Академический Документы

Профессиональный Документы

Культура Документы

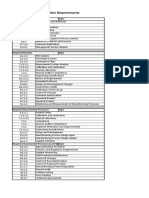

New Vendor System Audit Check Sheet

Загружено:

Jetesh DevgunАвторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

New Vendor System Audit Check Sheet

Загружено:

Jetesh DevgunАвторское право:

Доступные форматы

1 3 / 24 3 3 2

2 12 / 15 4 1 0

3 6 / 18 3 2 1

4 6 / 18 2 4 0

5 9 / 18 3 3 0

6 6 / 15 3 1 1

7 18 / 21 6 1 0

8 15 / 21 5 2 0

9 15 / 18 5 1 0

10 12 / 15 4 1 0

11 3 / 15 3 0 2

12 12 / 18 4 2 0

13 12 / 12 4 0 0

14 N/A / N/A 0 0 0

Total

(MSI

129 / 228 49 21 6

MARUTI SUZUKI INDIA LIMITED

Pre decided negative

marking (if any)

Issue Deptt.

(Audit Score)

Supplier name Copy to

Total

Vendor Qualitry System Audit Report

Part Number

Part Name:

Supplier Attendant Name

Prepared Verified Approved

Date of Issue

57

Achieved Score

228

Observation:-

129

Total Score

=

Subject: Vendor System Audit

Audit Date

Audit Person

Last Audit Rating

Improvement Submission

Date

Supplier code

0

20

40

60

80

100

1.Production

preparation

2.Regulation for initial

production control

3.Changing management

4.Standards

management

5.Education and training

6.Quality audit and process

verification

7.Supplier control

8.Handling abnormality

in quality

9.5S management

10.Equipment/

Inspection

equipment's

11.Implementation

of standards

12.Products

management

13.Handling Management

N/A

Achieved

Total

F003-3 QA/MT Ver. 5

Category Judgment Remarks Follow Up

Timing chart for new development parts are from RFQ to SOP

at customer end.

Production Prepration meeting reviews are being done at

defined frequency. (FM/EDD/45)

The Meetinj reviews are being done by Department heads.

Lesson learned are being transferred and taken care for new

projectes in initial RFQ Feasibility meetings.

Potential Defects are being captured in FMEA initial review.

FMEA are being updated during any critical issue at customer

or Inhouse.

Actions for Inhouse Quality issues are being taken to improve

the Product quality.

Initial Production parts are identified by Special Stickers.

Quality team involve in development activities and problem

observed during development stage is shared with Quality

team.

Responsible person defined for start / End of Initial

production.

Guidelines for verification of material at early production stage

is also there, verified WI/QAD/223

Items are defined which required special controls during initial

production controls.

Special Identification stickers are being put on initial

controlled items.

Verified WI/QAD/223, Guidelines for verification of material at

early production stage

Information are being shared among the team for actions /

Improvement. Also Shared with T-II Supplier.

Issues during initial are being take up with the team for

impovement.

Defect rate for initial production control parts are being

monitired.

Yes, changes are defined and are being processed through

ECN. (PR/EDD/06, Rev E, ECN Doc no. - FM/EDD/24). 4 M

change management being followed.

4 M change procedure WI/QAD/221 defined and are being monitored.

Records are being maintained with Retention peroid.

Before and after results are being monitored and recorded with

ECN. (EC/2013/0023)

To be define

Audit Area

Regulation

for

initial

production

control

1

Regarding

implementation rule

of production

preparation

2

Regarding

management

/implementation by

production

preparation

plan/report(master

plan)

Do you implement follow-up to control the schedule and

progress of production preparation items?

Do you share the information of initial production control

among the related department?

Do you pick up issues and improve them during initial

production control?

Do you control process capability and defect rate during

initial production control?

Do you define unexpected change (unusual) and planned

change clearly?

Defect prevention on

the stage of prosses

design by using

FMEA/Matrix diagram

4

Product/process

evaluation at the

quality evaluation

meeting in each trial

Do you record product quality check results to ensure

traceability?

Do you retroactively check about product quality when

unexpected change occurs?

Do you define initial part clearly?

How do you define items required special control during

initial production control? Do you set stricter inspection

methods than the ordinal inspection?

1

Regulation for

initial production

control

2

Implementation of

initial production

control

1

Definition and

implementation of

changing

management

3

Do you define procedure(rules applied from sharing

information to result confirmation) at change

occurrence?

Supplier

Name

Part Name

2

Definition and control

method for initial part

Changing

managemen

t

Production

preparation

MARUTI VENDOR QUALITY SYSTEM AUDIT CUM FOLLOW UP REPORT

Date : 17 /18/19.03.14

Are production preparation plan and report controlled by

a person in charge of progress(top management)

periodically?

Do you consider following items and reflect them to the

processes and stadards beforehand?

-Troubles in the past; -Defect items expected;

-Defect items unable to capture at customer;

-Defect items difficult to repair;

Do you review and improve FMEA or Matrix diagrams

when any critical issue occurs after SOP?

Do you prevent defects by quality improving activities of

cross-function team to evaluate quality performance?

Do you define condition to start mass production and

then check on the product line prior to SOP?

Do you define following items related to initial production

control by standards ?

-controlled parts; -controlled items; -inspection method;

-initial production control period;

-a person who annonce start/end of initial production

control; -finish condition;

Sigma

Vibracoustic

India Pvt. Ltd

Damper

Do you define in reguration following items for

production preperation?-scope of parts,-responsibility of

each department -control contents/items?

Concerning regulation

Do you define importance level during production

preparation for each product and clarify control items

based on it ?

Vendor Attendees

Auditors: Mr. Manil Gogia

F0003-1 QA/MT Ver. 5

Category Judgment Remarks Follow Up Audit Area

Supplier

Name

Part Name

MARUTI VENDOR QUALITY SYSTEM AUDIT CUM FOLLOW UP REPORT

Date : 17 /18/19.03.14

Sigma

Vibracoustic

India Pvt. Ltd

Damper

Concerning regulation

Vendor Attendees

Auditors: Mr. Manil Gogia

Initial parts are identified with unique identification numbers on each

part.

Control plan for each Part is available

Process flow for all the product is available.

Quality and production char. Are defined in Control plan.

Controal plan / Operation standard / WI contains Inspection Methos,

Ref. standard, Inspection Frequency, Sampling plan, Poka - yoke

etc. Procedure for prepairing control plan WI/QAD/222 is there

Operation standard prepration and maintaining the document is

defined with authority.

Retention period also defined for MSIL parts.

There is Coherence among Control plan, inspection standard,

operation standard and MIS -P.

List of history is updated on the control plan and operation standard.

Documents are issued with receiving information.

Internal Audits are being planned as per schedules. The audit

is planned as per standardized checksheet.

Process Audits are being done to identify issues and action

plan is made to improve them.

Methods are prepared during development stage and shared

during initial Trials for improvements.

The problem / Failure are linked with the preventive measures

by implement action on the checksheets , control plan, WI etc

1

Evaluation method for

new suppliers

New Suppliers are certified after audit by SQA Team as per

defined procedure of supplier selection, evaluation & approval

PR/PUR/01

Monthly supplier rating is being prepared and circulated to each

supplier.

Important control items are being instruct to supplier. Agrement of

insoection is signed off with supplier.

Process audit of supplier is done at defined frequency.

1

Activity to

keep/improve

production quality

2

Quality

audit and

process

verification

1

Training related to technical department wise (Functional

Training), HSE, 5S are being planned and records are being

maintained.

Skill Matrix is being evaluated six monthly as per procedure to

evaluate skill level WI/?

The training is being provided prior to SOP.

Trainings are being given to all levels in the organization.

Internal and external trainings are being organized.

Special education and Technical Training like customer

requirements etc are provided to Inspectors and Operators.

Certificated Operators are being monitored.

Do you clarify the department in charge of promoting

quality education,implement education based on annual

plan?

Do you define and implement the skill evaluation of

operator to determine whether operator can work without

surveillance?(e.g. acceptable revel/evaluation

freequency/evaluation method)

Do you control initial parts separetely and make quality

records about them?(both internal and outsourced

process are included)

Do you make process control standards for all products

which is shipped to SMC / MSIL?

Do you mention defined both characteristics of quality

and production control on the process control standars?

Procedure to control

standards

Process control

standards

Inspection

specifications

Operatoin

instructions

1

Education/ training

procedure

Procedure to make

process control

standards(QA

process charts)

Do you focus on useful know-how of operation,

operations with poor workabillty and operation which

need a lot of repair and standardize them?

Do you confirm consistancy between actual operation

and standard?

Do you confirm if countermeasures are taken properly to

prevent reoccuring of quality fail?

Do you define criteria to certificate new suppliers and

implement them?

Do you collect supplier failure information, determine

supplier grade according to quality level and conduct

audit and instruction periodically?

For outsourcing any production, do you instruct them

clearly about function and improtant control items of

products at the meeting ?

Prior to SOP, do you instruct each operator based on

actual operation instructions?

Do you implement planned education to supervisers for

skill improvement ?

Do you implement special education or technical training

to inspectors and operators of particular process

(required specialized skills)? Are training records kept?

Do you periodically monitor the skill of certificated

operators and follow up to improve their skill?

Do you conduct internal quality auditor periodically?

following are standardized:, -suditor team; -audit

frequency; -audit timing; -audit method; -audit

checksheet;

Do you conduct quality audit to identify issues and

properly improve them?

Supplier

control

2

Management, quality

evaluation and

instruction for

suppliers

2

Education for

managers/Inspectors/

Special operators

Education

and traning

2

Content of process

review

2

Definition and control

method for initial part

Changing

managemen

t

For outsourced process,do you control the progress of

production preparation and confirme issues ?

Standards

managemen

t

Standards

managemen

t

Do you mention followings on process control standards

required to each process?

-quality comfirmation method; -regulations;

-standards (operation instruction/items to be focused

on);

-boundary samples; -parmeter chart; -Pokayoke

Do you define following concerned abou standards?

-department in charge of making;

-a person in charge of making;

-a person in charge of authorizing;

-making period; -timing to submit to customer;

-revision rule; -retention period;

Do you have consistency to keep process control

standard, inspection specification, operation inspection

and parameter chart?

Do you make use of lists to control preparation and

revision of standards and share the updated information?

F0003-1 QA/MT Ver. 5

Category Judgment Remarks Follow Up Audit Area

Supplier

Name

Part Name

MARUTI VENDOR QUALITY SYSTEM AUDIT CUM FOLLOW UP REPORT

Date : 17 /18/19.03.14

Sigma

Vibracoustic

India Pvt. Ltd

Damper

Concerning regulation

Vendor Attendees

Auditors: Mr. Manil Gogia

Initial production parts are installed at supplier end and monitored

by SQA Engineer.

No product is being shipped directly to customer from supplier.

Record of initial parts (pilot lot) Inspection at sub supplier prepared

and verified by QA Engineer.

Confirmation taken from supplier for 4 m change.

Abnormal situation is denfined. Opearators are know about the

abnormal situation.

Standardized rules to handle customer cmplaint, Internal Failures

and supplier failures are defined. WI for handling Customer

complaints is also there WI/QAD/94A

The Suspected lots can be traceback based upon the Box no., Route

cards. Work instruction for handling abnormal situation WI/QAD/219

is there

Preventive actions are being taken to prevent recurrence of issue.

Corrective actions are reflect by adding in the check sheets and

poka- yoke verification where ever required.

Effectiveness is being checked and recorded.

Actions are being horizontally deployed for the similar parts and

process.

The store material, work-in-process, finished products,

inventory and container are plced at appropriate location to

avoid dust, Deformation Rain water.

Storage of RM, BOP,WIP&FG parts at designated location as per

storage standard defined.

Location no is provided for FG and Raw material.

Do and don't are displayed on the shop floor.

Work Instructions ( Do's & Do not's) for not having temporary

storage(storage on shop floor, over racks, on work tables, on

machines, in non standards bins / trolleys.

Inspection of critical operation inspection / testing at lab under

properly controlled environment:- temperature, humidity .

Lux level is maintained on Inspection table.

Location for Tools and Jigs are defined.

Inspection Equipments are keep properly with verification.

Production equipment, Dies, Jigs etc are being checked

regularly and records are being maintined.

Poka-yoke defined In a list and being verified at a defined frequency

and records are maintained.

Inspection equipement are calibrate as per defined frequency. Due

date is mentioned on each equipment.

5S

managemen

t

1

Location of

production site

2

Production

equipments

management

Equipment/I

nspection

equipments

managemen

t

1

Maintenance of

equipments , jigs and

tools

2

Maintenance of

inspection

equipments

Handling

abnormality

in quality

Supplier

control

2

Management, quality

evaluation and

instruction for

suppliers

1

Handling when

abnormal situation

occures

2

Prevention of

recurrence

Customer claims

In process failure

Suppliers failure

Do you have criteria to estimate the scope of suspected

lot for abnormal situation? When abnormal situation

occurs,do you trace suspected lot based upon the

criteria?

Do you prevent recurrence of issues by analyzing cause

of occuring defect based on process investigation result

such as 5-why analysis?

Do you reflect corrective action to improvement of

process control and review of standards?

After corrective action are taken, do you conduct on-site

checkup and evaluate the effectiveness?

Do you cascade information of corrective action to

similar parts and processes?

Do you keep store material, work-in-process, finished

products, inventory and container at appropriate storage

prevented from dust, lust, scratch, deformation and

rainwater?

Do you make suppliers to conduct initial production

control and decide department in charge of conduct?

Regarding the parts which are shipped directly to the

custmers from outsourced suppliers, do you have

method to assure product quality performance?

Do you make outsourced suppliers to conduct initial

parts and 4M changing management and is it possible to

trace?

Do you define clearly what is abnormal situation and

make operators know the definition?

Do you clarify and standardize the handling rules/routes

for customer claims, in process failure and supplier

failure?

Do you confirm regulary the function of Pokayoke,

automated stop and alarm? Are records of maintenance

kept?

Do you standardize frequency of polishing and

replacement for consumable

tools(blade/electrode/rubstone, etc.)?

Do you caliburate regulary inspection equipments and

put the expire date on them?

Do you control material, work-in-process and finished

product by designated location, volume and standard

using visual control?

Do you forbid operators to put temporary storage on

work place?

Do you implement inspection or critical operation under

the properly controlled enviroment luminance

/temperture/humidity/vibration/noise/work table, etc.)?

Do you keep condition of production equipments, jigs

and tools properly?

Do you keep condition of inspection equipments properly

to ensure accuracy?

Do you conduct daily/regulary check of production

equipments, dies and jigs? Are records of maintenance

kept?

F0003-1 QA/MT Ver. 5

Category Judgment Remarks Follow Up Audit Area

Supplier

Name

Part Name

MARUTI VENDOR QUALITY SYSTEM AUDIT CUM FOLLOW UP REPORT

Date : 17 /18/19.03.14

Sigma

Vibracoustic

India Pvt. Ltd

Damper

Concerning regulation

Vendor Attendees

Auditors: Mr. Manil Gogia

Boundary sampels are being reviewed at defined frequency with

objective is also mentioned.

Work instructions are availble for the operator for inspection.

WI are displayed on the inspection table, Near to operation & are

easily assessable to operators.

Standard Operation defined

Verification

Specification for parameters are provided and Defective

photographs are provided in WI.

Material WIP / FG are being identified with Identification tags

and FIFO is being maintained

Traceability of Production Date/ Lot/ Qty/ dispatch date maintained.

Similar parts are identified by colour dot marking.

Non- confirming parts are identified and stored separately in locked

room.

Procedure for control of non-conforming product PR/QAD/04

available defining handling of non-confirming parts & WI/QAD/94 for

control of Non-conforming products

Authority is defined to take final decision.

Root cause analysis,

Procedure to define Hold part & reporcess is define WI/QAD/ 220

and records are being mainatined.

Packing Aggrements are made with customer

Packing and storage conditions are defined to prevent material from

contamination and damage.

Returnable bins are being cleaned as per defined procedure WI/PRD-

02/26

Packing Aggrements are made with customer & Packing and

storage conditions are defined to prevent material from

contamination and damage.

NA

NA

NA

13.

Handling

Managemen

t

1 Bins/ Trolley

Management

14.

Critical

parts

Managemen

t

1 Maru A Parts

Management

Does the Packaging method prevent Transportation

damage

Do you have Special checks/Inspection for Maru A

parameters of Maru A part are available .

Products

managemen

t

1

management of parts

flow

2

Non-confirming parts

management

Implementat

ion of

standards

1

Implementation of

standards

Equipment/I

nspection

equipments

managemen

t

2

Maintenance of

inspection

equipments

Do you control follows production history by rproduct lot

numbers?

-production date; -production volume; -shipping date

Do you control identification of similar parts separetely?

Do you control deterioration (expire date) of boundary

samples for objective judgments such as appearance

inspection?

Do you use easy expression (visualizer, onomatopoeia

,etc.) for operation instractions? So that operator can

easily understand process and critical points.

Do you keep operation instractions on the accessible

place and post important quality points and critical

operation points on the place where operators can see it

easily?

Do you have Identification of Maru A Process/Operator on

Shop Floor.

Do you keep the repair history when repairing & using

Maru A items

Do you control identification of non-confirming parts and

parts on hold. Do you store them separetely?

Do you define procedure to handling (following items)

non-confirming parts and parts on hold?

-root cause analysis; -person responsible for final

judgment

-ttiming; -feedback procedure

Regarding repaire non-confirming parts and parts on

hold to re-use, do you define responsibility to implemet?

Are repair record kept?

Do you make arrangements with customers about the

packing style & transportation system to prevent damage

during handling of finished products & perform

accordingly.

Are the packaging style & storage environment controlled

with consideration to contamination

Do you have system to maintain Bins /Trolleys in Good

Condition.

Do operators and supervisers operate according to the

operation standards?

Do you regularly monitore that each operator operates

according to the operation instructions

Is it possible to judge OK/NG specificlly by each check

sheet (of daily equipment check, quality control report,

etc.) you use?

Do you keep first-in first-out of finished products and

work-in-process (matelial, reserve parts by using

identification tag or lot indication?

F0003-1 QA/MT Ver. 5

PLANNED CHECKED APPROVED

TOTAL 0

TOTAL 0

SUB ITEM

NO.

DATE ITEM NO. DESIRED IMPROVEMENT POINTS DETAIL OF IMPROVEMENT PLAN IN-CHARGE

RESULT OF

VERIFICATION

DEADLINE FOR

SUBMISSION OF PLAN

DEADLINE FOR SUBMISSION OF

ACTUAL RESULT

AUDIT POINT

AUDIT PART NAME

AUDIT PART NO.

AUDIT DATE

V

E

R

I

F

I

C

A

T

I

O

N

V

E

R

I

F

I

C

A

T

I

O

NRECEIVING DATE

V

E

R

I

F

I

C

A

T

I

O

N

COPY TO :

MARUTI VENDOR AUDIT- COUNTERMEASURE REPORT

P

L

A

N

N

I

N

G

RECEIVING DATE

P

L

A

N

N

I

N

G

VENDOR NAME

P

L

A

N

N

I

N

G

VENDOR CODE

F003-4 QA/MT Ver. 4

Вам также может понравиться

- System Audit RequirementДокумент37 страницSystem Audit Requirementavinashbatra171% (7)

- Manufacturing Process AuditДокумент1 страницаManufacturing Process AuditSachin Kumbhar100% (1)

- Evidences To Be Maintained As Per APQP For PMДокумент3 страницыEvidences To Be Maintained As Per APQP For PMSachin RamdurgОценок пока нет

- 4th Edition PPAPДокумент83 страницы4th Edition PPAPTerri Paleno Lebow100% (1)

- Procedure For NPD HandoverДокумент1 страницаProcedure For NPD HandoverTushar Wagh100% (1)

- IATF Objective Data Analysis - Quality - ExampleДокумент1 страницаIATF Objective Data Analysis - Quality - ExampleSachin RamdurgОценок пока нет

- IATF 16949 DocumenДокумент1 страницаIATF 16949 Documenpunitg_2Оценок пока нет

- Red Bin Analysis FormatДокумент1 страницаRed Bin Analysis FormatPRABHAT RANJAN100% (1)

- MACE Formats 1Документ46 страницMACE Formats 1Ashish VaidОценок пока нет

- Inital Flow Management Productivity ProcedureДокумент4 страницыInital Flow Management Productivity Procedureshaggyrahul100% (3)

- QMP-18 Initial Production ControlДокумент5 страницQMP-18 Initial Production Controlom cncОценок пока нет

- Operator Observance SheetДокумент5 страницOperator Observance SheetEr Avinash Kumar100% (2)

- T2 VSA With RequirementДокумент8 страницT2 VSA With RequirementSandeep K Malhotra100% (3)

- APQP ProcedureДокумент9 страницAPQP ProcedurePk Nimiwal100% (4)

- Apqp FormsДокумент67 страницApqp FormsNeumar NeumannОценок пока нет

- GP-9 Process Control Plan Audit Summary SheetДокумент5 страницGP-9 Process Control Plan Audit Summary SheetAsifОценок пока нет

- 3.6 Initial SupplyДокумент2 страницы3.6 Initial SupplySunil Kumar92% (12)

- Process & Product Audit Check SheetДокумент6 страницProcess & Product Audit Check SheetPrakashRai100% (7)

- APQP Phases & Elements of APQPДокумент6 страницAPQP Phases & Elements of APQPSachin Ramdurg100% (1)

- 1 2 3 - 4M Change Part TagДокумент4 страницы1 2 3 - 4M Change Part TagIt's me DJОценок пока нет

- Operator Observation SheetДокумент1 страницаOperator Observation Sheet25aprilОценок пока нет

- Operator Observance SheetДокумент2 страницыOperator Observance Sheetrajesh sharma100% (1)

- Ipc & Ipp Logbook or FlowДокумент8 страницIpc & Ipp Logbook or FlowKaran Malhi100% (1)

- 4M Change Procedure - PED 02Документ2 страницы4M Change Procedure - PED 02sathyabalaraman87% (23)

- Product Audit ReportДокумент2 страницыProduct Audit ReportManoharar R100% (2)

- Copy of APQP Check List - Ford (Blank)Документ9 страницCopy of APQP Check List - Ford (Blank)feiraluremaОценок пока нет

- Final Inspection: Roles, Responsibilities & Authority What Where When Who How Man Hours Sr. NoДокумент10 страницFinal Inspection: Roles, Responsibilities & Authority What Where When Who How Man Hours Sr. NoVikas KashyapОценок пока нет

- NPD Procedure & Apqp FormatДокумент132 страницыNPD Procedure & Apqp FormatKaramjit Singh100% (2)

- 14-QSP - 59 Procedure For Temporary Change of Process Controls PDFДокумент1 страница14-QSP - 59 Procedure For Temporary Change of Process Controls PDFsahyadri engineersОценок пока нет

- W.I - Abnormal SituationДокумент1 страницаW.I - Abnormal Situation25april100% (2)

- APQP Sample FormatДокумент32 страницыAPQP Sample FormatManigandan RОценок пока нет

- Process Audit - Sheet New ......Документ1 страницаProcess Audit - Sheet New ......MUKESH KUMARОценок пока нет

- APQP Timing PlanДокумент2 страницыAPQP Timing Plancertifiq8213100% (3)

- Required Doc For IATFДокумент3 страницыRequired Doc For IATFAbhayОценок пока нет

- NPD Check SheetДокумент6 страницNPD Check Sheets.charlieОценок пока нет

- Advanced Product Quality Planning Timing Chart: Plan and Define Programme - PP Trial StageДокумент6 страницAdvanced Product Quality Planning Timing Chart: Plan and Define Programme - PP Trial Stagerajesh sharma100% (2)

- Production Part Approval ProcessДокумент6 страницProduction Part Approval ProcessleonardoОценок пока нет

- Supplier 4M Change Request FormatДокумент1 страницаSupplier 4M Change Request FormatManoj KumarОценок пока нет

- Shriram Pistons & Rings LTD, Pathredi: Layered Audit Check Sheet Monthly (Plant Hod)Документ5 страницShriram Pistons & Rings LTD, Pathredi: Layered Audit Check Sheet Monthly (Plant Hod)deepak sharma100% (1)

- IMS Quality Manual MSSL 2018 LatestДокумент46 страницIMS Quality Manual MSSL 2018 LatestManjeet RanaОценок пока нет

- Product Audit Check SheetДокумент3 страницыProduct Audit Check SheetLakshmanan Venkatesan100% (1)

- Gate Check Review FormsДокумент7 страницGate Check Review FormsKamardeen Nazurudeen100% (1)

- GM 1927 08 Potential Supplier Assessment (PSA)Документ12 страницGM 1927 08 Potential Supplier Assessment (PSA)Juan Carlos Murillo Larrota100% (1)

- AIAG PPAP Cover SheetДокумент1 страницаAIAG PPAP Cover SheetSCHOPENHAUERОценок пока нет

- Poison Cake Test: Standard Operating ProcedureДокумент1 страницаPoison Cake Test: Standard Operating ProcedureGirdhar Sahu100% (3)

- Apqp FormsДокумент32 страницыApqp FormsAnonymous A2jnZ5MNPxОценок пока нет

- 4M Change MatrixДокумент1 страница4M Change MatrixAnkit SainiОценок пока нет

- Iso Ts 16949 Tamil Training ProgramДокумент51 страницаIso Ts 16949 Tamil Training ProgramGanesan Sankaranarayanan88% (8)

- .013-00-Checking AidsДокумент3 страницы.013-00-Checking Aidsdaniel_sasikumarОценок пока нет

- APQP (27) ElementsДокумент31 страницаAPQP (27) Elementssam1hi5Оценок пока нет

- Vishwas Electroplaters: Control Plan For Acid Zinc Barrel Plating & Hexavalent PassivationДокумент13 страницVishwas Electroplaters: Control Plan For Acid Zinc Barrel Plating & Hexavalent PassivationAnonymous YptJ5iDОценок пока нет

- Supplier Deviation Request Form N°:: Part Description Part No: Revision PO NumberДокумент1 страницаSupplier Deviation Request Form N°:: Part Description Part No: Revision PO Number57641Оценок пока нет

- The 5 Core ToolДокумент17 страницThe 5 Core ToolRajesh GhoshОценок пока нет

- QAF12 Process Audit Rev 09Документ4 страницыQAF12 Process Audit Rev 09ukavathekarОценок пока нет

- 4M Change Monitoring Sheet: If There Is Any Change During The Shift Mark It With RedДокумент1 страница4M Change Monitoring Sheet: If There Is Any Change During The Shift Mark It With RedDINESHCHOUDHARY88Оценок пока нет

- Meenakshi Polymers Pvt. LTD.: Poison Test SheetДокумент2 страницыMeenakshi Polymers Pvt. LTD.: Poison Test SheetKaran Malhi100% (2)

- QMS Audit Check SheetДокумент7 страницQMS Audit Check Sheetaboo2uОценок пока нет

- Role of QC & QA in OperationsДокумент6 страницRole of QC & QA in OperationsmaheshОценок пока нет

- QMS Audit Check SheetДокумент7 страницQMS Audit Check Sheetaboo2uОценок пока нет

- Free Ts 16949 Audit ChecklistДокумент8 страницFree Ts 16949 Audit ChecklistKumaravel100% (1)

- IQA Report Summary Sheet - Bolt & Zest Front Strut: 1 Mounting of PartДокумент33 страницыIQA Report Summary Sheet - Bolt & Zest Front Strut: 1 Mounting of PartJetesh DevgunОценок пока нет

- Terms Conditions For Apy FinalДокумент3 страницыTerms Conditions For Apy FinalJetesh DevgunОценок пока нет

- Shishu Niketan Model Sr. Sec. School: Sector 22-D, ChandigarhДокумент1 страницаShishu Niketan Model Sr. Sec. School: Sector 22-D, ChandigarhJetesh DevgunОценок пока нет

- REVISION Master - GM Customer Specifics - Rev141212 - FINALДокумент34 страницыREVISION Master - GM Customer Specifics - Rev141212 - FINALJetesh DevgunОценок пока нет

- Ticket: Terms & ConditionsДокумент1 страницаTicket: Terms & ConditionsJetesh DevgunОценок пока нет

- Worksheet in SQ Checksheet Part1Документ50 страницWorksheet in SQ Checksheet Part1Jetesh Devgun100% (1)

- Furnace Cleaning Rev 1Документ1 страницаFurnace Cleaning Rev 1Jetesh DevgunОценок пока нет

- Date Sheet Dec 2015 PDFДокумент126 страницDate Sheet Dec 2015 PDFamandeep651Оценок пока нет

- Site Assessment HandbookДокумент18 страницSite Assessment HandbookJetesh DevgunОценок пока нет

- Process CapabilityДокумент18 страницProcess CapabilitysigmasundarОценок пока нет

- Presentation On 7 Tools of Q.C.Документ25 страницPresentation On 7 Tools of Q.C.Jetesh DevgunОценок пока нет

- APQPДокумент38 страницAPQPJetesh DevgunОценок пока нет

- TQMДокумент42 страницыTQMJetesh Devgun0% (1)

- ISO TS 16949 2009 ChangesДокумент9 страницISO TS 16949 2009 ChangesfolorОценок пока нет

- MITC July4Документ7 страницMITC July4Jetesh DevgunОценок пока нет

- 17-11-2015 M Tech Cse 2015Документ21 страница17-11-2015 M Tech Cse 2015Jetesh DevgunОценок пока нет

- Westerman TableДокумент86 страницWesterman TableDipak88% (17)

- Detailed Advt CWE Clerks VДокумент33 страницыDetailed Advt CWE Clerks VRahul SoniОценок пока нет

- LL VNT.F,) SCRNF - L I: No.: " NoДокумент2 страницыLL VNT.F,) SCRNF - L I: No.: " NoJetesh DevgunОценок пока нет

- Presentation On MSA by TS16949 Auditors From UL IndiaДокумент16 страницPresentation On MSA by TS16949 Auditors From UL IndiaJetesh DevgunОценок пока нет

- Software Engineering Projects in Distant TeachingДокумент8 страницSoftware Engineering Projects in Distant TeachingJetesh DevgunОценок пока нет

- It's Time To Take A Smart Step!Документ2 страницыIt's Time To Take A Smart Step!Jetesh DevgunОценок пока нет

- BrochureДокумент1 страницаBrochureJetesh DevgunОценок пока нет

- Home Policy WordingsДокумент10 страницHome Policy WordingsJetesh DevgunОценок пока нет

- SCRCyberReceipt13 09 2015Документ1 страницаSCRCyberReceipt13 09 2015Jetesh DevgunОценок пока нет

- PPAP File - 1-Ilovepdf-Compressed.2Документ1 страницаPPAP File - 1-Ilovepdf-Compressed.2Jetesh DevgunОценок пока нет

- TATA GarageList (Updated 16.07.2013)Документ768 страницTATA GarageList (Updated 16.07.2013)Jetesh DevgunОценок пока нет

- Software Engineering Projects in Distant TeachingДокумент8 страницSoftware Engineering Projects in Distant TeachingJetesh DevgunОценок пока нет

- SynopsisДокумент15 страницSynopsisMeenu ChauhanОценок пока нет

- It's Time To Take A Smart Step!Документ2 страницыIt's Time To Take A Smart Step!Jetesh DevgunОценок пока нет

- Low Voltage Switchgear Specification: 1. ScopeДокумент6 страницLow Voltage Switchgear Specification: 1. ScopejendrikoОценок пока нет

- Lancru hzj105 DieselДокумент2 страницыLancru hzj105 DieselMuhammad MasdukiОценок пока нет

- Enrile v. SalazarДокумент26 страницEnrile v. SalazarMaria Aerial AbawagОценок пока нет

- March For Our LivesДокумент22 страницыMarch For Our LivesLucy HanОценок пока нет

- Arbans Complete Conservatory Method For Trumpet Arbans Complete ConservatoryДокумент33 страницыArbans Complete Conservatory Method For Trumpet Arbans Complete ConservatoryRicardo SoldadoОценок пока нет

- Description and Operating Instructions: Multicharger 750 12V/40A 24V/20A 36V/15AДокумент34 страницыDescription and Operating Instructions: Multicharger 750 12V/40A 24V/20A 36V/15APablo Barboza0% (1)

- Operating Instructions: HTL-PHP Air Torque PumpДокумент38 страницOperating Instructions: HTL-PHP Air Torque PumpvankarpОценок пока нет

- ইসলাম ও আধুনিকতা – মুফতি মুহম্মদ তকী উসমানীДокумент118 страницইসলাম ও আধুনিকতা – মুফতি মুহম্মদ তকী উসমানীMd SallauddinОценок пока нет

- Fire Prevention Plan Template - FINAL 5-30-08Документ5 страницFire Prevention Plan Template - FINAL 5-30-08Peter GeorgeОценок пока нет

- Microfinance Ass 1Документ15 страницMicrofinance Ass 1Willard MusengeyiОценок пока нет

- CUBE Dealer Book 2009Документ280 страницCUBE Dealer Book 2009maikruetzОценок пока нет

- EP001 LifeCoachSchoolTranscriptДокумент13 страницEP001 LifeCoachSchoolTranscriptVan GuedesОценок пока нет

- BSH 7005-15Документ129 страницBSH 7005-15Mark InnesОценок пока нет

- Chief Complaint: History TakingДокумент9 страницChief Complaint: History TakingMohamad ZulfikarОценок пока нет

- Guideline - Research ProposalДокумент38 страницGuideline - Research ProposalRASОценок пока нет

- A 138Документ1 страницаA 138pooja g pОценок пока нет

- Song LyricsДокумент13 страницSong LyricsCyh RusОценок пока нет

- Animal Health ChecklistДокумент4 страницыAnimal Health ChecklistcapsfastОценок пока нет

- PreviewpdfДокумент29 страницPreviewpdfSoemarlan ErlanОценок пока нет

- Body Systems Portfolio - Tommy JДокумент8 страницBody Systems Portfolio - Tommy Japi-554072790Оценок пока нет

- Beyond Models and Metaphors Complexity Theory, Systems Thinking and - Bousquet & CurtisДокумент21 страницаBeyond Models and Metaphors Complexity Theory, Systems Thinking and - Bousquet & CurtisEra B. LargisОценок пока нет

- SecurityFund PPT 1.1Документ13 страницSecurityFund PPT 1.1Fmunoz MunozОценок пока нет

- Research Group 3 11abmb1Документ32 страницыResearch Group 3 11abmb1arianeОценок пока нет

- IQAc 04-05Документ10 страницIQAc 04-05ymcacollegewebsiteОценок пока нет

- Operator'S Manual Diesel Engine: 2L41C - 2M41 - 2M41ZДокумент110 страницOperator'S Manual Diesel Engine: 2L41C - 2M41 - 2M41ZMauricio OlayaОценок пока нет

- Preparing For CPHQ .. An Overview of Concepts: Ghada Al-BarakatiДокумент109 страницPreparing For CPHQ .. An Overview of Concepts: Ghada Al-BarakatiBilal SalamehОценок пока нет

- Iec Codes PDFДокумент257 страницIec Codes PDFAkhil AnumandlaОценок пока нет

- Changed Report 2015 PDFДокумент298 страницChanged Report 2015 PDFAnonymous FKjeRG6AFnОценок пока нет

- B. Inggris X - 7Документ8 страницB. Inggris X - 7KabardiantoОценок пока нет

- Crisis of The World Split Apart: Solzhenitsyn On The WestДокумент52 страницыCrisis of The World Split Apart: Solzhenitsyn On The WestdodnkaОценок пока нет