Академический Документы

Профессиональный Документы

Культура Документы

Seating The Propeller: Gland Seal

Загружено:

Bhupender Ramchandani0 оценок0% нашли этот документ полезным (0 голосов)

27 просмотров7 страницmarine

Оригинальное название

Seating

Авторское право

© © All Rights Reserved

Доступные форматы

DOC, PDF, TXT или читайте онлайн в Scribd

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документmarine

Авторское право:

© All Rights Reserved

Доступные форматы

Скачайте в формате DOC, PDF, TXT или читайте онлайн в Scribd

0 оценок0% нашли этот документ полезным (0 голосов)

27 просмотров7 страницSeating The Propeller: Gland Seal

Загружено:

Bhupender Ramchandanimarine

Авторское право:

© All Rights Reserved

Доступные форматы

Скачайте в формате DOC, PDF, TXT или читайте онлайн в Scribd

Вы находитесь на странице: 1из 7

Seating the Propeller

PREPARING FOR SEATING THE PROPELLER

Before installing and seating the propeller on the shaft, the condition of

the propeller shall be checked, the gland seal fit shall be checked, and

the shaft shall be protected from damage.

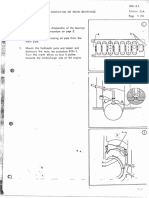

Gland Seal.

Check the fit of the gland seal onto the forward face of the propeller

hub. Install the gland seal, gland seal O-ring, studs, and nuts on the

forward face of the propeller hub while the propeller is still at the surface

to check their fit. Bench mark and then remove the gland seal with the

gland seal O-ring. Slide the gland seal and O-ring up the shaft to the

after face of the strut bearing.

Kes and Kewas. !uring propeller removal care should be taken to

monitor the kes. "he kes ma be loose in the shaft kewa and

remain in the propeller kewa or fall off. "o ensure a proper fit of kes

into kewas, measure and compare the width and depth of propeller

kewas to the width and height of the shaft kes. If necessar, shaft

kes ma be removed and machined down. #refer to figure $-%&

Immediatel prior to installing the replacement propeller, thoroughl

clean the entire shaft taper area to eliminate residual oils or

preservatives.

Occasionall new or refurbished read for issue propellers have gaps in

the gland seal O-ring seating surface where the kewas have been cut

into the propeller. If these gaps e'ist, the must be filled with weld

material and ground smooth to ensure a good seal around the entire

circumference of the propeller in accordance with the applicable

propeller drawing. ( )ualified welder trained to weld this material shall

perform this repair.

*(+,I,-

.ropeller blade edges are knifelike and ver sharp. "o prevent in/ur,

divers must wear gloves while inspecting propeller blades

Shaft Protection.

(fter protecting the threaded portion of the shaft from impact damage

#wrap with 0% thread&, place the propeller as far onto the shaft as the

rigging e)uipment will allow.

Pilgrim Nut Method.

"he .ilgrim nut is the preferred device for seating the propeller on the

shaft taper. "he original e)uipment manufacturer #O12& technical

manuals detail the installation and operation of .ilgrim nuts.

,O"1

"he water and air temperature shall be taken at the work site to ensure

the accurac of entries on the installation data form.

"o properl seat the propeller on the shaft taper, a specific advance

must be achieved. (dvance of the propeller is measured using a dial

indicator mounted. "he primar method #mounted to the shaft& is more

accurate and alwas preferred. "he secondar method #mounted to the

strut barrel& is onl to be used if the dial indicator will not fit between the

strut barrel and the propeller hub. "he re)uired advance is taken from

the ship3s propeller drawing.

*ith the .ilgrim nut properl in place, slowl pressuri4e it. +ecord and

plot .ilgrim nut pressure and dial indicator readings at 566 psi

increments. 1arl on in the plotting, the data points will tend to form a

straight line #slope&. *ith a loose seated propeller, the plot ma run off

the paper with considerable advance before an pressure is built up. If

this occurs, reset the dial indicator, tighten the pilgrim nut, and start over

with a fresh plot.

(fter about three data points have been obtained from this straight

portion of the plot, pro/ect a line back to the 4ero pressure a'is to

determine the initial seated position. "he actual propeller advance is

determined from the difference between the advance at the initial

seated position and the final advance achieved. #refer to figure $-7 8 $-

5&

Seating of the propeller and plotting of its advance shall continue until

the actual advance e)uals the re)uired advance determined earlier, to

within 9.665: -.666:. !esign slope #in psi versus advance& shall be

shown on the plot for comparison to actual measured data. !esign

slope curves are preplotted for selected ship classes. Because of the

lubrication effect of water, waterborne propeller advance curves ma be

slightl shallower then the design slopes which are based on drdock

installation. #refer to figure $-7 8 $-5&

If the plot does not continue in a smooth, straight line until the re)uired

advance is achieved, the propeller has caught on the shaft, shaft kes,

or propeller hub kewas, or there is insufficient contact between the

propeller hub and shaft taper. "he propeller shall be removed and the

specific problem corrected before the seating process can continue.

O12 .ilgrim nut technical manuals provide push-on pressure charts

that suppl estimates of the pressure which must be applied to the

.ilgrim nut in order to achieve the re)uired advance. "he pressure

estimates are based on the friction associated with drdock installation.

1'perience shows that waterborne installations will normall need less

pressure to achieve the re)uired advance because of the lubrication

effect of the water. ,ever seat a propeller using applied .ilgrim nut

pressure as the onl indicator of final seating achieved. +e)uired

advance must alwas be achieved.

CAUTION

"he propeller shaft shall be securel locked. Otherwise, the tor)ue

provided b the propeller nut wrench could be transmitted to the

reduction gears and cause considerable damage.

Propeller Nut Wrench Method.

If a .ilgrim nut cannot be located or provided in time for an emergent

/ob, the propeller nut wrench ma be used to seat the propeller on the

shaft taper. !etails on the propeller nut wrench method of installation

are provided. 1'perience has shown that the thrust bearing specified

should not be used because the propeller nut ma not catch sufficient

threads if the thrust bearing is installed. .ropeller advance tor)ue

values for selected ship classes are available. 1nsure that the shaft

locking device is engaged before attempting this seating method. "he

dial indicator must be mounted to the shaft. If the shaft moves based on

the high tor)ues re)uired, the advance measurement will not be

affected.

INSTALLING THE PRPELLER N!T

(fter the propeller is properl seated onto the shaft, install the propeller

nut flush with the after face of the propeller hub. If the locking ke will

not align with one of the holes in the hub, loosen the propeller nut /ust

enough to achieve alignment. !o not tighten the propeller nut. "he

friction between the propeller bore surface and the shaft taper is the

primar propeller holding force. ( balancing ke or kes must be

installed opposite the locking ke to balance weight on the shaft. "he

gland seal and gland seal O-ring must also be mounted to the forward

face of the propeller hub on the gland seal studs installed on the

surface. #refer to figure $-7&

Вам также может понравиться

- Lodge and Shipley Model A 12, 14, and 16 Inch Lathe ManualДокумент38 страницLodge and Shipley Model A 12, 14, and 16 Inch Lathe ManualJesse Anderson67% (3)

- 09 WA500-3 Shop ManualДокумент1 335 страниц09 WA500-3 Shop ManualCristhian Gutierrez Tamayo93% (14)

- Reed Prentice ManualДокумент25 страницReed Prentice ManualMikelyn Anderson100% (2)

- Multistage Pump RepairДокумент5 страницMultistage Pump RepairCheyanSathishОценок пока нет

- Welger RP12-15S BA - Eng2Документ50 страницWelger RP12-15S BA - Eng2Branko Mikulinjak50% (2)

- How To Mount and Operate Buck Adjust-Tru ChuckДокумент4 страницыHow To Mount and Operate Buck Adjust-Tru ChuckStronghold ArmoryОценок пока нет

- Alignment and Symmetry Check - Piper DakotaДокумент11 страницAlignment and Symmetry Check - Piper DakotaIlham GumelarОценок пока нет

- Viceversa Tarot PDF 5Документ1 страницаViceversa Tarot PDF 5Kimberly Hill100% (1)

- Fake PDFДокумент2 страницыFake PDFJessicaОценок пока нет

- Propeller Removal & Installation: Welded Rope Guard RemovalДокумент6 страницPropeller Removal & Installation: Welded Rope Guard RemovalBhupender RamchandaniОценок пока нет

- Propeller RemovalДокумент10 страницPropeller RemovalMedha Jog Katdare100% (1)

- Proclimb Procross Torsional Conversion KitДокумент8 страницProclimb Procross Torsional Conversion KitcpcracingОценок пока нет

- SUN Grate Height Adjustment 01-23-20 BTДокумент8 страницSUN Grate Height Adjustment 01-23-20 BTPablo Gasca RmzОценок пока нет

- Erection Procedure SCRДокумент23 страницыErection Procedure SCRvskreddy90% (10)

- Thomas Thomas Thomas Thomas: Type Cmr/AmrДокумент4 страницыThomas Thomas Thomas Thomas: Type Cmr/AmrGustavo Espinosa MartinezОценок пока нет

- g512 ManualДокумент20 страницg512 ManualValmac ServicesОценок пока нет

- 12-Mounting, Starting Up and Operating InstructionДокумент19 страниц12-Mounting, Starting Up and Operating InstructionGrisha Mari KosoyanОценок пока нет

- Erection & Installation ProcedureДокумент3 страницыErection & Installation ProcedureForos IscОценок пока нет

- Adjustable Pitch Propeller Taper-Lock HubДокумент2 страницыAdjustable Pitch Propeller Taper-Lock HubhaosfОценок пока нет

- 37 1 606Документ26 страниц37 1 606khalafОценок пока нет

- Wi QPC 008 Alignment ProcedureДокумент6 страницWi QPC 008 Alignment ProcedureBudimanОценок пока нет

- Procedure For Ship Propeller RenewalДокумент24 страницыProcedure For Ship Propeller RenewalJORGEОценок пока нет

- Rolling InstallnstructionsДокумент8 страницRolling InstallnstructionsANDIОценок пока нет

- Wood Prop Installation InstructionsДокумент4 страницыWood Prop Installation InstructionsskytypeОценок пока нет

- Compressor Overhaul3Документ7 страницCompressor Overhaul3mister pogiОценок пока нет

- Dfde EngineДокумент22 страницыDfde EngineARGONAFTISОценок пока нет

- Instruction Manual: For Intermediate To Advance Pilots OnlyДокумент20 страницInstruction Manual: For Intermediate To Advance Pilots OnlyBert BaradasОценок пока нет

- PropellerДокумент15 страницPropellerNavin Dipali100% (2)

- SPANCO FR WSB Instmaint Manual 103 0011 Rev06 11Документ24 страницыSPANCO FR WSB Instmaint Manual 103 0011 Rev06 11Eduardo OchaitaОценок пока нет

- S18 TextДокумент128 страницS18 TextAndy SetiawanОценок пока нет

- Rigging LevellingДокумент18 страницRigging LevellingmentariiОценок пока нет

- Manual Soldadura RidwellДокумент12 страницManual Soldadura RidwellPablo MazalanОценок пока нет

- Sensenich Ground Adjustable Propeller Log BookДокумент12 страницSensenich Ground Adjustable Propeller Log BookFaisОценок пока нет

- ASI Lab Record - StudentsДокумент24 страницыASI Lab Record - StudentsAVINASH SINGHОценок пока нет

- Max Prop 3 Blade Classic InstructionsДокумент12 страницMax Prop 3 Blade Classic InstructionsmruizОценок пока нет

- Reparación Inyectores DensoДокумент22 страницыReparación Inyectores DensoMarcoОценок пока нет

- Roatary Actuators - Micromatic Repair Manual - SS-0.2A & SS-0.5AДокумент7 страницRoatary Actuators - Micromatic Repair Manual - SS-0.2A & SS-0.5AtungОценок пока нет

- CVS Controls Series 470 Piston Actuators Sept 2014 PDFДокумент12 страницCVS Controls Series 470 Piston Actuators Sept 2014 PDFVIVIANA ESQUIVELОценок пока нет

- Install Guide Spunlite Poles 2015Документ6 страницInstall Guide Spunlite Poles 2015Balaji PalaniОценок пока нет

- Dmyi 000025Документ4 страницыDmyi 000025Sandeepa NimansithОценок пока нет

- Propeller Installation ProcedureДокумент2 страницыPropeller Installation Proceduredanilo laraОценок пока нет

- Dmyi 000060Документ2 страницыDmyi 000060mohammadfarsiinfoОценок пока нет

- Dodge Saf Pillow BlocksДокумент6 страницDodge Saf Pillow BlocksjvalkenburgОценок пока нет

- Bow Thruster Installation InstructionsДокумент9 страницBow Thruster Installation InstructionsRovert AlonzoОценок пока нет

- Repair Manual MP 1Документ11 страницRepair Manual MP 1Tiffany DacinoОценок пока нет

- Uputstvo Za Ventilator PDFДокумент7 страницUputstvo Za Ventilator PDFBrankoRadicevicОценок пока нет

- 2 Piece Threaded Steel Ball Valves Installation, Operation, & Maintenance GuideДокумент2 страницы2 Piece Threaded Steel Ball Valves Installation, Operation, & Maintenance GuideLucianОценок пока нет

- Challenger 24012 IOMДокумент19 страницChallenger 24012 IOMgmsapiensОценок пока нет

- BearingДокумент11 страницBearingThanh Luan NguyenОценок пока нет

- Reese SC Weight Distributing Hitch n66155Документ7 страницReese SC Weight Distributing Hitch n66155Bud HeberlingОценок пока нет

- Wood Propellers: Installation, Operation, & Maintenance Integral Flange CrankshaftsДокумент4 страницыWood Propellers: Installation, Operation, & Maintenance Integral Flange CrankshaftsPOUETОценок пока нет

- tw7591 UnlockedДокумент24 страницыtw7591 UnlockedCésar NoiratОценок пока нет

- Bell Housing To HSG TIRДокумент6 страницBell Housing To HSG TIRjitendrab83Оценок пока нет

- Blue Diamond Assembly Procedure 1593Документ2 страницыBlue Diamond Assembly Procedure 1593Stephen GerhauserОценок пока нет

- WWW 018999Документ39 страницWWW 018999Andhie OsloОценок пока нет

- Er 96 5 14Документ3 страницыEr 96 5 14DIEGO YECID MILLAN MENDOZAОценок пока нет

- WheelHorse Snow Thrower Completing Package Manual 6-9111Документ4 страницыWheelHorse Snow Thrower Completing Package Manual 6-9111Kevins Small Engine and Tractor ServiceОценок пока нет

- Kbu KBZ2Документ8 страницKbu KBZ2Andrew VОценок пока нет

- Main Bearing 'B & W'Документ5 страницMain Bearing 'B & W'aliakbar tavafiОценок пока нет

- Caja Reductora de EngranajeДокумент32 страницыCaja Reductora de EngranajeJesùs AmèsquitaОценок пока нет

- Lifting Plan V - 409 18ins Con ValДокумент9 страницLifting Plan V - 409 18ins Con ValAhmed Butt100% (1)

- Rotating Beam Fatigue Test MachineДокумент13 страницRotating Beam Fatigue Test MachineReОценок пока нет

- Plymouth and Chrysler-built cars Complete Owner's Handbook of Repair and MaintenanceОт EverandPlymouth and Chrysler-built cars Complete Owner's Handbook of Repair and MaintenanceОценок пока нет

- Marine Engineering Study Materials: Videocon d2h HD OfferДокумент6 страницMarine Engineering Study Materials: Videocon d2h HD OfferBhupender RamchandaniОценок пока нет

- Marine Engineering Study Materials: EFC InternationalДокумент5 страницMarine Engineering Study Materials: EFC InternationalBhupender RamchandaniОценок пока нет

- Isps CodeДокумент10 страницIsps CodeBhupender RamchandaniОценок пока нет

- Function: Marine Engineering at Operational LevelДокумент2 страницыFunction: Marine Engineering at Operational LevelBhupender RamchandaniОценок пока нет

- Function: Marine Engineering at Operational LevelДокумент3 страницыFunction: Marine Engineering at Operational LevelBhupender RamchandaniОценок пока нет

- Marine Engineering Study Materials: Videocon d2h HD OfferДокумент7 страницMarine Engineering Study Materials: Videocon d2h HD OfferBhupender RamchandaniОценок пока нет

- Marine Engineering Study Materials: Wall Paints in HD ShadesДокумент7 страницMarine Engineering Study Materials: Wall Paints in HD ShadesBhupender RamchandaniОценок пока нет

- Function: Marine Engineering at Operational LevelДокумент3 страницыFunction: Marine Engineering at Operational LevelBhupender RamchandaniОценок пока нет

- 95MEP 4 Sr. No. 1Документ2 страницы95MEP 4 Sr. No. 1Bhupender RamchandaniОценок пока нет

- 95 MEKM4 SR No4Документ3 страницы95 MEKM4 SR No4Bhupender RamchandaniОценок пока нет

- Mek 2001 Jan 95 SR - No.1Документ3 страницыMek 2001 Jan 95 SR - No.1Bhupender RamchandaniОценок пока нет

- Function: Marine Engineering at Operational LevelДокумент3 страницыFunction: Marine Engineering at Operational LevelBhupender RamchandaniОценок пока нет

- Function: Marine Engineering at Operational LevelДокумент2 страницыFunction: Marine Engineering at Operational LevelBhupender RamchandaniОценок пока нет

- Function: Marine Engineering at Operational LevelДокумент4 страницыFunction: Marine Engineering at Operational LevelBhupender RamchandaniОценок пока нет

- (Motor) (Time Allowed - 3 Hours) INDIA (2000) Afternoon Paper Total Marks 100Документ3 страницы(Motor) (Time Allowed - 3 Hours) INDIA (2000) Afternoon Paper Total Marks 100Bhupender RamchandaniОценок пока нет

- Mek 2000 March 95 SR - No.2Документ2 страницыMek 2000 March 95 SR - No.2Bhupender RamchandaniОценок пока нет

- Function: Marine Engineering at Operational LevelДокумент3 страницыFunction: Marine Engineering at Operational LevelBhupender RamchandaniОценок пока нет

- Function: Marine Engineering at Operational LevelДокумент3 страницыFunction: Marine Engineering at Operational LevelBhupender RamchandaniОценок пока нет

- 95SCS-4 Sr. No. 6 Examination of Marine Engineer OfficerДокумент3 страницы95SCS-4 Sr. No. 6 Examination of Marine Engineer OfficerBhupender RamchandaniОценок пока нет

- 95 Scs 4 Sr. No.5Документ3 страницы95 Scs 4 Sr. No.5Bhupender RamchandaniОценок пока нет

- 95SCS-4 Sr. No. 2 Examination of Marine Engineer OfficerДокумент4 страницы95SCS-4 Sr. No. 2 Examination of Marine Engineer OfficerBhupender RamchandaniОценок пока нет

- Mek 2000 April 95 SR - No.5Документ2 страницыMek 2000 April 95 SR - No.5Bhupender RamchandaniОценок пока нет

- Ship Construction & Stability (Time Allowed - 3 Hours) INDIA (2001) Afternoon Paper Total Marks 100Документ5 страницShip Construction & Stability (Time Allowed - 3 Hours) INDIA (2001) Afternoon Paper Total Marks 100Bhupender RamchandaniОценок пока нет

- 95 Scs 4 Sr. No. 9Документ4 страницы95 Scs 4 Sr. No. 9Bhupender RamchandaniОценок пока нет

- SME-Additional Matter As Per Latest Syllabus Implementation WorkshopДокумент14 страницSME-Additional Matter As Per Latest Syllabus Implementation WorkshopAvijeet BanerjeeОценок пока нет

- Catalog Celule Siemens 8DJHДокумент80 страницCatalog Celule Siemens 8DJHAlexandru HalauОценок пока нет

- General Diesel Engine Diagnostic Guide PDFДокумент3 страницыGeneral Diesel Engine Diagnostic Guide PDFan0th3r_0n3Оценок пока нет

- Accomplishment ReportДокумент1 страницаAccomplishment ReportMaria MiguelОценок пока нет

- Dry Canyon Artillery RangeДокумент133 страницыDry Canyon Artillery RangeCAP History LibraryОценок пока нет

- 2016 066 RC - LuelcoДокумент11 страниц2016 066 RC - LuelcoJoshua GatumbatoОценок пока нет

- Asphalt Plant Technical SpecificationsДокумент5 страницAsphalt Plant Technical SpecificationsEljoy AgsamosamОценок пока нет

- On CatiaДокумент42 страницыOn Catiahimanshuvermac3053100% (1)

- 2.1 Components and General Features of Financial Statements (3114AFE)Документ19 страниц2.1 Components and General Features of Financial Statements (3114AFE)WilsonОценок пока нет

- CANELA Learning Activity - NSPE Code of EthicsДокумент4 страницыCANELA Learning Activity - NSPE Code of EthicsChristian CanelaОценок пока нет

- Address MappingДокумент26 страницAddress MappingLokesh KumarОценок пока нет

- Use of EnglishДокумент4 страницыUse of EnglishBelén SalituriОценок пока нет

- SND Kod Dt2Документ12 страницSND Kod Dt2arturshenikОценок пока нет

- ADS 460 Management Principles and Practices: Topic 1: Introduction To ManagementДокумент33 страницыADS 460 Management Principles and Practices: Topic 1: Introduction To ManagementNURATIKAH BINTI ZAINOL100% (1)

- Aitt Feb 2017 TH Sem IIIДокумент6 страницAitt Feb 2017 TH Sem IIIMadhu KumarОценок пока нет

- Sky ChemicalsДокумент1 страницаSky ChemicalsfishОценок пока нет

- A320 Basic Edition Flight TutorialДокумент50 страницA320 Basic Edition Flight TutorialOrlando CuestaОценок пока нет

- IEC Blank ProformaДокумент10 страницIEC Blank ProformaVanshika JainОценок пока нет

- Sophia Program For Sustainable FuturesДокумент128 страницSophia Program For Sustainable FuturesfraspaОценок пока нет

- Cabling and Connection System PDFДокумент16 страницCabling and Connection System PDFLyndryl ProvidoОценок пока нет

- D - MMDA vs. Concerned Residents of Manila BayДокумент13 страницD - MMDA vs. Concerned Residents of Manila BayMia VinuyaОценок пока нет

- MDOF (Multi Degre of FreedomДокумент173 страницыMDOF (Multi Degre of FreedomRicky Ariyanto100% (1)

- Job Description For QAQC EngineerДокумент2 страницыJob Description For QAQC EngineerSafriza ZaidiОценок пока нет

- Departmental Costing and Cost Allocation: Costs-The Relationship Between Costs and The Department Being AnalyzedДокумент37 страницDepartmental Costing and Cost Allocation: Costs-The Relationship Between Costs and The Department Being AnalyzedGeorgina AlpertОценок пока нет

- Configuring Master Data Governance For Customer - SAP DocumentationДокумент17 страницConfiguring Master Data Governance For Customer - SAP DocumentationDenis BarrozoОценок пока нет

- Environmental Auditing For Building Construction: Energy and Air Pollution Indices For Building MaterialsДокумент8 страницEnvironmental Auditing For Building Construction: Energy and Air Pollution Indices For Building MaterialsAhmad Zubair Hj YahayaОценок пока нет

- BMA Recital Hall Booking FormДокумент2 страницыBMA Recital Hall Booking FormPaul Michael BakerОценок пока нет