Академический Документы

Профессиональный Документы

Культура Документы

P9 Natural Gas - Removal of Hydrates

Загружено:

omeshchemИсходное описание:

Оригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

P9 Natural Gas - Removal of Hydrates

Загружено:

omeshchemАвторское право:

Доступные форматы

TOPIC II

HYDRATES- INHIBITION-

DEHYDRATION

Controlling and/or Removal of Water

in Natural Gas

Hydrates Inhibition

Hydrates Removal

Glycol Absorption (high quantity of water)

Description of process

Field of application

Unit design:

a. foaming;

b. glycol degradation/corrosion

Adsorption (low to moderate amount of water)

Description of process

Adsorbent characteristic

Unit design:

a. choice of adsorbent

b. Dryer arrangement

c. Restricting the quantity of adsorbent required

Hydrates

Hydrates are:

crystal (solid) formed.

physical combination of water and light hydrcarbon

molecules.

Characteristics

resemble packed, wet snow flakes

density =0.9 kg/dm

3

regular cubic structure in shape

only small gas molecules can form hydrates

(i.e: CH

4

,C

2

H

6

,C

3

H

8

,C

4

H

10

, CO

2

,H

2

S and N

2

)

- hydrocarbon tend to be trapped in cavities of water molecule structures

large proportion of water (CH

4

.6H

2

0 methane hydrate)

Hydrates contain a very large proportion of water (CH4.6H2O for methane hydrate;

C3H8.17H2O for propane hydrate)

high concentration entails presence of liquid water

Conditions for Hydrates Formation : Primary cause

in presence of liquid water

temperature does not exceed the water dew point specification

(dew point=lowest temperature at which vapour starts to condense/liquefy)

Effects of hydrate formation

- increase processing difficulty; caused disruption of process during natural gas

treatment

- blockage; accumulation of hydrates at orifice plates or valves, reduce the

cross-sectional area.

- corrosion of equipment and lines by acid gases (CO

2

, H

2

S) in presence of

water

How to prevent hydrates formation

1. Operating Condition

- modify the operating condition of natural gas treatment.

at P=60 bar, hydrates formed at T <16

o

C

at P=100 bar, hydrates formed at T =20

o

C

2. Injecting a hydrate inhibitor into the natural gas, designed to lower hydrate

formation temperature.

3. Removing part of water contained in the natural gas.

These preliminary treatment is necessary for

1. To prevent hydrate formation

2. To prevent corrosion of equipment and lines by acids in gas (CO2, H2S) in the

presence of water

3. To meet dew point specification

HYDRATES INHIBITION

Methanol

Advantages:

effective in case of polar products especially water.

attractive due to low crystallization temperature, low viscosity

Disadvantages:

not economical

volatile product

high losses of vaporization in gas

Ethylene Glycol

Advantages:

more preferred than methanol.

used on intermittent basis as curative rather than preventive measurement.

important in drying natural gas.

loss through vaporization in natural gas can be neglected

Types of Glycols widely used:

monoethylene glycol, MEG (HOC

2

H

4

OH) for low T

diethylene glycol, DEG (HO(C

2

H

4

O)

2

H)

triethylene glycol, TEG (HO(C

2

H

4

O)

3

H) for high T

* depend on operating temperature that influence on viscosity

Properties of Hydrate Inhibitors

Quantity of Inhibitor to Inject

Ethylene Glycol

Properties:

MEG used for temperature below 5 to 10

o

C

TEG too viscous at T = -5 /-10

o

C

Hammerschmidt Formula

Quantity of inhibitor:

W = weight percentage of inhibitor in aqueous phase

dx = decrease in temperature of hydrate formation

M = molecular weight of inhibitor

K

i

= constant related inhibitor

Operation

remove free water from circuits first before start up process

drain the lower points

blow the circuits with dry air / nitrogen

monitor the variation in operating parameters (i.eP, T,deltaP)

DRYING GAS BY HYDRATE-INHIBITION

Type: MEG, DEG

T=-5 to -10

o

C

P=

T=

DEHYDRATION

Definition :

Dehydration is

a process of water removal or drying of natural gas.

compliance with a water dew point specification.

Purposes

to avoid the risk of condensation of water in the pipeline.

to avoid the formation of liquid slugs.

to prevent gradual plugging of the circuits by ice.

Types of dehydration processes

1. Glycol absorption dehydration

most suited is TEG (Triethylene Glycol)

TEG has low vapor pressure hence minimum losses in gas

high concentration of TEG give low gas dew point

temperature

2. Dehydration by adsorption

used adsorbent in dehydration process

principle based on porous solid with specific property,

able to fix water molecules on the surface of pores where

water vapor condensed.

Glycol Absorption Dehydration

Principle:

wet gas dehydrated by glycol in absorber

water contained glycol reconcentrated in regenerator

water removed from natural gas, recycled back at top of the column

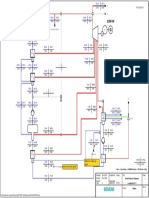

Process Description (refer to Fig 2):

wet natural gas (NG) pass through separator

on leaving the separator, the gas is fed into bottom of absorber

lean glycol solution is fed on top of absorber

rich glycol expanded in expansion drum to degas the light

hydrocarbons, H

2

S and CO

2

entering regenerator and reboiler to minimize risks of corrosion

exchanger is used to condense the regenerator reflux

the gas free water leaves the top of the column

DRYING GAS BY DEHYDRATION: GLYCOL ABSORPTION PROCESS

T

glycol

=-6 to -10

o

C(low dew point)

T

regenerate

=204

o

C

P =high

Glycol Absorption Dehydration

Main Operating Parameter:

Glycol concentration has to be highly concentrated to lower the dew point

The lower the dew point to be reached, the greater the degree of regeneration

of glycol required

The actual dew point reached in the absorber is bet. 6-10 deg C higher the

equilibrium dew point. The gap is called the approach

cannot obtain directly by reboiling-rectification, need to regenerate at high

temperature (204

o

C)

high T can caused glycol breakdown and formed of corrosive compound

Alternative Solution to Operate at T>204 deg

low pressure by vacuum operation (risk of oxygen inducing flammable

mixture)

fuel gas or natural gas (to decrease the water partial pressure , thus >ing

vaporisation

iso-octane (non miscible substance)

Phenomena for Optimal Dehydration Unit Design Operation:

Foaming

Glycol Degradation

Phenomena for Optimal Dehydration Operation

1. Foaming

i. Glycol has a tendency to foam when in contact with foaming promoters such as

liquid HC, solid particles (compound produced by thermal degradation of

glycol)

ii. develop in absorber, and can fill the entire column

iii. top of column no effect on foam

iv. the onset of foaming in absorber reflected by increase pressure drop in absorber

Prevention of foaming

i. Installation of separator (to remove free water, liq. HC, solid particles)

ii. Lean glycol inlet temperature need to be higher than temperatureof natural gas

to prevent condensation of HC

iii. TEG regeneration not exceeding its thermal degradation, 206

o

C

iv. Glycol filtering to extract foaming promoters:

i. Catridgefilter (polypropylene) to remove solid particles

ii. Activated carbon filter to remove HC and products of glycol degration

v. pH of solution maintain between 6 to 8; >8 there is a risk foaming

vi. Injection of small quantity of an anti-foaming agent

Phenomena for Optimal Dehydration Operation

2. Glycol degradation

thermal degradation of TEG at 206

o

C onwards

produce highly corrosive organic acid

glycol solution absorbs acid gases, lead to decrease pH

corrosion occur caused by presence of salt water

lead to give erosion-corrosion that caused by high rate of glycol

circulation in piping/bends.

Injection of a small amount of corrosion inhibitor, e.g. amines

Prevention of glycol degradation

limit the temperature in reboiler to 204oC

prevent air from enter unit

pH need to be maintained above 6 to avoid TEG breakdown

ensure satisfactory separation of free water

injection a small amount of corrosion inhibitor

Dehydration by Adsorption

Principle:

A physical process whereby a suitable porous solid with specificproperty is

able to fix water molecules on the surface of pores where water vapor

condensed

Is the fixation of molecules by reversible reaction on the surface of a solid.

Three different phenomena of adsorption:

Chemisorption

forming the first layer at low partial pressures.

Physisorption

due to the formation of multiple layers by hydrogen bonding in the adsorbent pores.

Capillary condensation

where localized condensation takes place at temperatures above that of the bulk

fluids dew point.

Characteristic of Adsorbents

have very large internal contact, 250-850 m2/g

Possess a strong affinity for water vapor and a high capacity for adsorption

Be easily and economically regenerable

Undergo slight pressure drop under flow of gas

Possess good mechanical strength

Adsorption Process Description

Water adsorbs and condenses on the surface of adsorbent

Beyond the pure surface adsorption, a secondary mechanism, capillary

condensation kicks-in when pore diameter is comparable to molecular diameter.

Pores in the adsorbent are asymmetrical, i.e. further down into the gel, the

narrower the pore becomes (like a volcano crater).

This capillary condensation is driven by differences of partial pressure outside

and inside of the pore.

To remove the water from the adsorbent surface, energy is used

After regeneration, the adsorbent can be put to use again after cooling to

ambient temperature.

Schematic Representation of Capillary

Condensation

ADSORBENT TYPES

Activated alumina

Alumina is the most widely used adsorbent because of:

The chemical properties of its surface

Its ability to be shaped with well-defined pores defined as follows:

(Ultra) Macropores(>1000 ) to enhance diffusion into the pore system.

Mesopores(30 to 1000 ) to accommodate medium size molecules.

Micropores(<30 ) to accommodate small molecules like water.

Zeolite/Molecular Sieve

Type A zeolite

With sodium cationshas a pore width of 4 , called MS4A.

Replacement of sodium by calcium cationsleads to 5 pores, called MS5A.

Replacement of sodium by potassium leads to molecular sieve MS3A.

Type X Zeolite

Gives pores of 10 and the calcium type corresponds to MS13X.

Silica gel

Activated carbon.

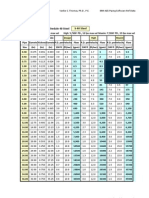

Types of Adsorbent

activated alumina

SA=280 m2/g; pore volume=0.4 m3/g; pore diameter=2-4 nm; density=720-820

kg/m3)

Reduce content by 1 ppmv

Regeneration T=150-220

o

C

silica gel

SA=550-800 m2/g; pore volume=0.35-0.5 m3/g; pore diameter=2.5 nm; density=

720-800 kg/m3)

Reduce content by 10 ppmv

Regeneration T=150-250

o

C

molecular sieves (or zeolites)

Composition oxides of (Si, Al) and Na or K or Ca

Zeolite3A (K), Zeolite4A(Ca); Zeolite5A(Na); ZeoliteX (10 A diameter)

SA=650-800 m2/g; pore volume=0.27 m3/g; pore diameter=3-5 nm; density=690-720

kg/m3)

Reduce content by 1 ppmv

Regeneration T=200-300

o

C

activated carbon

Adsorption of Water to the Alumina

Surface

MOLECULAR SIEVES

Dehydration by Adsorption

Characteristic of a Good Adsorbent:

should posses strong affinity for water vapor

high capacity for adsorption process

capacity of adsorbents depends on their nature

low value of relative humidity gives high capacity of molecular sieve

(ex: adsorbent)

easily and economically re-generable

undergo little drop in pressure

posses good mechanical strength

low dew point is required for cryogenic treatment of natural gas

ability to adsorb heavy HC can show the selectivity of adsorbent

DEHYDRATION UNITS

ADSORPTION PHASE:

Gas Flow: From top to bottom

Adsorbent : Saturated with H2O

Polarity of H2O: Stronger

HC Molecule: Less Stronger

REGENERATION PHASE:

T: 200-300

o

C

P: Low

Adsorbent : Activated Al, Si Gel, Mol Sieves

Stages of Regeneration: Heating Phase

Cooling Phase

Dehydration by Adsorption

Process Description:

using 2 columns called dryers packed with solid adsorbent

involve 2 phase: adsorption phase & regeneration phase

1. Adsorption Phase

gas flow through drier from top to bottom

adsorbent saturated with water

halted phase first before reach breakthrough point

polarity of water much stronger attraction on adsorbent

ejects hydrocarbon molecules that is less stronger

2. Regeneration Phase

regenerate bed of adsorbent

performed operation by increasing in T (200-300

o

C) or lowering the P, or by a

combination of both

can be performed by heating bed of adsorbent

2 stage of regeneration of drier: heating phase & cooling phase

Heating Phase: Hot air desorbthe water from the adsorbent

Cooling Phase: Drier is cooled at the end of the heating phase to the initial condition

Picture of EZ (Equilibrium Zone)

& MTZ (Mass Transfer Zone)

Adsorption and Regeneration for PSA and

TSA Processes

Pressure Swing Adsorption

(PSA)

Temperature Swing Adsorption

(TSA)

Block Diagram of Molecular Sieve Process

Field of Applications

Aging/Deactivation of Solid

Adsorbents

A gradual reduction in adsorption capacity is

caused by aging of the adsorbent.

Two types of aging exist;

1. Hydrothermal aging

- an irreversible change of adsorbent structure caused

by hydrothermal treatment during regeneration,

resulting in reduced active area.

2. Aging from contamination

- caused by co-adsorption of undesired species and

coke formation on the active surface of the adsorbent.

This phenomenon is not completely reversible, and

carbon deposits increase with each regeneration

Isotherms of Activated Alumina, Silica

and Molecular Sieves

Combination of Activated Alumina

and Molecular Sieves

Isotherm Activated Alumina and 4A Molecular Sieves

Life Factor vsNumber of Regenerations for

Al

2

O

3

/ MS 4A /MS 4A in Natural Gas Drying

Industrial Adsorbent Problems

Deep dehydration

Upstream process upsets, leading to dessicant

degradation (reduce adsorption capacity & pressure

drop, hence frequent regeneration)

Causes: liquid (free) water or entrainment of amine

deposition on the adsorbent, high CO2 concentrations,

and heavy metal adsorption

Free water entrainment can lead to caking and

powdering, which leads to >ed pressure drop and poor

gas distribution

Вам также может понравиться

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeОт EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeРейтинг: 4 из 5 звезд4/5 (5794)

- 2 X 22MW 2 HP 105535Документ1 страница2 X 22MW 2 HP 105535omeshchemОценок пока нет

- The Yellow House: A Memoir (2019 National Book Award Winner)От EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Рейтинг: 4 из 5 звезд4/5 (98)

- Abs-Stripper 13septДокумент2 страницыAbs-Stripper 13septomeshchemОценок пока нет

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryОт EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryРейтинг: 3.5 из 5 звезд3.5/5 (231)

- 2 X 22MW 2 HP 105535Документ1 страница2 X 22MW 2 HP 105535omeshchemОценок пока нет

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceОт EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceРейтинг: 4 из 5 звезд4/5 (895)

- 01 - Fluid FlowДокумент76 страниц01 - Fluid FlowMubarak AhmadОценок пока нет

- The Little Book of Hygge: Danish Secrets to Happy LivingОт EverandThe Little Book of Hygge: Danish Secrets to Happy LivingРейтинг: 3.5 из 5 звезд3.5/5 (400)

- Analysis of Condenser Shell Side Pressure Drop Based On The Mechanical Energy LossДокумент8 страницAnalysis of Condenser Shell Side Pressure Drop Based On The Mechanical Energy LossomeshchemОценок пока нет

- 4616 PDFДокумент9 страниц4616 PDFBob SmithОценок пока нет

- Never Split the Difference: Negotiating As If Your Life Depended On ItОт EverandNever Split the Difference: Negotiating As If Your Life Depended On ItРейтинг: 4.5 из 5 звезд4.5/5 (838)

- Glycol Dehydration Unit English LetterДокумент4 страницыGlycol Dehydration Unit English LetterRaulCamachoОценок пока нет

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureОт EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureРейтинг: 4.5 из 5 звезд4.5/5 (474)

- Heat 4e Chap11 LectureДокумент32 страницыHeat 4e Chap11 Lecturepradeepgautam1010198Оценок пока нет

- HVAC SystemДокумент6 страницHVAC SystemomeshchemОценок пока нет

- Natural Gas DehydrationДокумент34 страницыNatural Gas DehydrationJefMusОценок пока нет

- The Emperor of All Maladies: A Biography of CancerОт EverandThe Emperor of All Maladies: A Biography of CancerРейтинг: 4.5 из 5 звезд4.5/5 (271)

- Pressure Relief Valve Engineering HandbookДокумент93 страницыPressure Relief Valve Engineering Handbookakrouti92% (12)

- Heat Transfer InnovatorsДокумент9 страницHeat Transfer InnovatorsomeshchemОценок пока нет

- Team of Rivals: The Political Genius of Abraham LincolnОт EverandTeam of Rivals: The Political Genius of Abraham LincolnРейтинг: 4.5 из 5 звезд4.5/5 (234)

- HVAC System Design: Mark Hydeman, P.E., FASHRAE Taylor Engineering, LLCДокумент42 страницыHVAC System Design: Mark Hydeman, P.E., FASHRAE Taylor Engineering, LLCsardarmkhanОценок пока нет

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaОт EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaРейтинг: 4.5 из 5 звезд4.5/5 (266)

- Pipe Sizing Charts Tables.12890822Документ29 страницPipe Sizing Charts Tables.12890822forevertay2000Оценок пока нет

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersОт EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersРейтинг: 4.5 из 5 звезд4.5/5 (344)

- Heat Exchanger CalculationsДокумент12 страницHeat Exchanger CalculationsMichael J. BaneОценок пока нет

- Sizing Shell and Tube Heat ExchangerДокумент17 страницSizing Shell and Tube Heat ExchangerCallum Biggs100% (3)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyОт EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyРейтинг: 3.5 из 5 звезд3.5/5 (2259)

- Heat Exchanger CalculationsДокумент12 страницHeat Exchanger CalculationsMichael J. BaneОценок пока нет

- HVAC SystemДокумент6 страницHVAC SystemomeshchemОценок пока нет

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreОт EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreРейтинг: 4 из 5 звезд4/5 (1090)

- 2980245C HVAC Handbook 2013 WebДокумент35 страниц2980245C HVAC Handbook 2013 WebomeshchemОценок пока нет

- HSJFKKHFKKJDSGKSFMC Nbbbbzcgumkbwmscn, MLJFC S 544 SДокумент1 страницаHSJFKKHFKKJDSGKSFMC Nbbbbzcgumkbwmscn, MLJFC S 544 SomeshchemОценок пока нет

- ATM Tank DatasheetДокумент1 страницаATM Tank DatasheetomeshchemОценок пока нет

- The Unwinding: An Inner History of the New AmericaОт EverandThe Unwinding: An Inner History of the New AmericaРейтинг: 4 из 5 звезд4/5 (45)

- 2980245C HVAC Handbook 2013 WebДокумент35 страниц2980245C HVAC Handbook 2013 WebomeshchemОценок пока нет

- Hydrostatic Test Pressure PipingДокумент2 страницыHydrostatic Test Pressure PipingnitinchautreОценок пока нет

- Pump TrainingДокумент15 страницPump TrainingdalayeliОценок пока нет

- Api 54Документ2 страницыApi 54almandhari33100% (1)

- Pipe/connection Type Speed Possible Speed ValuesДокумент1 страницаPipe/connection Type Speed Possible Speed ValuesomeshchemОценок пока нет

- Comparison Horizontal Vs Vertical SeparatorДокумент54 страницыComparison Horizontal Vs Vertical SeparatorEng Kim Wei100% (6)

- Crosby Pressure Relief Valve HandbookДокумент93 страницыCrosby Pressure Relief Valve HandbookGlen AshwellОценок пока нет

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)От EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Рейтинг: 4.5 из 5 звезд4.5/5 (121)

- E2 Knockout Drum PDFДокумент2 страницыE2 Knockout Drum PDFKyaw Kyaw AungОценок пока нет

- Guidelines For Utility Impact Assessment For Local Roads in Developed Areas MME 2012 Cross-SectionДокумент81 страницаGuidelines For Utility Impact Assessment For Local Roads in Developed Areas MME 2012 Cross-Sectionirfan mohammedОценок пока нет

- EX - NO:1a Data Definition Languages (DDL) Commands of Base Tables and ViewsДокумент44 страницыEX - NO:1a Data Definition Languages (DDL) Commands of Base Tables and Viewslalit thakur100% (1)

- Chapter 1 AssignmentДокумент4 страницыChapter 1 Assignmenthamster808100% (3)

- 1716,1734,1751,1769 - Highrise and Earthquake Resistant ConstructionДокумент34 страницы1716,1734,1751,1769 - Highrise and Earthquake Resistant ConstructionFAB RAHIОценок пока нет

- 125 Tractor: (Specifications and Design Subject To Change Without Notice)Документ5 страниц125 Tractor: (Specifications and Design Subject To Change Without Notice)Gary LarsonОценок пока нет

- Opposite Corners CourseworkДокумент8 страницOpposite Corners Courseworkpqltufajd100% (2)

- Laboratory Work 1 Computation of Metrics of Productivity of Computer SystemДокумент12 страницLaboratory Work 1 Computation of Metrics of Productivity of Computer SystemHhhhhh75% (4)

- Smart Security Camera System For Video Surveillance Using Open CVДокумент6 страницSmart Security Camera System For Video Surveillance Using Open CVlambanaveenОценок пока нет

- SIF Corporate-Presentatie 2017Документ35 страницSIF Corporate-Presentatie 201766apenlullenОценок пока нет

- Powerflex 525 Devicenet Adapter: User ManualДокумент140 страницPowerflex 525 Devicenet Adapter: User ManualJahir Emerson Tantalean QuiñonesОценок пока нет

- Chapter 9 and 10Документ18 страницChapter 9 and 10billОценок пока нет

- 3g3JX InverterДокумент262 страницы3g3JX InverterdatdttvuОценок пока нет

- Astar - 23b.trace - XZ Bimodal Next - Line Next - Line Next - Line Next - Line Drrip 1coreДокумент4 страницыAstar - 23b.trace - XZ Bimodal Next - Line Next - Line Next - Line Next - Line Drrip 1corevaibhav sonewaneОценок пока нет

- Math 138 Functional Analysis Notes PDFДокумент159 страницMath 138 Functional Analysis Notes PDFAidan HolwerdaОценок пока нет

- (Solution Manual) Fundamentals of Electric Circuits 4ed - Sadiku-Pages-774-800Документ35 страниц(Solution Manual) Fundamentals of Electric Circuits 4ed - Sadiku-Pages-774-800Leo AudeОценок пока нет

- Magnetron PDFДокумент1 страницаMagnetron PDFmytrya debОценок пока нет

- Ratio Worksheet AKДокумент12 страницRatio Worksheet AKChika AuliaОценок пока нет

- New EM Quiz13Документ4 страницыNew EM Quiz13Singh KaranОценок пока нет

- Science July Assignment Grade 8Документ3 страницыScience July Assignment Grade 8G PОценок пока нет

- ME361 - Manufacturing Science Technology: Measurements and MetrologyДокумент20 страницME361 - Manufacturing Science Technology: Measurements and MetrologyKartikeyaОценок пока нет

- m1100 s12 v1.1f en - Fender - DesignДокумент48 страницm1100 s12 v1.1f en - Fender - Designdzul fiqarОценок пока нет

- MB-339A User ManualДокумент196 страницMB-339A User Manualkepakko75% (4)

- 2-Way Doherty Amplifier With BLF888AДокумент27 страниц2-Way Doherty Amplifier With BLF888AerdemsecenОценок пока нет

- A Deep Dive Into The Latest HPC SoftwareДокумент38 страницA Deep Dive Into The Latest HPC SoftwareSundar NilОценок пока нет

- Chapter26to29-Bolt Tightening TorqueДокумент36 страницChapter26to29-Bolt Tightening TorqueEnam SembilanОценок пока нет

- S3 3 TrigonometryДокумент81 страницаS3 3 TrigonometryEugene ChoongОценок пока нет

- Sony - HST 211 - Sen 211 SMДокумент30 страницSony - HST 211 - Sen 211 SMOswaldo CamposОценок пока нет

- VT Directed Io SpecДокумент297 страницVT Directed Io SpechobomanОценок пока нет

- Database Management Systems: Lecture - 5Документ37 страницDatabase Management Systems: Lecture - 5harisОценок пока нет