Академический Документы

Профессиональный Документы

Культура Документы

Diagrama Hidraulico D9T

Загружено:

Cristian ValenciaИсходное описание:

Оригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Diagrama Hidraulico D9T

Загружено:

Cristian ValenciaАвторское право:

Доступные форматы

Item

Part

Number

Description

Schematic

Location

1C 183-4584 SPEED SENSOR (STEERING MOTOR) B-8

2C 164-7577 CHARGE FILTER BYPASS SWITCH C-6

3C 237-0957 FAN PUMP PRES TRANSDUCER B-4

4C 237-0957 IMPLEMENT PUMP PRESS TRANSDUCER D-3

5C 224-4535 CHARGE PRESS TRANSDUCER C-7

6C 145-7028 TEMPERATURE SENSOR C-2

Component Locations

Item

Part

Number

Description

Schematic

Location

1 214-1093 STEERING PUMP A-5

2 214-1094 STEERING MOTOR B-7

3 212-2297 CHARGE FILTER C-7

4 212-0675 COLD OIL RELIEF VALVE A-6

5 214-1097 FAN PUMP B-4

6 214-1098 IMPLEMENT PUMP B-3

7 214-1099 FAN MOTOR B-5

8 124-8335 COOLER BYPASS A-5

9 206-7353 COOLER A-4

10 208-1558 SUCTION MANIFOLD B-3

11 223-8531 PRESSURE REDUCING VALVE E-4

12 200-0750 ACCUMULATORS D-4

13 201-0950 SHUT-OFF VALVE-PILOT E-4

214-1079

IMPLEMENT VALVE

(BULLDOZER/RIPPER)

211-7817

IMPLEMENT VALVE

(BULLDOZER/WINCH)

15 208-9683 END COVER D-7

16 217-4327 QUICK DROP VALVE E-5

165-8633 LIFT CYLINDER

225-6727 LIFT CYLINDER

18 109-6778 SINGLE TILT CYLINDER (RH) E-6

19 133-8269 CASE DRAIN MANIFOLD B-1

20 123-8098 R IPPER LIFT CYLINDER E-7, F-7

21 123-8097 RIPPER TIP CYLINDER E-7, F-7

22 6E-3113 PIN PULLER CYLINDER E-8

23 188-6140 PIN PULLER VALVE E-8

24 222-0491 TANK GP B-2

25 154-6165 VACUUM BREAKER C-2

26 126-1813 PILOT FILTER D-4

27 4E-1437 CHECK VALVE (FAN CIRCUIT) B-4

28 N/A PILOT MANIFOLD D-13

1A 217-4326 DUAL TILT VALVE F-6

2A 109-8832 DUAL TILT CYLINDER (RH) E-6

3A 109-8833 DUAL TILT CYLINDER (LH) F-6

1B 214-1100 REVERSING FAN MOTOR (OPTION) B-5

2B 229-1466 VALVE GP C-5

N/A: Part number unavalible at the time of publication.

Component Locations

DUAL TILT OPTION

REVERSING FAN OPTION

17

14 C-5

E-5

R

E

N

R

7

5

3

4

-

0

1

2

4

P

a

g

e

,

D

G

M

RENR7534-01

January 2005

D9T Track-Type Tractor

Hydraulic System

RJS1-UP

2005 Caterpillar

All Rights Reserved

Printed in U.S.A.

1

3

4 5

The steering charge filter (1) is a canister-type filter

with a replaceable element. It is located under the

triangular deck plate just outside the left operator

compartment door. Steering charge pump discharge

pressure can be checked using the pressure test

port (F) that is installed in the top of the filter housing

cover. The steering charge pump discharge pressure

sensor (3) is installed on top of the housing, at the

filter inlet (4). Not visible above is the steering charge

filter bypass switch (pressure differential switch). It is

installed in the housing between the filter inlet port (4)

and the filter outlet port (5). (The filter inlet hose in

the illustration above is in front of the switch from this

angle.)

The hydraulic oil cooler (1) is an oil-to-air cooler

and is mounted horizontally behind the radiator

and ATAAC cores. The hydraulic oil SOS tap

is located toward the top of the vertical tube on

the left side of the cooler, and is easily accessible

from the left side engine compartment opening.

The thermal bypass valve (3) for the hydraulic oil

cooler is an internal valve, located at the left side

of the cooler. It is also accessed from the left side

engine compartment. Also shown above is the

cooler inlet (4) and the cooler outlet (5).

HPDL HPTL HPRR HPSO

HPS

HA

AP

PILOT MANFOLD DUAL TILT / QUICK DROP VALVE HYDRAULIC OIL COOLER CHARGE FILTER

FAN DRIVE MOTOR

FAN PUMP

PIN PULLER / CYLINDER

IMPLEMENT VALVE STEERING PUMP

SOS

F

HD

HC

X1

X2

HFPD

Pin Puller Valve

Pin Puller Cylinder

Pin

D9T

22 21 AP

1C 20

23

14

10

19 25 24 6C

2

15 13 HB 12

26 28 4C

6 11 5 4

3 2C 16

17

HPS HA AP HFPD

3C

1B 7

1A

5C

8 9

2B 3A 18

X2 F

HD

S

HC

X1

2A

HPSO HPSI HPRR HPRL

HPTL HPTR HPDL HPDR

1

27

3

If the machine is equipped with dual tilt, the dual tilt valve (1) is

installed at the left front of the radiator guard, behind the left grill

door. The dual tilt solenoid (2) is located at the bottom of the

dual tilt valve.

The quick-drop valve (3) is located on top, center of the

radiator guard. The quick-drop valve for the D9T is

solenoid operated.

4

5

6

ONE POSITION TWO POSITION THREE POSITION

VENTED PRESSURIZED RETURN ABOVE FLUID LEVEL RETURN BELOW FLUID LEVEL

LINES CROSSING LINES JOINING

TWO-WAY THREE-WAY FOUR-WAY

SPRING CONTROL VALVES RESTRICTION LINE RESTRICTION

(FIXED)

2-SECTION PUMP

MAIN AUX.

SPRING

(ADJUSTABLE)

VARIABILITY LINE RESTRICTION

(VARIABLE)

LINE RESTRICTION

VARIABLE and PRESSURE COMPENSATED

PRESSURE

COMPENSATION

PUMP: VARIABLE and

PRESSURE COMPENSATED

ENERGY TRIANGLES

HYDRAULIC PNEUMATIC

MEASUREMENT

PRESSURE TEMPERATURE FLOW

ROTATING SHAFTS

UNIDIRECTIONAL BIDIRECTIONAL

PUSH-PULL LEVER PEDAL GENERAL MANUAL PUSH BUTTON SPRING

MANUAL CONTROL SYMBOLS

HYDRAULIC MOTORS

FIXED

DISPLACEMENT

VARIABLE DISPLACEMENT

NON-COMPENSATED

UNIDIRECTIONAL

BIDIRECTIONAL

HYDRAULIC PUMPS

FLUID STORAGE RESERVOIRS

CROSSING AND JOINING LINES

VALVE ENVELOPES VALVE PORTS

BASIC COMPONENT SYMBOLS

FLUID CONDITIONER PUMP or MOTOR

FLUID POWER SYMBOLS

FIXED

DISPLACEMENT

VARIABLE DISPLACEMENT

NON-COMPENSATED

UNIDIRECTIONAL

BIDIRECTIONAL

VALVES

PILOT CONTROL SYMBOLS

RELEASED PRESSURE

EXTERNAL RETURN INTERNAL RETURN

REMOTE SUPPLY PRESSURE

SIMPLIFIED COMPLETE INTERNAL

SUPPLY PRESSURE

ACCUMULATORS

SPRING LOADED GAS CHARGED

SOLENOID

or MANUAL

SOLENOID

and PILOT

SOLENOID and

PILOT or MANUAL

COMBINATION CONTROLS

SOLENOID SERVO THERMAL DETENT

HYDRAULIC AND PNEUMATIC CYLINDERS

DOUBLE ACTING SINGLE ACTING

BASIC

SYMBOL

SPRING

LOADED

CHECK VALVES

TWO

POSITION

INFINITE

POSITIONING

FLOW IN ONE

DIRECTION

FLOW ALLOWED IN

EITHER DIRECTION

THREE

POSITION

CROSS

FLOW

PARALLEL

FLOW

INTERNAL PASSAGEWAYS

NORMAL POSITION

A B

P T

A B

P T

SHIFTED POSITION INFINITE POSITION

CONTROL VALVES

ATTACHMENT

MANUAL SHUTOFF

SHUTTLE PILOT

CONTROLLED

Hydraulic Symbols (Electrical)

Electrical Symbols Table

325-AG135 PK-14

Circuit Identification

Number

Wire Color Wire Gauge

Harness identification code

This example indicates

wire 135 in harness "AG".

325-PK-14

Wire Gauge

Wire Color

Circuit Number

Identification

Wire Number Identification Codes

Current Standard

Previous Standard

Electrical Schematic Example Hydraulic Schematic Example

325-PK

Wire Color Circuit Number

Identification

B A

Wire

Wire

(EXAMPLE VALVE)

Current Standard

Transducer

(Fluid)

Transducer

(Gas / Air)

G

Generator

Electrical Wire

Pressure Switch

M

Electric Motor

Pressure Switch

(Adjustable)

Temperature Switch

T

Pressure

Symbol

Temperature

Symbol

Level

Symbol

Flow

Symbol

Electrical Symbols (Electrical)

Ripper

Raise

Ripper

Tip

Inlet Manifold

Solenoids

End Cover

3

4

5

6

1

2

1. pilot relief valve

2. pressure reducing valve

3. implement pump discharge pressure sensor

1

2

3

The steering pump is mounted to the upper left, rear of the flywheel housing.

Components identified in the two illustrations are:

1

2

1

3

4

5

Opening the grill on the front of the radiator guard gains access to

the fan (4) and the hydraulic fan motor (5). If the machine is equipped

with dual tilt, the dual tilt valve (6) is also located here. middle

of the radiator guard.

1

2

3

5

4

The hydraulic demand fan pump is mounted to the rear of the

implement pump at the upper right of of the flywheel housing.

The fan drive pump is a variable displacement axial piston

pump.The pump provides the oil flow that is needed to operate

the hydraulic fan motor. Service points for the demand fan

pump that are shown above are:

1. Hydraulic demand fan pump

2. Fan pump pressure sensor

3. Fan pump pressure control solenoid

4. Adjustment screw for the pump control spool

5. Adjustment screw for the pressure control spool

"HFPD". Hydraulic Fan Pump Discharge pressure test port

1

2

3

4

5

6

7

8

At the left side of the valve stack is the inlet manifold (1). The inlet manifold contains the charging valve (2) and

the main relief valve (3). Implement signal pressure (HB) can be tested at the pressure test port (4) that is

installed on the pump signal line, below the inlet manifold.

The case drain lines from the steering pump, the steering motor, the implement pump, the fan pump, the dual tilt

and quick drop valve all come together in the case drain manifold (5). The case drain oil is then returned to the

case drain filter, which is contained in the hydraulic tank. Each implement control valve contains a solenoid

controlled pilot valve (6) at either end of the control valve. (The solenoid controlled pilot valves located at the

bottom of each control valve are not visible in the illustration above.)

Each implement control valve also contains a pilot pressure test port (7) for testing pilot pressure at the end of

the valve. The other end of each implement control valve also contains a corresponding pressure test port (not -

visible above).

The float pilot boost line (8) directs pilot oil from the LOWER/FLOAT end of the dozer lift control valve to the last

(external) resolver in the signal resolver network. Pilot oil is used to signal the implement pump to upstroke when

the FLOAT function is requested by the operator.

4. pilot filter bypass check valve

5. implement lockout solenoid valve

6. accumulator check valve

Tap

Number

Description

Schematic

Location

AP ACCUMULATOR PRESSURE E-6

HA IMP-PUMP-DISCHARGE D-3

HB IMP-PUMP-SIGNAL C-4

HC LEFT STEER LOOP PRESSURE B-6

HD RIGHT STEER LOOP PRESSURE B-6

F CHARGE PUMP PRESSURE C-6

S OIL SAMPLING PORT C-7

HFPD FAN PUMP DISCHARGE B-4

HPS PILOT SUPPLY E-4

X1 STEER PUMP CONTROL PRESSURE (R) B-5

X2 STEER PUMP CONTROL PRESSURE (L) B-5

HPSO HYD PILOT RIPPER TIP-OUT D-7

HPSI HYD PILOT RIPPER TIP-IN D-7

HPRR HYD PILOT RIPPER RAISE D-6

HPRL HYD PILOT RIPPER LOWER D-6

HPTL HYD PILOT TILT LEFT D-6

HPTR HYD PILOT TILT RIGHT D-6

HPDL HYD PILOT DOER LOWER D-5

HPDR HYD PILOT DOZER RAISE D-5

Tap Locations

Pressure, Sampling, and Sensor

HPDR HPRL HPSI HPTR

Solenoids

Blade

Lift

Blade

Tilt

1. Left steer pump control solenoid

2. Right steer pump control solenoid

3. Steering charge pump

"HC". left steering loop pressure test port.

"HD". right steering loop pressure test port.

"X1". pressure test port (steer right)

"X2". pressure test port (steer left)

MACHINE VIEW

COMPONENT AND TAP LOCATIONS

THIS SCHEMATIC IS FOR THE D9T TRACK-TYPE TRACTOR

Part #: 207-4792 CHG02

Components are shown installed on a fully operable machine with the key and engine

off and transmission shifter in neutral.

R

E

N

R

7

5

3

4

-

0

1

2

4

P

a

g

e

,

C

o

l

o

r

2

,

D

G

M

DRAIN / RETURN LINE

LINES GROUP COLOR DESCRIPTIONS

MAIN PUMP OUTPUT

STEERING PUMP OUTPUT

LIFT and TIP CYLINDER (RIPPER)

PILOT OIL

LOAD SENSING

LIFT CYLINDER (BLADE)

SUPPLY LINE

PIN PULLER

CYLINDER SINGLE TILT / DUAL TILT (OPTION) (BLADE)

VALVE GROUP (REVERSING FAN OPTION)

FAN MOTOR

T P

C1 C2

1 2 3 4 5 6 7 8

A

C

D

E

F

1 2 3 4 5 6 7 8

A

B

C

D

E

F

B

TILT CYL LINES

SINGLE TILT CYL LINES

DUAL TILT CYL LINES

(SERIES 31) (SERIES 31)

C2

T

C1

P

SCREEN

R

2

TRANS

P

T

22

18

16

17

24

25

3A

2A

20

20

21

11

15

14

1A

23

3

7

9

5

8

12

11

6

4

2C

3C

6C

1

26

HC

13

2B

4C

LINE PATTERNS

Drain / Return Lines

Component Group

Pilot / Load Sensing Pressure

Pressure Line

Attachment

Air Line

CALLOUTS

Taps (Pressure, Sampling,Sensor) by letter

Components by number

YY

52

X2 X1

HFPD

F

HPS

HB

AP

HA

HD

27

S

5C

1C

1B

HPDL HPTL HPRR HPSO

HPSI

HPRL HPTR

HPDR

28

19

RIPPER TIP RIPPER RAISE BLADE TILT BLADE LIFT INLET MANIFOLD

Вам также может понравиться

- 422e 428e Hydo PDFДокумент2 страницы422e 428e Hydo PDFdenis100% (1)

- Cargador 966 M Plano Electrico PDFДокумент35 страницCargador 966 M Plano Electrico PDFgerardo100% (1)

- 735, 740 and 740E Electrical System Articulated Truck: Machine Harness Connector and Component LocationsДокумент2 страницы735, 740 and 740E Electrical System Articulated Truck: Machine Harness Connector and Component LocationsMiguel Bustamante100% (3)

- Main Control Valve: 345C Excavator Hydraulic SystemДокумент2 страницыMain Control Valve: 345C Excavator Hydraulic SystemPablo Luis Pérez PostigoОценок пока нет

- System Operation Steering 950FДокумент20 страницSystem Operation Steering 950FEsteban MunaresОценок пока нет

- A - Plano Electrico 330clДокумент2 страницыA - Plano Electrico 330clJorgee La Rosa LopezОценок пока нет

- Tractores d9r D10r-HeuiДокумент49 страницTractores d9r D10r-HeuiRodrigo Chacca100% (1)

- 950H Wheel Loader Hydraulic SystemДокумент2 страницы950H Wheel Loader Hydraulic Systemwtn2013100% (16)

- d8r Diagrama PDFДокумент13 страницd8r Diagrama PDFENRIQUE ARANDA100% (3)

- Diagrama Minicargador 262CДокумент4 страницыDiagrama Minicargador 262CFabian Lopez100% (1)

- 320BL PDFДокумент2 страницы320BL PDFRobinson EspinosaОценок пока нет

- Plano Hidraulico D10T PDFДокумент2 страницыPlano Hidraulico D10T PDFJHOSMAR_22Оценок пока нет

- Diagrama Hidraulico Caterpillar 345cДокумент2 страницыDiagrama Hidraulico Caterpillar 345cJose Miguel Gary Vargas100% (1)

- Hydraulic Schematic 320dlДокумент2 страницыHydraulic Schematic 320dlIsaque Mateus67% (3)

- Hidraulico D9T PDFДокумент2 страницыHidraulico D9T PDFOswaldo Andrade100% (1)

- Fuse Block Wiring Cab Wiring (Right Side) Cab and Chassis ConnectionsДокумент4 страницыFuse Block Wiring Cab Wiring (Right Side) Cab and Chassis Connectionsedwin quirozОценок пока нет

- Plano Hidráulico EXCAVADORA 324DДокумент2 страницыPlano Hidráulico EXCAVADORA 324Dgerardo100% (1)

- Cat - Dcs.sis - Controller.pdf 773BДокумент2 страницыCat - Dcs.sis - Controller.pdf 773BOswaldo Andrade100% (1)

- Diagrama Electrico 325d A3rДокумент15 страницDiagrama Electrico 325d A3rManuel BarronОценок пока нет

- D8T HidraulicoДокумент2 страницыD8T HidraulicoCristian Huarachi100% (1)

- 330C Excavator Hydraulic System: Fluid Power SymbolsДокумент2 страницы330C Excavator Hydraulic System: Fluid Power SymbolsVictor Nunez100% (1)

- Bulldozer D8N SERIE 9TS ELECTRICДокумент2 страницыBulldozer D8N SERIE 9TS ELECTRICjuancarlosjass100% (3)

- 416 eДокумент2 страницы416 earmando vara chavezОценок пока нет

- Hydraulic Technical LibraryДокумент158 страницHydraulic Technical LibraryMarian Ion100% (1)

- D8TДокумент35 страницD8Tmiguel100% (4)

- D8R II Plano Electrico PDFДокумент2 страницыD8R II Plano Electrico PDFDarío Ache EmeОценок пока нет

- Plano Hyd d8tДокумент2 страницыPlano Hyd d8tMilton Frank Bobadilla100% (1)

- D10TДокумент2 страницыD10TjoseluisyalicoОценок пока нет

- Cooling Fan Motor, Charge Air Cooler, Checking/adjusting High RPMДокумент6 страницCooling Fan Motor, Charge Air Cooler, Checking/adjusting High RPMAli KuncoroОценок пока нет

- Plano Electrico 336 d2lДокумент8 страницPlano Electrico 336 d2lFreddy VillegasОценок пока нет

- Plano Hidraulico Motoniveladora 12h 140h CatДокумент2 страницыPlano Hidraulico Motoniveladora 12h 140h CatCicero Melo100% (1)

- Sistema Electrico D6NДокумент14 страницSistema Electrico D6NKardo Her Lim100% (7)

- Hydraulic System 420E, 430E PDFДокумент23 страницыHydraulic System 420E, 430E PDFDavid100% (1)

- Boiler MannualДокумент49 страницBoiler MannualShailenderОценок пока нет

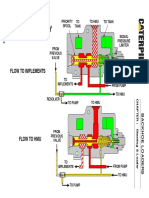

- Steering Priority Valve: Flow To ImplementsДокумент19 страницSteering Priority Valve: Flow To ImplementsAnonymous M28U3D100% (2)

- Interactive Schematic: This Document Is Best Viewed at A Screen Resolution of 1024 X 768Документ11 страницInteractive Schematic: This Document Is Best Viewed at A Screen Resolution of 1024 X 768Richard Perez MedinaОценок пока нет

- D10T Track-Type Tractor Hydraulic System: Dozer Control Valve 5Документ2 страницыD10T Track-Type Tractor Hydraulic System: Dozer Control Valve 5Roberto Antonio Chihuaihuan Araya100% (2)

- Diagrama Electrico 950GДокумент2 страницыDiagrama Electrico 950GpercyОценок пока нет

- d8n Wiring HardnessДокумент2 страницыd8n Wiring HardnessandraОценок пока нет

- Diagrama Hidraulico 962g CaterpillarДокумент4 страницыDiagrama Hidraulico 962g CaterpillarRonald Gareca Rueda100% (1)

- CG956G (208) Service Manual PDFДокумент76 страницCG956G (208) Service Manual PDFDanilo Marin100% (2)

- (R01) BQ R-OKA RSAU PontianakДокумент2 страницы(R01) BQ R-OKA RSAU Pontianakتيجوه سلاميتОценок пока нет

- Esquema Electrico 336dl Serie m4t023XXДокумент24 страницыEsquema Electrico 336dl Serie m4t023XXrjan7pe100% (1)

- Steam Power Reviewer Terms and Problem SolvingДокумент9 страницSteam Power Reviewer Terms and Problem SolvingCherry May Basinang-RamosОценок пока нет

- Part2 06 AuxДокумент15 страницPart2 06 AuxNoel Olvera100% (1)

- SENR6982 - Systems Operation PDFДокумент14 страницSENR6982 - Systems Operation PDFmetanirvanaОценок пока нет

- 330c InteractiveДокумент9 страниц330c InteractiveRajan Mullappilly100% (2)

- 426F2 Diagrama Electrico PDFДокумент2 страницы426F2 Diagrama Electrico PDFRICHARD75% (4)

- Testeo Transmisión 966HДокумент9 страницTesteo Transmisión 966HVictorОценок пока нет

- So Do Thuy Luc 345C PDFДокумент2 страницыSo Do Thuy Luc 345C PDFdoxuanquylcОценок пока нет

- Plano Electrico Cb22bДокумент17 страницPlano Electrico Cb22bRichard Zapata100% (1)

- Pump Training 1Документ45 страницPump Training 1Anonymous CMS3dL1T100% (1)

- Component Locations: 777F and 777F OEM Off-Highway Truck Hydraulic SystemДокумент4 страницыComponent Locations: 777F and 777F OEM Off-Highway Truck Hydraulic SystemMScLxОценок пока нет

- Hanson e Martin (2002) - Low Capital Revamp Increases Vacuum Gas Oil YieldДокумент8 страницHanson e Martin (2002) - Low Capital Revamp Increases Vacuum Gas Oil Yieldvazzoleralex6884Оценок пока нет

- Tesmec Trenchers Catalogue 2016 en 1475 RHДокумент2 страницыTesmec Trenchers Catalogue 2016 en 1475 RHDejan Pantic100% (1)

- Plano Hidráulico D8T CaterpillarДокумент10 страницPlano Hidráulico D8T CaterpillarLuis Angel Culqui Vasquez100% (3)

- Diagrama Hidráulico Topadora Caterpillar D7RДокумент9 страницDiagrama Hidráulico Topadora Caterpillar D7RJose Alberto IzquielОценок пока нет

- Data Sheets 966F-E (80e)Документ20 страницData Sheets 966F-E (80e)abdelrhmangbr86Оценок пока нет

- Renr5369renr5369-01 Sis PDFДокумент2 страницыRenr5369renr5369-01 Sis PDFEdgard MarroquinОценок пока нет

- 972 TransmissionДокумент20 страниц972 TransmissionMahmoud KhattabОценок пока нет

- RENR8305RENR8305-04 - SIS 777f 1Документ4 страницыRENR8305RENR8305-04 - SIS 777f 1gadolineo100% (1)

- 950H, 962H, and IT62H Wheel Loader Hydraulic System: Command Control SteeringДокумент2 страницы950H, 962H, and IT62H Wheel Loader Hydraulic System: Command Control SteeringPacoОценок пока нет

- Diagrama Hidraulico 777FДокумент4 страницыDiagrama Hidraulico 777Ffabioalbor100% (1)

- Marvel Carbureter and Heat Control As Used on Series 691 Nash Sixes Booklet SОт EverandMarvel Carbureter and Heat Control As Used on Series 691 Nash Sixes Booklet SОценок пока нет

- Broad Crested Weir and FlumeДокумент12 страницBroad Crested Weir and FlumeRana Talal RaziОценок пока нет

- A Study On The Performance of Different Radiator Cooling Systems in Large-Scale Electric Power TransformerДокумент12 страницA Study On The Performance of Different Radiator Cooling Systems in Large-Scale Electric Power TransformerOsama AhmedОценок пока нет

- Factories Works Act - Pressure Vessel RegsДокумент7 страницFactories Works Act - Pressure Vessel Regschrissy zee1Оценок пока нет

- Process Simulation Essentials - Example BookДокумент63 страницыProcess Simulation Essentials - Example BookRebeca LópezОценок пока нет

- Data 1 Boiler Efficiency by Indirect Method Coal Fired BoilerДокумент14 страницData 1 Boiler Efficiency by Indirect Method Coal Fired BoilerM Ziaul ArifОценок пока нет

- Lab #3 - Flow Over WeirsДокумент12 страницLab #3 - Flow Over WeirsDeborah SongОценок пока нет

- Chapter 6. Hydraulic Machinery: BFC21103 HydraulicsДокумент45 страницChapter 6. Hydraulic Machinery: BFC21103 HydraulicsshahidahbasunanОценок пока нет

- 07 - Seguridad en ProcesosДокумент49 страниц07 - Seguridad en ProcesosAlejandra BuenoОценок пока нет

- Jurnal Iptek: Kajian Potensi Air Tanah Dan Pembagian Wilayah Potensi Di Cekungan Air Tanah MaumereДокумент8 страницJurnal Iptek: Kajian Potensi Air Tanah Dan Pembagian Wilayah Potensi Di Cekungan Air Tanah Maumeremuhammad affanОценок пока нет

- Pump-Through Flapper Safety Valve: Applications DescriptionДокумент1 страницаPump-Through Flapper Safety Valve: Applications DescriptionYves-donald MakoumbouОценок пока нет

- Hmtmta2 Main PDFДокумент10 страницHmtmta2 Main PDFONNDWELA RAMALAMULAОценок пока нет

- Terminal Velocity ParticleДокумент12 страницTerminal Velocity ParticleOscar SalОценок пока нет

- Beer Benefits From Aerator TreatmentДокумент2 страницыBeer Benefits From Aerator TreatmentSam MurrayОценок пока нет

- Pipes - CIFДокумент13 страницPipes - CIFsolebОценок пока нет

- Chapter 12 - Fluid MachineriesДокумент98 страницChapter 12 - Fluid MachineriesWaw0% (1)

- MDPN457 - Final Exam 2023-Spring SemesterДокумент3 страницыMDPN457 - Final Exam 2023-Spring SemestermemarawanОценок пока нет

- Unclassified: Armed Services Technical Information Agency Arlington Hall Station Arlington 12, VirginiaДокумент174 страницыUnclassified: Armed Services Technical Information Agency Arlington Hall Station Arlington 12, VirginiaNebojsaSaracОценок пока нет

- Presidency University Bengaluru School of Engineering: Test - 2Документ11 страницPresidency University Bengaluru School of Engineering: Test - 2Jit MukherheeОценок пока нет

- Co-Current vs. Counter Current DryingДокумент7 страницCo-Current vs. Counter Current Dryinghridita purbaОценок пока нет

- Engineering Information For PDC Butterfly Valves: Valve SizingДокумент9 страницEngineering Information For PDC Butterfly Valves: Valve SizingAnonymous NwnJNOОценок пока нет

- OE ReviewДокумент3 страницыOE ReviewRalph Mattew Palomaria100% (1)

- 1 - Design and Analysis of Impeller Blade For Axial Flow Pumps PDFДокумент31 страница1 - Design and Analysis of Impeller Blade For Axial Flow Pumps PDFtafocanОценок пока нет

- Mechanics of Fluids: V. KrishnaДокумент13 страницMechanics of Fluids: V. KrishnaAditya RaoОценок пока нет

- Types of Sprinkler Systems PDFДокумент4 страницыTypes of Sprinkler Systems PDFAhmad SirojiОценок пока нет