Академический Документы

Профессиональный Документы

Культура Документы

EHS Manual For Refrence

Загружено:

desurkarb0 оценок0% нашли этот документ полезным (0 голосов)

98 просмотров14 страницEHS Manual For Refrence

Оригинальное название

EHS Manual For Refrence

Авторское право

© © All Rights Reserved

Доступные форматы

PDF, TXT или читайте онлайн в Scribd

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документEHS Manual For Refrence

Авторское право:

© All Rights Reserved

Доступные форматы

Скачайте в формате PDF, TXT или читайте онлайн в Scribd

0 оценок0% нашли этот документ полезным (0 голосов)

98 просмотров14 страницEHS Manual For Refrence

Загружено:

desurkarbEHS Manual For Refrence

Авторское право:

© All Rights Reserved

Доступные форматы

Скачайте в формате PDF, TXT или читайте онлайн в Scribd

Вы находитесь на странице: 1из 14

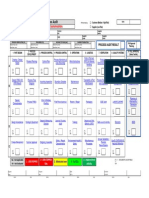

Aerospace Products Van Petty Operations

Document: EHS 50.000.1.0

EHS OPERATING PROCEDURE

Revision:

Date:

DCN:

1

September 7, 2012

1557

ENVIRONMETNAL, HEALTH & SAFETY MANAGEMENT SYSTEMS MANUAL

________________________________________________________________________________________________________________________

When printed, this document is uncontrolled; user is responsible to ensure revision compliance.

Page 1 of 14

1. General Requirements (ISO 14001 4.1; OHSAS 18001 4.1)

1.1. Alcoa Fastening Systems Van Petty Operations (AFS Van Petty) has established,

documented, implemented, maintains, and continuously improves an EH&S

management system that meets the requirements of the international standard ISO

14001:2004 and OHSAS 18001:2007.

1.2. This policy shall be communicated to all persons working under the control of the

organization with the intent that they are made aware of their individual EHS obligations.

This includes all contractors, visitors, suppliers working for or on behalf of AFS Van

Petty.

2. EH&S Policy (ISO 14001 4.2; OHSAS 18001 4.2)

2.1. EHS Policy Statement

AFS Van Petty operates in a safe, responsible manner, which respects the environment, focuses

on prevention of pollution, and the health of our employees, our customers, and the community

where we operate. We will not compromise the EHS values for profit or production. We will

continually work towards the elimination of EH&S hazards, control of unsafe acts/behaviors,

exposures that may cause ill health and ensuring compliance with AFS Van Petty policies and

local, state, and federal regulations as well as continual improvement in EHS management and

EHS performance.

2.2. Vision

AFS Van Pettys management is committed to conducting business in a safe and healthful

manner, which includes the prevention of injuries and illnesses, the control of hazardous

materials, and the protection of the environment. This will be accomplished through leadership

and sustained commitment, and utilizing the best available technology, when possible.

2.3. Mission

AFS Van Petty will continually work towards the elimination of hazards and unsafe

acts/behaviors, in order to reduce the number of accidents, EHS incidents, and job related

injuries/illnesses. We will work safely in a manner that promotes the health and well-being of the

individual and the environment.

2.4. Goals

Identify the actual and potential effects our operation has on the environment. Commit to the

prevention of pollution and the continual improvement of company programs by reviewing stated

EHS objectives. Develop internal methods that meet all relevant regulations, laws and other

requirements. Invest in appropriate technologies that are designed to conserve natural resources

and provide positive benefits to the environment and society. Provide on-going documented

education to raise the awareness and abilities of all employees. Foster a spirit of interaction

throughout the community by making this statement available to the public.

Aerospace Products Van Petty Operations

Document: EHS 50.000.1.0

EHS OPERATING PROCEDURE

Revision:

Date:

DCN:

1

September 7, 2012

1557

ENVIRONMETNAL, HEALTH & SAFETY MANAGEMENT SYSTEMS MANUAL

________________________________________________________________________________________________________________________

When printed, this document is uncontrolled; user is responsible to ensure revision compliance.

Page 2 of 14

2.5. EHS Principles

We value human life above all else and manage risks accordingly.

We relentlessly pursue an EHS incident free workplace.

AFS - Van Petty works to prevent incidents or adverse impacts, in addition to responding to

them after an occurrence. EHS Incidents, including environmental spills, excursions and

other impacts, whether immediate, latent or cumulative, can be prevented. Our goal is a

work place that is incident free. Line management is accountable for assuring the means to

accomplish this goal and employees must contribute to this goal. Training to equip

employees with the skills necessary to recognize and prevent potential incidents will be

provided.

We comply with all laws and set higher standards for our suppliers and ourselves where

unacceptable risks are identified.

We support sustainable development by incorporating social responsibility, economic

success and EHS excellence in our decision making process.

AFS - Van Petty integrates EHS management with business and operating management to

ensure that EHS issues are considered in conjunction with financial aspects, when decisions

are made regarding new and existing facilities, processes, products, services, acquisitions

and divestitures.

We measure and assess our performance and are open and transparent in our

communications.

AFS - Van Petty in cooperation with Alcoa, audits its manufacturing operations EHS

performance on a regular basis to evaluate EHS Policy conformance, strengths/weaknesses

in environmental, health and safety management processes and plans; and to identify actions

that need to be taken to prevent incidents or correct deficiencies. Appropriate AFS - Van

Petty Directors and Senior Managers will periodically be informed of the audit findings. AFS -

Van Petty will communicate promptly and openly with individuals, concerned parties and

communities who request information regarding our EHS policy and the significant

environmental, health and safety potentials or impacts of our operations.

We supply and use safe and reliable products and services.

AFS - Van Petty takes reasonable and practical precautions to assure that the products and

services that AFS - Van Petty supplies to its customers are consistent with the EHS Policy.

Customers are provided complete and accurate product information.

We use our EHS knowledge to enhance the safety and well being of our communities.

AFS - Van Petty periodically sponsors internal or external activities that reduce or minimize

potential EHS impacts of our operations, our products or that advance EHS in the

communities where we are located.

We are all accountable for conforming with and deploying our EHS Value, Policy, and

Principles.

AFS Van Petty Employees, including contractor employees, are responsible for working in

a manner that respects the health and safety of the individual and the environment. Such

behavior is a requirement of the workplace. Line management is accountable for assuring

compliance with the EHS Policy and responding to environmental, health and safety issues or

concerns.

Aerospace Products Van Petty Operations

Document: EHS 50.000.1.0

EHS OPERATING PROCEDURE

Revision:

Date:

DCN:

1

September 7, 2012

1557

ENVIRONMETNAL, HEALTH & SAFETY MANAGEMENT SYSTEMS MANUAL

________________________________________________________________________________________________________________________

When printed, this document is uncontrolled; user is responsible to ensure revision compliance.

Page 3 of 14

3. Planning (ISO 14001 4.3; OHSAS 18001 4.3)

3.1. Environmental, Health & Safety Aspects and Risks (ISO 14001 4.3.1; OHSAS 18001

4.3.1)

a. Includes a commitment to prevention of injury and ill health and continual improvement in

management and performance:

i. The management team is required to identify the EHS aspects and risks of its activities,

products and services to determine which have or can have significant EHS aspects

and/or risks, in accordance with EHS-50.120.1.2, "EHS Aspects and Impacts.

Department Managers will provide assistance and guidance to assist the EHS group to

identify the EHS aspects within their respective departments.

ii. AFS Van Pettys EHS aspects and risks are documented in a log that is updated in

response to changing circumstances.

iii. EHS aspects and/or risks are subjected to a systematic evaluation of their significance,

using a disciplined and documented method. Evaluation criteria and method, and final

selection of significant aspects/risks are documented.

b. EHS Aspect and Risk Identification

i. The Core (C4) Four, consisting of two executive coordinators, four primary coordinators

and four back-up coordinators, representing various departments and functions, identifies

initial EHS aspects and/or risks.

ii. On an annual basis, or as needed, the management team manages changes in activities,

products, and services that create new EHS aspects / risks, or in-validate previously

identified aspects/risks. New aspects and/or risks may also be identified through the

management review or by internal or external audits of the EHS.

iii. EHS aspects are documented and maintained by the EHS Manager.

c. Determination of Significant EHS Aspects and/or Risks

i. The Managers evaluate significance of initial EHS aspects and/or risks. On an ongoing

basis, the management carries out evaluation of significance as necessary.

ii. Significance of EHS aspects and/or risks is evaluated using a systematic risk analysis

methodology. Aspects and/or risks are rated with regard to the severity of associated

impacts/risks and probability of occurrence. The combined significance rating is

calculated using a formula by which an average of individual input by the group is taken.

These aspects/risks are taken into account in establishing, implementing, and

maintaining the AFS Van Petty EHS management system.

iii. Selected significant EHS aspects and/or risks are reviewed and are recorded.

Aerospace Products Van Petty Operations

Document: EHS 50.000.1.0

EHS OPERATING PROCEDURE

Revision:

Date:

DCN:

1

September 7, 2012

1557

ENVIRONMETNAL, HEALTH & SAFETY MANAGEMENT SYSTEMS MANUAL

________________________________________________________________________________________________________________________

When printed, this document is uncontrolled; user is responsible to ensure revision compliance.

Page 4 of 14

3.2. Legal and Other Requirements (ISO 14001 4.3.2; OHSAS 18001 4.3.2)

a. General

i. The management team is responsible for identifying the applicable regulatory and other

requirements, or for coordinating, the internal or external experts engaged to identify

these requirements in accordance with EHS-50.140.1.3, "EHS Legal and Other

Requirements.

ii.

iii. Based on the recommendations of the ISO Management Representative, the

Management team is responsible for deciding whether in-house resources and expertise

are sufficient to identify the legal, regulatory, and other requirements that apply, or

whether the outside assistance of an attorney, consultant, or other expert is required.

iv.

v. AFS Van Petty identifies and has access to legal, regulatory, and other requirements to

which the company subscribes.

b. The process of identifying legal, regulatory and other requirements is developed in the

following phases

i. Identification of current compliance programs, and preliminary research of activities and

products that could potentially be subject to EHS regulations;

ii.

iii. Management review to determine whether in-house expertise and resources are

sufficient to identify all applicable requirements;

iv.

v. Initial identification and documentation of specific laws, regulations, and other

requirements that apply to the facility;

vi.

vii. Ongoing identification of new or modified activities that could potentially be subject to

EHS regulations; and

viii.

ix. Ongoing review of new EHS regulations and changes in legal and other requirements

that may apply to the facility.

c. Legal, regulatory, and other requirements are documented.

3.3. Objectives, Targets and Programs (ISO 14001 4.3.3; OHSAS 18001 4.3.3 )

a. General

i. Establishing relevant objectives and targets for attaining the goals of the EHS policy

begins with the commitment of senior management within each department. Each

operating department is required to adhere to the objectives and targets to attain the

goals of AFS Van Pettys EHS policy. Based on regular review of significant aspects,

goals and objectives are determined by the management team and reviewed by upper

management.

Aerospace Products Van Petty Operations

Document: EHS 50.000.1.0

EHS OPERATING PROCEDURE

Revision:

Date:

DCN:

1

September 7, 2012

1557

ENVIRONMETNAL, HEALTH & SAFETY MANAGEMENT SYSTEMS MANUAL

________________________________________________________________________________________________________________________

When printed, this document is uncontrolled; user is responsible to ensure revision compliance.

Page 5 of 14

ii. AFS Van Petty establishes EHS objectives and targets to fulfill the EHS policy and

improve EHS performance in areas related to significant EHS aspects, legal and other

requirements, and views of interested parties.

iii. Objectives, targets, and/or programs are maintained in areas pertaining to prevention of

pollution.

iv. Objectives, targets, and programs shall be measurable, committed to continual

improvement, and consistent with legal and other requirements.

4. Implementation and Operation (ISO 14001 4.4; OHSAS 18001 4.4)

AFS Van Petty shall take into account planning, performance, measurement results, audit

checking, and corrective action during the implementation and operation of the EH&S.

4.1. Structure and Responsibility (ISO 14001 4.4.1; OHSAS 18001 4.4.1)

a. General

i. The Director of Operations provides guidance to the organization with regards to

positions and reporting structure, and is responsible for ensuring that the EHS is properly

established, resourced, implemented, and maintained. The Director of Operations

provides the EHS organizational structure, including identification of the ISO

Management Representative, in accordance with the organizational chart.

ii. All departments and functions in the company are responsible for implementing,

maintaining, and supporting the EHS.

b. ISO Management Representative

i. AFS Van Petty appoints the EHS Manager (or designee) as the ISO Management

Representative for EHS. The ISO Management Representative has the authority and

responsibility to ensure that the EHS is established, implemented, and maintained in

accordance with the requirements of ISO 14001 and OHSAS 18001.

c. Organization and Responsibilities

i. Interrelation of personnel who manage, perform, and verify activities comprising EHS is

defined in the organizational chart.

4.2. Training, Awareness and Competence (ISO 14001 4.4.2; OHSAS 18001 4.4.2)

a. General

i. Personnel (including contractors and person's not directly employed by AFS Van Petty)

performing tasks that can cause significant EHS impacts and/or present Health and

Safety hazards are required to be evaluated for competence on the basis of appropriate

education, training, and/or experience, in accordance with Human Resources.

Aerospace Products Van Petty Operations

Document: EHS 50.000.1.0

EHS OPERATING PROCEDURE

Revision:

Date:

DCN:

1

September 7, 2012

1557

ENVIRONMETNAL, HEALTH & SAFETY MANAGEMENT SYSTEMS MANUAL

________________________________________________________________________________________________________________________

When printed, this document is uncontrolled; user is responsible to ensure revision compliance.

Page 6 of 14

ii. Employees shall be made aware of:

The importance of conformance with the EHS policy and procedures and with the

requirements of EHS.

The significant EHS impacts and/or hazards, actual or potential, of their work

activities and the EHS benefits of improved personal performance.

Their roles and responsibilities in achieving conformance with the EHS policy and

procedures and with the requirements of EHS, including emergency preparedness

and response requirements.

The potential consequences of departure from specified operating procedures

iii. The Training and Information Coordinator (TIC), Department Managers, and Human

Resources will establish the framework per Human Resources, for a training program,

which meets the above requirements. The TIC, Human Resources, and Department

Managers are responsible for providing employee training.

iv. AFS Van Petty identifies training needs and provides EHS awareness and EHS training

to all personnel.

b. The EHS Awareness Program is comprised of EHS new hire orientation training, ongoing

employee training, communication of the EHS policy and other information about EHS (EHS

Bulletin Board), distribution, and instruction in the use of, procedures and work instructions;

and training in emergency response.

c. Personnel whose work can cause a significant EHS impact or expose them to significant risks

will be provided with the appropriate EHS competence and skill training.

d. Training programs are reviewed and amended to address new developments and changes,

and response to nonconformances identified through the system of corrective and preventive

actions and internal audits of EHS.

e. All EHS training is recorded.

4.3. Communication (ISO 14001 4.4.3; OHSAS 18001 4.4.3)

a. General

i. The Managers and the rest of the senior team are responsible for maintaining appropriate

communications regarding EHS, its effectiveness, and performance in accordance with

EHS Consultation and Communication, which includes but is not limited to:

Internal communication between various functions and levels of the organization.

Receiving, documenting, and responding to relevant communication from external

interested parties.

External communication regarding AFS Van Pettys significant EHS aspects and/or

risks.

Aerospace Products Van Petty Operations

Document: EHS 50.000.1.0

EHS OPERATING PROCEDURE

Revision:

Date:

DCN:

1

September 7, 2012

1557

ENVIRONMETNAL, HEALTH & SAFETY MANAGEMENT SYSTEMS MANUAL

________________________________________________________________________________________________________________________

When printed, this document is uncontrolled; user is responsible to ensure revision compliance.

Page 7 of 14

ii. The ISO Management Representative and/or the Core (C

4

) Four are responsible for

reviewing relevant communications from external interested parties and determining the

appropriate responses and actions.

iii. AFS Van Petty maintains systems for internal communication concerning EHS and EHS

issues. AFS Van Petty also maintains a procedure for communicating with external

interested parties, including instructions for receiving, documenting, and responding to

relevant communication.

b. Internal Communication

i. The leadership team communicates to the organization significant EHS aspects, risks,

the EHS policy, objectives, targets, and management programs; EHS procedures and

work instructions; major events and achievements, and recognition of individual

employees and groups.

ii. The organization communicates to the leadership team information and data regarding

new EHS aspects, risks, status of EHS performance; progress in achieving objectives

and targets, status of implementation effectiveness of EHS, specific concerns regarding

the environment; and suggestions on how to improve EHS and its performance.

iii. Information is communicated through:

distribution of EHS documentation,

EHS alerts

EHS reports

EHS Committee

Monthly all-hands facility meeting

Monthly Business Review

c. External Communication regarding EHS issues

i. All incoming external communication regarding EHS issues is forwarded to the EHS

Manager and is recorded in the external communications log.

ii. The EHS Manager forwards the communication to the Core (C

4

) Four for review. The ISO

Management Representative and the Core (C

4

) Four determine which other functions

should be informed or involved, what response should be given to the originator, and

whether any internal actions should be considered to address issues raised in the

communication.

iii. However, if a copy of the significant EHS aspects is requested by external parties in

writing, the Core (C

4

) Four will evaluate the request and decide if it should be granted.

The decision will be recorded in the meeting minutes. If the request is approved, the

requested material will be provided to the requestor by the EHS Manager.

iv. The EHS policy is available to the public. The policy is posted in the main lobby,

employee area in the entrance, and on the EHS Bulletin Board within the company. A

copy of the policy is available to interested parties upon request.

Aerospace Products Van Petty Operations

Document: EHS 50.000.1.0

EHS OPERATING PROCEDURE

Revision:

Date:

DCN:

1

September 7, 2012

1557

ENVIRONMETNAL, HEALTH & SAFETY MANAGEMENT SYSTEMS MANUAL

________________________________________________________________________________________________________________________

When printed, this document is uncontrolled; user is responsible to ensure revision compliance.

Page 8 of 14

4.4. EHS Management System Documentation (ISO 14001 4.4.4; OHSAS 18001 4.4.4)

a. General

i. EHS, standard operating procedures, work instructions, and other related documentation,

are documented in accordance with EHS-50.240.2.8 "Control of Documents.

ii. Departmental management and the management team is responsible for identifying

specific documents that need to be controlled by the EHS and to:

Describe the core elements of management system and their interaction.

Provide direction to related documentation.

b. Documents pertaining to the EHS include:

i. EHS Manual and standard operating procedures;

ii. Documentation defining significant EHS aspects, risks, objectives and targets, legal and

regulatory requirements, and management programs for reaching objectives and for

monitoring EHS performance and compliance

iii. Laws, regulations, standards, codes of practice, and other such documents defining

applicable requirements

iv. Training programs and materials

v. Emergency preparedness and response procedures

vi. Work instructions, operational data sheets, and other written instructions for personnel

whose work can create a significant EHS impact and/or risk

vii. Documentation defining equipment and other operational controls, and instructions for

their use and maintenance

4.5. Document Control (ISO 14001 4.4.5; OHSAS 18001 4.4.5)

a. General

i. Departmental management and the Core (C

4

) Four are responsible for identifying specific

documents that need to be controlled. The Document Control Coordinator is responsible

for coordinating all activities to control documents, so that:

documents can be located;

documents are periodically reviewed, revised as necessary, and approved for

adequacy by authorized personnel;

Aerospace Products Van Petty Operations

Document: EHS 50.000.1.0

EHS OPERATING PROCEDURE

Revision:

Date:

DCN:

1

September 7, 2012

1557

ENVIRONMETNAL, HEALTH & SAFETY MANAGEMENT SYSTEMS MANUAL

________________________________________________________________________________________________________________________

When printed, this document is uncontrolled; user is responsible to ensure revision compliance.

Page 9 of 14

current versions of relevant documents are available through the document control

system;

obsolete documents are promptly removed from all points of issue and points of use

or otherwise treated to prevent unwanted access;

obsolete documents that are retained for legal and/or historical purposes are suitably

identified.

ii. AFS Van Petty controls all documents related to the EHS to ensure that they are

reviewed and approved by authorized personnel, that current versions of documents are

available where they are required, that obsolete documents are promptly removed, and to

ensure the integrity of documents.

b. As applicable, documents are identified by their title, procedure number, and revision

number.

c. Prior to issue and release, documents are reviewed for adequacy, correctness, and

conformity with the EHS policy.

d. Changes to documents are reviewed and approved by the same function or department that

approved the initial document, unless specified otherwise. Revised documents are

distributed with a change brief summarizing the changes.

e. Obsolete documents are removed from points of use and are retained for historical purposes

in a manner such that they are accessible only to authorized personnel.

f. Where documents are controlled in hardcopy form, master copies of obsolete documents are

stamped OBSOLETE and are stored separate from active documents.

g. Documents may be issued to personnel and outside parties who are not affected by the

document, but need a copy for information only. These documents are stamped or printed

with a statement declaring that the document is UNCONTROLLED.

4.6. Operational Control (ISO 14001 4.4.6; OHSAS 18001 4.4.6)

a. General

i. The management team is responsible for identifying operations and activities that are

associated with significant EHS aspects in accordance with EHS Health & Safety

Management Programs so that:

AFS Van Petty Newburys EHS policy, objectives and targets are met;

Procedures are established, maintained and implemented to:

o Identify activities, products, and services which may have significant EHS

impacts and/or risks;

o Address situations in which deviations from the EH&S policy, objectives, or

targets could occur

o Communicate relevant requirements to suppliers and subcontractors.

Aerospace Products Van Petty Operations

Document: EHS 50.000.1.0

EHS OPERATING PROCEDURE

Revision:

Date:

DCN:

1

September 7, 2012

1557

ENVIRONMETNAL, HEALTH & SAFETY MANAGEMENT SYSTEMS MANUAL

________________________________________________________________________________________________________________________

When printed, this document is uncontrolled; user is responsible to ensure revision compliance.

Page 10 of 14

ii. Managers conducting operations and activities associated with significant EHS aspects

and identified risks are responsible for planning these operations and for ensuring that

they are carried out under specified and controlled conditions.

iii. AFS Van Petty communicates EHS requirements to any suppliers and/or subcontractors

working for or on behalf of AFS Van Petty.

b. Operational Controls

i. Operational controls are methods, systems, processes, equipment to safeguard the

environment, and eliminate, reduce or control risks. This includes operational criteria and

procedures, work instructions, and inspection and preventive maintenance programs.

c. Purchasing and Subcontractor Control

i. Purchasing is controlled by specifying and communicating EHS requirements, and by

monitoring of supplier performance.

ii. The following categories of purchased products and subcontractors are controlled by the

EHS:

Hazardous materials, substances and chemicals, equipment for processing, storing

and handling hazardous wastes, hazardous waste haulers, treatment, and disposal

facilities

Personal protective equipment and equipment to be used for emergency response

Measuring and test equipment intended for monitoring EHS performance and

regulatory compliance (including calibration)

Subcontractors performing services at the facility, who bring in hazardous materials

or chemicals, or generate hazardous waste

Additional products and services that may be identified by the department because of

their association with significant EHS aspects, identified risks, objectives or targets

4.7. Emergency Preparedness and Response (ISO 14001 4.4.7, OHSAS 18001 4.4.7)

a. General

i. The relevant Department Managers are responsible for inventorying materials, wastes

and other substances, which, because of their characteristics, quantities, and other

aspects, create a potential hazard and can, cause an emergency, in accordance with

Emergency Preparedness and Response.

ii. The management team, with input from relevant departments, is also responsible for

identifying and evaluating potential emergencies and for developing appropriate response

plans and procedures.

iii. AFS Van Petty identifies potential accidents and emergency situations, and develops

appropriate response plans for preventing and mitigating associated EHS impacts.

Emergency response procedures are tested where practicable, and are reviewed, in

particular, after occurrence of accidents or emergency situations.

Aerospace Products Van Petty Operations

Document: EHS 50.000.1.0

EHS OPERATING PROCEDURE

Revision:

Date:

DCN:

1

September 7, 2012

1557

ENVIRONMETNAL, HEALTH & SAFETY MANAGEMENT SYSTEMS MANUAL

________________________________________________________________________________________________________________________

When printed, this document is uncontrolled; user is responsible to ensure revision compliance.

Page 11 of 14

The facility and other relevant departments identify potential hazards that can cause

accidents and emergency situations, to include hazardous materials and substances,

dangerous activities, and potential hazards created by outside forces and natural

disasters.

Each potential hazard is evaluated to determine whether emergency response plans

are warranted and, where relevant, appropriate emergency plans and procedures are

developed.

Emergency preparedness and response procedures are documented. Relevant

personnel are made aware of the procedures and where they are located. Where

practicable, emergency procedures are periodically tested.

The management team is responsible for reviewing and, as necessary, revising

emergency procedures after each occurrence of accidents and emergencies.

5. Checking and Corrective Action (ISO 14001 4.5; OHSAS 18001 4.5)

AFS Van Petty shall take into account implementation and operation, performance measurement results

audits and management review when implementing its policy via the relevant procedures.

5.1. Monitoring and Measurement (ISO 14001 4.5.1; OHSAS 18001 4.5.1)

a. General

i. The management team is responsible for reviewing relevant data and information on

activities, products, and services that are associated with significant EHS aspects and/or

risks, in accordance with stated significant aspects. The Management team is also

responsible for reviewing data and information relevant to EHS and/or compliance. The

EHS Manager is responsible for reporting incidents and the general compliance

evaluation.

ii. Departmental management is responsible for the identification, calibration, and

maintenance of measuring and test equipment, in accordance with stated calibration

protocol.

iii. AFS Van Petty monitors and measures the performance of operations and activities that

have the potential for a significant EHS impact and evaluates its compliance with

applicable laws and regulations.

b. For each monitored or measured characteristic, the management team determines the

measurement or test method, frequency, acceptance criteria, responsibility, and the manner

for recording results.

c. When EHS performance falls below desirable level, the management team determines

corrective/preventive actions, or establishes appropriate objectives and targets to improve

performance. If there is a possibility of a noncompliance against laws or regulations, the EHS

Aerospace Products Van Petty Operations

Document: EHS 50.000.1.0

EHS OPERATING PROCEDURE

Revision:

Date:

DCN:

1

September 7, 2012

1557

ENVIRONMETNAL, HEALTH & SAFETY MANAGEMENT SYSTEMS MANUAL

________________________________________________________________________________________________________________________

When printed, this document is uncontrolled; user is responsible to ensure revision compliance.

Page 12 of 14

Manager initiates corrective/preventive actions, or refers this decision to the ISO

Management Representative.

5.2. Evaluation of Compliance (ISO 14001 4.5.2)

AFS Van Petty will periodically evaluate compliance with relevant EHS legislation and regulations

including other requirements as necessary.

5.3. Nonconformance and Corrective and Preventive Action (ISO 14001 4.5.3; OHSAS

18001 4.5.2)

a. General

i. Corrective or preventive actions taken to eliminate the causes of actual or potential

nonconformance situations shall be appropriate to the magnitude of the problems and

commensurate with the potential EHS impact and/or risk, in accordance with, EHS-

50.320.1.12 Nonconformance and Corrective and Preventative Action.

ii. Each operating department is required to assist in maintaining procedures and processes

for identifying, investigating, and correcting actual or potential nonconformance

situations. Each operating department shall implement these procedures for its

operations, utilizing its monitoring and measurement system to assess compliance with

applicable requirements and the EHS policy.

iii. The Corrective Action Coordinator will provide guidance to the operating departments in

identifying, investigating, and correcting nonconformance and will periodically assess the

adequacy of each departments nonconformance process.

iv. AFS Van Petty maintains corrective and preventive action procedures for handling and

investigating nonconformances, and for eliminating their causes. Corrective and

preventive actions are followed up to verify their implementation and effectiveness.

b. Corrective/Preventive Action Requests (CARs) are initiated and implemented to address EHS

nonconformances. Nonconformance is a deviation from a policy, procedure, standard,

instruction, specification, legal or regulatory, or from any other requirement, which the

company established, or to which it subscribes.

c. CARs assign the responsibility for handling and investigating the nonconformance, for

mitigating any impacts caused, and for implementing measures to prevent recurrence of the

nonconformance.

d. CARs may be issued to internal departments of the company as well as to its suppliers and

subcontractors.

e. Upon implementation of corrective or preventive action, CARs are followed up to verify that

the action was indeed implemented and that it is effective.

f. CARs are initiated, documented, processed, and monitored.

Aerospace Products Van Petty Operations

Document: EHS 50.000.1.0

EHS OPERATING PROCEDURE

Revision:

Date:

DCN:

1

September 7, 2012

1557

ENVIRONMETNAL, HEALTH & SAFETY MANAGEMENT SYSTEMS MANUAL

________________________________________________________________________________________________________________________

When printed, this document is uncontrolled; user is responsible to ensure revision compliance.

Page 13 of 14

5.4. Records (ISO 14001 4.5.4; OHSAS 18001 4.5.3)

a. General

i. AFS Van Petty maintains EHS records in accordance with Control of Records to

demonstrate conformance with legal, regulatory, and other requirements.

ii. The Document Control Coordinator, with the assistance of the management team, is

responsible for defining which specific records need to be established and maintained

and for coordinating related activities.

b. Storage locations and retention times for records are specified in, EHS-50.360.1.13 "EHS

Records.

5.5. Internal EH&S Audit (ISO 14001 4.5.5; OHSAS 18001 4.5.4)

a. General

i. AFS Van Petty periodically conducts internal audits of the EH&S in accordance with,

EHS-50.380.1.14 "EHS Management System Audits. Internal audits shall:

determine whether the EHS management system conforms to the stated policy

determine whether the EHS management system conforms to the stated standard

determine whether the EHS management system has been properly implemented

and maintained

provide information on the audit results to management.

b. All elements and activities of the EHS are audited at least once a year. The actual frequency

depends on the status, importance, and past conformance history of the element of activity.

c. Internal audits are conducted in accordance with a documented internal audit plan

established by the Internal Audit Coordinator.

d. Personnel assigned to carry out internal audits shall have freedom from bias or other

influences that could affect their objectivity and are appropriately trained and, if possible, are

independent from those responsible for the audited activities. The selected auditors shall

ensure objectivity and impartiality during the audit process.

e. Results from internal audits are reported using a corrective action. The form is used to

document identified nonconformances and for initiating and processing related corrective

actions.

f. Results of internal audits are reported to the Core (C

4

) Four and are discussed within the

framework of management reviews.

5.6. Management Review (ISO 14001 4.6; OHSAS 18001 4.6)

Aerospace Products Van Petty Operations

Document: EHS 50.000.1.0

EHS OPERATING PROCEDURE

Revision:

Date:

DCN:

1

September 7, 2012

1557

ENVIRONMETNAL, HEALTH & SAFETY MANAGEMENT SYSTEMS MANUAL

________________________________________________________________________________________________________________________

When printed, this document is uncontrolled; user is responsible to ensure revision compliance.

Page 14 of 14

a. General

Periodically management reviews of the EHS management system will be conducted in

accordance with EHS-50.500.1.15 EHS Management Review. Director of Operations and

senior management team conduct annual management review meetings and evaluates EHS

results and performance of the EHS management system, and considers changes to policy,

objectives, and other elements of the system. The purpose is to ensure the continuing

suitability, adequacy, and effectiveness. The review is documented.

5.7. Fatality Prevention (Alcoa ASAT 1.16)

a. General

Risk Significance Matrix has been developed to identify fatality risks, rate them and plans

are developed to correct them. A fatality team is in place to identify new risks as well. The

Alcoa fatality database has been populated with fatality risks that been identified and closed.

Вам также может понравиться

- Environment, Health & Safety Policy: Revision No.: 00 DateДокумент1 страницаEnvironment, Health & Safety Policy: Revision No.: 00 Dateanand shankarОценок пока нет

- Health Safety & Environment WI - C PDFДокумент134 страницыHealth Safety & Environment WI - C PDFNilesh DeoreОценок пока нет

- ACE Integrated HSE ManualДокумент26 страницACE Integrated HSE ManualAli Zafar100% (1)

- Appendix 3 01 Health Safety and Fire Regulations 3rd EditionДокумент168 страницAppendix 3 01 Health Safety and Fire Regulations 3rd EditionB.Peer Muhammad NishathОценок пока нет

- Procedure For Identification of Environmental Aspects, Hazards, Evaluation of Impacts, Risks and Determination of Control MeasuresДокумент10 страницProcedure For Identification of Environmental Aspects, Hazards, Evaluation of Impacts, Risks and Determination of Control MeasuresradhouaneОценок пока нет

- Preventing Heat-Related IllnessesДокумент16 страницPreventing Heat-Related Illnessesroland magoОценок пока нет

- Safety ManualДокумент31 страницаSafety ManualJosue Sandoval MenaОценок пока нет

- HIRA in Process Safety PDFДокумент16 страницHIRA in Process Safety PDFAlvin AlfiyansyahОценок пока нет

- Environmental Conservation Rules, 1997 (ECR'97)Документ2 страницыEnvironmental Conservation Rules, 1997 (ECR'97)নরকেররাজপুত্রОценок пока нет

- Autoclaves - Generic Assessment - L Use of AutoclavesДокумент1 страницаAutoclaves - Generic Assessment - L Use of AutoclavesaKureishiОценок пока нет

- Jsa Ndt-BuildingДокумент5 страницJsa Ndt-BuildingFirdaus RidzuanОценок пока нет

- ISO 45001 Case Study Risk Management INTLДокумент2 страницыISO 45001 Case Study Risk Management INTLGlenn MalloОценок пока нет

- Subcontractor Competence / Resource Questionnaire: Commercial Services To CompleteДокумент31 страницаSubcontractor Competence / Resource Questionnaire: Commercial Services To CompleteNaba majeadОценок пока нет

- First Aid Box Details and ChecklistДокумент16 страницFirst Aid Box Details and ChecklistSafety DeptОценок пока нет

- Employers LiabilityДокумент43 страницыEmployers LiabilitysaifulmuslimzОценок пока нет

- EHS Calendar September 2019 Training Fire Safety PPE AuditsДокумент1 страницаEHS Calendar September 2019 Training Fire Safety PPE AuditsSiddharth RanaОценок пока нет

- Contractor EHS Requirements StandardДокумент25 страницContractor EHS Requirements Standardamitbanerjee51Оценок пока нет

- Basic Safety Procedure in High Risk Activities and IndustriesДокумент10 страницBasic Safety Procedure in High Risk Activities and IndustriesKent Daniel DinopolОценок пока нет

- Risk Assessment Checklist For New and Expectant MothersДокумент2 страницыRisk Assessment Checklist For New and Expectant MothersDave NalugonОценок пока нет

- RISK Mba 17Документ22 страницыRISK Mba 17Cecily Sandra100% (1)

- 2) SOP-01 Handling Hazardous ChemicalДокумент6 страниц2) SOP-01 Handling Hazardous ChemicalMohd ZaeinОценок пока нет

- Environment Aspect Impact Analysis (ISO 14001:2015) - GENERALДокумент1 страницаEnvironment Aspect Impact Analysis (ISO 14001:2015) - GENERALpramodcgnrОценок пока нет

- Definitions and Objectives of Environmental AuditsДокумент5 страницDefinitions and Objectives of Environmental AuditsMayank BangarОценок пока нет

- Intel Construction EHS: Processes and Procedures ManualДокумент127 страницIntel Construction EHS: Processes and Procedures ManualRanjan BhaumikОценок пока нет

- Safety Committee ConstitutionДокумент3 страницыSafety Committee ConstitutionHarsh VaidyaОценок пока нет

- Ocm1 Confined SpaceДокумент2 страницыOcm1 Confined SpacerapidsicuminteОценок пока нет

- Aspects & Impacts Register Evaluates Company Environmental EffectsДокумент1 страницаAspects & Impacts Register Evaluates Company Environmental EffectsRASHEED YUSUFОценок пока нет

- 10 Review Your Fire Risk Assessment GuideДокумент10 страниц10 Review Your Fire Risk Assessment GuidexaviОценок пока нет

- Factories Act 1948Документ70 страницFactories Act 1948akanungoОценок пока нет

- 2.2 A Lead & Lag Indicator Dec2022Документ2 страницы2.2 A Lead & Lag Indicator Dec2022subodh kumarОценок пока нет

- Environmental Aspects, Impacts and Its Evaluation: AuthorizationДокумент7 страницEnvironmental Aspects, Impacts and Its Evaluation: AuthorizationMukilan ThiruОценок пока нет

- SG-14 Safety Guideline For Work On Electric Overhead Travelling (EOT) CraneДокумент19 страницSG-14 Safety Guideline For Work On Electric Overhead Travelling (EOT) CraneAbhishek GadatiaОценок пока нет

- Integrated HSE Management and Permit To WorkДокумент75 страницIntegrated HSE Management and Permit To WorkKamakshi JoshiОценок пока нет

- IS0 9001 - 2008 OHSAS 18001 and ISO 14001 Requirements SummaryДокумент9 страницIS0 9001 - 2008 OHSAS 18001 and ISO 14001 Requirements Summaryジェイ センニュリンОценок пока нет

- EHS PolicyДокумент2 страницыEHS Policysujit5584Оценок пока нет

- HSE Procedure For Garbage DisposalДокумент4 страницыHSE Procedure For Garbage DisposalKhuda BukshОценок пока нет

- WHS P11 Fatigue Management ProcedureДокумент8 страницWHS P11 Fatigue Management Procedurehse bptОценок пока нет

- Hazard Assessment For PPE - XX-DRAFTДокумент4 страницыHazard Assessment For PPE - XX-DRAFTWayne VanderhoofОценок пока нет

- Demobilization and Demolition Activies of Porta Cabins and Containers For Laydown AreaДокумент10 страницDemobilization and Demolition Activies of Porta Cabins and Containers For Laydown AreaNasrullahОценок пока нет

- 11-2.3.02 Coshh (Control of Substances Hazardous To Health)Документ17 страниц11-2.3.02 Coshh (Control of Substances Hazardous To Health)Francisco M. RamosОценок пока нет

- Environmental Aspects and ObjectivesДокумент4 страницыEnvironmental Aspects and Objectivesum erОценок пока нет

- 4.4.3.3 Data and Trend AnalysisДокумент6 страниц4.4.3.3 Data and Trend AnalysisIndermohan MehtaОценок пока нет

- Office Worker Safety TrainingДокумент38 страницOffice Worker Safety TrainingSutanОценок пока нет

- Police Verification Form PDF in Hindi 2021Документ2 страницыPolice Verification Form PDF in Hindi 2021MOHD SUHAIL0% (1)

- GNPOC List ofДокумент3 страницыGNPOC List ofHSE S4Оценок пока нет

- OSH Risk Register - 01Документ28 страницOSH Risk Register - 01M.usmanОценок пока нет

- Oregon OSHA's guide to controlling hazardous energyДокумент36 страницOregon OSHA's guide to controlling hazardous energyYoga PradanaОценок пока нет

- PRO-00861 Corporate Safety - Cranes and Lifting Equipment Safety ProcedureДокумент30 страницPRO-00861 Corporate Safety - Cranes and Lifting Equipment Safety ProcedureGustavo Alonso BerettaОценок пока нет

- Chemical - Regulations in India PDFДокумент50 страницChemical - Regulations in India PDFSANDAMARОценок пока нет

- 022 - Compressed Gas Cylinder - HandlingДокумент3 страницы022 - Compressed Gas Cylinder - HandlingAbhijit JanaОценок пока нет

- Health and Safety Monthly Performance Summary Report: ReactiveДокумент2 страницыHealth and Safety Monthly Performance Summary Report: ReactivegkОценок пока нет

- Record Retention Checklist Rev.0Документ2 страницыRecord Retention Checklist Rev.0Sameer ParambathОценок пока нет

- 4.2 Unit GC2: Controlling Workplace Hazards: Learning OutcomesДокумент18 страниц4.2 Unit GC2: Controlling Workplace Hazards: Learning Outcomesnavin100% (2)

- Working at Height Rescue Plan SampleДокумент7 страницWorking at Height Rescue Plan SampleAnvarsha SharafudheenОценок пока нет

- First Aid Box ContentДокумент1 страницаFirst Aid Box ContentwaytobhushanОценок пока нет

- Safety Engineer JobДокумент3 страницыSafety Engineer Jobخلف الله التوم0% (1)

- Lead Exposure Control PlanДокумент3 страницыLead Exposure Control PlanShahzeb HassanОценок пока нет

- Check Hard Hat Expiry Dates Before UseДокумент1 страницаCheck Hard Hat Expiry Dates Before UsetimbulОценок пока нет

- EMS Awareness PosterДокумент2 страницыEMS Awareness PosterShahfiee AbdullahОценок пока нет

- VDA6.3 Procss QuestionaireДокумент24 страницыVDA6.3 Procss Questionairedesurkarb100% (1)

- Attribute study data collectionДокумент54 страницыAttribute study data collectiondesurkarbОценок пока нет

- Sop WarehouseДокумент6 страницSop WarehouseVamsee Deepak100% (1)

- Risk Assessment Tool for Laboratory ActivitiesДокумент5 страницRisk Assessment Tool for Laboratory ActivitiesdesurkarbОценок пока нет

- Failure Modes ExplainedДокумент31 страницаFailure Modes ExplaineddesurkarbОценок пока нет

- EMS Planning WorkbookДокумент85 страницEMS Planning WorkbookdesurkarbОценок пока нет

- Heat Treatment S.G IronДокумент58 страницHeat Treatment S.G IronShafiqul Chowdhury100% (2)

- Safety EvaluationДокумент29 страницSafety EvaluationdesurkarbОценок пока нет

- FMEA analysis manufacturing assembly processesДокумент2 страницыFMEA analysis manufacturing assembly processesSantosh BaladhyeОценок пока нет

- Manage SBA Warehouse OrdersДокумент11 страницManage SBA Warehouse Ordersdesurkarb0% (1)

- Understanding People Disc Personality TraitsДокумент8 страницUnderstanding People Disc Personality TraitsVirginia FernandezОценок пока нет

- Guide Managing Risks Associated Foundry WorkДокумент53 страницыGuide Managing Risks Associated Foundry WorkdesurkarbОценок пока нет

- Self Certification Training MatrixДокумент1 страницаSelf Certification Training MatrixdesurkarbОценок пока нет

- Safety During FireДокумент9 страницSafety During Firetksundaravel100% (1)

- MSA For Attribute or Categorical DataДокумент18 страницMSA For Attribute or Categorical DatadesurkarbОценок пока нет

- Overall Equipment EffectivenessДокумент13 страницOverall Equipment EffectivenessdesurkarbОценок пока нет

- Too Much Safety Ebook Rev 01Документ16 страницToo Much Safety Ebook Rev 01desurkarbОценок пока нет

- Introduction To Overall Equipment EffectivenessДокумент16 страницIntroduction To Overall Equipment EffectivenessdesurkarbОценок пока нет

- SHRI HANUMAN CHALISAДокумент2 страницыSHRI HANUMAN CHALISAAdarsh PradhanОценок пока нет

- Attrition Rate CalculatorДокумент1 страницаAttrition Rate CalculatorvikramnathawatОценок пока нет

- 2006AFS SandCastingLCAДокумент16 страниц2006AFS SandCastingLCAdesurkarbОценок пока нет

- Sequence and Interaction Process 1Документ5 страницSequence and Interaction Process 1desurkarbОценок пока нет

- Questionnaire For Casting FoundriesДокумент10 страницQuestionnaire For Casting FoundriesAmit PintoОценок пока нет

- Sequence and Interaction Process 1Документ5 страницSequence and Interaction Process 1desurkarbОценок пока нет

- FoundriesДокумент22 страницыFoundriesdesurkarbОценок пока нет

- VAVE The Forgotten Lean Technique ShortДокумент4 страницыVAVE The Forgotten Lean Technique ShortParvateshОценок пока нет

- 4.01.1 Fish Bone Diagram InvoicesДокумент19 страниц4.01.1 Fish Bone Diagram InvoicesdesurkarbОценок пока нет

- CAPA ProcДокумент1 страницаCAPA ProcdesurkarbОценок пока нет

- SWOT Analysis - Internal: Strengths Weaknesses Opportunities ThreatsДокумент2 страницыSWOT Analysis - Internal: Strengths Weaknesses Opportunities ThreatsdesurkarbОценок пока нет

- Process AuditДокумент15 страницProcess Auditdesurkarb100% (2)

- Program Evaluation and Review TechniqueДокумент2 страницыProgram Evaluation and Review TechniqueUmesh PatilОценок пока нет

- In An Assembly Model, Components Are Brought Together To Define A Larger, More Complex Product RepresentationДокумент34 страницыIn An Assembly Model, Components Are Brought Together To Define A Larger, More Complex Product Representationpalaniappan_pandianОценок пока нет

- Statistics Assignment Sample With SolutionsДокумент10 страницStatistics Assignment Sample With SolutionsHebrew JohnsonОценок пока нет

- Work GRP 2 Multinomial Probit and Logit Models ExamplesДокумент5 страницWork GRP 2 Multinomial Probit and Logit Models ExamplesDeo TuremeОценок пока нет

- Impacts of Brotherhoods and Sisterhoods on Academic PerformanceДокумент8 страницImpacts of Brotherhoods and Sisterhoods on Academic PerformanceLsk MatammuОценок пока нет

- MDM4U Lesson Assignment 19 AnalysisДокумент11 страницMDM4U Lesson Assignment 19 AnalysisJhyneJazarenoAtutubo0% (1)

- Adaptive Reuse As A StrategyДокумент10 страницAdaptive Reuse As A StrategyAlexandru ȚîrcăОценок пока нет

- Going Chapter 4Документ38 страницGoing Chapter 4maricar's channelОценок пока нет

- Research Paper FinalДокумент45 страницResearch Paper FinalEricson B. PetagaraОценок пока нет

- Chemometrics and The Medieval Scriptorium LopesДокумент1 страницаChemometrics and The Medieval Scriptorium LopesKita de AzevedoОценок пока нет

- Research Project GuidelinesДокумент8 страницResearch Project GuidelinesPRAKHAR KAUSHIKОценок пока нет

- Mindfulness Based Cognitive Therapy For Depression PDFДокумент73 страницыMindfulness Based Cognitive Therapy For Depression PDFKatya BlackОценок пока нет

- Final Sample Letter and Instrument ValidationДокумент5 страницFinal Sample Letter and Instrument Validationgomer baniagaОценок пока нет

- University of Miami Graduate School DissertationДокумент4 страницыUniversity of Miami Graduate School DissertationHelpWithWritingAPaperForCollegeFargo100% (1)

- Benchmarking Forecast ErrorsДокумент15 страницBenchmarking Forecast ErrorsShikhar SaxenaОценок пока нет

- History of CMU A Brief Historical BackgroundДокумент1 страницаHistory of CMU A Brief Historical BackgroundMariane Rae AndrionОценок пока нет

- Croatian Noble Kindred History BookДокумент3 страницыCroatian Noble Kindred History BookAnonymous PXFOfWОценок пока нет

- Science 2Документ5 страницScience 2snah_88Оценок пока нет

- Conscious BusinessДокумент19 страницConscious BusinessparadescartarОценок пока нет

- Formal Report 6Документ8 страницFormal Report 6PAUL CEDRIC BERNARDOОценок пока нет

- Standardizing Completion and Workover Riser AssessmentsДокумент26 страницStandardizing Completion and Workover Riser Assessmentsvictor gerardoОценок пока нет

- Lexical Semantic Problems in TranslationДокумент13 страницLexical Semantic Problems in Translationvargas199511100% (2)

- Customer Retention Practices of Microfinance BanksДокумент7 страницCustomer Retention Practices of Microfinance BanksIkechukwu AchaОценок пока нет

- HCLДокумент10 страницHCLaakritiОценок пока нет

- Enterprise Project Management Office (Epmo) : Prepared By: Michael Mccormick, Management Consultant - September 2011Документ11 страницEnterprise Project Management Office (Epmo) : Prepared By: Michael Mccormick, Management Consultant - September 2011ToniMattaОценок пока нет

- Activity For Central TendencyДокумент3 страницыActivity For Central TendencyJessel TagalogОценок пока нет

- Conan Dissertation 2018Документ248 страницConan Dissertation 2018john carlo bengalaОценок пока нет

- Persuasive Essay Assignment SheetДокумент3 страницыPersuasive Essay Assignment SheetKelsey Staub50% (2)

- RS10-PHYSICAL Air FilterДокумент21 страницаRS10-PHYSICAL Air FilterRalph David AbellaОценок пока нет

- Nineteenth Semiannual Report To Congress 1 January - 30 June 1968Документ257 страницNineteenth Semiannual Report To Congress 1 January - 30 June 1968Bob Andrepont100% (1)