Академический Документы

Профессиональный Документы

Культура Документы

Duct Testing

Загружено:

Asan IbrahimАвторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Duct Testing

Загружено:

Asan IbrahimАвторское право:

Доступные форматы

Duct Testing

TECH

BRIEF

WHY IS IT IMPORTANT?

Studies indicate that 10%-30% of the heated

or cooled air is lostalong with the money

spent to heat or cool that airthrough leaky

ducts. Properly sized, installed, and sealed

ductwork will make your heating and cooling

systems significantly more efficient. Energy

loss is not the only concern. Duct systems

can also involve the comfort of your family,

employees, tenants, or customers, as well as

your indoor air quality. Testing the ducts will

locate leaks or damage and focus repair work

in the right areas.

A properly operating heating, ventilation, and

air conditioning (HVAC) system will help

reduce overall energy useespecially during

hot summer days when air conditioners are

working harder and putting a strain on the

electric systemand will deliver greater

comfort and cleaner air to every room.

YOUR DUCT SYSTEM

In most residential and small commercial

central heating and cooling systems, the

conditioned (heated or cooled) air is delivered

to each room through supply ducts and

returned through the return duct to the furnace

or air conditioner. The condition of both

sections of this ductwork is vital to the overall

efficiency of your heating and cooling system.

What can go wrong? In some buildings,

air escapes through poorly connected,

disconnected, or deteriorated ducts, which

can result in little conditioned air actually

reaching your living or work space, leaving

the area too warm or too cold. If the return

duct system is leaky, it could be drawing in

outside, stale, or polluted air and distributing

it throughout the building; this air could come

from an attic, a crawl space, or combustion

air from a gas furnace, clothes dryer, stove,

or water heater. If the supply duct system

is leaking, the building can become

depressurized, and air from outside may be

drawn in to the ducting and distributed into

the building. Either situation may decrease

the quality of the indoor air. Research

performed in the last 10 to 15 years has

established these facts, and steadily

increasing numbers of qualified HVAC

contractors are learning how to eliminate

duct leakage.

How do you know if your duct system is in

good condition? The most reliable and

cost-effective way to find out is to have a

duct test performed by a qualified contractor

or technician using the proper test equipment.

Duct testing is the process of using calibrated

mechanical equipment to measure the

amount of airflow that is lost through the

duct system when it is at normal operating

pressure. While some joints or seams may

have only small leaks, other sections may

be completely disconnected. Duct testing

can indicate the relative leakiness of the ducts

and help determine whether the duct system

should be sealed, repaired, or renovated.

The ducts that are part of central

heating and cooling systems offer

one of the best opportunities to

increase your energy efficiency,

increase your comfort, and manage

your energy bills.

WHEN TO TEST

Duct testing is strongly recommended when a

new heating and/or air conditioning unit is

being installed. If the existing duct system is

leaky and inefficient before the new unit is

installed, it will still be leaky and inefficient

after the new unit is installedunless the

ducts are tested and sealed by a qualified

contractor. It does not make sense to install

a new, energy-efficient heating and/or air

conditioning unit unless the duct system is

also energy efficient.

Duct testing is also recommended when a

diagnostic tune-up is performed on a heating

and air conditioning unit. A diagnostic tune-up

can improve the operating efficiency of the

heating or air conditioning unit itself, but

the overall efficiency will still be less than

adequate if the duct system is not in good

condition. A duct test is necessary to

determine leaks, needed repairs, and/or

renovations.

Duct testing can be performed at any time,

however, whether or not new energy

efficiency equipment is being installed.

It is not unusual to find that sealing,

repair, or renovation must be

performed to complement a

comprehensive HVAC installation.

TESTING METHODS

AND EQUIPMENT

There are two main methods of testing.

The pressurization subtraction method utilizes

a pressurization unit (i.e. a high-powered fan

set up in a doorway and connected to

pressure gauges) to pressurize first the

entire space that is heated and/or cooled

and then the same space with the duct

system blocked off. This method is less

accurate than the duct testing method.

The duct testing method uses a calibrated

fan that gently pressurizes the ducts and

measures the airflow through the ducts to

indicate total leakage. The duct tester

consists of a portable fan with calibrated

digital pressure gauges that is connected at

the blower compartment of the air handler,

or attached to the main return grill. All of

the duct registers and grills are temporarily

sealed, and the duct tester fan is turned on

to pressurize the system. The fan pressure

is read from the gauges and converted to an

equivalent duct leakage rate in cubic feet per

minute (cfm). If the amount of air loss falls

outside acceptable limits, sealing will be

required to correct the condition. This

method of testing is preferred, because

it measures low airflow accurately, and

simulates what takes place under normal

operating conditions.

Duct testing can be performed at

any time, however, whether or not

new energy efficiency equipment

is being installed.

TESTING PROCEDURE

What should you expect when a contractor

performs a duct test at your home or

business? The test should take about an

hour from initial setup to completion.

You may be present while the test is being

conducted, although the heating and air

conditioning system must be shut off during

testing. A properly conducted test will not

damage your heating or air conditioning

system or your building.

The contractor will have to attach the duct

tester to the blower compartment of the air

handler or the main return grill using

masking tape. Next the supply registers

and any remaining return grills must be

taped closed. After the duct system is

temporarily sealed, the duct tester fan will

be turned on to pressurize the duct system

to a predetermined level (usually 25 Pascals,

which is 0.1 inches of water column), and the

contractor will adjust the gauges until the

pressure level is stabilized. The contractor

then records the fan pressure and converts

this to a fan flow in cubic feet per minute.

The results will show how leaky your duct

system is and help you and your contractor

decide whether sealing or repair work

is necessary.

WHAT TO DO WITH THE RESULTS

If the test indicates the leakage is greater

than acceptable, the ducts should be

sealed, repaired, or renovated (replaced).

The threshold is set by the October 2005

Title 24 Building Code, which requires

duct leakage to be reduced by 15% of the

pre-work leakage found. In every case the

closer to zero leakage attained, the better

your duct system will perform.

Sealing

Duct sealing involves following established

procedures and applying approved materials

to seal air leaks. Locations where sealing is

typically performed include the supply and

return plenums (which are connected to the

furnace cabinet), starting collars (where ducts

are connected to the plenums), fittings in the

duct runs (Ys, where ducts branch off, and

elbows), splices within the duct run, and

terminations where the ducts connect to the

supply registers. The most important leakage

areas are in the supply and return plenums,

because these areas are closest to the air

handler and under the highest pressures

when the system is operating.

All sealing must be performed according

to Title 24 building codes and any related

energy efficiency program standards. These

codes and standards address the type of

mastic sealant, pressure sensitive tape, and

drawbands used to correctly seal duct

systems. Your contractor should be familiar

with and follow the standards and codes for

duct sealing. The proper materials are

becoming more available, and good

old- fashioned cloth duct tape should

never be substituted. The proper tape used

for duct sealing will have a UL 181 marking

or label on the outside surface of the tape,

and the proper duct mastic sealant will have

a UL 181 label on the product container.

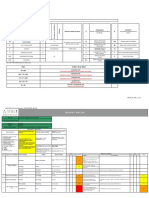

DUCT PROBLEMS

Ripped

Outer Cover

Peeling

Duct

Tape

No Drawband

Uncertain

R-Value

Exposed Metal

Unlabeled

Duct Tape

PG&E refers to Pacific Gas and Electric Company, a subsidiary of PG&E Corporation. 2007 Pacific Gas & Electric Company. All rights reserved.

These offerings are funded By California utility customers and administered by PG&E under the auspices of the California Public Utilities Commission.

2006 Pacific Gas & Electric Company. Rev. October 2007 C-1304

Repair

Duct system repair involves reconnecting

parts that have become separated, and

replacing or repairing any damaged or

missing component parts, which could

include flexible metallic and non-metallic

plastic flex ducts, rigid metal ducts, sheet

metal duct components, duct supports,

register boots, and registers.

Renovation

Duct renovation should be performed if the

duct system is in poor condition or improperly

sized. Renovation involves replacing a

significant portion of the ductwork, either to

restore it to proper operation or to increase

the capacity of the return air ducting. Some

systems have return ducts that are too small,

causing whistling filters, noisy ducts, and

reduced energy efficiency. If size is not the

problem, often only a portion of the ductwork

needs replacement. But if the entire duct

system needs to be replaced, your contractor

must correctly size the ducts and registers to

ensure that the new ductwork will provide the

most comfort and greatest energy efficiency.

For more information about energy efficiency

and other PG&E energy management

solutions visit our Web site at pge.com

Related Fact Sheets:

A Whole-System Approach to

Heating and Cooling

Heating

Cooling

Heat Pump

What Is HVAC System Sizing?

Air Conditioner Refrigerant

Charge and Airflow

Buying a Central Air Conditioner?

Ask for a TXV!

Buying an Air Conditioner?

Remember the EER!

Residential customers call our

Smarter Energy Line at 800-933-9555.

Business customers call our Business

Customer Service Center at 800-468-4743.

OPTIMIZING THE ENERGY

EFFICIENCY OF YOUR

VENTILATION SYSTEM

REDUCES YOUR ENERGY

COSTS AND BENEFITS THE

ENVIRONMENT BY CONSERVING

OUR NATURAL RESOURCES

AND REDUCING AIR EMISSIONS.

Вам также может понравиться

- PPEs Budget Aug 2021 11Документ29 страницPPEs Budget Aug 2021 11Asan IbrahimОценок пока нет

- Safety Training FormatsДокумент11 страницSafety Training FormatsAsan IbrahimОценок пока нет

- Accident Explanation 24.08.2021Документ2 страницыAccident Explanation 24.08.2021Asan IbrahimОценок пока нет

- IAP Report - 17.08.2021Документ1 страницаIAP Report - 17.08.2021Asan IbrahimОценок пока нет

- VR4059 2020 1st Half & 2nd HalfДокумент10 страницVR4059 2020 1st Half & 2nd HalfAsan IbrahimОценок пока нет

- VR4059 2017 1st HalfДокумент12 страницVR4059 2017 1st HalfAsan IbrahimОценок пока нет

- VR4059 2020 1st Half & 2nd HalfДокумент10 страницVR4059 2020 1st Half & 2nd HalfAsan IbrahimОценок пока нет

- Guidelines 07032016Документ17 страницGuidelines 07032016Manjunath MadiwalarОценок пока нет

- Compresed GasДокумент3 страницыCompresed GasAsan IbrahimОценок пока нет

- VR4059 2017 1st HalfДокумент12 страницVR4059 2017 1st HalfAsan IbrahimОценок пока нет

- PR-1073 - Gas Freeing, Purging and Leak Testing of Process Equipment (Excluding Tanks)Документ35 страницPR-1073 - Gas Freeing, Purging and Leak Testing of Process Equipment (Excluding Tanks)romedic36100% (1)

- Pressure VesselДокумент12 страницPressure VesselAsan IbrahimОценок пока нет

- VR4059 2017 1st HalfДокумент12 страницVR4059 2017 1st HalfAsan IbrahimОценок пока нет

- Oxygen Generator Check ListДокумент1 страницаOxygen Generator Check ListAsan IbrahimОценок пока нет

- Jsa - LPG GasДокумент8 страницJsa - LPG GasAsan IbrahimОценок пока нет

- UpdateddraftT4S LPG23032018Документ147 страницUpdateddraftT4S LPG23032018Asan IbrahimОценок пока нет

- Proposal For - TPI For Oxygen Generator - BVQS - Ver02 (EN)Документ11 страницProposal For - TPI For Oxygen Generator - BVQS - Ver02 (EN)Asan IbrahimОценок пока нет

- Environmental, Occupational Health and Safety Management SystemДокумент4 страницыEnvironmental, Occupational Health and Safety Management SystemAsan IbrahimОценок пока нет

- SCUD Procedure CONST004 Purging With Gas Air or Inert GasДокумент4 страницыSCUD Procedure CONST004 Purging With Gas Air or Inert GasAsan IbrahimОценок пока нет

- 2190 First-Aid Fire ExtinguishersДокумент20 страниц2190 First-Aid Fire ExtinguishersAsan IbrahimОценок пока нет

- The Oxyacetylene Process: Safe Practice and Accident AvoidanceДокумент6 страницThe Oxyacetylene Process: Safe Practice and Accident AvoidanceAsan IbrahimОценок пока нет

- Environmental, Occupational Health and Safety Management SystemДокумент4 страницыEnvironmental, Occupational Health and Safety Management SystemAsan IbrahimОценок пока нет

- 3521 Industrial Safety Belts and Harnesses - Specification PDFДокумент17 страниц3521 Industrial Safety Belts and Harnesses - Specification PDFMohammad AbdullahОценок пока нет

- Open Book Examination: NeboshДокумент9 страницOpen Book Examination: NeboshAsan IbrahimОценок пока нет

- Mines Rule 1955Документ79 страницMines Rule 1955atanu_moharana100% (1)

- SIPCOT Environment PolicyДокумент9 страницSIPCOT Environment PolicyAsan IbrahimОценок пока нет

- Construction VentilationДокумент50 страницConstruction VentilationAsan IbrahimОценок пока нет

- WeldingДокумент4 страницыWeldingAsan IbrahimОценок пока нет

- Open Book Examination: NeboshДокумент9 страницOpen Book Examination: NeboshAsan IbrahimОценок пока нет

- PWD Boiler Servicerules 0Документ6 страницPWD Boiler Servicerules 0Asan IbrahimОценок пока нет

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeОт EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeРейтинг: 4 из 5 звезд4/5 (5794)

- The Yellow House: A Memoir (2019 National Book Award Winner)От EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Рейтинг: 4 из 5 звезд4/5 (98)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryОт EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryРейтинг: 3.5 из 5 звезд3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceОт EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceРейтинг: 4 из 5 звезд4/5 (895)

- The Little Book of Hygge: Danish Secrets to Happy LivingОт EverandThe Little Book of Hygge: Danish Secrets to Happy LivingРейтинг: 3.5 из 5 звезд3.5/5 (400)

- Never Split the Difference: Negotiating As If Your Life Depended On ItОт EverandNever Split the Difference: Negotiating As If Your Life Depended On ItРейтинг: 4.5 из 5 звезд4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureОт EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureРейтинг: 4.5 из 5 звезд4.5/5 (474)

- The Emperor of All Maladies: A Biography of CancerОт EverandThe Emperor of All Maladies: A Biography of CancerРейтинг: 4.5 из 5 звезд4.5/5 (271)

- Team of Rivals: The Political Genius of Abraham LincolnОт EverandTeam of Rivals: The Political Genius of Abraham LincolnРейтинг: 4.5 из 5 звезд4.5/5 (234)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaОт EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaРейтинг: 4.5 из 5 звезд4.5/5 (266)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersОт EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersРейтинг: 4.5 из 5 звезд4.5/5 (344)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyОт EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyРейтинг: 3.5 из 5 звезд3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreОт EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreРейтинг: 4 из 5 звезд4/5 (1090)

- The Unwinding: An Inner History of the New AmericaОт EverandThe Unwinding: An Inner History of the New AmericaРейтинг: 4 из 5 звезд4/5 (45)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)От EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Рейтинг: 4.5 из 5 звезд4.5/5 (121)

- Checklist Energy ConservationДокумент3 страницыChecklist Energy ConservationRita MitraОценок пока нет

- Huawei FM1000A40 V200R003C00 IT 380V Product DescriptionДокумент101 страницаHuawei FM1000A40 V200R003C00 IT 380V Product DescriptionJesusОценок пока нет

- Teri Case StudyДокумент1 страницаTeri Case StudyRithika Raju ChallapuramОценок пока нет

- A Risk-Responsive Framework For Green Retrofit Projects in Sri Lanka PDFДокумент15 страницA Risk-Responsive Framework For Green Retrofit Projects in Sri Lanka PDFcebiОценок пока нет

- Solar Powered Street LightsДокумент6 страницSolar Powered Street Lightsdexterjardin_06Оценок пока нет

- Mobil Serv - Plastics - 5 StepsДокумент1 страницаMobil Serv - Plastics - 5 StepsSly LumbaОценок пока нет

- Plusy I Minusy Samochodów Elektrycznych I HybrydowychДокумент10 страницPlusy I Minusy Samochodów Elektrycznych I Hybrydowychpawel korobowiczОценок пока нет

- Efficiency Assessment of Condensing Steam Turbine-DL From Wseas - UsДокумент6 страницEfficiency Assessment of Condensing Steam Turbine-DL From Wseas - UsGirish OniyilОценок пока нет

- CEM 2 Lesson 8 Structural Engg ApplicationДокумент39 страницCEM 2 Lesson 8 Structural Engg ApplicationReynalyn Mae BaylinОценок пока нет

- Siemens Demand FlowДокумент2 страницыSiemens Demand FlowloveywarkeОценок пока нет

- 1 Why Preserve Historic Buildings & Neighborhoods?: Liberty ParkДокумент6 страниц1 Why Preserve Historic Buildings & Neighborhoods?: Liberty ParkBadr KaziОценок пока нет

- File 2Документ328 страницFile 2Arjyajyoti Goswami100% (1)

- Gea - Cooling TowersДокумент25 страницGea - Cooling TowersFREDIELABRADOR100% (1)

- Jurnal Coca Cola 1Документ8 страницJurnal Coca Cola 1Nadia MarastikaОценок пока нет

- Blueprint For Green CampusДокумент46 страницBlueprint For Green CampusPuneet Singh100% (1)

- Smart Cities Saudi Arabia StudyДокумент39 страницSmart Cities Saudi Arabia StudyTayyab Khan100% (2)

- A Designer's Guide To The Options For Ventilation and CoolingДокумент40 страницA Designer's Guide To The Options For Ventilation and CoolingSonny RamosОценок пока нет

- BERDE+FOR+EXISTING+BUILDINGS+V1 0dfДокумент127 страницBERDE+FOR+EXISTING+BUILDINGS+V1 0dfpatОценок пока нет

- 10 Fusing Machines EДокумент20 страниц10 Fusing Machines EskgolbanОценок пока нет

- ASHRAE HVAC Design Manual For Hospitals and ClinicsДокумент297 страницASHRAE HVAC Design Manual For Hospitals and ClinicsIrsyad Ahmad - FGVPISB KS JENGKA 21100% (2)

- Balance CG SLB057 GB - 0820Документ7 страницBalance CG SLB057 GB - 0820Said ZubizaОценок пока нет

- Energy ManagmentДокумент226 страницEnergy ManagmentEcy Yghi0% (1)

- Advantage-Disadvantage VRFДокумент13 страницAdvantage-Disadvantage VRFRatnasariPurnadewi100% (3)

- Strategic Analysis On Ford MotorДокумент20 страницStrategic Analysis On Ford Motorm_ebad93% (30)

- Sustainable Procurement PolicyДокумент1 страницаSustainable Procurement PolicyEdelmanОценок пока нет

- Hong Kong Building Energy Code 2012Документ70 страницHong Kong Building Energy Code 2012Sam C M HuiОценок пока нет

- Green Rating Manual April 2019 PDFДокумент34 страницыGreen Rating Manual April 2019 PDFRAHUL BRОценок пока нет

- CEBC Energy Efficiency in The GCC January 2018 REV2Документ14 страницCEBC Energy Efficiency in The GCC January 2018 REV2Muhammed ThaslimОценок пока нет

- Intelligent Energy Europe - Environmental Design in University Curricula and Architectural Training in EuropeДокумент7 страницIntelligent Energy Europe - Environmental Design in University Curricula and Architectural Training in EuropeElena EfodiОценок пока нет

- The Great Remake Manufacturing For Modern Times Full Compenium October 2017 FinalДокумент134 страницыThe Great Remake Manufacturing For Modern Times Full Compenium October 2017 FinalAxel VanraesОценок пока нет