, No. 7 burner.

Propane only 93.1 MJ / m3 (2500 BTU / ft3.) - Ref. 5428/25 or

7458/25.

Butane-air 23.3 - 24.2 MJ / m3 (625 - 650 BTU / ft3.) - Ref.

5034/100.

The Automatic Gas Cut-off device is used for shutting off the gas

supply in the event of the water supply failing.

4.0

Experimental Procedures

1.

Check all the equipment is in good condition and is installed in

the right sequence

2.

Ignite the fire sources, followed by flowing the gas

3.

Put the burner into the calorimeter

4.

Flow the water into the boys calorimeter

5.

Keep the water flow constantly until the changes of temperature

constant.

6.

Note the inlet and outlet temperature for every cycle of the

hydro meter. Meanwhile, collect the water by the container.

Note it for 4 cycles.

7.

Remove the container and weight it

8.

Turn off the gas and the water source.

5.0

Results

BKG3741 Fuel and Combustion Lab

5.1

Sem 11-2012/2013

Calculating for Calorific Value

Table 5.1: Experimental Data

Set 1

Ti1

To1

Set2

Ti2

Set3

To2

Ti3

To3

Average

Temperature, (oC)

Ti

To

1st

Quadrant

2nd

Quadrant

3rd

Quadrant

4th

Quadrant

Mass of

collected

water

Mass of empty beaker, (g)

: ______________________________

Mass of (beaker + water), (g)

: _____________________________

Ambient Temperature,(oC)

: ______________________________

Barometric Pressure, (mmHg)

: ______________________________

Average Inlet Temperature, Ti ,(oC)

:_____________________

Average Oulet Temperature, To ,(oC)

:_____________________

Average Difference of Temperature, T , ( C)

o

:_____________________

6.0 ANALYSIS

6.1 Calculating for Calorific Value , CV (MJ/m3):

Formulae;

BKG3741 Fuel and Combustion Lab

Sem 11-2012/2013

1

4

CV = T W 4.187 GVF

10

3

metersize

,

(

m

)

revs

Where:

W

GVF

Meter Size

Revs

= collected water, (ml)

= gas volume factor (Appendix 1, Table 1)

= 20dm3,capacity of one revolution of the meter in m3

= number of revolutions of the meter (Appendix 1, Table 2)

Calculation examples:-

6.2

Calculating for gas volume correction at other pressures and

temperatures.

Formulae;

V

n a

Vo =

1 + 0.00367 t 760 ao

Where:

V0 = Gas volume at 0C and 760mmHg pressure

V = Gas volume at ambient temperature and pressure

n = Barometric pressure in mmHg

a0 = Vapor pressure in mmHg at temperature t

a = Vapor pressure in mmHg at temperature 0C

t = Ambient temperature

Calculation examples:-

BKG3741 Fuel and Combustion Lab

Sem 11-2012/2013

a)

From the result, described briefly process occurred in the calorimeter?

b)

Why is it important to determine the calorific value of gaseous fuels?

BKG3741 Fuel and Combustion Lab

Sem 11-2012/2013

BKG3741 Fuel and Combustion Lab

Appendix

Sem 11-2012/2013

BKG3741 Fuel and Combustion Lab

Sem 11-2012/2013

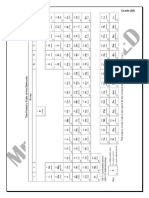

Table 1: Gas Volume Factors relative to 0"C and 760 mmHg. Note A formula for calculating the gas volume at

other temperatures and Pressures is given in the text.

mm 10C 11C 12C 13C 14C 15C 16C 17C 18C 19C 20C 21C 22C 23C 24C 25C 26C mmH

Hg 1.09 1.09 1.10 1.10 1.10 1.11 1.11 1.12 1.12 1.15 1.13 1.14 1.14 1.15 1.16 1.16 1.17 730

g

730

732 1.09 1.09 1.09 1.10 1.10 1.10 1.11 1.11 1.12 1.12 1.13 1.13 1.14 1.15 1.15 1.16 1.16 732

734 1.08 1.09 1.09 1.09 1.10 1.10 1.11 1.11 1.12 1.12 1.13 1.13 1.14 1.14 1.15 1.16 1.16 734

736 1.08 1.08 1.09 1.09 1.09 1.10 1.10 1.11 1.11 1.12 1.12 1.13 1.15 1.14 1.15 1.15 1.16 736

738 1.08 1.08 1.08 1.09 1.09 1.09 1.10 1.10 1.11 1.11 1.12 1.13 1.15 1.14 1.14 1.15 1.16 738

740 1.07 1.08 1.08 1.08 1.09 1.09 1.10 1.10 1.11 1.11 1.12 1.12 1.13 1.13 1.14 1.15 1.15 740

742 1.07 1.07 1.08 1.08 1.08 1.09 1.09 1.10 1.10 1.11 1.11 1.12 1.13 1.13 1.14 1.14 1.15 742

744 1.07 1.07 1.07 1.06 1.08 1.09 1.09 1.10 1.10 1.11 1.11 1.12 1.12 1.13 1.13 1.14 1.15 744

746 1.06 1.07 1.07 1.07 1.08 1.08 1.09 1.09 1.10 1.10 1.11 1.11 1.12 1.13 1.13 1.14 1.14 746

748 1.06 1.06 1.07 1.07 1.08 1.08 1.08 1.09 1.09 1.10 1.11 1.11 1.12 1.12 1.13 1.13 1.14 748

750 1.06 1.06 1.07 1.07 1.07 1.08 1.08 1.09 1.09 1.10 1.10 1.11 1.11 1.12 1.12 1.13 1.14 750

752 1.05 1.06 1.06 1.07 1.07 1.07 1.08 1.08 1.09 1.09 1.10 1.10 1.11 1.12 1.12 1.13 1.13 752

754 1.05 1.06 1.06 1.06 1.07 1.07 1.08 1.08 1.09 1.09 1.10 1.10 1.11 1.11 1.12 1.12 1.13 754

756 1.05 1.05 1.06 1.06 1.06 1.07 1.07 1.08 1.08 1.09 1.09 1.10 1.10 1.11 1.12 1.12 1.13 756

758 1.05 1.05 1.05 1.06 1.06 1.06 1.07 1.07 1.08 1.08 1.09 1.10 1.10 1.11 1.11 1.12 1.13 758

760 1.04 1.05 1.05 1.05 1.06 1.06 1.07 1.07 1.08 1.08 1.09 1.09 1.10 1.10 1.11 1.12 1.12 760

762 1.04 1.04 1.05 1.05 1.05 1.06 1.06 1.07 1.07 1.08 1.08 1.09 1.10 1.10 1.11 1.11 1.12 762

764 1.04 1.04 1.04 1.05 1.05 1.06 1.06 1.07 1.07 1.08 1.08 1.09 1.09 1.10 1.10 1.11 1.12 764

766 1.03 1.04 1.04 1.05 1.05 1.05 1.06 1.06 1.07 1.07 1.08 1.08 1.09 1.09 1.10 1.11 1.11 766

768 1.03 1.04 1.04 1.04 1.05 1.05 1.05 1.06 1.06 1.07 1.08 1.08 1.09 1.09 1.10 1.10 1.11 768

770 1.05 1.03 1.04 1.04 1.04 1.05 1.05 1.06 1.06 1.07 1.07 1.08 1.08 1.09 1.10 1.10 1.11 770

772 1.03 1.03 1.03 1.04 1.04 1.04 1.05 1.05 1.06 1.06 1.07 1.08 1.08 1.09 1.09 1.10 1.10 772

774 1.02 1.03 1.03 1.03 1.04 1.04 1.05 1.05 1.06 1.06 1.07 1.07 1.08 1.08 1.09 1.09 1.10 774

776 1.02 1.02 1.03 1.03 1.03 1.04 1.04 1.05 1.05 1.06 1.06 1.07 1.08 1.08 1.09 1.09 1.10 776

778 1.02 1.02 1.03 1.03 1.03 1.04 1.04 1.05 1.05 1.06 1.06 1.07 1.07 1.03 1.06 1.09 1.09 778

780 1.02 1.02 1.02 1.03 1.03 1.03 1.04 1.04 1.05 1.05 1.06 1.06 1.07 1.07 1.08 1.09 1.09 780

BKG3751 Fuel and Combustion Lab

mmH

730

732

734

736

738

740

742

744

746

748

750

752

754

756

758

760

762

764

766

768

770

772

774

776

778

780

27C

1.18

1.17

1.17

1.17

1.16

1.16

1.16

1.15

1.15

1.15

1.14

1.14

1.14

1.13

1.13

1.13

1.13

1.12

1.12

1.12

1.11

1.11

1.11

1.10

1.10

1.10

28C

1.18

1.18

1.18

1.17

1.17

1.17

1.16

1.16

1.16

1.15

1.15

1.15

1.14

1.14

1.14

1.14

1.13

1.13

1.12

1.12

1.12

1.12

1.11

1.11

1.11

1.10

29C

1.19

1.19

1.18

1.18

1.18

1.17

1.17

1.17

1.16

1.16

1.16

1.15

1.15

1.15

1.14

1.14

1.14

1.13

1.13

1.13

1.13

1.12

1.12

1.12

1.11

1.11

30C

1.20

1.19

1.19

1.19

1.18

1.18

1.1B

1.17

1.17

1.17

1.16

1.16

1.16

1.15

1.15

1.15

1.14

1.14

1.14

1.13

1.13

1.13

1.13

1.12

1.12

1.12

31C

1.20

502.

1.20

1.19

1.19

1.19

1.18

1.18

1.18

1.17

1.17

1.17

1.16

1.16

1.16

1.15

1.15

1.15

1.14

1.14

1.14

1.14

1.13

1.13

1.13

1.12

32C

1.21

1.21

1.20

1.20

1.20

1.19

1.19

1.19

1.18

1.18

1.18

1.17

1.17

1.17

1.16

1.16

1.16

1.15

1.15

1.15

1.15

1.14

1.14

1.14

1.13

1.15

33C

1.22

1.22

1.21

1.21

1.20

1.20

1.20

1.20

1.19

1.19

1.16

1.18

1.18

1.18

1.17

1.17

1.17

1.16

1.16

1.16

1.15

1.15

1.15

1.14

1.14

1.14

Sem II-2007/2008

34C

1.23

1.22

1.22

1.22

1.21

1.21

1.21

1.20

1.20

1.20

1.19

1.19

1.19

1.18

1.18

1.18

1.17

1.17

1.17

1.16

1.16

1.16

1.15

1.15

1.15

1.14

35C

1.23

1.23

1.23

1.22

1.22

1.22

1.21

1.21

1.21

1.20

1.20

1.20

1.19

1.19

1.19

1.13

1.13

1.13

1.17

1.17

1.17

1.16

1.16

1.16

1.15

1.15

36C

1.24

1.24

1.24

1.23

1.23

1.23

1.22

1.22

1.22

1.21

1.21

1.20

1.20

1.20

1.19

1.19

1.19

1.18

1.18

1.18

1.17

1.17

1.17

1.16

1.16

1.16

37C

1.25

1.25

1.24

1.24

1.24

1.23

1.23

1.23

1.22

1.22

1.22

1.21

1.21

1.21

1.20

1.20

1.20

1.19

1.19

1.19

1.18

1.18

1.13

1.17

1.17

1.16

38C

1.26

1.26

1.25

1.25

1.25

1.24

1.24

1.24

1.23

1.23

1.22

1.22

1.22

1.21

1.21

1.21

1.20

1.20

1.20

1.19

1

1.19

1.1B

1.18

1.18

1.17

39C

1.27

1.27

1.26

1.26

1.26

1.25

1.25

1.24

1.24

1.24

1.23

1.23

1.23

1.22

1.22

1.22

1.21

1.21

1.21

1.20

1.20

1.20

1.19

1.19

1.18

1.18

11

40C

1.26

1.26

1.27

1.27

1.26

1.26

1.26

1.25

1.25

1.25

1.24

1.24

1.23

1.23

1.23

1.22

1.22

1.22

1.21

1.21

1.21

1.20

1.20

1.20

1.19

1.19

mmH

730

732

734

736

738

740

742

744

746

748

750

752

754

756

758

760

762

764

766

768

770

772

774

776

778

780

BKG3751 Fuel and Combustion Lab

Sem II-2007/2008

Table 2: Meter Gas Rates & Water Collection Rates

Approximate

Calorific Value

Time for 1

rev of Meter

Pointer

Number of

rev of Meter

Pointer in

test

Water

Collected

during

Pointer in

test

Factor to be

used in

calculation 1/

(0.2m3xrevs)

18-19 MJ per m3

(500

B.

Th.

Us /cu ft)

52s-54s

2160-2260g

37-38 MJ per m3

(1000 B. Th. Us

/cu ft)

1min44s1min49s

864-904g

2.5

75-76 MJ per m3

(2000 B. Th. Us

/cu ft)

3min34s3min-38s

432-452g

12

BKG3751 Fuel and Combustion Lab

Sem II-2007/2008

Example:Outlet Temperature, C

Inlet Temperature, C

16.2

16.2

16.2

16.2

36.4

36.5

36.6

36.5

Average Inlet Temperature = 16.2C.

Average Outlet Temperature = 36.5C

Gives Average difference of temperature = 20.3 C

Number of revs

Meter Capacity

Water collected

Barometer

Meter temp.

G.V. Factor

5

0.2m3

2100 ml.

754 mm,

17.8C

1,089

Calorific Value =20.3*2100*4.187*1.089*(1 / (0.2 *5))*10 -4

=19.438MJ/m3

To convert MJ / m3 into BTU/ ft3. multiply MJ / m3

by 26.8413 Therefore in example A calorific value

in BTU/ ft3

19.438 x 26.8413 = 521.7 BTU/ ft3

13

Вам также может понравиться

- Lab 1 Boys CalorimeterДокумент11 страницLab 1 Boys CalorimeterHafizszul Feyzul100% (1)

- Calorific ValueДокумент14 страницCalorific Valuenfar100% (1)

- s2158812 Boys CalorimeterДокумент15 страницs2158812 Boys CalorimeterOmar A-gОценок пока нет

- Gas1 ManДокумент11 страницGas1 ManLahiru DilshanОценок пока нет

- Junkers Gas CalorimeterДокумент2 страницыJunkers Gas Calorimeterghambira83% (6)

- Operating Instruction Manual Of: Junker's Gas CalorimeterДокумент5 страницOperating Instruction Manual Of: Junker's Gas CalorimeterService MMIОценок пока нет

- V. Ganapathy. Simplify Heat Recovery Steam Generator Evaluation PDFДокумент7 страницV. Ganapathy. Simplify Heat Recovery Steam Generator Evaluation PDFgonzalezpcjОценок пока нет

- Boiler EfficiencyДокумент28 страницBoiler Efficiencybzkizo_sbbОценок пока нет

- To 2Документ32 страницыTo 2Miguel MatallanaОценок пока нет

- Boiler Fuel Savings by Heat Recovery and Reduced Standby Losses B. GrabsДокумент7 страницBoiler Fuel Savings by Heat Recovery and Reduced Standby Losses B. GrabsPhilip ShihОценок пока нет

- UOP 603 Trace CO and CO2 in Hydrogen and Light Gases Hydrocarbon by GCДокумент6 страницUOP 603 Trace CO and CO2 in Hydrogen and Light Gases Hydrocarbon by GCMorteza SepehranОценок пока нет

- 4.1 BoilerДокумент28 страниц4.1 Boilerrashm006ranjanОценок пока нет

- M.E. Lab 2 Act. 2Документ3 страницыM.E. Lab 2 Act. 2Patricia GalorioОценок пока нет

- By Adapted Plant Physical Compared: An To Can MeansДокумент15 страницBy Adapted Plant Physical Compared: An To Can MeansrajuОценок пока нет

- ASTM D5865 07A 53 3286 Poder Calorifico PDFДокумент14 страницASTM D5865 07A 53 3286 Poder Calorifico PDFCarol Perez TОценок пока нет

- 03po Ar 3 6 PDFДокумент4 страницы03po Ar 3 6 PDFMarcelo Varejão CasarinОценок пока нет

- The Invention: Zadgaonkars' ProcessДокумент3 страницыThe Invention: Zadgaonkars' ProcessHimanshu SukhadwalaОценок пока нет

- Sunway Practical Lab Bicarbonate Decomposition 2012Документ11 страницSunway Practical Lab Bicarbonate Decomposition 2012venkieeОценок пока нет

- Lab 1 CalorimeterДокумент3 страницыLab 1 CalorimeterAndrian NasirОценок пока нет

- Junker Gas CalorimeterДокумент1 страницаJunker Gas Calorimeterakashshinde648Оценок пока нет

- Bomb CalorimetryДокумент17 страницBomb Calorimetryglendale aguillonОценок пока нет

- Trace Hydrocarbons in Hydrogen or LPG by Gas ChromatographyДокумент12 страницTrace Hydrocarbons in Hydrogen or LPG by Gas ChromatographyDavinОценок пока нет

- Santosh Kumar: Producl Engineer / BPP FBДокумент17 страницSantosh Kumar: Producl Engineer / BPP FBjp mishraОценок пока нет

- NG Lab Report As at 2012Документ27 страницNG Lab Report As at 2012Amir O. Osho50% (2)

- BombCalorimeterManual1 PDFДокумент20 страницBombCalorimeterManual1 PDFAgnes YogaОценок пока нет

- Engineering Bulletin No 1: Boiler and Furnace TestingОт EverandEngineering Bulletin No 1: Boiler and Furnace TestingРейтинг: 4.5 из 5 звезд4.5/5 (2)

- Determination of Low Water Contents in PlasticsДокумент5 страницDetermination of Low Water Contents in Plasticsyouni_2005Оценок пока нет

- LP-Gas Service Mans ManualДокумент52 страницыLP-Gas Service Mans Manualprocha1100% (1)

- Experiment No 5 FinalДокумент27 страницExperiment No 5 FinalJule Renz PaguiaОценок пока нет

- Aph FireДокумент25 страницAph Firesekhar_ntpcОценок пока нет

- Astm D5865Документ14 страницAstm D5865Jaime Maciel71% (7)

- Astm D 5865-04Документ12 страницAstm D 5865-04Luis Alberto Curtidor GuataquiОценок пока нет

- Energy Performance Assessment of BoilersДокумент15 страницEnergy Performance Assessment of BoilersVishwarajОценок пока нет

- Mec554 Thermalfluid Lab: Experiment's TitleДокумент20 страницMec554 Thermalfluid Lab: Experiment's TitleMuhammad Khairul Afnan RoslanОценок пока нет

- Mohamed Ibrahim Darwish 15101468 12th ReportДокумент45 страницMohamed Ibrahim Darwish 15101468 12th ReportMohamed DarwishОценок пока нет

- Laboratory Manual Engineering Thermodynamics (ME-203)Документ30 страницLaboratory Manual Engineering Thermodynamics (ME-203)Ahmed AlrubeayОценок пока нет

- Testing Process For Bio Medical Waste IncineratorДокумент97 страницTesting Process For Bio Medical Waste IncineratorJeetendra KulkarniОценок пока нет

- Capacity Regulator CpceДокумент8 страницCapacity Regulator CpceNovan AndriantoОценок пока нет

- L-545 Servicemans ManualДокумент56 страницL-545 Servicemans ManualingenerproОценок пока нет

- Energy Performance Assessment of BoilersДокумент5 страницEnergy Performance Assessment of BoilersUsama SufyanОценок пока нет

- IEICOS Boys Gas Calorimeter Catalog 2011Документ1 страницаIEICOS Boys Gas Calorimeter Catalog 2011Shaho Abdulqader MohamedaliОценок пока нет

- Document 1Документ13 страницDocument 1Muhammad SaifuddinОценок пока нет

- M.E LAB 3 Experiment 5 Steam Generator Without Super Heating SurfaceДокумент14 страницM.E LAB 3 Experiment 5 Steam Generator Without Super Heating SurfaceDrw Arcy0% (1)

- 2 ERG 401 2015 Energy Performance Analysis of BOILERДокумент57 страниц2 ERG 401 2015 Energy Performance Analysis of BOILERnaveenОценок пока нет

- 08 Chapter 3Документ22 страницы08 Chapter 3BALAJI CHOUHANОценок пока нет

- Thermax BoilerДокумент10 страницThermax Boileramitrawal0100% (1)

- ASME - PTC4.1 .Boiler Efficiency TestДокумент29 страницASME - PTC4.1 .Boiler Efficiency TestBC Harish92% (13)

- Energy Efficiency Assessment BookДокумент170 страницEnergy Efficiency Assessment BookNoel Dunn100% (4)

- Process Steam Systems: A Practical Guide for Operators, Maintainers, and DesignersОт EverandProcess Steam Systems: A Practical Guide for Operators, Maintainers, and DesignersОценок пока нет

- Marvel Carbureter and Heat Control: As Used on Series 691 Nash Sixes Booklet SОт EverandMarvel Carbureter and Heat Control: As Used on Series 691 Nash Sixes Booklet SОценок пока нет

- Contemporary Anaesthetic Equipments.: An Aid for Healthcare ProfessionalsОт EverandContemporary Anaesthetic Equipments.: An Aid for Healthcare ProfessionalsОценок пока нет

- Heat Exchanger Design Guide: A Practical Guide for Planning, Selecting and Designing of Shell and Tube ExchangersОт EverandHeat Exchanger Design Guide: A Practical Guide for Planning, Selecting and Designing of Shell and Tube ExchangersРейтинг: 4 из 5 звезд4/5 (13)

- Advanced Temperature Measurement and Control, Second EditionОт EverandAdvanced Temperature Measurement and Control, Second EditionОценок пока нет

- Installation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitОт EverandInstallation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitОценок пока нет

- Respiration Calorimeters for Studying the Respiratory Exchange and Energy Transformations of ManОт EverandRespiration Calorimeters for Studying the Respiratory Exchange and Energy Transformations of ManОценок пока нет

- Boiler Operation Engineer Exam, Interview Q&A, Terminology, and Boiler OverviewОт EverandBoiler Operation Engineer Exam, Interview Q&A, Terminology, and Boiler OverviewОценок пока нет

- Heating Systems Troubleshooting & Repair: Maintenance Tips and Forensic ObservationsОт EverandHeating Systems Troubleshooting & Repair: Maintenance Tips and Forensic ObservationsОценок пока нет

- Cell As A Unit of LifeДокумент40 страницCell As A Unit of LifeRenu SekaranОценок пока нет

- For Section A, Write Your Answer in The Answer Sheet Provided in Page 12Документ12 страницFor Section A, Write Your Answer in The Answer Sheet Provided in Page 12Renu SekaranОценок пока нет

- Chemistry Perfect Score Module Form 4 Set 1Документ22 страницыChemistry Perfect Score Module Form 4 Set 1siti zalikhaОценок пока нет

- Wesley Methodist School Klang MONTHLY TEST 1 (2019) Chemistry Form 4 Total: 50 MarksДокумент8 страницWesley Methodist School Klang MONTHLY TEST 1 (2019) Chemistry Form 4 Total: 50 MarksRenu SekaranОценок пока нет

- Rate of ReactionДокумент27 страницRate of ReactionziziОценок пока нет

- Science Form 1Документ15 страницScience Form 1Renu SekaranОценок пока нет

- 06 Chapter 1 Rate of ReactionДокумент35 страниц06 Chapter 1 Rate of ReactionRenu SekaranОценок пока нет

- Lesson Plan (Subject: SCIENCE)Документ3 страницыLesson Plan (Subject: SCIENCE)Renu SekaranОценок пока нет

- Lesson Plan Format 27-1 (Opal)Документ4 страницыLesson Plan Format 27-1 (Opal)Renu SekaranОценок пока нет

- Lesson Plan Format 28-3 TopazДокумент3 страницыLesson Plan Format 28-3 TopazRenu SekaranОценок пока нет

- Lesson Plan Format 24-2 (Opal)Документ3 страницыLesson Plan Format 24-2 (Opal)Renu SekaranОценок пока нет

- Lesson Plan Format 27-1Документ4 страницыLesson Plan Format 27-1Renu SekaranОценок пока нет

- Lesson Plan Format 24-2Документ3 страницыLesson Plan Format 24-2Renu SekaranОценок пока нет

- Lesson Plan Format 31-3Документ3 страницыLesson Plan Format 31-3Renu SekaranОценок пока нет

- E E:sl: Et Isl If:: I Ii:i I Il", 3:p:r I Et:sfДокумент1 страницаE E:sl: Et Isl If:: I Ii:i I Il", 3:p:r I Et:sfRenu SekaranОценок пока нет

- Lesson Plan Format 28-3Документ3 страницыLesson Plan Format 28-3Renu SekaranОценок пока нет

- Intensive 4 Page 2Документ1 страницаIntensive 4 Page 2Renu SekaranОценок пока нет

- Form 2 - Page 2Документ1 страницаForm 2 - Page 2Renu SekaranОценок пока нет

- Form 2 - Page 1Документ1 страницаForm 2 - Page 1Renu SekaranОценок пока нет

- Lesson Plan (Subject: SCIENCE)Документ2 страницыLesson Plan (Subject: SCIENCE)Renu SekaranОценок пока нет

- Intensive 4 Page 3 PDFДокумент1 страницаIntensive 4 Page 3 PDFRenu SekaranОценок пока нет

- Intensive 3 Page 2Документ1 страницаIntensive 3 Page 2Renu SekaranОценок пока нет

- Intensive 4 Page 4Документ1 страницаIntensive 4 Page 4Renu SekaranОценок пока нет

- Form 2 - Page 2Документ1 страницаForm 2 - Page 2Renu SekaranОценок пока нет

- School Culture Climate & AchievementДокумент13 страницSchool Culture Climate & AchievementPutra Rahmat ArmyОценок пока нет

- Form 1 Assessment OCTOBER 2015 Form 1 Science: (Duration: 25 Minutes)Документ8 страницForm 1 Assessment OCTOBER 2015 Form 1 Science: (Duration: 25 Minutes)Renu SekaranОценок пока нет

- Teacher Leaders Impacting School CultureДокумент10 страницTeacher Leaders Impacting School CultureYugesh D PANDAYОценок пока нет

- The Significance of Assumptions Underlying School Culture in The Process of ChangeДокумент6 страницThe Significance of Assumptions Underlying School Culture in The Process of ChangeRenu SekaranОценок пока нет

- Form 1 Assessment OCTOBER 2015 Form 1 Science: (Duration: 25 Minutes)Документ8 страницForm 1 Assessment OCTOBER 2015 Form 1 Science: (Duration: 25 Minutes)Renu SekaranОценок пока нет

- Venturi Meter and Orifice Plate Lab ReportДокумент11 страницVenturi Meter and Orifice Plate Lab Reportprajwal m100% (1)

- 2022 - Hyd 443 - 1Документ201 страница2022 - Hyd 443 - 1api-620585842Оценок пока нет

- Energetics: Pharmaceutical Enzymes Kraft PulpingДокумент6 страницEnergetics: Pharmaceutical Enzymes Kraft Pulping박우진Оценок пока нет

- Sewage Treatment PlantДокумент32 страницыSewage Treatment Plantjamroze496114100% (2)

- Fluids Lec1 Pump TurbinesДокумент46 страницFluids Lec1 Pump TurbinesPrem LoveОценок пока нет

- 1 - Intro + Basic ConceptsДокумент48 страниц1 - Intro + Basic ConceptsShawki BsatОценок пока нет

- Abstractions From Precipitation: AbstractionДокумент10 страницAbstractions From Precipitation: AbstractionmarkhanОценок пока нет

- MAN Energy Develops IMOKAT II Catalyst To Reduce Methane SlipДокумент10 страницMAN Energy Develops IMOKAT II Catalyst To Reduce Methane Slipali.khalifaОценок пока нет

- 1E ME0084RevDДокумент12 страниц1E ME0084RevDkarthickmectrОценок пока нет

- ARTESA 394 - 01-25-17 - 12-46-38PM - ACU - ReportДокумент1 страницаARTESA 394 - 01-25-17 - 12-46-38PM - ACU - ReportPedro Antonio Mejia SuarezОценок пока нет

- Topic 1 ACMVДокумент21 страницаTopic 1 ACMVEmi ArisОценок пока нет

- 30J - APCI LNG Liquefaction ProcessesДокумент27 страниц30J - APCI LNG Liquefaction ProcessesPutu Indra Mahatrisna100% (2)

- CV Prop - Termof PG 518-19-20Документ3 страницыCV Prop - Termof PG 518-19-20MargaritaОценок пока нет

- Entry Exam - M.Sc. / 2015-2016 Chemical Engineering Department University of Baghdad Date 13/8/2015 Time: 3 HrsДокумент5 страницEntry Exam - M.Sc. / 2015-2016 Chemical Engineering Department University of Baghdad Date 13/8/2015 Time: 3 Hrshiba thamirОценок пока нет

- Introduction To Fusion: Advantages of Fusion PowerДокумент2 страницыIntroduction To Fusion: Advantages of Fusion PowerThe milk goes firstОценок пока нет

- T10206 XG02 P1PGB - 110001 - Pid CCWДокумент1 страницаT10206 XG02 P1PGB - 110001 - Pid CCWtuyencntnОценок пока нет

- Ch. 1 Particulate Nature of MatterДокумент10 страницCh. 1 Particulate Nature of MatterهندОценок пока нет

- SURGE CONTROL SYSTEMS FOR CENTRIFUGAL COMPRESSORS - Part 7Документ2 страницыSURGE CONTROL SYSTEMS FOR CENTRIFUGAL COMPRESSORS - Part 7Ali QureshiОценок пока нет

- Hoshizaki IM-500SAA Icemaker Service ManualДокумент39 страницHoshizaki IM-500SAA Icemaker Service ManualBenjamin DoverОценок пока нет

- Surface WaterДокумент22 страницыSurface WaterLuis MenendezОценок пока нет

- Default Separator CalculationДокумент209 страницDefault Separator CalculationzamijakaОценок пока нет

- Compressed Air Process FiltrationДокумент20 страницCompressed Air Process FiltrationOgut AjaОценок пока нет

- Note Ideal Gas TutorialДокумент5 страницNote Ideal Gas TutorialGnabryОценок пока нет

- Amine TreatmentДокумент2 страницыAmine TreatmentEmamokeОценок пока нет

- 006 Intro To BHS (Cased Hole)Документ17 страниц006 Intro To BHS (Cased Hole)VanVietRoanОценок пока нет

- Gas Laws Problem Set (Edited)Документ2 страницыGas Laws Problem Set (Edited)Kurt Bidua0% (1)

- Water Lect 2 - Project CyclesДокумент70 страницWater Lect 2 - Project CyclesNur Hazirah Sadon100% (1)

- VCS Guidelines Rev 10 01 2Документ15 страницVCS Guidelines Rev 10 01 2DMYTRO STRYZHKOVОценок пока нет

- Cien 30143 - Hydraulics 2Документ44 страницыCien 30143 - Hydraulics 2VincentОценок пока нет

- Oct27 2012Документ1 страницаOct27 2012pribhor2Оценок пока нет