Академический Документы

Профессиональный Документы

Культура Документы

Man B&W Serv LTR Sl09-509-Sb-j

Загружено:

afsal9990 оценок0% нашли этот документ полезным (0 голосов)

187 просмотров7 страницService letter isssued by MAN B&W for S60MC main engines

Оригинальное название

Man b&w Serv Ltr Sl09-509-Sb-j

Авторское право

© © All Rights Reserved

Доступные форматы

PDF, TXT или читайте онлайн в Scribd

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документService letter isssued by MAN B&W for S60MC main engines

Авторское право:

© All Rights Reserved

Доступные форматы

Скачайте в формате PDF, TXT или читайте онлайн в Scribd

0 оценок0% нашли этот документ полезным (0 голосов)

187 просмотров7 страницMan B&W Serv LTR Sl09-509-Sb-j

Загружено:

afsal999Service letter isssued by MAN B&W for S60MC main engines

Авторское право:

© All Rights Reserved

Доступные форматы

Скачайте в формате PDF, TXT или читайте онлайн в Scribd

Вы находитесь на странице: 1из 7

Service Letter SL09-509/SBJ MAN Diesel

Action code: WHEN G0HVENIENT

ANGLO-EASTERN SHIP

MANAGEMENT LIMITED

23lF MLC TOWER

248 QUEEN S ROAD EAST WANCHAI

HONG KONG

Dear Sirs

Based on the latest service experience and experience with Condition

Based Overhaul (CBO), we are pleased to issue a revised version of

Guiding Overhaul lntervals tables. The guiding overhaul intervals apply

to both electronically controlled engines (ME types) and mechanically,

controlled engines (MC types).

Please note that the intervals in the lists apply only to engines with so-

called high topland pistons. High topland pistons are pistons where the

topland is significantly higher than the ringland.

For engines with high topland pistons, overhauls can normally be ex-

tended even further than described in the tables, typically to more than

32,000 hours. The means to obtain and document this are described in

sL07-483/HRF.

Please direct any inquiries and questions regarding tables or condition-

based overhaul to our Operation Department at leo@mandiesel.com or

to our Service Department at PrimeServ-cph@mandiesel.com.

Yours faithfully

Vice President, Engineering Senior Manager, Engineering

Head office (& postal address)

MAN Diesel

Teglholmsgade 41

2450 Copmhagen SV

Denmark

Phone: +45 33 85 1 1 0O

Fax: +45 33 85 10 30

mmdesel-cph@mandiesel com

ww mandiesel com

Prmeserv

leglholmsgade 41

2450 Copenhagm SV

Denmarl<

Phone: +45 33 85 11 0O

Fa: +45 33 85 10 49

PrimeSeru-cph@mandesel com

Producton

Teglholmsgade 35

2450 Copenhagen SV

Denmark

Phone: +45 33 85 11 00

Fd: +45 33 85 1017

manufacturing dk@mandiesel com

Forwarding & Receiving

Teglholmsgade 35

2450 Copenhagen SV

Denmark

Phone: +45 33 85 1 1 00

Fax: +45 33 85 10'16

MAl Diesel

Brarch of MAN Diesel SE, Germany

CVR No:31611792

Head offce: Teglholmsgade 41

2450 Copenhagen SV Denmark

Geman Reg No: HRB 2205

Amtsgerjcht Augsburg

MAN Diesel- a member of the IV1AN Group

Service Letter SL09-509/SBJ MAltl Diesel

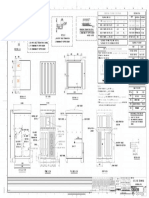

Cylinder liner Bore sizes

60-50 16,000

46-3s 12,000

Bore sizes

60-46 60,000

40-35 50,000

Check the overall cylinder condition

through the scavenge ports at least

once a month.

Bore sizes

60-50 16,000

46-35

.12,000

Bore sizes

60-35

'16,000

Piston crown Bore sizes

60-50 16,000

46-35 12,000

Bore sizes

60-46 60,000

40-35 50,000

Pressure test at every 2d piston

overhaul, recondition/rechrome when

required (typically every 24-32,000

hours). Piston crown can be recondi-

tioned by welding-up twice.

Stuffing box Bore sizes

60-50 16,000

46-35 12,000

Check lamelas

Bore sizes

60-50 32,000

46-35 24,000

Renew lamellas

lnspection of seat and air spring:

Bore sizes

60-35

Frst inspection 1) 6,000

Bore sizes

50-35

Subsequent inspections 2) 16,000

Bore size

60

Subsequent inspections 2) 32,000

Bore sizes

50-35

DuraSpindle exhaust valve 50,000

Bore size

60

DuraSpindle or

Nimonic exhaust valve 100,000

To be obtained for DuraSpindle and

Nimonic valve with reconditioning of

seat and possible re-welding of disk

underside

Normally, HVOF coated stems need

no reconditioning,

Usually only light grinding of seats is

required at subsequent inspections.

1) Condition check

lnspection of air spring according

to instruction manual. Two or three

valves to be inspected.

2) Subsequent inspection

Condition check + possible complete

overhaul. Max burn off rate of spindle

disc underside to be estimated and

calculated for lifetime of spindle. All

valves to be inspected.

Main hydraulic pump 32,000 Engine lifetime Check and replace hydrostatic bear-

ings at overhaul. Check and replace

cylinder set and piston if required.

Proportional valve for

main hydraulic pump

20,000 Replace valve after 20,000 hours

40 000 Engine lifetime Replace sealings at overhaul

Exhaust valve actuator 32,000 Engine lifetime Replace static sealing rings at over-

haul.

ELFI valve 32,000 64,000 Check and replace if required

Fuel valve 8,000

- depending on fuel quality

Valve nozzle

'16,000

Spindle guide 16,000

Check and replace if required

Fuel oil pressure booster 32,000

- based on engine observations

64,000

Replace or recondition

Change piston rings on hydraulic pis-

ton and suction valve at overhaul.

Guiding Overhaul lntervals. Page 2 of 7 pages

Service Letter SL09-509/SBJ MAl,l Diesel

Cylinder cover 96,000 Check for burned grooves at fuel valve

nozzle holes. Weld-up if required, up

to 2-3 times during service life.

Starting valve 12,000 Engine lifetime

Cylinder lubricator 24,000 Engine lifetime Check timing and adjustment

Check clearances and crankshaft

deflection: once a year.

Check bearing edges by wire gauges:

once a year

Do not open bearings unless

bearing material fragments fall out or

other bearing inspection measures

indicate so,

Tie rods including

bracing screws

Tighten rods and screws:

once a year

Engine lifetime

Holding down bolts Tighten: once a year Engine lifetime

Turbocharger According to manufacturer's

recommendations.

According to manufacturer's

recommendations.

According to manufacturer's

recommendations.

Air coole(s) Cleaning:

based on engine observations

45,000

or according to manufacturer's rec-

ommendations.

Clean before differential pressure has

increased 50% compared to sea trial

value.

Flaps and butterfly

valves in scavenge air

recerver

Check movement at every

scavenge port inspection.

Engine lifetime

Various fuel and

lubricating oil filters

Cleaning:

based on engine observations

Lubricating oil bottom

tank

Cleaning: 32,000 Typically done at 5 years docking

Cha ns Retighten chains: 3,000-4,000

- every six months

96,000 New or overhauled chains to be

checked/retightened after 500, 1,500

hours.

Accumulators on

HPS and HCU

N2 pressure 3,000

Rubber membranes: 32,000

Engine lifetime Replace membranes after 5 years

Hydraulic hoses 32,000 Replace after 5 years

Angle encoder Visual inspection: 6,000 64,000 Replace if failing

Marker sensor Visual inspection: 6,000 64,000 Replace if failing

MPC, MOP A, MOP B Visual inspection: 6,000 64,000 Replace if failing

Cables Visual inspection: 6,000 96,000 Replace if failing

Guiding Overhaul lntervals. Page 3 of 7 pages

Service Letter SL09-509/SBJ MAN Diesel

Cylinder liner Bore sizes

98-80 24,000

Bore sizes

98'90 80,000

80-6s 70,000

60-50 60,000

Check the overall cylinder condition

through the scavenge ports at least

once a month.

Bore sizes

70-50 16,000

Piston rings Bore sizes

98-80 24,000

Bore sizes

98-80 24,000

Bore sizes

70-50 16,000

Bore sizes

70-50 16,000

Piston crown Bore sizes

98-90 24,000

Bore sizes

98-90 80,000

80-65 70,000

60-50 60,000

Pressure test at every 2nd piston

overhaul, recondition/rechrome when

required (typically euery 24-32,000

hours). Fiston crown can be recondi-

tioned by welding-up twice.

Bore sizes

70-50

'16,000

Stuffing box Bore sizes

98-80 24,000

70-50 16,000

Check lamellas

32,000

32,000

Renew lamellas

Exhaust valve spindle

and bottom piece (cage)

lnspection of seat and air spring:

Bore sizes

98-50

First inspection 1) 6,000

Bore sizes

98-50

Subsequent inspections 2) 32,000

Bore sizes

98-60

Nimonic exhaust valve 100,000

To be obtained for Nimonic valve with

reconditioning of seat and possible

re-welding of disk underside

Normally, HVOF coated stems need

no reconditioning.

Usually only light grinding of seats is

required at subsequent inspections,

1) Condition check

lnspection of air spring according

to instruction manual. Two or three

valves to be inspected.

2) Subseq. lnspection

Condition check + possible complete

overhaul. Max burn off rate of spindle

disc underside to be estimated and

calculated for lifetime of spindle.

All valves to be inspected.

Main hydraulic pump

32,000 Engine lifetime Check and replace hydrostatic bear-

ings at overhaul. Cheek and replace

cylinder set and piston if required,

Proportional valve for

main hydraulic pump

20 000 Replace valve after 20,000 hours

Pressure relief valve for

main hydraulic pumps

40,000 Engine lifetime Replace sealings at overhaul

Exhaust valve actuator 32,000 Engine lifetime Replace static sealing rings at over-

haul.

FIVA valve 32,000 64,000 Check and replace if required

Fuel valve 8,000

- depending on fuel quality

Valve nozzle 16,000

Spindle guide 16,000

Check and replace if required

Fuel oil pressure booster 32,000

- based on engine observations

64,000

Replace or recondition

Change piston rings on hydraulic pis-

ton and suction valve at overhaul,

Guiding Overhaul lntervals. Page 4 of 7 pages

Service Letter SL09-509/SBJ MAI{ DieseI

Cylinder cover 96,000 Check for burned grooves at fuel valve

nozzle holes, Weld-up if required, up

to 2-3 times during service life.

12,000 Engine lifetime

Cylinder lubricator 24 000 Engine lifetime Check timing and adjustment

Check clearances and crankshaft

deflection: once a year.

Check bearing edges by wire gauges:

once a

year

64,000

96,000

96,000

96,000

Do not open bearings unless

bearing material fragments fall out or

other bearing inspection measures

indicate so.

Tie rods including

bracing screws

Tighten rods and screws:

once a year

Engine lifetime

Holding down bolts Tighten: once a

year Engine lifetime

Turbocharger According to manufacturer's

recommendations.

According to manufacturer's

recommendations.

According to manufacturer's

recommendations.

Air coole(s) Cleaning:

based on engine observations

45,000

or according to manufacturefs rec-

ommendations

Clean before differential pressure has

increased 50% compared to sea trial

value.

Flaps and butterfly

valves in scavenge air

recetver

Check movement at every

scavenge port inspection

Engine lifetime

Various fuel and

lubricating oil filters

Cleaning:

based on engine observations

Lubricating oil bottom

tank

Cleaning: 32,000 Typically done at 5 years docking

Chains Retighten chains: 3,000-4,000

- every six months

96,000 New or overhauled chains to be

checked/retightened after 500, 1,500

hours.

Gear wheel drive for

hydraulic pumps

First inspection: 500

Subsequent inspections: 6,000

Gear wheel: Engine lifetime

Gear wheel bearings: 96,000

Accumulators on

HPS and HCU

N2 pressure: 3,000

Rubber membranes: 32,000

Engine lifetime Replace membranes after 5 years

Hydraulic hoses 32,000 Replace after 5 years

MPC, MOP A, MOP B Visual inspection: 6,000 64,000 Replace if failing

CCU and ACU amplifiers Visual inspection: 6,000 64,000 Replace if failing

Visual inspection: 6,000 64,000 Replace if failing

Fuel booster sensor Visual inspection: 6,000 64,000 Replace if failing

Exhaust valve sensor Visual inspection: 6,000 Replace if failing

Angle encoder Visual inspection: 6,000 64,000 Replace if failing

Visual inspection: 6,000 64,000 Replace if failing

Cables Visual inspection: 6,000 96,000

Guiding Overhaul lntervals. Page 5 of 7 pages

Service Letter SL09-509/SBJ MAN Diesel

Cylinder liner Bore sizes

98-50 16,000

46-26 12,000

Bore sizes

98-90 80,000

80-70 70,000

60-50 60,000

46-35 50,000

26 40,000

Check the overall cylinder condition

through the scavenge ports at least

once a month.

Piston rings Bore sizes

98-50 16,000

46-26 12,000

Bore sizes

98-50 16,000

46-26 12,000

Piston crown Bore sizes

98-50 16,000

46-26 12,000

Bore sizes

98-90 80,000

80-70 70,000

60-50 60,000

46-35 50,000

26 40,000

Pressure test at every 2nd piston

overhaul, recondition/rechrome when

required (typically every 24-32,000

hours). Piston crown can be recondi-

tioned by welding-up twice.

Stuffing box Bore sizes

98-50 16,000

46-26 12,000

Check lamellas

Bore sizes

98-50 32,000

46-26 24,000

Renew lamellas

Exhaust valve spindle

and bottom piece (cage)

lnspection of seat and air spring:

Bore sizes

98-35

First inspection 1) 6,000

Bore sizes

50-35

Subsequent inspections 2) 16,000

Bore sizes

98-60

Subsequent inspections 2) 32,000

Bore sizes

50-35

DuraSpindle exhaust valve 50,000

Bore size

60

DuraSpindle or

Nimonic exhaust valve 100,000

To be obtained for DuraSpindle and

Nimonic valve with reconditioning of

seat and possible re-welding of disk

underside.

Normally, HVOF coated stems need

no reconditioning.

Usually only light grinding of seats is

required at subsequent inspections.

1) Condition check

lnspection of air spring according

to instruction manual. Two or three

valves to be inspected.

2) Subsequent inspection

Condition check + possible complete

overhaul. Max burn off rate of spindle

disc underside to be estimated and

calculated for lifetime of spindle. All

valves to be inspected.

Actuator gear Hydraulic system 32,000 64,000

Fuel valve 8,000

- depending on fuel quality

Valve nozzle 16,000

Spindle guide 16,000

Check and replace if required

Fuel pump plunger and

barrel, suction valve,

puncture valve and

shock absorber

16,000

- based on engine observations

8,000

For suction valve and puncture valve

Renew or recondition: 40,000 Change sealing rings on barrel,

plunger, puncture valve and suction

valve.

Cylinder cover 96,000 Check for burned grooves at fuel valve

nozzle holes. Weld-up if required, up

to 2-3 times during service life.

Starting valve, safety

valve and indicator cock

12,000 Engine lifetime

Guiding Overhaul lntervals. Page 6 of 7 pages

Service Letter SL09-509/SBJ MAltl Diesel

Alpha Lubricator ChecURefillaccumulators 8,000

0verhaul lubricators 32,000

Engine lifetime

Crosshead bearings

Main bearings

Crank bearings

Thrust bearings

Check clearances and crankshaft

deflection: once a year.

Check bearing edges by wire gauges:

once a year

64,000

96,000

96,000

96,000

Do not open bearings unless

bearing material fragments fall out or

other bearing inspection measures

indicate so.

Roller guide for fuel

pump and exhaust valve

Check condition in situ:

'1,500

Engine lifetime Check running surfaces and free ro-

tation of roller.

Chains Tighten chains: 3,000-4,000

- every six months

96,000 New or overhauled chains to be

checked/retightened after 500, 1,500

hours.

Chain wheels and rub-

ber guide bars

Visual inspection: 3,000-4,000 Chain wheels: 96,000

Guide bars: 32,000

First inspections and retightenings

after 500, 1,000 and 1,500 hours in

total service.

Reversing and regulat-

ing gear

Check moving parts:

3,000-4,000

Engine lifetime Pneumatic/hydraulic governor:

0il change every 4,000 hours.

Tie rods including brac-

rng screws

Tighten rods and screws:

once a year

Engine lifetime

Holding down bolts Tighten: once a year Engine lifetime

Turbocharger According to manufacturer's

recommendations.

According to manufacturer's

recommendations.

According to manufacturer's

recommendations.

Air coole(s) Cleaning:

based on engine observations

45,000 Clean before differential pressure

has increased 5070 compared to sea

trial value,

Flaps and butterfly

valves in scavenge air

recerver

Check movement at every scavenge

port inspection.

Engine lifetime.

Various fuel and lubri-

cating oil filters.

Camshaft filters and

TCS filters, if any

Cleaning:

based on engine observations

Lubricating oil boom

tank

Cleaning; 32,000 Typically done at 5 years docking

Guiding Overhaul lntervals. PageT of 7 pages

Вам также может понравиться

- SL2017-643SRJ-Guiding Overhaul Intervals 2017Документ13 страницSL2017-643SRJ-Guiding Overhaul Intervals 2017pavlo_790317697Оценок пока нет

- Service Details Man BW PDFДокумент7 страницService Details Man BW PDFTapas ChaudhuriОценок пока нет

- Slide Fuel ValvesДокумент2 страницыSlide Fuel ValvesSpasoje100% (1)

- MAN B&W Diesel A/S: Service LetterДокумент5 страницMAN B&W Diesel A/S: Service LetterParthiban NagarajanОценок пока нет

- SN183Документ18 страницSN183papaki2Оценок пока нет

- GRS - Group Recess Surface - Cylinder LinerДокумент6 страницGRS - Group Recess Surface - Cylinder Linerg arvОценок пока нет

- Gas Tight Lock Piston RingДокумент2 страницыGas Tight Lock Piston RingArun SОценок пока нет

- Techno News: Introduction of Safety Screen Filter For Control Valve With FIVA / ELFI / ELVAДокумент6 страницTechno News: Introduction of Safety Screen Filter For Control Valve With FIVA / ELFI / ELVASrivatsanОценок пока нет

- Main EngineДокумент10 страницMain EngineFe CaprichoОценок пока нет

- Service Letter SL2019-673/PRP: Accumulators All Makes, Brands and Types in The Hydraulic SystemДокумент6 страницService Letter SL2019-673/PRP: Accumulators All Makes, Brands and Types in The Hydraulic Systembhaswath2000Оценок пока нет

- 2-Stroke Table of Content Temp PDFДокумент11 страниц2-Stroke Table of Content Temp PDFlavkesh100% (1)

- MAN Tech Paper Low SpeedДокумент16 страницMAN Tech Paper Low SpeedfusedОценок пока нет

- MAN B&W Diesel A/S: Licence LetterДокумент3 страницыMAN B&W Diesel A/S: Licence Letterbhaswath2000Оценок пока нет

- Electronic Marine Engine VibrationДокумент1 страницаElectronic Marine Engine Vibrationvran77Оценок пока нет

- Service Letter SL2020-698/KAMO: CPR Piston Ring PackДокумент4 страницыService Letter SL2020-698/KAMO: CPR Piston Ring PackPrinceSadhotraОценок пока нет

- ME Cyloil DosingДокумент8 страницME Cyloil DosingLucian Iftemie100% (1)

- SL96-339 B&W Service LetterДокумент5 страницSL96-339 B&W Service LetterkamalОценок пока нет

- Cylinder Liner Cold Corrosion ControlДокумент8 страницCylinder Liner Cold Corrosion ControlarunОценок пока нет

- Instruction of Adjustment For Tacho System: 2016.03.10 Diesel Engine DepartmentДокумент8 страницInstruction of Adjustment For Tacho System: 2016.03.10 Diesel Engine DepartmentDurgesh k singhОценок пока нет

- Typical Wear Mechanism 2 Stroke Exhaust ValvesДокумент5 страницTypical Wear Mechanism 2 Stroke Exhaust ValvesdragoscodОценок пока нет

- SL2016 632AAB Alpha LubricatorДокумент3 страницыSL2016 632AAB Alpha Lubricatorpavlo_790317697Оценок пока нет

- Service Note: Guidance For Cylinder Oil ConsumptionДокумент16 страницService Note: Guidance For Cylinder Oil ConsumptionNeofytosОценок пока нет

- SL00 383Документ5 страницSL00 383bekavacsОценок пока нет

- MC EnginesДокумент12 страницMC EnginesHarpreet Singh100% (1)

- MSC Carina Delivery 6 June 2013: Main Engine MAN 6S60ME-C 8.1 AuxiliariesДокумент10 страницMSC Carina Delivery 6 June 2013: Main Engine MAN 6S60ME-C 8.1 AuxiliariesПетрОценок пока нет

- 07-013E Cylinder Gauge For Use With RH Turbocharger A PDFДокумент2 страницы07-013E Cylinder Gauge For Use With RH Turbocharger A PDFrpichoОценок пока нет

- Operational Evaluation of Piston Ring WearДокумент10 страницOperational Evaluation of Piston Ring WearDarmawan PutrantoОценок пока нет

- Dimensi MesinДокумент28 страницDimensi MesinSyahrir QoimОценок пока нет

- SL2017-650 - Guiding Overhaul IntervalsДокумент14 страницSL2017-650 - Guiding Overhaul IntervalsajeshkrishnanОценок пока нет

- The Turnomat Valve RotatorДокумент5 страницThe Turnomat Valve RotatorBharatiyulam100% (1)

- Cylinder LubricationДокумент8 страницCylinder LubricationVinay Kumar Neelam100% (1)

- Man B&W SL2007-479Документ7 страницMan B&W SL2007-479Charalampos BarОценок пока нет

- GG 05 09 2012 200 PDFДокумент4 страницыGG 05 09 2012 200 PDFpapaki2100% (1)

- Reduction Gearbox 1500 AGSC KPДокумент1 страницаReduction Gearbox 1500 AGSC KPΣπύρος ΛελούδαςОценок пока нет

- Coupling 17.6Документ102 страницыCoupling 17.6Carlos MohanОценок пока нет

- Service Note 179 Mitsui MAN B&WДокумент6 страницService Note 179 Mitsui MAN B&WИгорьОценок пока нет

- SL98 356 B W Service Letter PDFДокумент14 страницSL98 356 B W Service Letter PDFKamlakarPatwariОценок пока нет

- Ter396 Vol.1Документ518 страницTer396 Vol.1CM ChenОценок пока нет

- ALPHA Commissioning ManualДокумент43 страницыALPHA Commissioning Manualgmegoulis_772534693100% (1)

- LDCL Cooling MANДокумент69 страницLDCL Cooling MANJoseph AbrahamОценок пока нет

- Nomogram For Determination of CCAI: Description Page 1 (2) Edition 02Документ2 страницыNomogram For Determination of CCAI: Description Page 1 (2) Edition 02Atanasio PerezОценок пока нет

- MAN-PMI Off PDFДокумент92 страницыMAN-PMI Off PDFarunОценок пока нет

- Fuel Injection Valve Condition: Service Letter SL2016-628/KELДокумент4 страницыFuel Injection Valve Condition: Service Letter SL2016-628/KELVitalii KorolОценок пока нет

- RT Flex 05Документ12 страницRT Flex 05George Domusciu100% (1)

- SL2020-692 LDCL Update PDFДокумент7 страницSL2020-692 LDCL Update PDFg arvОценок пока нет

- Man B&W WarningДокумент284 страницыMan B&W WarningMarcin SrokaОценок пока нет

- 0743674-2 6 PDFДокумент11 страниц0743674-2 6 PDFAlexandru AlexОценок пока нет

- RT FlexДокумент3 страницыRT FlexGaby CrisОценок пока нет

- 2 Stroke Diesel Engine Components-1Документ72 страницы2 Stroke Diesel Engine Components-1EdemОценок пока нет

- Gioi Thieu Dong Co MANBW ME-CДокумент26 страницGioi Thieu Dong Co MANBW ME-CMitdac HP0% (1)

- MT VICTORY Report On Decarbonization of Auxiliary EnginesДокумент3 страницыMT VICTORY Report On Decarbonization of Auxiliary Engineskailash behera100% (1)

- Int Eng Prospects MAN BWДокумент19 страницInt Eng Prospects MAN BWWsm HNОценок пока нет

- Guiding Overhaul Intervals: Service Letter SL09-509/SBJДокумент7 страницGuiding Overhaul Intervals: Service Letter SL09-509/SBJajeshkrishnanОценок пока нет

- DG Maintenance Work List and Maintenance Track Record:-Ht DG Name Plate DetailsДокумент11 страницDG Maintenance Work List and Maintenance Track Record:-Ht DG Name Plate DetailsMugeshОценок пока нет

- LandRover Discovery Service SheetДокумент2 страницыLandRover Discovery Service Sheetmichkapp0% (1)

- General Information: (BK00050 (ALL) 08/95)Документ33 страницыGeneral Information: (BK00050 (ALL) 08/95)Ebied Yousif AlyОценок пока нет

- Maintenance and Electric ChartДокумент9 страницMaintenance and Electric Chartakamalapuri388100% (1)

- Vehicle Maintenance Sheet: 2.9 Litre, 3.6 Litre and 4.0 Litre SALOONSДокумент2 страницыVehicle Maintenance Sheet: 2.9 Litre, 3.6 Litre and 4.0 Litre SALOONSgordoninklОценок пока нет

- Man B&W Serv LTR Sl09-510-Sb-jДокумент43 страницыMan B&W Serv LTR Sl09-510-Sb-jafsal999Оценок пока нет

- Graco PumpДокумент20 страницGraco Pumpafsal999Оценок пока нет

- Hatch Cover Types and InspectionДокумент21 страницаHatch Cover Types and Inspectionafsal999100% (9)

- Man B&W Serv LTR Sl09-509-Sb-jДокумент7 страницMan B&W Serv LTR Sl09-509-Sb-jafsal999Оценок пока нет

- Man B&W Serv LTR Sl09-511-MtsДокумент7 страницMan B&W Serv LTR Sl09-511-Mtsafsal999Оценок пока нет

- Man B&W Serv LTR Sl09-511-MtsДокумент7 страницMan B&W Serv LTR Sl09-511-Mtsafsal999Оценок пока нет

- Dynamic Optimization of Reaction Less Four-Bar LinkagesДокумент11 страницDynamic Optimization of Reaction Less Four-Bar Linkagesafsal999Оценок пока нет

- Refrigerant Charging ProcedureДокумент3 страницыRefrigerant Charging ProcedureRiyas UdheenОценок пока нет

- Troubleshooting Electronic CirДокумент50 страницTroubleshooting Electronic Cirafsal999Оценок пока нет

- Variable Sensitivity-Based Deter Minis Tic Robust Design For Nonlinear SystemДокумент7 страницVariable Sensitivity-Based Deter Minis Tic Robust Design For Nonlinear Systemafsal999Оценок пока нет

- Variable Sensitivity-Based Deter Minis Tic Robust Design For Nonlinear SystemДокумент7 страницVariable Sensitivity-Based Deter Minis Tic Robust Design For Nonlinear Systemafsal999Оценок пока нет

- Improving The Performance of Two Strokes EnginesДокумент6 страницImproving The Performance of Two Strokes EnginespistonbreakerОценок пока нет

- PALRUF 100 Technical Guide (En)Документ6 страницPALRUF 100 Technical Guide (En)mohammed nafethОценок пока нет

- Chapter ThreeДокумент29 страницChapter ThreeAbel OmweriОценок пока нет

- Windows 10 Volume Licensing GuideДокумент19 страницWindows 10 Volume Licensing GuideVijayОценок пока нет

- 7-Strengthening Mechanisms - SlidesДокумент74 страницы7-Strengthening Mechanisms - SlidesRyan TorresОценок пока нет

- Syllabus Compendium For PCN Aerospace Sector ExaminationsДокумент27 страницSyllabus Compendium For PCN Aerospace Sector ExaminationstomcanОценок пока нет

- RSAFRAMEДокумент2 страницыRSAFRAMETIOCA01Оценок пока нет

- 11 - Hashing PDFДокумент24 страницы11 - Hashing PDFKealeboga Duece ThoboloОценок пока нет

- JSA Basket TransferДокумент3 страницыJSA Basket TransferCristina Rican100% (1)

- AXE400P User Manual With Centos6.0 Dahdi V2.0 D130603 enДокумент12 страницAXE400P User Manual With Centos6.0 Dahdi V2.0 D130603 enCartimex S.A.Оценок пока нет

- Datasheet: G185XW01V2Документ33 страницыDatasheet: G185XW01V2فؤاد عشيشОценок пока нет

- Pvu-L0880er GaДокумент1 страницаPvu-L0880er GaarunghandwalОценок пока нет

- 03 Vetotouch Europa - Group 170821Документ2 страницы03 Vetotouch Europa - Group 170821HalaОценок пока нет

- 4.0L EngineДокумент347 страниц4.0L EngineCapssa Oscar100% (2)

- Honpe CatalogueДокумент23 страницыHonpe CatalogueGrupo XDSОценок пока нет

- Sin EncoderДокумент6 страницSin Encoderboynew87Оценок пока нет

- Project Management Dashboard TemplateДокумент10 страницProject Management Dashboard Templateindra prasetyaОценок пока нет

- Presentation 1Документ8 страницPresentation 1JACKMAAAAОценок пока нет

- MT6603 DMS Unt 3 PDFДокумент39 страницMT6603 DMS Unt 3 PDFKarthi KeyanОценок пока нет

- Silo Culture at SonyДокумент2 страницыSilo Culture at Sonydasarup24123Оценок пока нет

- ML10 OwnersManualДокумент16 страницML10 OwnersManualSalvador OlivasОценок пока нет

- Agri Brochure PDFДокумент20 страницAgri Brochure PDFMichaelОценок пока нет

- Optis - Ow - LM - Ug - 2014 SP1 PDFДокумент251 страницаOptis - Ow - LM - Ug - 2014 SP1 PDFRaghavОценок пока нет

- Armor Piercing Bullets With Sintered Carbide Cores PDFДокумент137 страницArmor Piercing Bullets With Sintered Carbide Cores PDFfogdartОценок пока нет

- Recovery of Spent CatalystДокумент4 страницыRecovery of Spent CatalystUtsav PatelОценок пока нет

- Analysis and Design of Gravity Retaining Structures PDFДокумент37 страницAnalysis and Design of Gravity Retaining Structures PDFChin Tiong LeeОценок пока нет

- Cs Acrovyn CatalogueДокумент83 страницыCs Acrovyn CatalogueBoboc AndreiОценок пока нет

- Bioreactor Design: Mata Kuliah: Pengantar Teknologi BioprosesДокумент33 страницыBioreactor Design: Mata Kuliah: Pengantar Teknologi BioprosesyassinharanОценок пока нет

- Isolation Selector GuideДокумент12 страницIsolation Selector GuidesandeepbhallaОценок пока нет

- Automatic Room Light Controller With Visitor Counter-1Документ2 страницыAutomatic Room Light Controller With Visitor Counter-1Amitosh MishraОценок пока нет