Академический Документы

Профессиональный Документы

Культура Документы

Calibration of A Pressure Transducer

Загружено:

Yougchu LuanИсходное описание:

Оригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Calibration of A Pressure Transducer

Загружено:

Yougchu LuanАвторское право:

Доступные форматы

Calibration of a pressure transducer

The aim of the measurement

The aim of this measurement training is to learn the calibration of a pressure transducer. Calibration

is a process when the output signal of the sensor is compared to the value measured by an accurate

device, and the relationship between the measured and the accurate value is determined.

Description of the measurement rig

The pressure transducer is connected to an air reservoir L, and the pressure in the reservoir is

measured by a manometer filled with water. The pressure transducer is connected to the reservoir

and has an electric current output. This way the pressure measured by the manometer and the output

current of the pressure transducer can be related.

The scheme of the measurement rig is shown in Figure 1. The pressure transducer (N) receives its

electrical power from the power supply (T). The pressure transducer and the manometer are

connected to the reservoir tank via a T-junction.

The height of the water column (h) of the manometer can be read from the mm scale attached to the

glass pipe. The height has to be read at the horizontal tangent of the curved water surface (the

meniscus).

Figure 1. Scheme of the measurement rig

The output signal of the pressure transducer can be measured by a digital multimeter (D). As the

output of the sensor varies between 4 mA and 20 mA, so the digital multimeter should be used in

the 20 mA setting.

Description of the measurement process

Before the beginning of the measurement make sure that the measurement rig is built up as shown

in Figure 1. Open the L0 throttle valve, and if needed set the mm scale placed next to the glass tube

of the manometer to have its 0 mm point at the meniscus of the water surface. Close the L0 valve.

water

Attach a hand pump (P) to the valve denoted by G0, and pump air into the reservoir tank until the

height of the water column in the manometer reaches at least 95 cm but less than 100 cm. The

pressure transducer used for the calibration is capable of measuring pressures in the [0 Pa; 10000

Pa] range which means somewhat more than 1 m water column. The pump should be operated with

small but fast pushes, because this way the oscillation of the water column in the manometer is

reduced. After the desired water column height is reached close valve G0, and detach the pump. For

a short time make sure that the measurement rig is not leaking, by watching the height of the water

column. If it does not change, then the measurement process can be started.

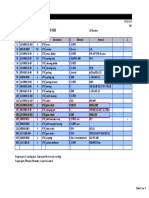

15 measurement points are needed. By gently opening/closing valve L0 set the pressure in the

reservoir to have approximately equidistantly placed pressures during the calibration. Read the

corresponding (h

j

, l

j

) value pairs and write them to a table as in Table 1.

The height of the water column (h

j

) should be written down with 1 mm accuracy while the output

current of the pressure transducer should be written down as the display of the digital multimeter

(with 0.01 mA accuracy).

After the measurement, fill out the other columns of the table in the report. The pressure at the

reservoir can be calculated from the height of the water column of the manometer with the

following formula: p

j

= gh

j

, where =

water

= 1000 kg/m

3

where the height of the water column in

the manometer (h

j

) is meant in meter.

j

h

j

[mm]

I

j

[mA]

p

j

= gh

j

[Pa]

I

j

2

[mA

2

]

p

j

I

j

[Pa*mA]

1.

15.

Table 1.

Calculation of the parameters of the fitted line using the method of least squares

After the calibration process and calculating the pressures, the output current (I [mA]) and the

pressure acting on the sensor (p [Pa]) values are paired. From the measured (p

j

, I

j

) pairs the

parameters of the regression line have to be calculated:

b aI p + =

This will be done using the method of least squares. For this, at first the difference of the regression

line and the measured pressure has to be calculated at each calibration point:

b aI p

j j j

=

Make the sum of its square over the measure points and denote it by D.

( )

= =

= =

n

j

j j

n

j

j

b aI p b a D

1 1

2

,

Find the values for the a and b parameters for whose D is the smallest. To find them, one has to

calculate the derivatives of D:

0 , 0 =

b

D

a

D

After the derivation we obtain:

= =

= = =

= +

= +

n

j

j

n

j

j

n

j

j j

n

j

j

n

j

j

p bn I a

I p I b I a

1 1

1 1 1

2

Yielding:

( ) ( )( )

( ) ( )

= =

= =

= = =

=

=

n

j

j

n

j

j

n

j

j

n

j

j

n

j

j

n

j

j

n

j

j j

I

n

a

p

n

b

I

n

I

I p

n

I p

a

1 1

2

1 1

2

1 1 1

1

1

1

The report of the measurement should contain:

i) the measured values, the calculated pressure, the calculation of the parameters of the

regression line in table 1

ii) the equation of the regression line

iii) the type and serial number of the used equipment (pressure transducer, power supply,

digital multimeter).

iv) a mm scale paper on which the measured values (the pressure against the output current

of the sensor) and the regression line are plotted. The regression line output to be drawn

by calculating two points of it, using the formula.

Вам также может понравиться

- Agilent 34401A Multimeter 33K8!4!1029-1Документ14 страницAgilent 34401A Multimeter 33K8!4!1029-1Serrot OnaivlisОценок пока нет

- ATS Certifications Inc Cert and Scope File 12-08-2018 1544299953Документ2 страницыATS Certifications Inc Cert and Scope File 12-08-2018 1544299953Tash BОценок пока нет

- The Impact of Accreditation To ISO/IEC 17025 in Testing Laboratories in MauritiusДокумент105 страницThe Impact of Accreditation To ISO/IEC 17025 in Testing Laboratories in Mauritiusfayiz100% (1)

- MetCal 8 Calibration SoftwareДокумент16 страницMetCal 8 Calibration SoftwareMorosanu Andreea-DianaОценок пока нет

- Calibrador Electrico FLUKE 5502A CatalogoДокумент22 страницыCalibrador Electrico FLUKE 5502A CatalogoJavier AguilarОценок пока нет

- NI 4065 Calibration Procedure - Oct - 2007Документ88 страницNI 4065 Calibration Procedure - Oct - 2007rmmachado1Оценок пока нет

- Thermometer Liquid in Glass Calibrationvvs102Документ10 страницThermometer Liquid in Glass Calibrationvvs102juncar25100% (1)

- Iso 14042 2000 en FR PDFДокумент8 страницIso 14042 2000 en FR PDFMOHAMED MANSOURОценок пока нет

- Ombudsperson Future Generations in The Netherlands Legal Background PaperДокумент32 страницыOmbudsperson Future Generations in The Netherlands Legal Background PaperWorldconnectorsОценок пока нет

- Introduction of KUT650 Ultrasonic Flaw Detector - HongTuoДокумент3 страницыIntroduction of KUT650 Ultrasonic Flaw Detector - HongTuolovaldes62Оценок пока нет

- User Manual: Fisher Scientific Accumet AE150 PH Benchtop MeterДокумент28 страницUser Manual: Fisher Scientific Accumet AE150 PH Benchtop MeterPedroОценок пока нет

- GV57 @track Air Interface Firmware Update R1.01Документ12 страницGV57 @track Air Interface Firmware Update R1.01rarison fortesОценок пока нет

- As ISO IEC 17010-2003 General Requirements For Bodies Providing Accreditation of Inspection BodiesДокумент8 страницAs ISO IEC 17010-2003 General Requirements For Bodies Providing Accreditation of Inspection BodiesSAI Global - APACОценок пока нет

- Instruments (Meriam)Документ44 страницыInstruments (Meriam)Bhartendu PatniОценок пока нет

- IFIA Test Question Book Spanish - August 2010Документ98 страницIFIA Test Question Book Spanish - August 2010Luz Ma R C100% (1)

- GV57 Quick StartДокумент2 страницыGV57 Quick Startrarison fortesОценок пока нет

- Sample Calibration CertificateДокумент1 страницаSample Calibration CertificateSherwin John NavarroОценок пока нет

- Auditing Gas Measurement and Accounting Systems 2006 PDFДокумент4 страницыAuditing Gas Measurement and Accounting Systems 2006 PDFMalouk CheniouniОценок пока нет

- Background Material: Ecodesign Information Improving Products With EcodesignДокумент18 страницBackground Material: Ecodesign Information Improving Products With Ecodesignfrank niel fajilan100% (1)

- Sartorius+Quintix+Model+224 1S+ManualДокумент120 страницSartorius+Quintix+Model+224 1S+ManualDiKeer Black COreОценок пока нет

- CIE84Y1989Документ57 страницCIE84Y1989Elys MendezОценок пока нет

- ISO 39001 and ISO 39002 - Road Traffic Safety Management System StandardsДокумент17 страницISO 39001 and ISO 39002 - Road Traffic Safety Management System StandardsSander GianОценок пока нет

- h111-h216 Hipot en EsДокумент118 страницh111-h216 Hipot en Esjaved shaikh chaandОценок пока нет

- Copia de Ecnc Rosa Calc 2015.11.12Документ3 страницыCopia de Ecnc Rosa Calc 2015.11.12Maricela Benitez RojasОценок пока нет

- Astm d2986 1995 PDFДокумент7 страницAstm d2986 1995 PDFHsaam HsaamОценок пока нет

- List NFPAДокумент3 страницыList NFPAleon aulia100% (1)

- Calibracion de OsciloscopioДокумент12 страницCalibracion de OsciloscopioCarlos GuanipaОценок пока нет

- Balance Ohaus AS200Документ89 страницBalance Ohaus AS200Abraham Farias AОценок пока нет

- A911a911m PDFДокумент3 страницыA911a911m PDFMac100% (1)

- As ISO 14050-1999 Environmental Management - VocabularyДокумент8 страницAs ISO 14050-1999 Environmental Management - VocabularySAI Global - APACОценок пока нет

- CIPM MRA Appendix C Calibration and Measurement Capability (CMC) DeclarationsДокумент31 страницаCIPM MRA Appendix C Calibration and Measurement Capability (CMC) DeclarationskarthickОценок пока нет

- Omega DP-41 User's GuideДокумент222 страницыOmega DP-41 User's GuidersudjianОценок пока нет

- 4500-SO Sulfate 4500-SO A.: 1. OccurrenceДокумент7 страниц4500-SO Sulfate 4500-SO A.: 1. OccurrenceShadiaMilenaOquendoMuñozОценок пока нет

- Manual UN-01-260 Rev. E Sypris Test & Measurement All Rights ReservedДокумент59 страницManual UN-01-260 Rev. E Sypris Test & Measurement All Rights ReservedChin Lung LeeОценок пока нет

- Portable Single Gas Detector User Manual: Ver BSA20150424005Документ12 страницPortable Single Gas Detector User Manual: Ver BSA20150424005Jose GarciaОценок пока нет

- Metrología: Angela Maria Aguirre Londoño Diego Fernando Hernandez Baldovino Leiny Dayana Ordoñez AristizabalДокумент30 страницMetrología: Angela Maria Aguirre Londoño Diego Fernando Hernandez Baldovino Leiny Dayana Ordoñez AristizabalOrdoñez DayanaОценок пока нет

- Series Calibration ProcedureДокумент89 страницSeries Calibration ProcedureTinh NguyenОценок пока нет

- Self Audit For VDA 6.3 and FQF 8.0: The Report The GoalДокумент2 страницыSelf Audit For VDA 6.3 and FQF 8.0: The Report The GoalJavier Alejandro Roman MoncadaОценок пока нет

- Inspection Body Accreditation RequirementsДокумент22 страницыInspection Body Accreditation RequirementsDimeji FolamiОценок пока нет

- Reporte de AuditoriaДокумент47 страницReporte de AuditoriaAdcani MedinaОценок пока нет

- WBL5001 E98031Документ16 страницWBL5001 E98031Tony Gregory100% (1)

- Data Table CarbonДокумент5 страницData Table CarbonEmily Hoot0% (1)

- English For Industrial Machinery StudentsДокумент4 страницыEnglish For Industrial Machinery StudentsDíaz YvonneОценок пока нет

- OIML R 148-3: Nternational EcommendationДокумент23 страницыOIML R 148-3: Nternational EcommendationJAVIER GONZALEZОценок пока нет

- Uncertainty Budget TablesДокумент11 страницUncertainty Budget TablesJepri PurwantoОценок пока нет

- MetrologyДокумент157 страницMetrologyVishwajit HegdeОценок пока нет

- Fluid Mechanics 2 Flow in PipesДокумент6 страницFluid Mechanics 2 Flow in PipesAdrian CamilleriОценок пока нет

- Fluids Lab Venturi Meter - 4Документ5 страницFluids Lab Venturi Meter - 4augur886Оценок пока нет

- Case StudyДокумент7 страницCase StudyPantheia DadpouОценок пока нет

- TEP 4160 Aerodynamics. Lab-Exercise Pressure Distribution Over The HOG AirfoilДокумент3 страницыTEP 4160 Aerodynamics. Lab-Exercise Pressure Distribution Over The HOG Airfoiljaco90cОценок пока нет

- Barometric Pressure Measurement Using Semiconductor Pressure SensorsДокумент12 страницBarometric Pressure Measurement Using Semiconductor Pressure Sensorssoldadorx01Оценок пока нет

- Fluids Lab Orifice MeterДокумент3 страницыFluids Lab Orifice Meterharun_4uОценок пока нет

- Experiment 8 - The Venturi Meter, The Determination of Discharge From A PipeДокумент8 страницExperiment 8 - The Venturi Meter, The Determination of Discharge From A Pipebkewill6Оценок пока нет

- Digital Transmitter OverviewДокумент2 страницыDigital Transmitter OverviewalbertofgvОценок пока нет

- Industrial InstrumentationДокумент23 страницыIndustrial InstrumentationMohsin Sidi100% (5)

- Experiment 2: Flow MeasurementДокумент3 страницыExperiment 2: Flow MeasurementVicky RajasekharanОценок пока нет

- 7 Examples: General RemarksДокумент12 страниц7 Examples: General RemarksTammanun ChayruttanarojОценок пока нет

- Engineering Metrology Lab ManualДокумент24 страницыEngineering Metrology Lab ManualcanilkumarrichithaОценок пока нет

- Pressure DistributionДокумент10 страницPressure DistributionSubharanjani MathiОценок пока нет

- What Is A Differential Pressure Transmitter?Документ6 страницWhat Is A Differential Pressure Transmitter?Tolera WorkuОценок пока нет

- Test Procedure For Sand Wash SystemsДокумент1 страницаTest Procedure For Sand Wash SystemsYougchu LuanОценок пока нет

- Job Description - Technical AssistantДокумент1 страницаJob Description - Technical AssistantYougchu LuanОценок пока нет

- TCP Perforating ProgrammeДокумент3 страницыTCP Perforating ProgrammeYougchu LuanОценок пока нет

- Setting Up Drilling OfficesДокумент2 страницыSetting Up Drilling OfficesYougchu LuanОценок пока нет

- Reporting Requirements - Drilling OperationsДокумент2 страницыReporting Requirements - Drilling OperationsYougchu Luan100% (1)

- Job Description - Drilling SuperintendentДокумент1 страницаJob Description - Drilling SuperintendentYougchu LuanОценок пока нет

- Job Description - Senior Drilling SupervisorДокумент1 страницаJob Description - Senior Drilling SupervisorYougchu Luan100% (1)

- Job Description - Technical Assistant DrillingДокумент1 страницаJob Description - Technical Assistant DrillingYougchu LuanОценок пока нет

- Job Description - Drilling AssistantДокумент1 страницаJob Description - Drilling AssistantYougchu LuanОценок пока нет

- 1 Problems Setting The Packer: Contingency ProceduresДокумент1 страница1 Problems Setting The Packer: Contingency ProceduresYougchu LuanОценок пока нет

- Mud PolicyДокумент1 страницаMud PolicyYougchu LuanОценок пока нет

- Sand Content - Mud TestingДокумент1 страницаSand Content - Mud TestingYougchu Luan100% (2)

- Solids Content - Mud TestingДокумент1 страницаSolids Content - Mud TestingYougchu LuanОценок пока нет

- مستر رمضان عوضДокумент24 страницыمستر رمضان عوضSamuel SaadОценок пока нет

- Battery Installation ProcedureДокумент5 страницBattery Installation ProceduresantoshkumarОценок пока нет

- AssignmentДокумент13 страницAssignmentSwakshar DebОценок пока нет

- Assignment 1 - Statistics ProbabilityДокумент3 страницыAssignment 1 - Statistics ProbabilityAzel Fume100% (1)

- Holowicki Ind5Документ8 страницHolowicki Ind5api-558593025Оценок пока нет

- Onitsuka Tiger PDFДокумент67 страницOnitsuka Tiger PDFAhmad Bilal MawardiОценок пока нет

- Sop ExcelДокумент104 страницыSop ExcelRizky C. AriestaОценок пока нет

- Part 3-Chap 2 - Classification of Buildings Based On OccupanciesДокумент60 страницPart 3-Chap 2 - Classification of Buildings Based On Occupanciesfaruque65Оценок пока нет

- Vegetable Rates - 02-01-2021Документ454 страницыVegetable Rates - 02-01-2021Saurabh RajputОценок пока нет

- Veg Dum Biryani - Hyderabadi Veg Biryani Recipe - Hyderabadi Biryani - Hebbar's KitchenДокумент2 страницыVeg Dum Biryani - Hyderabadi Veg Biryani Recipe - Hyderabadi Biryani - Hebbar's KitchenmusicalcarpetОценок пока нет

- E Numbers Are Number Codes ForДокумент3 страницыE Numbers Are Number Codes ForaradhyaОценок пока нет

- The Common Reader-Virginia WoolfДокумент216 страницThe Common Reader-Virginia WoolfRusudan VardiashviliОценок пока нет

- North Central Mindanao College: Maranding, Lala, Lanao Del NorteДокумент8 страницNorth Central Mindanao College: Maranding, Lala, Lanao Del NorteAnalyn FielОценок пока нет

- Boundary ScanДокумент61 страницаBoundary ScanGéza HorváthОценок пока нет

- Handbook For ASHA On Home Based Care For Young Child-EnglishДокумент116 страницHandbook For ASHA On Home Based Care For Young Child-EnglishDr. Vanitha BОценок пока нет

- Burst Abdomen 3Документ12 страницBurst Abdomen 3Satvik BansalОценок пока нет

- Bahasa Inggris PATДокумент10 страницBahasa Inggris PATNilla SumbuasihОценок пока нет

- Chemical Process DebottleneckingДокумент46 страницChemical Process DebottleneckingAhmed Ansari100% (2)

- Etl 213-1208.10 enДокумент1 страницаEtl 213-1208.10 enhossamОценок пока нет

- ADC ManualДокумент47 страницADC ManualRavi ShuklaОценок пока нет

- Famous Bombers of The Second World War - 1st SeriesДокумент142 страницыFamous Bombers of The Second World War - 1st Seriesgunfighter29100% (1)

- Accessories 162-USДокумент20 страницAccessories 162-USعايد التعزيОценок пока нет

- Biasing Opamps Into Class AДокумент11 страницBiasing Opamps Into Class AsddfsdcascОценок пока нет

- Mathematics 7 LAS Quarter 3Документ97 страницMathematics 7 LAS Quarter 3Villamor Baculi82% (17)

- Mono 108Документ438 страницMono 108pasaricaОценок пока нет

- Tyba S4 Syntax PDFДокумент107 страницTyba S4 Syntax PDFIndahОценок пока нет

- Science7 q2 Mod6of8 Asexual Sexualrep v2Документ26 страницScience7 q2 Mod6of8 Asexual Sexualrep v2Ishi OcheaОценок пока нет

- TXN Alarms 18022014Документ12 страницTXN Alarms 18022014Sid GrgОценок пока нет

- Ae 2 PerformanceДокумент4 страницыAe 2 PerformanceankitОценок пока нет

- Frequency Converter English ManualДокумент33 страницыFrequency Converter English Manualproduccion multipack100% (2)