Академический Документы

Профессиональный Документы

Культура Документы

Tensioning: Home Printer-Friendly

Загружено:

Bhupender RamchandaniОригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Tensioning: Home Printer-Friendly

Загружено:

Bhupender RamchandaniАвторское право:

Доступные форматы

4/23/2014 Tensioning

http://www.enerpac.com/en/print/10315 1/3

Published on Enerpac (http://www.enerpac.com)

Home > Pri nter-fri endl y

Tensioning

What is Bolt Tensioning

Tensioning is the direct axial stretching of the bolt to achieve preload. Inaccuracies created through

friction are eliminated. Massive mechanical effort to create torque is replaced with simple hydraulic

pressure. A uniform load can be applied by tensioning multiple studs simultaneously.

Tensioning requires longer bolts, and a seating area on the assembly around the nut. Tensioning

can be done using detachable Bolt Tensioners or Hydraulic Nuts.

* Preload (residual load) = Applied Load minus Load Losses *

What is Load Loss

Load loss is a loss of bolt elongation depending on factors such as thread deflections, radial

expansion of the nut, and embedding of the nut into the contact area of the joint. Load loss is

accounted for in calculation and is added to the preload value to determine the initial Applied

Load.

The preload depends on Applied Load and Load Loss (load loss factor).

Manufacturer's rating of pressure and load are maximum safe limits. Good practice

encourages using only 80% of these ratings!

Tensioning Operation

Tensioning permits the simultaneous tightening of multiple bolts; the tools are connected in

sequence via a high-pressure hose assembly to a single pump unit. This ensures each tool

develops the exact same load and provides a uniform clamping force across the joint. This is

especially important for pressure containing vessels requiring even gasket compression to affect a

seal.

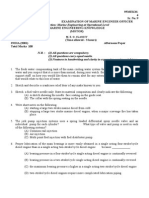

General Procedure

Step 1: The bolt tensioner is fitted over the stud

Step 2: Hydraulic pressure is applied to the tensioner which then stretches the stud

Step 3: The stud's nut is wound down against the joint face

Step 4: Pressure is released and the tool removed

The bolt behaves like a spring, when the pressure is released the bolt is under tension and attempts

to contract, creating the required clamping force across the joint.

4/23/2014 Tensioning

http://www.enerpac.com/en/print/10315 2/3

Less than 100% Tensioning

Not all applications allow for the simultaneous fit of a tensioning device on each bolt, in these cases

at least two tensioning pressures are applied. This is to account for a load loss in those bolts

already tensioned as the next sets are tightened. The load losses are accounted for in calculation

and a higher load is applied to allow the first sets to relax back to the target preload.

Set-up using a 100% tensioning procedure

All bolts are tensioned simultaneously.

Set-up using a 50% tensioning procedure

Half the bolts are tensioned simultaneously, the tools are relocated on the remaining bolts and they

are subsequently tensioned.

2014 ENERPAC. All rights reserved.

4/23/2014 Tensioning

http://www.enerpac.com/en/print/10315 3/3

Source URL: http://www.enerpac.com/en/tensioning

Вам также может понравиться

- Ship security levels and duties guideДокумент10 страницShip security levels and duties guideBhupender RamchandaniОценок пока нет

- P 57Документ7 страницP 57Bhupender RamchandaniОценок пока нет

- Marine Engineering Study Materials: Videocon d2h HD OfferДокумент6 страницMarine Engineering Study Materials: Videocon d2h HD OfferBhupender RamchandaniОценок пока нет

- Marine Engineering Study Materials: Videocon d2h HD OfferДокумент7 страницMarine Engineering Study Materials: Videocon d2h HD OfferBhupender RamchandaniОценок пока нет

- 95MEKM-4 Marine Engineer Officer Exam QuestionsДокумент3 страницы95MEKM-4 Marine Engineer Officer Exam QuestionsBhupender RamchandaniОценок пока нет

- 95MEP-4 Exam of Marine Engineer Officer Maintenance & RepairДокумент2 страницы95MEP-4 Exam of Marine Engineer Officer Maintenance & RepairBhupender RamchandaniОценок пока нет

- Marine engineering exam questionsДокумент3 страницыMarine engineering exam questionsBhupender RamchandaniОценок пока нет

- Marine Engineering Study Materials: EFC InternationalДокумент5 страницMarine Engineering Study Materials: EFC InternationalBhupender RamchandaniОценок пока нет

- Marine Engineering Study Materials: Wall Paints in HD ShadesДокумент7 страницMarine Engineering Study Materials: Wall Paints in HD ShadesBhupender RamchandaniОценок пока нет

- ArticrlДокумент9 страницArticrlBhupender RamchandaniОценок пока нет

- 95 MEKM4 SR No2Документ2 страницы95 MEKM4 SR No2Bhupender RamchandaniОценок пока нет

- Function: Marine Engineering at Operational LevelДокумент2 страницыFunction: Marine Engineering at Operational LevelBhupender RamchandaniОценок пока нет

- ArticlДокумент11 страницArticlBhupender RamchandaniОценок пока нет

- Function: Marine Engineering at Operational LevelДокумент2 страницыFunction: Marine Engineering at Operational LevelBhupender RamchandaniОценок пока нет

- Function: Marine Engineering at Operational LevelДокумент2 страницыFunction: Marine Engineering at Operational LevelBhupender RamchandaniОценок пока нет

- 95 MEKM4 SR No5Документ3 страницы95 MEKM4 SR No5Bhupender RamchandaniОценок пока нет

- 95 MEKM4 SR No4Документ3 страницы95 MEKM4 SR No4Bhupender RamchandaniОценок пока нет

- Function: Marine Engineering at Operational LevelДокумент3 страницыFunction: Marine Engineering at Operational LevelBhupender RamchandaniОценок пока нет

- 95 MEKM4 SR No5Документ3 страницы95 MEKM4 SR No5Bhupender RamchandaniОценок пока нет

- Marine Engineer Exam QuestionsДокумент4 страницыMarine Engineer Exam QuestionsBhupender RamchandaniОценок пока нет

- 95 MEKM SR No.3Документ3 страницы95 MEKM SR No.3Bhupender RamchandaniОценок пока нет

- 95 MEKM4 SR No.7Документ3 страницы95 MEKM4 SR No.7Bhupender RamchandaniОценок пока нет

- 95MEKM4 SrNo10Документ3 страницы95MEKM4 SrNo10Bhupender RamchandaniОценок пока нет

- Marine engineering exam questionsДокумент3 страницыMarine engineering exam questionsBhupender RamchandaniОценок пока нет

- 95MEKM4 SrNo6Документ3 страницы95MEKM4 SrNo6Bhupender RamchandaniОценок пока нет

- 95MEKM4 SrNo8Документ3 страницы95MEKM4 SrNo8Bhupender RamchandaniОценок пока нет

- Examination of Marine Engineer Officer - MotorДокумент3 страницыExamination of Marine Engineer Officer - MotorBhupender RamchandaniОценок пока нет

- Marine Engineer Exam QuestionsДокумент4 страницыMarine Engineer Exam QuestionsBhupender RamchandaniОценок пока нет

- Function: Marine Engineering at Operational LevelДокумент3 страницыFunction: Marine Engineering at Operational LevelBhupender RamchandaniОценок пока нет

- 95MEKM4 SrNo2Документ3 страницы95MEKM4 SrNo2Bhupender RamchandaniОценок пока нет

- Never Split the Difference: Negotiating As If Your Life Depended On ItОт EverandNever Split the Difference: Negotiating As If Your Life Depended On ItРейтинг: 4.5 из 5 звезд4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureОт EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureРейтинг: 4.5 из 5 звезд4.5/5 (474)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeОт EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeРейтинг: 4 из 5 звезд4/5 (5782)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceОт EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceРейтинг: 4 из 5 звезд4/5 (890)

- The Yellow House: A Memoir (2019 National Book Award Winner)От EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Рейтинг: 4 из 5 звезд4/5 (98)

- The Little Book of Hygge: Danish Secrets to Happy LivingОт EverandThe Little Book of Hygge: Danish Secrets to Happy LivingРейтинг: 3.5 из 5 звезд3.5/5 (399)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryОт EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryРейтинг: 3.5 из 5 звезд3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnОт EverandTeam of Rivals: The Political Genius of Abraham LincolnРейтинг: 4.5 из 5 звезд4.5/5 (234)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaОт EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaРейтинг: 4.5 из 5 звезд4.5/5 (265)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersОт EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersРейтинг: 4.5 из 5 звезд4.5/5 (344)

- The Emperor of All Maladies: A Biography of CancerОт EverandThe Emperor of All Maladies: A Biography of CancerРейтинг: 4.5 из 5 звезд4.5/5 (271)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyОт EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyРейтинг: 3.5 из 5 звезд3.5/5 (2219)

- The Unwinding: An Inner History of the New AmericaОт EverandThe Unwinding: An Inner History of the New AmericaРейтинг: 4 из 5 звезд4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreОт EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreРейтинг: 4 из 5 звезд4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)От EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Рейтинг: 4.5 из 5 звезд4.5/5 (119)

- GENERATORS SPECIFICATIONSДокумент2 страницыGENERATORS SPECIFICATIONSefmartin21Оценок пока нет

- Leverage Air CompressorДокумент9 страницLeverage Air CompressorJanice WilliamsОценок пока нет

- Lapomatic: Paper Tape DispenserДокумент2 страницыLapomatic: Paper Tape Dispenserapi-516941116Оценок пока нет

- Service Manual: Mb97 IdtvДокумент64 страницыService Manual: Mb97 IdtvAli Rawefi100% (1)

- Advanced Programming Methods of CNC Machine ToolsДокумент8 страницAdvanced Programming Methods of CNC Machine Toolsomar tahaОценок пока нет

- XC10002X4R12U 11894 DatasheetДокумент2 страницыXC10002X4R12U 11894 DatasheetSteve SimpsonОценок пока нет

- Airplane Engine Encyclopedia (En) Part 2Документ281 страницаAirplane Engine Encyclopedia (En) Part 2Bea100% (3)

- ESQUEMA REPAROS JANDS - Event - Plus - Esp2 - Espii EVENT-EVENT PLUS ESP II - SMДокумент62 страницыESQUEMA REPAROS JANDS - Event - Plus - Esp2 - Espii EVENT-EVENT PLUS ESP II - SMpaulo3jord3oОценок пока нет

- Moeller Sasy 60iДокумент50 страницMoeller Sasy 60iOscar TorresОценок пока нет

- Karisma ManualДокумент23 страницыKarisma ManualNurrohman HestiyonoОценок пока нет

- Autoclave Harvey 5000Документ16 страницAutoclave Harvey 5000Cesar Alfonso Saldivar MontoyaОценок пока нет

- V-1100 Visible Spectrophotometer ManualДокумент15 страницV-1100 Visible Spectrophotometer ManualbashirОценок пока нет

- ASX 500 AutosamplerДокумент10 страницASX 500 AutosamplerCuong Ngo MinhОценок пока нет

- Eje/F: Chapter 28 - Fuel SystemДокумент46 страницEje/F: Chapter 28 - Fuel SystemJose danielОценок пока нет

- Bill of Quantity for Civil WorksДокумент16 страницBill of Quantity for Civil WorksHmОценок пока нет

- KA5L0565R: Fairchild Power Switch (FPS)Документ10 страницKA5L0565R: Fairchild Power Switch (FPS)miloud1911Оценок пока нет

- Drilling of 1 No Bore Well at SRS, NDRI, Adugodi, Bangalore. SH:-Pdg. Pump SetsДокумент5 страницDrilling of 1 No Bore Well at SRS, NDRI, Adugodi, Bangalore. SH:-Pdg. Pump SetsRatnakar SeethiniОценок пока нет

- Iq Plus 710 ManualДокумент84 страницыIq Plus 710 Manualluiscgh55Оценок пока нет

- Pressure Indicator Data SheetДокумент2 страницыPressure Indicator Data SheetnwabukingzОценок пока нет

- CEL Single Section Digital Axle Counter Installation GuideДокумент13 страницCEL Single Section Digital Axle Counter Installation Guidesuraj srivastavОценок пока нет

- BJT input-output characteristicsДокумент17 страницBJT input-output characteristicsRayan NezarОценок пока нет

- Fact Sheet Variable Inlet Guide Vane PDFДокумент1 страницаFact Sheet Variable Inlet Guide Vane PDFemadОценок пока нет

- AR68.20-P-4800GZ Remove/install Floor Covering in Rear 14.12.09 Model 164 (Floor Covering, 2nd Seat Row)Документ2 страницыAR68.20-P-4800GZ Remove/install Floor Covering in Rear 14.12.09 Model 164 (Floor Covering, 2nd Seat Row)KammoeОценок пока нет

- AT89C51Документ24 страницыAT89C51Kavin SengodanОценок пока нет

- Hardware AccessoriesДокумент2 страницыHardware Accessoriesliewqiying3354Оценок пока нет

- GVAV85 HVF85A Service ManualДокумент13 страницGVAV85 HVF85A Service ManualUEEОценок пока нет

- 735B and 740B Articulated Truck 740B Ejector Articulated TruckДокумент4 страницы735B and 740B Articulated Truck 740B Ejector Articulated Truckomar100% (2)

- Earth Compactor Daily Check ListДокумент2 страницыEarth Compactor Daily Check ListpjosesmОценок пока нет

- 16742028Документ64 страницы16742028ep915197Оценок пока нет

- The Appropriate Tool Used in Cutting Flexible Armored CableДокумент3 страницыThe Appropriate Tool Used in Cutting Flexible Armored CableJussa Leilady Alberba67% (6)