Академический Документы

Профессиональный Документы

Культура Документы

7 Segment LA5622-S2 Datasheet

Загружено:

cris_itd0 оценок0% нашли этот документ полезным (0 голосов)

136 просмотров6 страниц2 digit 7 Segment LA5622-S2 Datasheet

Авторское право

© © All Rights Reserved

Доступные форматы

PDF, TXT или читайте онлайн в Scribd

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документ2 digit 7 Segment LA5622-S2 Datasheet

Авторское право:

© All Rights Reserved

Доступные форматы

Скачайте в формате PDF, TXT или читайте онлайн в Scribd

0 оценок0% нашли этот документ полезным (0 голосов)

136 просмотров6 страниц7 Segment LA5622-S2 Datasheet

Загружено:

cris_itd2 digit 7 Segment LA5622-S2 Datasheet

Авторское право:

© All Rights Reserved

Доступные форматы

Скачайте в формате PDF, TXT или читайте онлайн в Scribd

Вы находитесь на странице: 1из 6

LEDTECH ELECTRONICS CORP.

NANYA ROAD,MUGANG ZHAOQING

CITY GUANGDONG CHINA.

TEL:86-758-2875541,2870651,2877464,2876185,2877017

FAX:86-758-2878014

Http://www.ledtech.com.tw

SPECIFICATION

PART NO. : LA(C)5622-S2 EWAK

0.56"(14.22mm) DUAL DIGIT DISPLAY

Approved by Checked by Prepared by

Tung Andy Feng

LA(C)5622-S2

0.56" DUAL DIGIT

DISPLAY

VER.: 01 Date: 2007/01/30 Page: 1/5

Dimensions

8.0

19.0

25.0

12.7

14.22

1.3

8

15.24

0.5 DIA

2.54X8=20.32

3.5 MIN

8.13

MARK

1.68 DIA

DIGIT1 DIGIT2

Notes:

1. The slope angle of any PIN may be 5.0 Max.

2. All dimensions are in mm, tolerance is 0.25mm unless otherwise noted.

Internal Circuit Diagram

LA5622-S2

LC5622-S2

A

14

16

B

15

C

3

D

2

E

1

F

18

G

17

DP

4

A

13

11

B

10

C

8

D

6

E

5

F

12

G

7

DP

9

DIGIT 1 DIGIT 2

A

14

16

B

15

C

3

D

2

E

1

F

18

G

17

DP

4

A

13

11

B

10

C

8

D

6

E

5

F

12

G

7

DP

9

DIGIT 1 DIGIT 2

PIN. PIN.

PIN.

PIN. PIN.

PIN.

LA(C)5622-S2

0.56" DUAL DIGIT

DISPLAY

VER.: 01 Date: 2007/01/30 Page: 2/5

Description

LED Chip Face Color

Part No.

Material Emitting Color Surface Segments

LA5622-S2 EWAK GaP/GaP Green Grey White

LC5622-S2 EWAK GaP/GaP Green Grey White

Absolute Maximum Ratings at Ta=25

Parameter Symbol Rating Unit

Power Dissipation Per Segment PD 78 mW

Pulse Current(1/10Duty Cycle,0.1ms Pulse Width.)

Per Chip

IFP 100 mA

Forward Current Per Chip IF 30 mA

Reverse (Leakage)Current Per Chip Ir 100 uA

Reverse Voltage Per Chip VR 5 V

Operating Temperature Range Topr. -25 to +85

Storage Temperature Range Tstg. -40 to +100

Soldering Temperature. Tsol.

Dip Soldering: 260 for 5 sec.

Hand Soldering: 350 for 3 sec.

LA(C)5622-S2

0.56" DUAL DIGIT

DISPLAY

VER.: 01 Date: 2007/01/30 Page: 3/5

Electrical and Optical Characteristics:

Parameter Symbol Condition Min. Typ. Max. Unit

Luminous Intensity Per Segment IV If=10mA/seg. 0.72 2.9 mcd

Forward Voltage Vf If=20mA/seg. 2.1 2.6 V

Peak Wavelength p If=20mA/seg. 567 nm

Dominant Wavelength d If=20mA/seg. 572 nm

Reverse Current Per Chip

(Leakage Current Per Chip)

Ir Vr=5V 100 A

Spectrum Line Halfwidth If=20mA/seg. 30 nm

Response Time T ----------- 250 ns

Note: Customers special requirements are also welcome.

LA(C)5622-S2

0.56" DUAL DIGIT

DISPLAY

VER.: 01 Date: 2007/01/30 Page: 4/5

Typical Electrical/Optical Characteristic Curves

(25 Ambient Temperature Unless Otherwise Noted)

Fig.1 RELATIVE INTENSITY VS.

WAVELENGTH

Wavelength (nm)

R

e

l

a

t

i

v

e

I

n

t

e

n

s

i

t

y

0.5

1.0

530 590 650 470

1

0

0

H

Z

Fig.2 MAXIMUM TOLERABLE PEAK

CURRENT VS. PULSE DURATION

R

a

t

i

o

o

f

M

a

x

i

m

u

m

O

p

e

r

a

t

i

n

g

P

e

a

k

C

u

r

r

e

n

t

t

o

T

e

m

p

e

r

a

t

u

r

e

D

e

r

a

t

e

d

D

C

C

u

r

r

e

n

t

1

1

10

100

3

K

H

Z

10

1

0

K

H

Z

1

K

H

Z

1000

3

0

0

H

Z

100

10000

OPERATION IN THIS

REGION REOUIRES

TEMPERATURE

DERATING OF IDC

MAXIMUM

tp - Pulse Duration - s

I

F

P

E

A

K

I

D

C

M

A

X

F

o

r

w

a

r

d

C

u

r

r

e

n

t

I

F

(

m

A

)

Forward Voltage VF(V)

Fig .3 FORWARD CURRENT VS.

FORWARD VOLTAGE PER CHIP

1.6

10

2.0 1.8 2.2 2.4 2.6

20

40

50

30

20

F

o

r

w

a

r

d

C

u

r

r

e

n

t

I

F

(

m

A

)

Ambient Temperature Ta (C)

Fig.4 FORWARD CURRENT VS.

DERATING CURVE

0 20 40 60 100 80

30

40

10

50

Fig.5 RELATIVE LUMINOUS INTENSITY

VS. FORWARD CURRENT

R

e

l

a

t

i

v

e

L

u

m

i

n

o

u

s

I

n

t

e

n

s

i

t

y

4.0

N

o

r

m

a

l

i

z

e

d

a

t

1

0

m

A

6.0

8.0

Forward Current (mA)

10

10

2.0

0 20 30 40

30

Ambient Temperature Ta (C)

Fig.6 LUMINOUS INTENSITY VS.

AMBIENT TEMPERATURE

R

e

l

a

t

i

v

e

L

u

m

i

n

o

u

s

I

n

t

e

n

s

i

t

y

-30

0.1

0.5

0.2

1.0

0 -20 -10 10 20

2.0

60 40 50 70

LA(C)5622-S2

0.56" DUAL DIGIT

DISPLAY

VER.: 01 Date: 2007/01/30 Page: 5/5

Precautions in Use:

PLEASE PAY SPECIAL ATTNTION TO THE NEXT POINT TO INCORPORATE OPTO

DEVICE TO HIGH RELIABILITY

1. Do not bend the lead. Bending leads could cause breakage of leads or the degradation of the chip.

When bending is unavoidable, strictly follow the cautionary instruction below.

(1)Bend the leads before soldering.

(2)Bending a lead must be done by fixing a lead tightly and applying no stress on the resin part.

(3) The lead bending point must be more than 1.6mm away from the edge or the resin part.

(4)When a pin is tested for its endurance, bending degree should be 45and repeated no more than two times.

2. Setting a product by using tool such as a holder should be avoided.

When necessary, no stress should be applied to the resin part and lead to consider dimension tolerance,

thermal expansion, thermal contraction of holder, product and circuit board etc.

3. The hole pitch of a circuit board must fit into the lead pitch of products.

4. When soldering, care the followings:

(1)Do not heat a product under any stress (i.e.: twist) to leads.

(2)Do not heat ( for example, by soldering ) a product while out side force is applied the resin part.

(3 The lead bending point must be more than 1.6mm away from the edge or the resin part.

(4)Soldering with PC Board should be conducted with following conditions.

(a) For dip soldering

Pre-heating : 90 Max. for within 60 Sec.

Soldering Max. : 2605(Solder Temp.) for within 5 Sec.

(b) Soldering iron : 350(Soldering iron tip) for within 3 Sec.

5. Flux could corrode the leads.Use flux that contains as little chlorine as possible (RA, RMA,

less than 0.2 wt%) and need not be washed way. When, however, washing is necessary, partially wash

around the leads, instead of the entire LED, by the following conditions.

Cleaning agent : Methyl Alcohol

Cleaning temp : 45Max.

Cleaning time : 30Sec. Max.

6. Minimum amount of soldering flux should be used. Soldering flux should be applied only to the pin portion.

7. The following may damage products or LED chips: Attachment or contact of residual flux solvent

onto the product surface or to LED chips, or invasion of the same into the product.

Вам также может понравиться

- LEDTECH 0.43Документ6 страницLEDTECH 0.43ordenador90Оценок пока нет

- Full-Color LED Lamp Specification SheetДокумент8 страницFull-Color LED Lamp Specification SheetNicholas RichardsonОценок пока нет

- Luckylight: 0.56" Triple Digit Numeric Displays Technical Data SheetДокумент6 страницLuckylight: 0.56" Triple Digit Numeric Displays Technical Data SheetSergiu BadalutaОценок пока нет

- Technical Data Sheet 0.56" Quadruple Digit SMD Displays: ELSF-512SYGWA/S530-E2/S290Документ8 страницTechnical Data Sheet 0.56" Quadruple Digit SMD Displays: ELSF-512SYGWA/S530-E2/S290StuxnetОценок пока нет

- Technical Data Sheet 0.56" Triple Digit SMD Displays: ELST-511SYGWA/S530-E2/S290Документ8 страницTechnical Data Sheet 0.56" Triple Digit SMD Displays: ELST-511SYGWA/S530-E2/S290StuxnetОценок пока нет

- White Backlight LED Technical SpecificationДокумент6 страницWhite Backlight LED Technical SpecificationanzuresinkОценок пока нет

- LED data sheet summaryДокумент5 страницLED data sheet summaryAdrianRamiroОценок пока нет

- Technical Data Sheet 0.51" Single Digit SMD Displays: ELSS-505SYGWA/S530-E2Документ8 страницTechnical Data Sheet 0.51" Single Digit SMD Displays: ELSS-505SYGWA/S530-E2StuxnetОценок пока нет

- Data SheetДокумент3 страницыData SheetDavid Salgado SalgadoОценок пока нет

- Data Sheet: HLMP-RL20, HLMP-SL20Документ9 страницData Sheet: HLMP-RL20, HLMP-SL20Anonymous pMVR77x1Оценок пока нет

- Specification LR770D: SSC CustomerДокумент12 страницSpecification LR770D: SSC CustomerMangesh GaikwadОценок пока нет

- ET-3528W-1B1W: Cool WhiteДокумент22 страницыET-3528W-1B1W: Cool Whitesonyfrancis1970Оценок пока нет

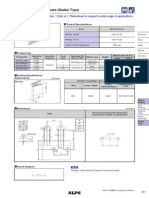

- 4.5×3.55mm Side Push Type (Surface Mount Type) : Sidepush With High Solder Strength & Tactile FeelingДокумент3 страницы4.5×3.55mm Side Push Type (Surface Mount Type) : Sidepush With High Solder Strength & Tactile FeelingshyhuОценок пока нет

- Specification For Approval: Shenzhen CND-TEK Industrial Co.,LtdДокумент4 страницыSpecification For Approval: Shenzhen CND-TEK Industrial Co.,LtdLeonardo Armando RomeroОценок пока нет

- Product Specification: PLBT3-WDRG2613Документ6 страницProduct Specification: PLBT3-WDRG2613api-62031994Оценок пока нет

- Shielded Power Inductors GuideДокумент2 страницыShielded Power Inductors Guidemauricio alfonsoОценок пока нет

- Datasheet Techman OMIT SS 124LMДокумент2 страницыDatasheet Techman OMIT SS 124LMSteve MurphyОценок пока нет

- Side Push Half-Mount Type With 1.6mm Height (Surface Mount Type)Документ3 страницыSide Push Half-Mount Type With 1.6mm Height (Surface Mount Type)shyhuОценок пока нет

- RELAY APPLICATIONS AND SPECIFICATIONSДокумент2 страницыRELAY APPLICATIONS AND SPECIFICATIONSSilas Ismael100% (1)

- Everlight Electronics Co.,Ltd.: Technical Data Sheet 0.56" Dual Digit DisplaysДокумент6 страницEverlight Electronics Co.,Ltd.: Technical Data Sheet 0.56" Dual Digit DisplaysStuxnetОценок пока нет

- Relay 5 Volts PDFДокумент3 страницыRelay 5 Volts PDFesmerilnr12Оценок пока нет

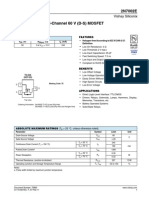

- Vishay Siliconix: Features Product SummaryДокумент8 страницVishay Siliconix: Features Product Summaryaldo_suviОценок пока нет

- Relay 5vДокумент2 страницыRelay 5vNgoc Loi Nguyen HoОценок пока нет

- Everlight Electronics Co.,Ltd.: Technical Data Sheet 0.36" Single Digit DisplaysДокумент6 страницEverlight Electronics Co.,Ltd.: Technical Data Sheet 0.36" Single Digit DisplaysStuxnetОценок пока нет

- Everlight Electronics Co.,Ltd.: 5.0mm Round Type LED Lamps Part No.: FeaturesДокумент4 страницыEverlight Electronics Co.,Ltd.: 5.0mm Round Type LED Lamps Part No.: FeaturesDhuck DhОценок пока нет

- Especificacion Tecnica LEDДокумент10 страницEspecificacion Tecnica LEDJorge Herrero GarcíaОценок пока нет

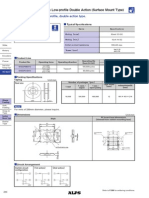

- 7.8mm Square (Radial Type) : Varieties of 1mm, 1.2mm or 1.75mm-Travel To Support A Wide Range of ApplicationsДокумент3 страницы7.8mm Square (Radial Type) : Varieties of 1mm, 1.2mm or 1.75mm-Travel To Support A Wide Range of ApplicationsshyhuОценок пока нет

- Led 5mm yДокумент6 страницLed 5mm yMarcos PainenahuelОценок пока нет

- An17831 PDFДокумент9 страницAn17831 PDFBalmiroHernandezОценок пока нет

- Technical Data Sheet 0.56" Quadruple Digit SMD Displays: ELSF-511SYGWA/S530-E2Документ8 страницTechnical Data Sheet 0.56" Quadruple Digit SMD Displays: ELSF-511SYGWA/S530-E2StuxnetОценок пока нет

- 4 Chip Built in RGBW Smd5050Документ5 страниц4 Chip Built in RGBW Smd5050ZmecleuPeBatzОценок пока нет

- PRG21BBMB1RK e 1485189Документ7 страницPRG21BBMB1RK e 1485189Alberto CruzОценок пока нет

- LM118KFWL2 Solomon DispДокумент10 страницLM118KFWL2 Solomon Dispto_netiksОценок пока нет

- Color Monitor: Service ManualДокумент39 страницColor Monitor: Service ManualAndres DugarteОценок пока нет

- Subminiature Dip Relay: ZettlerДокумент2 страницыSubminiature Dip Relay: ZettlerSergiu BadalutaОценок пока нет

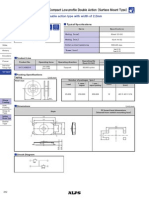

- 4.3×2.2mm Compact Low-Profile Double Action Surface Mount TypeДокумент3 страницы4.3×2.2mm Compact Low-Profile Double Action Surface Mount TypeshyhuОценок пока нет

- D+led-Ld5rДокумент6 страницD+led-Ld5rJulia EchazarretaОценок пока нет

- 1.25mm Height Low-Profile Side Push Surface Mount TypeДокумент3 страницы1.25mm Height Low-Profile Side Push Surface Mount TypeshyhuОценок пока нет

- Delta Electronics DC Fan SpecificationДокумент9 страницDelta Electronics DC Fan SpecificationElias CoelhoОценок пока нет

- Sample Specifications: For Customer'S ApprovalДокумент11 страницSample Specifications: For Customer'S ApprovalMilton Pereira Dos SantosОценок пока нет

- AQH2223 DatasheetДокумент6 страницAQH2223 DatasheetleonttiОценок пока нет

- TACT Switch GuideДокумент3 страницыTACT Switch GuideshyhuОценок пока нет

- lsd815 65 XX PFДокумент9 страницlsd815 65 XX PFDavid MoodyОценок пока нет

- Varistor 222k.6kvДокумент5 страницVaristor 222k.6kvJess AJОценок пока нет

- To56 10g DFB Laser Diode 1310nm Data Sheet 602002Документ3 страницыTo56 10g DFB Laser Diode 1310nm Data Sheet 602002GLsun MallОценок пока нет

- Takamisawa Sy 24w K PCB Mount Relay 24vdc 1 Co SPDT Sy 24w K Data SheetДокумент5 страницTakamisawa Sy 24w K PCB Mount Relay 24vdc 1 Co SPDT Sy 24w K Data Sheetremon thereminОценок пока нет

- Data Sheet For 8mm Super Bright White LED Dip Type 1/2watt High Power LED SeriesДокумент2 страницыData Sheet For 8mm Super Bright White LED Dip Type 1/2watt High Power LED SeriesEtbn SnoaОценок пока нет

- Everlight Electronics Co.,Ltd.: Technical Data Sheet 2.24" Single Digit DisplaysДокумент6 страницEverlight Electronics Co.,Ltd.: Technical Data Sheet 2.24" Single Digit DisplaysLuis Angel PОценок пока нет

- SKQM 6 × 3.5mm Compact (Surface Mount TypeДокумент3 страницыSKQM 6 × 3.5mm Compact (Surface Mount TypeshyhuОценок пока нет

- N-Channel Enhancement Mode Field Effect Transistor: Lead Free/Rohs Compliant (Note 2)Документ3 страницыN-Channel Enhancement Mode Field Effect Transistor: Lead Free/Rohs Compliant (Note 2)broken80Оценок пока нет

- Side Push Surface Mount Type With 1.55mm Height SKTD SeriesДокумент3 страницыSide Push Surface Mount Type With 1.55mm Height SKTD SeriesshyhuОценок пока нет

- TR 5 VДокумент4 страницыTR 5 VЯн ПавловецОценок пока нет

- Flyback Transformers: SchematicsДокумент2 страницыFlyback Transformers: Schematicscatsoithahuong84Оценок пока нет

- SI-8100QL Switching RegulatorsДокумент2 страницыSI-8100QL Switching RegulatorsiamisterdОценок пока нет

- AZ820 Subminiature DIP Relay Features and SpecificationsДокумент2 страницыAZ820 Subminiature DIP Relay Features and SpecificationsDiego OliveiraОценок пока нет

- To56 10g DFB Laser Diode 1330nm Data Sheet 602003Документ3 страницыTo56 10g DFB Laser Diode 1330nm Data Sheet 602003GLsun MallОценок пока нет

- Semiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsОт EverandSemiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsОценок пока нет

- User Manual DVR H264-18 PDFДокумент1 страницаUser Manual DVR H264-18 PDFcris_itdОценок пока нет

- User Manual DVR h264-18Документ1 страницаUser Manual DVR h264-18cris_itdОценок пока нет

- User Manual DVR h264-17Документ2 страницыUser Manual DVR h264-17cris_itdОценок пока нет

- User Manual DVR h264-10Документ2 страницыUser Manual DVR h264-10cris_itdОценок пока нет

- User Manual DVR h264-7Документ3 страницыUser Manual DVR h264-7cris_itdОценок пока нет

- User Manual DVR h264-16Документ2 страницыUser Manual DVR h264-16cris_itdОценок пока нет

- User Manual DVR h264-15Документ2 страницыUser Manual DVR h264-15cris_itdОценок пока нет

- User Manual DVR h264-11Документ2 страницыUser Manual DVR h264-11cris_itdОценок пока нет

- User Manual DVR h264-14Документ5 страницUser Manual DVR h264-14cris_itdОценок пока нет

- User Manual DVR h264-13Документ3 страницыUser Manual DVR h264-13cris_itdОценок пока нет

- User Manual DVR h264-12Документ3 страницыUser Manual DVR h264-12cris_itdОценок пока нет

- User Manual DVR h264-9Документ4 страницыUser Manual DVR h264-9cris_itdОценок пока нет

- Press Select To Find An Existing Site or Add A New One: Location of The Mosquito Breeding SiteДокумент1 страницаPress Select To Find An Existing Site or Add A New One: Location of The Mosquito Breeding Sitecris_itdОценок пока нет

- User Manual DVR h264-5Документ3 страницыUser Manual DVR h264-5cris_itdОценок пока нет

- User Manual DVR h264-8Документ5 страницUser Manual DVR h264-8cris_itdОценок пока нет

- LM35 Temperature SensorДокумент13 страницLM35 Temperature Sensorapi-3799604100% (1)

- User Manual DVR h264-6Документ4 страницыUser Manual DVR h264-6cris_itdОценок пока нет

- User Manual DVR h264-4Документ7 страницUser Manual DVR h264-4cris_itdОценок пока нет

- Stra6252m SK PDFДокумент13 страницStra6252m SK PDFcris_itdОценок пока нет

- User Manual DVR h264-1Документ2 страницыUser Manual DVR h264-1cris_itdОценок пока нет

- Zika Tracker-1Документ3 страницыZika Tracker-1cris_itdОценок пока нет

- User Manual DVR h264-3Документ4 страницыUser Manual DVR h264-3cris_itdОценок пока нет

- Manual AVC 791 796 798 KPD 674 677 679Документ60 страницManual AVC 791 796 798 KPD 674 677 679Agunk Rassasusucokelatelezat RasanyamenimaknyossОценок пока нет

- lm355 PDFДокумент12 страницlm355 PDFCesar VilledaОценок пока нет

- Manual AVC 791 796 798 KPD 674 677 679Документ60 страницManual AVC 791 796 798 KPD 674 677 679Agunk Rassasusucokelatelezat RasanyamenimaknyossОценок пока нет

- Learn Arduino Manual 3Документ31 страницаLearn Arduino Manual 3cris_itdОценок пока нет

- Concentration WorksheetДокумент2 страницыConcentration Worksheetcris_itdОценок пока нет

- Product Data Cisco Catalyst 2960-S and 2960 Series SwitchesДокумент29 страницProduct Data Cisco Catalyst 2960-S and 2960 Series Switchescris_itdОценок пока нет

- Atmel 2486 8 Bit Avr Microcontroller Atmega8 L DatasheetДокумент331 страницаAtmel 2486 8 Bit Avr Microcontroller Atmega8 L DatasheetRolando IrrazabalОценок пока нет

- Axiaaudio Cisco2960s Switch ConfigurationДокумент4 страницыAxiaaudio Cisco2960s Switch Configurationiri_iri_aОценок пока нет

- Catalog Iluminat Cooper PDFДокумент79 страницCatalog Iluminat Cooper PDFAnonymous 8SzjduJrQYОценок пока нет

- VMVS2A150GP-RD70 LuminariaДокумент8 страницVMVS2A150GP-RD70 LuminariaivanОценок пока нет

- Telys 2 AnglaisДокумент158 страницTelys 2 AnglaisTomaBogdanovОценок пока нет

- Lighting For Residential Buildings (LG9) 2015 IETДокумент66 страницLighting For Residential Buildings (LG9) 2015 IETrasanavaneethan100% (1)

- Smartengine 0521 LowДокумент17 страницSmartengine 0521 Lowatif_aman123Оценок пока нет

- B752 eДокумент24 страницыB752 eRoberto Villegas83% (6)

- Unit 1 (FOLI)Документ17 страницUnit 1 (FOLI)VarsaОценок пока нет

- Veinlite LEDX Flyer VAДокумент1 страницаVeinlite LEDX Flyer VAcesare.alcesteОценок пока нет

- An Overview of Spy RobotДокумент23 страницыAn Overview of Spy RobotNihaОценок пока нет

- MRU1 WoodWArdДокумент28 страницMRU1 WoodWArdYago PereiraОценок пока нет

- MB Ec 2 en 1018Документ16 страницMB Ec 2 en 1018Michelle BrownОценок пока нет

- Current and Voltage Sensors Catalog ABB 2Документ116 страницCurrent and Voltage Sensors Catalog ABB 2paulo-956880Оценок пока нет

- PAVIRO Installation Note EnUS 22237432587 en 54 16Документ46 страницPAVIRO Installation Note EnUS 22237432587 en 54 16queueisnottrueОценок пока нет

- 3-1400561 Philips 4pp Product Datasheet Refresh-V4-Hi Res PDFДокумент4 страницы3-1400561 Philips 4pp Product Datasheet Refresh-V4-Hi Res PDFwaseemОценок пока нет

- JAR 66 Category B1 Module 4 Electronic FundamentalsДокумент88 страницJAR 66 Category B1 Module 4 Electronic Fundamentalsghuran khatweОценок пока нет

- Prototype of Cathodoluminescent Lamp For General Lighting Using Carbon Fiber Field Emission CathodeДокумент6 страницPrototype of Cathodoluminescent Lamp For General Lighting Using Carbon Fiber Field Emission CathodeРуслан Владимирович МусаевОценок пока нет

- Dryer: Refer To Page 4 For Model IdentificationДокумент80 страницDryer: Refer To Page 4 For Model IdentificationIgmarОценок пока нет

- 2019 Winter Model Answer Paper (Msbte Study Resources)Документ13 страниц2019 Winter Model Answer Paper (Msbte Study Resources)Yatiraj VhanmaratheОценок пока нет

- Electronic kits supplier FUTURE KIT product catalogДокумент58 страницElectronic kits supplier FUTURE KIT product catalogMuhammad IkhsanОценок пока нет

- Tle Exam 1ST Quarter G10Документ3 страницыTle Exam 1ST Quarter G10HARONОценок пока нет

- 0 Q 2 JQQZXGX EДокумент72 страницы0 Q 2 JQQZXGX EKatamba RogersОценок пока нет

- Wipro LHДокумент144 страницыWipro LHNishant SinghОценок пока нет

- Commercial Presentation Led SLM Gen3Документ6 страницCommercial Presentation Led SLM Gen3dingeo11Оценок пока нет

- Ew Blast Powercore 4000K 21degree SpecSheetДокумент2 страницыEw Blast Powercore 4000K 21degree SpecSheetsanguinaria123Оценок пока нет

- Golden - Owners's Manual - LiteRider EnvyДокумент42 страницыGolden - Owners's Manual - LiteRider EnvyParker EastmanОценок пока нет

- AS200Документ1 страницаAS200vitgahiОценок пока нет

- Prometer 100 User Manual (Cewe) BGX501-943-R07Документ92 страницыPrometer 100 User Manual (Cewe) BGX501-943-R07Jumhanter hutagaolОценок пока нет

- Rero User ManualДокумент109 страницRero User ManualMOHAMAD KHAIRUL MUSTAQIM BIN MOHAMED FO'AD KPM-GuruОценок пока нет

- Nelson Tansu, PH.D.: Office Contact InformationДокумент41 страницаNelson Tansu, PH.D.: Office Contact InformationRio WidarobiОценок пока нет

- Easy Harmony d22Документ22 страницыEasy Harmony d22chili1974Оценок пока нет