Академический Документы

Профессиональный Документы

Культура Документы

Qelia Canal Earth Works Method Statement - Rev 1

Загружено:

Mohammad Bader Al-DeinАвторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Qelia Canal Earth Works Method Statement - Rev 1

Загружено:

Mohammad Bader Al-DeinАвторское право:

Доступные форматы

CONVEYOR 800 MAK JV

CDR

HYDRO AGRICULTURAL DEVELOPMENT OF SOUTH LEBANON

IRRIGATION AND WATER SUPPLY SCHEME

CONVEYOR 800 - Contract No. 3429

(Contract Section 2 - Fixed Part)

Construction Methods

Earth Works (Qelia Canal Structure)

A. Site Clearance

B. Excavation

C. Backfilling

Hydro Agricultural Development of South Lebanon

Irrigation and Water Supply Scheme

Conveyor 800

CONVEYOR 800 MAK JV

Construction Method Qelia Canal Earth Works

Page 1 of 39

Contents

A. Site Clearance ................................................................................................................................................... 5

1. Introduction .................................................................................................................................................. 5

2. Scope ................................................................................................................................................................ 5

3. Definitions ...................................................................................................................................................... 5

4. Quantities ....................................................................................................................................................... 5

5. Time Schedule .............................................................................................................................................. 6

5.1 Progress Calculations ....................................................................................................................... 6

5.2 Time Schedule...................................................................................................................................... 7

6. Services ........................................................................................................................................................... 7

6.1 Lighting .................................................................................................................................................. 7

6.2 Communication ................................................................................................................................... 7

6.3 Dewatering ............................................................................................................................................ 7

7. Health and Safety Requirements ........................................................................................................... 8

8. Environmental Requirements ................................................................................................................ 9

8.1 Site Disturbance .................................................................................................................................. 9

8.2 Disturbance beyond the ROW ....................................................................................................... 9

8.3 Public Roads Disturbance ............................................................................................................... 9

8.4 Water Pollution ................................................................................................................................ 10

8.5 Noise and Dust .................................................................................................................................. 10

9. Risk Assessment ....................................................................................................................................... 10

10. Quality Assurance and Quality Control Requirements ......................................................... 11

11. Responsibilities .................................................................................................................................... 11

12. Resource Allocations .......................................................................................................................... 12

13. Methodology .......................................................................................................................................... 12

Hydro Agricultural Development of South Lebanon

Irrigation and Water Supply Scheme

Conveyor 800

CONVEYOR 800 MAK JV

Construction Method Qelia Canal Earth Works

Page 2 of 39

13.1 Clearing and Grubbing .............................................................................................................. 12

13.2 Removal of Existing Structures ............................................................................................. 13

13.3 Stripping and Stockpiling of Topsoil ................................................................................... 14

14. Document References ........................................................................................................................ 15

B. Excavation ...................................................................................................................................................... 16

1. Introduction ............................................................................................................................................... 16

2. Scope ............................................................................................................................................................. 16

3. Definitions ................................................................................................................................................... 16

4. Quantities .................................................................................................................................................... 17

5. Time Schedule ........................................................................................................................................... 17

5.1 Progress Calculations .................................................................................................................... 18

5.2 Time Schedule................................................................................................................................... 18

6. Services ........................................................................................................................................................ 19

6.1 Lighting ............................................................................................................................................... 19

6.2 Communication ................................................................................................................................ 19

6.3 Dewatering ......................................................................................................................................... 19

7. Health and Safety Requirements ........................................................................................................ 19

7.1 Personnel and Equipment............................................................................................................ 19

7.2 Existing Utilities ............................................................................................................................... 20

7.3 Protection of Excavated Face ...................................................................................................... 20

7.4 Fall into Excavation ........................................................................................................................ 20

7.5 Excavation by Blasting .................................................................................................................. 20

8. Environmental Requirements ............................................................................................................. 21

9. Risk Assessment ....................................................................................................................................... 21

10. Quality Assurance and Quality Control Requirements ......................................................... 22

Hydro Agricultural Development of South Lebanon

Irrigation and Water Supply Scheme

Conveyor 800

CONVEYOR 800 MAK JV

Construction Method Qelia Canal Earth Works

Page 3 of 39

11. Responsibilities .................................................................................................................................... 22

12. Resource Allocations .......................................................................................................................... 23

13. Methodology .......................................................................................................................................... 24

13.1 Prior Activities ............................................................................................................................. 24

13.2 Excavation ...................................................................................................................................... 24

13.3 Surface Preparation ................................................................................................................... 26

13.4 Reinstatement .............................................................................................................................. 26

14. Document References ........................................................................................................................ 26

C. Backfilling ....................................................................................................................................................... 27

1. Introduction ............................................................................................................................................... 27

2. Scope ............................................................................................................................................................. 27

3. Definitions ................................................................................................................................................... 27

4. Quantities .................................................................................................................................................... 27

5. Time Schedule ........................................................................................................................................... 27

5.1 Progress Calculations .................................................................................................................... 28

5.2 Time Schedule................................................................................................................................... 28

6. Services ........................................................................................................................................................ 28

6.1 Lighting ............................................................................................................................................... 28

6.2 Communication ................................................................................................................................ 29

6.3 Dewatering ......................................................................................................................................... 29

7. Health and Safety Requirements ........................................................................................................ 29

8. Environmental Requirements ............................................................................................................. 30

9. Risk Assessment ....................................................................................................................................... 31

10. Quality Assurance and Quality Control Requirements ......................................................... 31

11. Responsibilities .................................................................................................................................... 32

Hydro Agricultural Development of South Lebanon

Irrigation and Water Supply Scheme

Conveyor 800

CONVEYOR 800 MAK JV

Construction Method Qelia Canal Earth Works

Page 4 of 39

12. Resource Allocations .......................................................................................................................... 33

13. Methodology .......................................................................................................................................... 34

13.1 Prior Activities ............................................................................................................................. 34

13.2 Execution ........................................................................................................................................ 34

13.3 Precautions .................................................................................................................................... 35

14. Document References ........................................................................................................................ 36

Annexures ................................................................................................................................................................ 37

Annex I - Subsections ........................................................................................................................................... 38

Annex II - Organization Chart ........................................................................................................................... 39

Hydro Agricultural Development of South Lebanon

Irrigation and Water Supply Scheme

Conveyor 800

CONVEYOR 800 MAK JV

Construction Method Qelia Canal Earth Works

Page 5 of 39

A. Site Clearance

1. Introduction

The purpose of this procedure is to outline the Site clearance, Grubbing and Topsoil removal

in respect to Hydro Agricultural Development of South Lebanon Irrigation and Water Supply

Scheme CONVEYOR 800 Project.

The detailed guide will provide the clear steps undertaken to complete the process of the site

clearance activities in a safe, systematic and efficient manner in compliance to the statutory

and environmental requirements.

2. Scope

The procedure will include the removal and disposal of all plants, equipment, components,

materials, waste, existing structures and topsoil stripping and grading, prior to the initiation

of the earthworks and structural works within the boundary of the construction of the Qelia

Canal Structure and the maintenance road.

3. Definitions

All terms used in the development of this procedure are defined in Item Specifications.

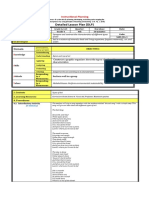

4. Quantities

The total length of the Qelia Canal Structure and the maintenance road is summarized here

below in the table as follows:

From Station To Station

Length

[m]

0+200.00 0+720.00 520.00

0+720.00 1+165.00 445.00

1+165.00 3+385.00 2220.00

3+972.00 5+066.00 1094.00

5+352.00 5+756.00 404.00

6+170.00 7+438.25 1268.25

5951.25 Total Canal Length [m]

Hydro Agricultural Development of South Lebanon

Irrigation and Water Supply Scheme

Conveyor 800

CONVEYOR 800 MAK JV

Construction Method Qelia Canal Earth Works

Page 6 of 39

The total quantities of clearing and grubbing as well as the stripping and stockpiling of

topsoil for the canal structure and the maintenance road are 65,800 m

2

and 6,580 m

3

respectively as mentioned in the bill of quantities.

The following figure shows a typical section of the canal and the maintenance road:

5. Time Schedule

Throughout the Contractor planning for earth works, the working areas for Qelia Canal

Structure are divided into 5 subsections (excluding siphons and other structures) based on

concrete teams allocation as follows:

1. Section A: 0+200 1+600, L= 1,400m

2. Section B: 1+600 3+000, L= 1,400m

3. Section C: 3+972 5+066, L= 1,094m

4. Section D: 5+352 5+756, L= 404m

5. Section E: 6+170 7+300, L= 1,130m

Dissection of the above mentioned subsections is shown in Annex I enclosed to the present

method statement.

Based on the Contractor planning study in relevant to the quantities included in the bill of

quantities, (1) site clearance team (Clearing, Grubbing and stripping of Topsoil) is enough to

execute the required quantities in approximately 4 calendar months.

5.1 Progress Calculations

The assumption adopted for the productivity rate with the assigned resources is as follows:

Hydro Agricultural Development of South Lebanon

Irrigation and Water Supply Scheme

Conveyor 800

CONVEYOR 800 MAK JV

Construction Method Qelia Canal Earth Works

Page 7 of 39

ACTIVITY UNIT

PRODUCTIVITY

OF TEAM / DAY

EQUIPMENTS PER

TEAM

MANPOWER PER

TEAM

Clear and grub

area

m

2

2,000

(1) 977 Shovel Track + (2)

Trucks + (1) Excavator 320

(2) Unskilled labor

Strip topsoil and

stockpile

m

3

250

(1) 977 Shovel Track + (2)

Trucks + (1) Excavator 320

(2) Unskilled labor

5.2 Time Schedule

Detailed Time Schedule is to be submitted along with the program of work for the approval

of the Engineer.

The program depicts the sequence of work for the execution of Qelia Canal Structure and

duration of each activity.

6. Services

6.1 Lighting

Contractor will provide the necessary lighting equipment to ensure appropriate lighting in

all the working areas when working at night. Additionally, working machineries and

equipment will also be equipped with lighting accessories.

6.2 Communication

Contractor will provide a radio stations to enable communication between the working

groups.

6.3 Dewatering

The water that appears at the working areas due to surface water inflow during rainy

weather shall be discharged by installing adequate dewatering system through suction

pumps and pipelines to dispose water in accordance with the method statement for

dewatering activities, to be submitted when required.

Hydro Agricultural Development of South Lebanon

Irrigation and Water Supply Scheme

Conveyor 800

CONVEYOR 800 MAK JV

Construction Method Qelia Canal Earth Works

Page 8 of 39

7. Health and Safety Requirements

The occurrence of site accidents should be kept to a minimal.

Health, Safety and Environment Plan will be provided at site to ensure smooth running of

works in safe manner, taking into consideration the following precautions:

1. Ensure that all safety precautions and recommendations outlined in the Risk

Assessments have been applied.

2. Make sure that:

All personnel including Third Parties are safety inducted prior to site entry.

Workers are trained and competent in their duties.

Operators are qualified, hold license for machine operation and trained in the

maintenance of machinery.

All tools and equipment are in safe and good conditions.

3. Provide Frist Aide Facility on working site in case of minor injury treatment.

4. Arrange for all personnel the pertinent Personal Protective Equipment (PPE)

including safety helmet, safety boots (Boots up to the knees are required when

clearing shrubs and trees, to avoid snake bites), ear / eye protectors, dust mask,

gloves and reflective vest (When working in vicinity of the road or nearby the

excavator or other heavy machines).

5. Place warning signs, barricades, lightings or fences at relevant locations such as:

Critical excavations

Pedestrian crossings

Main roads where traffic flow is disturbed by work - Use signalmen wearing

high visibly clothes to arrange traffic.

6. Arrange with the owners of third party services like telephone lines, cables, pipelines

or other types of utilities, to make secure the use and operation of the utilities.

Consider all cables as Live unless otherwise indicated, and adopt a safe system of

work when such cables cannot be terminated.

7. Contact Authorities to determine the presence of any explosive or unexploded bombs,

or upon finding any suspected danger.

8. Investigate fall prevention method to identify the presence of any abandoned wells or

drainage systems to prevent personals from falling in it.

9. Ensure safe access to the Canal ROW and maintain the permanent and temporary

access roads in a good condition during construction activities.

10. Prevent sliding of materials along the slope.

11. Check and secure all materials debris prior to its movement outside the site.

Hydro Agricultural Development of South Lebanon

Irrigation and Water Supply Scheme

Conveyor 800

CONVEYOR 800 MAK JV

Construction Method Qelia Canal Earth Works

Page 9 of 39

8. Environmental Requirements

ROW Clearing, Topsoil Stripping and Grading shall be carried out in accordance with

requirements as described in the Contractor's Environmental Management and Monitoring

Plan, taking into consideration the following precautions.

8.1 Site Disturbance

1. Ensure that the site is kept in a tidy condition at all times and that all the waste

generated by the works is cleared from the site.

2. Do not burn combustible material arising from clearance on site without the written

consent of the Engineer; otherwise it shall be disposed of as spoil.

3. Switch off all vehicle engines when not in use to minimize combustion emissions.

4. Collect and Dispose used chemicals and engine oils in appropriate containers,

prohibiting its discharge to land or surface waters.

5. Store all removable items which are to be preserved on site in a safe location and

manner appropriate to their nature.

6. Protect all trees, shrubs, walls, buildings and other items that are to be preserved

from injury or damage.

7. Nesting birds are not to be disturbed as far as practicable.

8. Install all required drainage measures to prevent erosion and washout caused by

surface water during times of inclement weather conditions.

8.2 Disturbance beyond the ROW

1. Minimize disruption caused by clearing along the Canal route that passes through

built up areas.

2. Prevent trespassing beyond the ROW for any personnel or equipment.

3. Avoid or minimize the land damage caused by the operation of vehicles.

4. Protect all Ecological areas or Archaeological sites from any damage.

5. Report any complain by the public to the Community Relation Manager.

8.3 Public Roads Disturbance

1. Carry out appropriate survey prior to construction activities on roads that will be

used to access the ROW, following notifications and approvals received by community

relations.

2. There shall be no unauthorized creation of access routes to otherwise inaccessible

areas.

3. Reinstate any damage caused by construction traffic to roads.

Hydro Agricultural Development of South Lebanon

Irrigation and Water Supply Scheme

Conveyor 800

CONVEYOR 800 MAK JV

Construction Method Qelia Canal Earth Works

Page 10 of 39

4. Minimize the project footprint at the ROW and any access roads.

8.4 Water Pollution

1. Identify any watercourses surface or field drains that maybe affected by the work.

2. Do not strip soil up to tile edges at any watercourse, stream or drainage.

3. Do not discharge or allow water contaminated with silt to enter a watercourse or

drain.

4. Consider surface water path once vegetation is cleared.

8.5 Noise and Dust

1. Check with residents or occupied premises that they are aware of the risk.

2. Keep noise to the lowest possible amounts and wear ear protection when necessary.

3. Use selective water sprays or other pertinent controls to minimize dust created

during demolition and loading activities causing hazardous to surrounding vicinity

and works.

4. Put eye goggles and dust mask to avoid eye wound and dust inhalation.

9. Risk Assessment

Works shall be carried out in line with the detailed project procedures below that shall be

used in conjunction with this method statement:

Health and Safety Plan

Environment Plan

Inspection Plan

Contractor's Emergency Management and Monitoring Plan

Pollution Prevention Plan

Reinstatement Plan

Waste Management Plan

Cultural Heritage Management Plan

Training Procedure

Risk Assessment sheet of each activity shall be prepared by our specialist before

commencing any activity.

The process of hazard identification, risk assessment and control is made up of the following

steps:

1. Identify the nature and level of hazards.

2. Assess the health and safety risk arising from the hazard.

Hydro Agricultural Development of South Lebanon

Irrigation and Water Supply Scheme

Conveyor 800

CONVEYOR 800 MAK JV

Construction Method Qelia Canal Earth Works

Page 11 of 39

3. Eliminate human exposure to the threat or hazard.

4. Determine the suitable safeguard and systems of work that shall be implemented.

5. Monitor and evaluate any new control measures to ensure that they are effective and

safe and that new hazards are not created by them.

10. Quality Assurance and Quality Control Requirements

Quality assurance and quality control covers the records formed from site inspections,

examinations and tests that serve as documentation of the conformance of site construction

and erection to the drawings, specifications and regulations.

Develop Test and Inspection Plan in line with the work to be constructed showing 'Hold and

Inspection' points.

The following steps shall be followed by the engineer in charge before proceeding with the

next activities:

1. Fill the inspection check list to ensure that all activates are being performed as per

the expected quality. The inspection check list shall include the specific requirements,

safety and environmental measures.

2. Prepare inspection request, as per QA/QC Plan, and submit to the Engineer for

approval.

3. Follow up on the Engineer's site inspection and comments, until the RFI form is

approved.

4. Circulate the approved RFI form to the Corporate Quality Department for records

keeping, and issue order to proceed with next activities.

11. Responsibilities

The construction manager is responsible in ensuring the implementation of construction

procedure and method statement, supervising the work and reporting the progress of work

to the planning engineer.

The site manager is responsible for induction, briefing and advising of all personnel and site

visitors.

The QA / QC engineer is responsible in monitoring the execution and performance of the

works in relation to this method statement, approved drawings and technical specifications.

The site engineer is responsible for organizing all the works on site in a safe manner,

ensuring it is in accordance with the schedule and the construction drawing. He must also

Hydro Agricultural Development of South Lebanon

Irrigation and Water Supply Scheme

Conveyor 800

CONVEYOR 800 MAK JV

Construction Method Qelia Canal Earth Works

Page 12 of 39

assure the method statement procedure is followed and must notify the consultant for

inspection.

The safety officer is responsible in ensuring that all activities are carried out safely at site,

establishing the site safety plan, conducting continuous safety inspection and stopping any

unsafe work.

The Labor is responsible to properly wear the protective equipment provided and obey all

the safety rules. He must also perform the work as described in the method statement.

12. Resource Allocations

12.1 Man Power

Site Engineer: 01

Surveyor: 01

Safety Manager: 01

Supervisor: 01

Flagman: As Required

Operators: 04

Vehicle Driver: 01

Plant Mechanic: 01

Unskilled Labors: 02

12.2 Equipment/Machinery Required

Excavator 320: 01

977 Shovel: 01

Dump Trucks: 02

Pickup: 01

The major equipment used for site clearance works include, but are not limited to the above.

Organization chart for earth works is shown in Annex II enclosed to the present method

statement.

13. Methodology

13.1 Clearing and Grubbing

The process of clearing and grubbing is the removal of all trees, bushes, vegetation, rubbish

and any other relevant obstruction within the line of work.

Hydro Agricultural Development of South Lebanon

Irrigation and Water Supply Scheme

Conveyor 800

CONVEYOR 800 MAK JV

Construction Method Qelia Canal Earth Works

Page 13 of 39

1. Establish the survey markers to indicate the working area for the site clearance.

2. Produce a record of conditions that includes a photographic survey to be agreed by

the Engineer, Landowners and any relevant authorities prior to commencement.

3. Takeout a topographic survey on land that may be affected by ROW operations and

serve as a basis for final reinstatement.

4. Inspect Measure and Agree with the Engineer where trees require to be felled.

5. Identify and Mark clearly all the trees to be felled prior to commencement of the

operation.

6. Remove all the marked trees, bushes, vegetation, stumps and roots to their full depth,

while ensuring that the following precautions are implanted:

Minimizing the felling of trees and loss of topsoil.

Agree with the Engineer for any individual trees which have to be retained

within the ROW.

Avoid unnecessary damage to the trees, crops, trunks and canopy by machines

or other disturbances.

Do not totally remove the vegetation over the slop, to avoid the potential risk

of soil erosion on the slope.

7. Construct access roads when needed, to provide better access to vehicles and

equipment.

8. Remove unusable and hazardous materials accordingly to the following:

Remove any loose boarders or materials located outside the ROW that may

impose danger to the constructions.

Separate and Load all materials to locations shown on drawings or approved

by the Engineer.

Obtain the written arrangement for the disposal locations outside the ROW

from the owner or governmental authorities.

9. Maintain the surface in a clean, tidy and stable condition allowing it to fall water and

to prevent ponding.

13.2 Removal of Existing Structures

The procedure involves the safe removal of all existing structures such as walls, fences,

drainage, water pipes and cables while ensuring that alternatives are found to resume their

existing functions.

1. Inspect Measure and Report to the Engineer for major structures, underground

structures, manholes, wells and similar items to be removed.

No action will be taken until the Engineer provides his instruction for disposal.

Hydro Agricultural Development of South Lebanon

Irrigation and Water Supply Scheme

Conveyor 800

CONVEYOR 800 MAK JV

Construction Method Qelia Canal Earth Works

Page 14 of 39

2. Backfill and Compact voids lift after removal with suitable material and compacted

density similar to that in the surrounding ground.

Fill with aggregate or sand in case of compaction is impractical, unless another

treatment is shown on the drawings or instructed by the Engineer.

Backfilling procedure is carried out in the Backfilling Method Statement.

3. Avoid unnecessary damage to fences, walls, hedges and property on or adjacent to the

ROW.

The places where a section of an existing fence is removed shall be supported to

maintain the tension in the fence wire.

4. Flume existing drainage ditches and small watercourses across the running track to

provide access to construction at crossed area and prevent water flow interruption.

The temporary drainage management plan will be submitted separately considering

the following precautions:

Complete the diversion before the original drain is cut minimizing the

interruptions to its operation.

Ensure that the free flow of water through the flume pipes is maintained

throughout the project and that discharging location is suitable and agreed by

the Engineer.

Make sure that fill material used to make up the grade level of the flume pipe

does not spill into the watercourse and blocks the channel.

5. Ensure the following steps are undertaken where cables and underground services

are detected:

Use cable detector and/or hand excavation (Trial Holes) where the presence of

a cable is suspected.

Inform the Engineer immediately of the presence of any telephone or

electricity cables that require moving and contact the relevant authority to

arrange the work accordingly.

Mark clearly any underground services indicating the service details and

depth.

13.3 Stripping and Stockpiling of Topsoil

1. Establish survey markers to identify the working area in which the removal of topsoil

is required.

2. Strip the topsoil to subsoil level or as instructed by the Engineer.

3. Use tracked equipment such as bulldozer.

4. Dispose and Stockpile the topsoil separately from subsoil or other excavated material

for subsequent re-use in covering the required areas.

Hydro Agricultural Development of South Lebanon

Irrigation and Water Supply Scheme

Conveyor 800

CONVEYOR 800 MAK JV

Construction Method Qelia Canal Earth Works

Page 15 of 39

5. Place the topsoil in piles at locations shown on drawings or approved by the

Engineer.

Storing of topsoil shall be prohibited in the following areas:

Under overhead L.V. electrical cables.

Areas where structures are to be erected or materials are to be stored.

Within 5 meters of a watercourse or ditch.

Within flood plains, unless gaps in possible water pounding areas are left in

the stockpile to allow water to pass through.

6. Spread the topsoil over the required areas in a uniform pattern, followed by

compaction and leave it with a neat and tidy appearance.

7. Grade sufficient portions of the ROW that are necessary to assist with subsequent

construction operations after completion of clearing works and topsoil striping.

14. Document References

All site clearance works on the project shall be executed as per the following sections of the

technical Specification - Volume 2.2:

Section 1.2 - Site Clearance and Topsoil

Section 5.3.2.3 - Stripping of Topsoil, Clearing and Grubbing

Hydro Agricultural Development of South Lebanon

Irrigation and Water Supply Scheme

Conveyor 800

CONVEYOR 800 MAK JV

Construction Method Qelia Canal Earth Works

Page 16 of 39

B. Excavation

1. Introduction

This method statement serves as a guideline for the excavation works undertaken during the

construction of the Qelia Canal Structure in the Hydro Agricultural Development of South

Lebanon Irrigation and Water Supply Scheme CONVEYOR 800 Project.

The process will include methods to carry out the excavation and surface preparation under

which the Canal foundation will be placed, in compliance with the environmental and safety

measures required.

2. Scope

This procedure is applicable to the excavation works and surface preparation for the Qelia

Canal of about 6Km length.

In order to achieve the required locations and levels of the canal foundation, excavation will

be carried out to a width of 9.5m and an average depth of 3m. Excavation will continue at

stages to reach the formation level, where the preparation of the surface will be executed

prior to placing the 100mm blinding concrete.

This method statement intends to describe the tasks briefly to ensure the smooth running of

all the excavation activities that are undertaken during the construction of Qelia Canal.

3. Definitions

The following words used in the development of this procedure are explained below:

Barricade: Any object or structure that creates a barrier obstacle to control, block

passage or force the flow of traffic in the desired direction.

Battering: To form the face, side or wall of an excavation to an angle to prevent earth

slippage.

Benching: The horizontal stepping of the face, side or wall of an excavation.

Competent Person: A person who has acquired through training, qualification or

experience the knowledge and skills to carry out the task.

Face: An exposed sloping or vertical surface resulting from the excavation of material.

Safe Slope: The steepest slope, at which an excavated face is stable against slips and

slides, having regard to the qualities of the material in the face, the height of the face, the

load above the face and the moisture conditions.

Hydro Agricultural Development of South Lebanon

Irrigation and Water Supply Scheme

Conveyor 800

CONVEYOR 800 MAK JV

Construction Method Qelia Canal Earth Works

Page 17 of 39

Shoring: The use of timber, steel or other structural material to support an excavation in

order to prevent collapse so that construction can proceed.

All other terms are defined in Item Specifications.

4. Quantities

The total excavation quantity of the Qelia Canal Structure is 85,500 m

3

. This quantity is

distributed according to the bill of quantities into three types:

1. Excavation in material other than hard material or rock: 34,200 m

3

2. Excavation in hard material: 34,200 m

3

3. Excavation in rock: 17,100 m

3

These quantities are suspected to re-measurements according to site classification as to the

satisfaction of the Engineer.

5. Time Schedule

Throughout the Contractor planning for earth works, the working areas for Qelia Canal

Structure are divided into 5 subsections (excluding siphons and other structures) based on

concrete teams allocation as follows:

4. Section A: 0+200 1+600, L= 1,400m

5. Section B: 1+600 3+000, L= 1,400m

6. Section C: 3+972 5+066, L= 1,094m

7. Section D: 5+352 5+756, L= 404m

8. Section E: 6+170 7+300, L= 1,130m

Dissection of the above mentioned subsections is shown in Annex I enclosed to the present

method statement.

Based on the Contractor planning study in relevant to the quantities included in the bill of

quantities, (1) excavation team is enough for the (6) concrete teams (Number of concrete

teams is explained in Qelia Canal Structure - Concrete method statement). Seeing that every

(2) concrete teams is assigned in 3 different sections (sections as mentioned above), thus (1)

principal excavation team is divided into (3) sub teams, each of 1/3 daily productivity rate to

excavate the required quantity and to get the trench ready for the (2) concrete teams to

proceed with concreting works taking into consideration that blinding concrete will be

executed in advance.

Hydro Agricultural Development of South Lebanon

Irrigation and Water Supply Scheme

Conveyor 800

CONVEYOR 800 MAK JV

Construction Method Qelia Canal Earth Works

Page 18 of 39

5.1 Progress Calculations

The assumption adopted for the productivity rate with the assigned resources is as follows:

ACTIVITY UNIT

PRODUCTIVITY

OF TEAM / DAY

EQUIPMENTS PER

TEAM

MANPOWER PER

TEAM

Excavation in

any type of Soil

m

3

Average

300

(1) D8 Tractor Bulldozer +

(1) D9 Tractor Bulldozer +

(2) Excavator 320 + (2)

Excavator including

Jackhammer + (2) air

compressor + (4) Trucks

(4) Unskilled labor

The (3) Teams are planned to finish the entire excavation work in approximately 14 months

as follows:

Sequence work of Teams as per stations

1. Team Exc (A): 0+200 1+600

2. Team Exc (B): 1+600 3+000, then 6+170 7+300

3. Team Exc (C): 3+972 5+066, then 5+352 5+756

5.2 Time Schedule

Detailed Time Schedule is to be submitted along with the program of work for the approval

of the Engineer.

Hydro Agricultural Development of South Lebanon

Irrigation and Water Supply Scheme

Conveyor 800

CONVEYOR 800 MAK JV

Construction Method Qelia Canal Earth Works

Page 19 of 39

The program depicts the sequence of work for the execution of Qelia Canal Structure and

duration of each activity.

6. Services

6.1 Lighting

Contractor will provide the necessary lighting equipment to ensure appropriate lighting in

all the working areas when working at night. Additionally, working machineries and

equipment will also be equipped with lighting accessories.

6.2 Communication

Contractor will provide a radio stations to enable communication between the working

groups.

6.3 Dewatering

There is no significant groundwater problems anticipated on this site, but if ingress of water

occurs during any time the excavation is open, install adequate dewatering system through

suction pumps and pipelines to dispose water in accordance with the method statement for

dewatering activities, to be submitted when required.

7. Health and Safety Requirements

Safety precautions shall be of paramount importance in order to prevent danger to the

public and ensure a safe working environment during the entire construction period. A

survey shall be carried out on areas on the site that may require specific Health and Safety

attention to moderate and remove any hazards or risks.

The following safety measures shall be implemented on site during the execution of the canal

excavation works, along with the measures undertaken in the Site Clearance and

Backfilling method statements and the approved HSE plan:

7.1 Personnel and Equipment

1. Prevent persons to enter a work area where there is a risk of injury.

2. Control all activities involving moving plant using nominated banks man.

Hydro Agricultural Development of South Lebanon

Irrigation and Water Supply Scheme

Conveyor 800

CONVEYOR 800 MAK JV

Construction Method Qelia Canal Earth Works

Page 20 of 39

3. Ensure that defective or suspect equipment, which has been withdrawn from service,

does not get back into service without the inspection and approval of a competent

person.

7.2 Existing Utilities

1. Use cable detector to identify and locate the underground utilities and ensure it is

protected.

2. Where overhead lines cannot be diverted or quarantined, ensure that plant is selected

or modified so that it cannot reach the lines.

7.3 Protection of Excavated Face

1. Considering soil condition and depth of excavation, batter sides of the excavation to a

safe slope.

2. Lower the underground water table if encountered to below the invert of the canal

and always check the pumps to ensure its workability.

7.4 Fall into Excavation

1. Establish a barricaded zone, 2m back from the left excavation face, in areas where

there is a risk of falling and where the depth of excavation exceeds 2m.

2. Ensure that all barriers, cones and flagging warning tapes are in place prior to leaving

the site.

7.5 Excavation by Blasting

1. Hire licensed hot firer prior to commencing any blasting works.

2. Ensure that the use of explosives is limited to competent, licensed personnel who

have experience in the work to be undertaken.

3. Check that all safety measures are being taken else blasting will be prohibited.

4. Secure all areas affected by blasting by flagmen to avoid any intrusions.

5. Relocate any vehicles and equipment parked within the blasting zone to safer

locations.

6. Stop any influenced traffic prior to blasting.

7. Limit the use of blasting in built up areas.

8. Control ground vibration by limiting the blast size and the use of delays.

9. Take special care in order to avoid over breaks other than geological ones.

Hydro Agricultural Development of South Lebanon

Irrigation and Water Supply Scheme

Conveyor 800

CONVEYOR 800 MAK JV

Construction Method Qelia Canal Earth Works

Page 21 of 39

8. Environmental Requirements

Canal excavation and surface preparation works shall be carried out in accordance with

requirements of the Contractor's Environmental Management and Monitoring Plan as

described in the Site Clearance and Backfilling method statement.

In addition, the following precautions are essential and must be considered:

1. Undertake the suitable procedures to avoid the slit of soil during excavation activities

in rainy seasons.

2. Take appropriate measures to minimize the effect of oil/diesel spill in case of

machine failure.

3. Reduce noise from machineries to avoid disturbing the surrounding. Machines shall

be turned off when not in use.

4. Set up the lighting needed for night works in such a manner that neighboring

residents are not disturbed. However, the light should be sufficient for the crew to

undertake their works safely.

9. Risk Assessment

Works shall be carried out in line with the detailed project procedures below that shall be

used in conjunction with this method statement:

Health and Safety Plan

Environment Plan

Inspection Plan

Contractor's Emergency Management and Monitoring Plan

Pollution Prevention Plan

Reinstatement Plan

Waste Management Plan

Cultural Heritage Management Plan

Training Procedure

Risk Assessment sheet of each activity shall be prepared by our specialist before

commencing any activity.

The process of hazard identification, risk assessment and control is made up of the following

steps:

1. Identify the nature and level of hazards.

2. Assess the health and safety risk arising from the hazard.

3. Eliminate human exposure to the threat or hazard.

Hydro Agricultural Development of South Lebanon

Irrigation and Water Supply Scheme

Conveyor 800

CONVEYOR 800 MAK JV

Construction Method Qelia Canal Earth Works

Page 22 of 39

4. Determine the suitable safeguard and systems of work that shall be implemented.

5. Monitor and evaluate any new control measures to ensure that they are effective and

safe and that new hazards are not created by them.

10. Quality Assurance and Quality Control Requirements

Quality assurance and quality control covers the records formed from site inspections,

examinations and tests that serve as documentation of the conformance of site construction

and erection to the drawings, specifications and regulations.

Quality Assurance officer should periodically inspect the materials being excavated and

compare it with the material initially tested. Suitable materials are to be kept on site for

future use while unsuitable materials shall be disposed to an approved spoil areas.

He must also follow up with the Engineer for classifying the excavated materials as materials

other than hard or rock, hard materials or rock materials. Such classification shall be

submitted according to stations and depths of excavated layers for the approval of the

Engineer.

Blasting is also controlled by QA officer regarding the perimeter of blasting in accordance

with the safety officer.

The following steps shall be followed by the engineer in charge before proceeding with the

next activities:

1. Fill the inspection check list to ensure that all activates are being performed as per

the expected quality. The inspection check list shall include the specific requirements,

safety and environmental measures.

2. Prepare inspection request, as per QA/QC Plan, and submit to the Engineer for

approval.

3. Follow up on the Engineer's site inspection and comments, until the IR form is

approved.

4. Circulate the approved IR form to the Corporate Quality Department for records

keeping, and issue order to proceed with next activities.

11. Responsibilities

The construction manager is responsible in ensuring the implementation of construction

procedure and method statement, supervising the work and reporting the progress of work

to the planning engineer.

Hydro Agricultural Development of South Lebanon

Irrigation and Water Supply Scheme

Conveyor 800

CONVEYOR 800 MAK JV

Construction Method Qelia Canal Earth Works

Page 23 of 39

The site manager is responsible for induction, briefing and advising of all personnel and site

visitors.

The QA / QC engineer is responsible in monitoring the execution and performance of the

works in relation to this method statement, approved drawings and technical specifications.

The site engineer is responsible for organizing all the works on site in a safe manner,

ensuring it is in accordance with the schedule and the construction drawing. He must also

assure the method statement procedure is followed and must notify the consultant for

inspection.

The safety officer is responsible in ensuring that all activities are carried out safely at site,

establishing the site safety plan, conducting continuous safety inspection and stopping any

unsafe work.

The Labor is responsible to properly wear the protective equipment provided and obey all

the safety rules. He must also perform the work as described in the method statement.

12. Resource Allocations

12.1 Man Power:

Site Engineer: 01

Surveyors: 02

Safety Manager: 01

Supervisor: 01

Flagman: As Required

Unskilled Labors: 04

Plant Mechanic: 01

Operators: 10

Vehicle Drivers: 02

12.2 Equipment/Machinery Required:

D8 Tractor Bulldozer: 01

D9 Tractor Bulldozer: 01

Excavator 320: 02

Excavator including Jackhammer: 02

Air Compressor: 02

Dump Trucks: 04

Pickup: 02

Hydro Agricultural Development of South Lebanon

Irrigation and Water Supply Scheme

Conveyor 800

CONVEYOR 800 MAK JV

Construction Method Qelia Canal Earth Works

Page 24 of 39

The major equipment used for the canal excavation works include, but are not limited to the

above.

Organization chart for earth works is shown in Annex II enclosed to the present method

statement.

13. Methodology

13.1 Prior Activities

1. Prepare, check and submit verified construction drawings of excavation areas

including setting out, levels and service drawings for the approval of the Engineer.

2. Upon obtaining all the necessary survey data, carry out a survey to obtain original

ground levels and submit for the approval of the Engineer.

3. Set out the coordinates of excavation using steel rods driven into the ground and

indicate on these rods the required depth to be excavated, where the maximum

distance between rods is 20 meters.

4. Prepare access to the working area and plan for the dump truck and plant movement

avoiding any close approach to the edge of excavation. Access shall be approved by

the Engineer taking into account the site traffic management plan and the storage

area for materials.

5. Carry out a survey with the coordination with the relevant authorities to identify any

existing services and use cable detection tools and hand digging measures to clearly

mark these services on the ground.

6. It has been identified that the ground conditions will allow for the excavated faces to

stand within a slope of 1/4 without the use of supports, however if this is not the case,

obtain more information about ground conditions to determine the appropriate

support system such as benching or battering.

13.2 Excavation

1. Strip and store topsoil within the working width as indicated in the site clearance

method statement.

2. Carry out the excavation of the Canal in accordance with the relevant approved

drawings and cross sections, to the widths and slopes shown thereon:

Hydro Agricultural Development of South Lebanon

Irrigation and Water Supply Scheme

Conveyor 800

CONVEYOR 800 MAK JV

Construction Method Qelia Canal Earth Works

Page 25 of 39

3. Recheck the excavated elevations and locations at the end of excavation to ensure

that the face of excavation is finished to the required slope.

4. Carry out excavation works using a bulldozer with ripper and / or a 360 excavator

assisted at all times by a competent banks man.

5. As the excavation progresses, use a combination of 360 excavator fitted with a

hydraulic breaker and an excavator with a small bucket attachment, to excavate the

side ditch of dimensions in accordance to the drawings and a distance from the left

wall of the canal to be agreed with the Engineer, to prevent the flow of water into the

excavation or behind the canal wall during the construction period.

6. It is the intention to excavate rocky areas by mechanical methods, however should

the occasion arise, carry out blasting technique.

7. Execute drilling by hydraulic rock drill with the sides of the excavation to be smoothly

blasted in order to form straight lines.

8. Saw cut all the edges of excavated areas on concrete or bituminous footways and

roadways using asphalt cutter to form trimmed edges and minimise damages.

9. Stockpile the excavated materials that are justified by the Engineer as suitable

backfilling material, at the lower side of the excavation far away from the area

retained for maintenance road construction, but ensure not to exceed the limit of LRA

property as indicated on the drawings.

10. Transport the surplus of such materials using dump trucks to stockpile areas

designated by the Engineer for future use.

11. Dispose unsuitable excavated materials to spoil areas approved by the Engineer.

Hydro Agricultural Development of South Lebanon

Irrigation and Water Supply Scheme

Conveyor 800

CONVEYOR 800 MAK JV

Construction Method Qelia Canal Earth Works

Page 26 of 39

12. Upon completion of excavation, verify set out locations and check the edge slope and

the bottom founding level of excavation.

13.3 Surface Preparation

1. Trim the finished surface of formation to the required profiles and levels within the

approved shop drawings.

2. If the surface is other than rock, apply water spray and compact using a vibratory

roller, immediately prior to placing the 100 mm blinding concrete.

3. Where instructed by the Engineer, establish a site investigation to identify the

properties of the ground on which the structure will be founded and provide details

on bearing capacity.

4. Replace any removed loose soil encountered at formation level, or any excess depth

excavated below the formation level, with soil-cement mix or with approved

imported fill material compacted in accordance to specification.

5. Wash the rocky foundation surface using water or air compressor and clean it from

dust, mud, loose or fractured material and other debris, immediately prior to placing

the 100mm blinding concrete.

6. Where rock surfaces reach high temperatures under the influence of the sun, carry

out washing at night or in the early morning, to avoid fracturing due to thermal shock.

13.4 Reinstatement

1. Upon completion of work, reinstate all occurring damages or deficiencies to

channeling, kerbing or paving consisting of dressed stone, bricks, precast concrete

slabs or the like, to its original condition.

14. Document References

All canal excavation works on the project shall be executed as per the following sections of

the technical Specification - Volume 2.2:

Section 1.3 - Excavation

Section 5.3.2 - Construction of Cuts and Fills

Hydro Agricultural Development of South Lebanon

Irrigation and Water Supply Scheme

Conveyor 800

CONVEYOR 800 MAK JV

Construction Method Qelia Canal Earth Works

Page 27 of 39

C. Backfilling

1. Introduction

This method statement outlines the backfilling works associated with the construction of

Hydro Agricultural Development of South Lebanon Irrigation and Water Supply Scheme

CONVEYOR 800 Project.

The process describe the uniform work methods that are carried out during backfilling

operations, taking into consideration all safety measures and environmental requirements.

2. Scope

This procedure is applicable to all backfilling works requested for the construction of the

Qelia Canal Structure and maintenance road.

It intends to co-relate and control all the tasks required in order to achieve satisfactory

completion of backfilling activities on the project.

3. Definitions

All terms used in the development of this procedure are defined in Item Specifications.

4. Quantities

Backfilling quantities of the Qelia Canal Structure and the maintenance road shown here

below are according to the bill of quantities:

1. Backfill to canal: 7,500 m

3

2. Common fill to maintenance road embankment: 90,000 m

3

3. Fill layer above covered canal: 8,200 m

3

5. Time Schedule

Throughout the Contractor planning for earth works, the working areas for Qelia Canal

Structure are divided into 5 subsections (excluding siphons and other structures) based on

concrete teams allocation as follows:

4. Section A: 0+200 1+600, L= 1,400m

5. Section B: 1+600 3+000, L= 1,400m

Hydro Agricultural Development of South Lebanon

Irrigation and Water Supply Scheme

Conveyor 800

CONVEYOR 800 MAK JV

Construction Method Qelia Canal Earth Works

Page 28 of 39

6. Section C: 3+972 5+066, L= 1,094m

7. Section D: 5+352 5+756, L= 404m

8. Section E: 6+170 7+300, L= 1,130m

Dissection of the above mentioned subsections is shown in Annex I enclosed to the present

method statement.

Based on the Contractor planning study in relevant to the quantities included in the bill of

quantities, (1) backfilling team is enough to execute the required quantities in approximately

15 calendar months.

5.1 Progress Calculations

The assumption adopted for the productivity rate with the assigned resources is as follows:

ACTIVITY UNIT

PRODUCTIVITY

OF TEAM / DAY

EQUIPMENTS PER

TEAM

MANPOWER PER

TEAM

Backfilling m

3

420

(1) Excavator 320 + (2)

Bobcats + (1) Water Tanker

+ (1) Roller 8 tons + (1)

Roller 1.5 tons + (1) Plate

Compactor + (1) Motor

Grader + (2) Trucks

(5) Unskilled labor

5.2 Time Schedule

Detailed Time Schedule is to be submitted along with the program of work for the approval

of the Engineer.

The program depicts the sequence of work for the execution of Qelia Canal Structure and

duration of each activity.

6. Services

6.1 Lighting

Contractor will provide the necessary lighting equipment to ensure appropriate lighting in

all the working areas when working at night. Additionally, working machineries and

equipment will also be equipped with lighting accessories.

Hydro Agricultural Development of South Lebanon

Irrigation and Water Supply Scheme

Conveyor 800

CONVEYOR 800 MAK JV

Construction Method Qelia Canal Earth Works

Page 29 of 39

6.2 Communication

Contractor will provide a radio stations to enable communication between the working

groups.

6.3 Dewatering

The water that appears at the working areas due to surface water inflow during rainy

weather shall be discharged by installing adequate dewatering system through suction

pumps and pipelines to dispose water in accordance with the method statement for

dewatering activities, to be submitted when required.

7. Health and Safety Requirements

To ensure a safe working environment during the entire backfilling process, it is necessary

to control all occurrences of injuries and damages to equipment and properties in

accordance to the approved HSE plan and the following mentioned measures:

1. Check that safe working condition is obtained and identify any specific site hazards

prior to any backfilling works.

2. Ensure that all personnel follow the Health and Safety Rules by attending Site Safety

Induction Courses relevant to their work activities.

3. Confirm that all operators and drivers are equipped with valid drivers / operators

license.

4. Alert all drivers to use safety belts, slow down and obey speed limits.

5. Ensure that drivers are not operating the machines in a manner likely to endanger

themselves.

6. Employ authorized signalman with the operator or driver when necessary.

7. Check that any machine or equipment at site, is authorized, inspected and certified by

qualified person prior to using.

8. Carry out a periodic preventive maintenance on all equipment and machines to

ensure it is in a good working condition.

9. Assign a stand-by man with radio to coordinate for providing a rescue team when the

emergency action is required.

10. Provide Frist Aide Facility on working site in case of minor injury treatment.

11. Enforce all workmen, supervisors and engineers to wear proper personnel protective

equipment including safety helmet, safety shoes, ear / eye protectors, dust mask,

gloves and / or high visibility vest.

Hydro Agricultural Development of South Lebanon

Irrigation and Water Supply Scheme

Conveyor 800

CONVEYOR 800 MAK JV

Construction Method Qelia Canal Earth Works

Page 30 of 39

12. Agree with the Engineer and the relative authority for all traffic routes and access

points used for fill material delivery in such a way to minimize contact with

pedestrians prior to commencement of operations.

13. Provide and Maintain barricades and signs sufficiently when required, as

precautionary measures during the entire stage of construction, to protect the work,

workmen and safety of the public.

14. Ensure that the weight of dump truck containing fill material is not exceeding the

limited weight allowed by the local traffic law.

15. Take all precautions to avoid fire in storage of fuel and oil.

8. Environmental Requirements

Backfilling works shall be carried out in accordance with requirements as described in the

Contractor's Environmental Management and Monitoring Plan, taking into consideration the

following precautions:

1. Ensure that there is no dumping of garbage, waste, construction debris, motor oils

and the same on the site or on the adjoining vegetated areas.

2. Mark fuel containers with contents and prohibit its storage near to watercourses or

drains.

3. Identify any watercourses surface or field drains that maybe affected by the work.

4. Take preventive measures to contain water containing silt or sediment and prevent it

entering drains and water courses.

5. Take steps to ensure that water is not wasted during watering the fill.

6. Alert all residents or occupiers near working area for the risk due to noise and dust.

7. Minimize noise by selecting pertinent plant and equipment.

8. Take Arrangements for controlling the flying dust created during backfilling activities.

9. Wear eye goggles and use dust mask to avoid eye wound and dust inhalation.

10. Check and secure all fill materials prior to its movement and prevent overloading and

overfilling of transporting vehicles.

11. Ensure that the transportation path from site to stock area is always clean and free

from soil or waste matter that may fall down during transportation.

12. Assign areas for washing vehicles wheel before leaving the site to public roads.

13. Carry out appropriate survey on roads that will be used for transporting fill material

before commencing any works.

14. Reinstate all damages accompanying transportation of the fill material.

15. Switch off all vehicle engines when not in use to minimize combustion emissions.

Hydro Agricultural Development of South Lebanon

Irrigation and Water Supply Scheme

Conveyor 800

CONVEYOR 800 MAK JV

Construction Method Qelia Canal Earth Works

Page 31 of 39

9. Risk Assessment

Works shall be carried out in line with the detailed project procedures below that shall be

used in conjunction with this method statement:

Health and Safety Plan

Environment Plan

Inspection Plan

Contractor's Emergency Management and Monitoring Plan

Pollution Prevention Plan

Reinstatement Plan

Waste Management Plan

Cultural Heritage Management Plan

Training Procedure

Risk Assessment sheet of each activity shall be prepared by our specialist before

commencing any activity.

The process of hazard identification, risk assessment and control is made up of the following

steps:

1. Identify the nature and level of hazards.

2. Assess the health and safety risk arising from the hazard.

3. Eliminate human exposure to the threat or hazard.

4. Determine the suitable safeguard and systems of work that shall be implemented.

5. Monitor and evaluate any new control measures to ensure that they are effective and

safe and that new hazards are not created by them.

10. Quality Assurance and Quality Control Requirements

Quality assurance and quality control covers the records formed from site inspections,

examinations and tests that serve as documentation of the conformance of site construction

and erection to the drawings, specifications and regulations.

Develop Test and Inspection Plan in line with the work to be constructed showing 'Hold and

Inspection' points.

Earth work plan describes land backfilling of the site, including materials selection and

placement methods for fill, specific materials to be used and its compaction to achieve site

stability.

Hydro Agricultural Development of South Lebanon

Irrigation and Water Supply Scheme

Conveyor 800

CONVEYOR 800 MAK JV

Construction Method Qelia Canal Earth Works

Page 32 of 39

The following steps shall be followed by the engineer in charge before proceeding with the

next activities:

1. Fill the inspection check list to ensure that all activates are being performed as per

the expected quality. The inspection check list shall include the specific requirements,

safety and environmental measures.

2. Prepare inspection request, as per QA/QC Plan, and submit to the Engineer for

approval.

3. Follow up on the Engineer's site inspection and comments, until the IR form is

approved.

4. Circulate the approved IR form to the Corporate Quality Department for records

keeping, and issue order to proceed with next activities.

Quality Control testing schedule for backfilling works is shown in the following table:

Test Parameter Test Method

Minimum QC Testing

Frequency

Grain-size distribution ASTM D422

1 per stockpile and source

change

Moisture content Moisture ASTM D678

As requested by the

Engineer

Selected and Common fill

material

Suitable or unsuitable as per

specification

Considering a section of

500m

2

Compaction Test

As to the satisfaction of the

Engineer

After compacting each layer

All the above mentioned tests will be performed in our laboratory located at the site

establishment area, to be inspected and approved by the Engineer upon completion.

All other tests that cannot be done in our laboratory will be performed in a third-party lab

ACTS approved by the Engineer.

11. Responsibilities

The construction manager is responsible in ensuring the implementation of construction

procedure and method statement, supervising the work and reporting the progress of work

to the planning engineer.

Hydro Agricultural Development of South Lebanon

Irrigation and Water Supply Scheme

Conveyor 800

CONVEYOR 800 MAK JV

Construction Method Qelia Canal Earth Works

Page 33 of 39

The site manager is responsible for induction, briefing and advising of all personnel and site

visitors.

The QA / QC engineer is responsible in monitoring the execution and performance of the

works in relation to this method statement, approved drawings and technical specifications.

The site engineer is responsible for organizing all the works on site in a safe manner,

ensuring it is in accordance with the schedule and the construction drawing. He must also

assure the method statement procedure is followed and must notify the consultant for

inspection.

The safety officer is responsible in ensuring that all activities are carried out safely at site,

establishing the site safety plan, conducting continuous safety inspection and stopping any

unsafe work.

The Labor is responsible to properly wear the protective equipment provided and obey all

the safety rules. He must also perform the work as described in the method statement.

12. Resource Allocations

12.1 Man Power:

Site Engineer: 01

Surveyor: 02

Safety Manager: 01

Supervisor: 01

Flagman: As Required

Operators: 10

Vehicle Drivers: 02

Plant Mechanic: 01

Unskilled Labors: 05

12.2 Equipment / Machinery Required:

Excavator 320: 02

Dump Trucks: 02

Bobcat: 02

Motor Grader: 01

Roller 8 tons: 01

Roller 1.5 tons: 01

Plate Compactor: 01

Water Tanker: 01

Hydro Agricultural Development of South Lebanon

Irrigation and Water Supply Scheme

Conveyor 800

CONVEYOR 800 MAK JV

Construction Method Qelia Canal Earth Works

Page 34 of 39

Pickup: 02

The major equipment used for backfilling works include, but are not limited to the above.

Organization chart for earth works is shown in Annex II enclosed to the present method

statement.

13. Methodology

13.1 Prior Activities

Use suitable material obtained from excavation of works and from reservoir areas to

construct embankments, if this quantity is inadequate use materials from approved borrow

areas or quarries.

1. Stock the backfill material in piles and add appropriate water quantity.

2. Submit details to the Engineer of the material to use including at least three sets of

test results comprising sieve analysis, optimum moisture content and maximum dry

density.

3. Prepare access to the working area and plan for the dump truck and plant

movements.

4. Ensure that all repair work for concrete surfaces -if any- have been done and

inspected.

5. Remove all vegetation, topsoil and any other unsuitable overburden from areas on

which fill is to be placed.

6. Compact the existing surface using a steel vibratory roller.

7. Carry out survey to obtain original surface levels and submit the results to the

Engineer for agreement.

8. Set out and mark the limits of embankment fill using a steel rod driven into the

ground with a maximum distance of 10 meters between rods, where the offset

distance from edge of embankment depends on the height of fill and the edge slope.

9. Indicate the reference level of the layers on the offset rods or on shuttering or

concrete sides -if any- taking into consideration the difference in levels between the

final edge of embankment and the offset rods.

10. Check these rods and the marks on them routinely.

13.2 Execution

1. Use a front end loader or hydraulic excavator to load the fill materials into tippers and

transport it for spreading by dozer / hydraulic motor grader combination.

Hydro Agricultural Development of South Lebanon

Irrigation and Water Supply Scheme

Conveyor 800

CONVEYOR 800 MAK JV

Construction Method Qelia Canal Earth Works

Page 35 of 39

2. Place the fill in successive layers not exceeding 300 mm after compaction. The layers

shall be parallel to the final fill surface covering the full width and length of the area

to be filled to ensure the area is built up evenly.

3. Remove oversize materials with a maximum dimension greater than the compacted

layer thickness, and ensure that no segregation is allowed by thoroughly mixing on

the surface with a motor grader.

4. Add water required to achieve optimum moisture content by applying it evenly and

uniformly over the area concerned.

5. Compact each layer by using steel vibratory rollers, in a series of continuous

operations in a longitudinal direction over the whole width of the layer so that each

roll laps over half of the previous roll.

6. Use hand compactors in confined areas adjacent to structures where heavy

equipment may cause damage.

7. Carry out a compaction test as to the satisfaction of the engineer at the end of each

layer.

8. After reaching the invert level of the HDPE cable conduit according to the approved

drawings, install the conduit taking care not to damage it during compaction.

9. Recheck embankment levels at the end of backfilling to ensure they are in compliance

with the drawings.

10. Finish the fill slopes with neat lines disposing all loose rocks and uncompact material.

13.3 Precautions

1. Ensure that the fill material do not contain boulders of height more than 2/3 of the

compacted thickness of the layer. The Fill shall not include any substances that are

injurious to the permanent works such as peat, timber, tree roots or stumps, refuse,

degradable matter, organic content, chlorides, sulphates or other chemicals.

2. Cease the work when disposed fill material that have not been compacted becomes

too wet due to rain or other causes until the fill dries and its suitable to resume

compaction, if necessary harrow the material.

3. Decrease the depth of layer, increase the number of passes or change the type of

equipment when the dry density is not obtained.

4. Ensure that water sprays are not directed on the fill with such force as to cause fines

to be washed out.

5. Place the fill so that the surface has sufficient camber to shed surface water and to

avoid ponding.

Hydro Agricultural Development of South Lebanon

Irrigation and Water Supply Scheme

Conveyor 800

CONVEYOR 800 MAK JV

Construction Method Qelia Canal Earth Works

Page 36 of 39

14. Document References

All backfilling works on the project shall be executed as per the following sections of the

technical Specification - Volume 2.2:

Section 1.4 - Filling

Section 5.2.1 - Crushed Stone Materials

Section 5.3.1 - Natural Road Materials

Section 5.3.2.2 Classification of Compaction

Section 5.3.2.6 - Treatment of the Roadbed

Section 5.3.2.7 Fill

Hydro Agricultural Development of South Lebanon

Irrigation and Water Supply Scheme

Conveyor 800

CONVEYOR 800 MAK JV

Construction Method Qelia Canal Earth Works

Page 37 of 39

Annexures

Annex I Subsections

Annex II - Organization Chart

Hydro Agricultural Development of South Lebanon

Irrigation and Water Supply Scheme