Академический Документы

Профессиональный Документы

Культура Документы

Handbook Neyrfor Nov2012

Загружено:

alekz89Исходное описание:

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Handbook Neyrfor Nov2012

Загружено:

alekz89Авторское право:

Доступные форматы

Neyrfor

Turbodrill

Handbook

Neyrfor

Turbodrill

Handbook

Schlumberger

3750 Briarpark Drive

Houston, Texas 77042

www.slb.com

Produced by Schlumberger Marketing Communications

Copyright 2012 Schlumberger. All rights reserved.

No part of this book may be reproduced, stored in a retrieval system,

or transcribed in any form or by any means, electronic or mechanical,

including photocopying and recording, without the prior written permission

of the publisher. While the information presented herein is believed to be

accurate, it is provided as is without express or implied warranty.

12-DT-0100

An asterisk (*) is used throughout this document to denote a mark of Schlumberger.

Other company, product, and service names are the properties of their respective owners.

Turbodrill Handbook

Innovative Leaders in Superior

Performance Turbodrilling

Neyrfor* turbodrilling technology has led the industry for over half a

century. With a history of unmatched drilling performance and reliability

in the industry, our tools, technology and operational expertise provide

customers with superior drilling efficiency in a broad range of drilling

applications.

While turbodrills are often associated with extreme applications such

as HPHT or hard rock drilling, Neyrfor Turbodrills* consistently deliver

enhanced performance in conventional drilling applications including:

vertical performance drilling

s-shape, tangent, and horizontal directional drilling

sidetracking

milling

re-entries

extended reach

medium- and long-radius drilling

Regardless of the application, Neyrfor Turbodrills provide high performance

and precise directional control without sacrificing hole quality or ROP,

even at extreme depths and downhole environments.

The Turbodrilling Advantage

Energy Efficiency

Both Neyrfor turbodrills and PDMs are in essence energy conversion

devices, converting the hydraulic energy of the drilling fluid into mechanical

energy to drive the drill bit. As such the actual power delivered is very

dependent on the efficiency of the energy conversion. Because of the

intrinsic nature of the free-running and concentric balanced design of a

turbodrill, it is far more efficient than conventional drilling motors.

Power Output

The superior energy efficiency of the turbodrill translates directly into more

power available at the bit to sheer and grind the rock faster for higher

rates of penetration. And, because the power output of the turbodrill does

not deteriorate over time, the turbodrill maintains its uniformly high power

output throughout every run.

Reliability and Operating Life

Neyrfor turbodrills, designed as precision high performance downhole

tools, routinely achieve downhole run times of over 400 hours and, in some

circumstances, even above 600 hours.

Vibration Mitigation

Excessive downhole vibrations have been shown to damage expensive

downhole electronics, contribute to accelerated bit wear and adversely

affect the efficiency of the total drilling operation. The concentric rotation

of the turbodrill allows the passage of drilling fluid through the tool to

rotate the drive shaft at a high RPM while remaining dynamically stable

about the geometric axis. The absence of lateral vibration (off-center

motion) means that a greater portion of the available energy generated by

the turbodrill is applied directly to the formation.

HPHT Capability

The all metallic turbodrill configuration has no elastomer material in the

power section to degrade in harsh drilling environments, therefore tool

performance is exceptional even in high temperatures and pressures.

Turbodrill Handbook

Directional Capability

For any given bent housing angle, turbodrills have been shown to provide

greater directional responsiveness and thus can deliver a higher DLS when

it is necessary to achieve directional objectives or can achieve normal

requirements with a lesser bend. Also, turbodrills operate with much

less fluctuating and reactive torque than PDMs making it much easier to

control and predict the tool face and resultant directional response.

Underbalanced Drilling Capability

Turbodrills can operate effectively in applications where two-phase

drilling fluid is used. In critical applications where there are concerns

about fluid contamination of the reservoir, turbodrilling with highly gas-cut

mud systems can help ensure that both drilling and production objectives

are met.

Borehole Quality

Goal: Maximize Wellbore Value. turbodrills consistently deliver a smooth

and concentric wellbore. With the superior toolface control and use

of stabilization on the turbodrill, hole spiraling and micro doglegs are

minimized. The result is a hole with minimal rugosity, this enhances

wellbore evaluation, casing running, cementing, and the minimization of

problems drilling ahead

Cost-per-Foot

The ultimate advantage of a turbodrill is the tools ability to consistently

deliver lower operating cost by reducing drilling time. The value of the

more robust, high performance turbodrill is realized by increased ROP, the

substantial reduction in tripping time due to non-planned events and the

increase in operational efficiency derived from more time on bottom due

to high tool reliability than conventional drilling motors.

Custom Configurations for Every Application

Straight-Hole High-Performance Turbodrilling

In straight-hole vertical applications, the stabilizer configuration of

the Neyrfor turbodrill combined with the much lighter weight on bit

required compared to rotary or PDM assemblies, results in a natural

dropping tendency. This tendency provides a high-performance drilling

solution which maximizes ROP, produces a high-quality wellbore and very

consistently maintains verticality. Coupled with unsurpassed downhole

longevity and reliability, this makes the turbodrill the obvious choice for

operators seeking to minimize drilling time and reduce operating costs.

Directional and Horizontal Turbodrilling

Neyrfor turbodrills excel in the demanding world of directional and

horizontal drilling.

With the ability to offer consistent, predictable build rates, combined with

unmatched toolface control, the Neyrfor Delta* and Neyrfor Traditional*

turbodrills ensure that directional objectives can be achieved in the most

demanding applications. The directional turbodrill has an outstanding

track record providing superior performance in extreme applications such

as sidetracking operations below 22,000 ft TVD in HPHT environments.

In its robust, all-metallic configuration, the exceptional durability of the

turbodrill has allowed it to completely drill both legs of dual-lateral wells

in a single run without tripping out of the hole.

Thru-Tubing Turbodrilling

With the most power of any slim-hole drive system, the Neyrfor TTT*

thru-tubing turbodrill offers the operator the ability to achieve maximum

performance in any thru-tubing operation. The design superiority of

turbodrills makes them the preferred solution to provide a performance

advantage in low bottom-hole pressure environments, in two-phase gasified

fluid systems, in acidizations, and in hot-hole production environments.

Notably, the Neyrfor TTTs ability to run on large percentages of gas, rather

than just fluid, allows continuous well production during remedial and

underbalanced drilling operations.

Turbodrill Handbook

Contents

Neyrfor LC3 Turbodrill Locking Clutch ..............................................1

Neyrfor TTT Series ................................................................................5

Tool Size Old Nomenclature New Nomenclature

2

7

8-in ...........T111 MK2 FBS .............. Neyrfor TTT .................................. 6

Neyrfor Traditional Series .................................................................11

Tool Size Old Nomenclature New Nomenclature

2

7

8-in ...........T1 MK2 FBS .................. T112 Steerable ........................... 12

2

7

8-in ...........T2 MK2 FBS .................. T122 Steerable ........................... 14

3

3

8-in ...........T1 MK2 FBS .................. T112 Steerable ........................... 16

3

3

8-in ...........T2 MK2 FBS .................. T122 Steerable ........................... 18

4

3

4-in ...........T1 MK1 FBS .................. T111 Steerable ........................... 20

4

3

4-in ...........T1XL MK1 FBS ............. T111XP Steerable...................... 22

4

3

4-in ...........T1 MK2 FBS .................. T112 Steerable ........................... 24

4

3

4-in ...........T1XL MK2 FBS ............. T112XP Steerable...................... 26

4

3

4-in ...........T1 MK3 FBS .................. T113 Steerable ........................... 28

4

3

4-in ...........T1XL MK3 FBS ............. T113XP Steerable...................... 30

4

3

4-in ...........T2 MK1 FBS .................. T121 Steerable ........................... 32

4

3

4-in ...........T2 MK2 FBS .................. T122 Steerable ........................... 34

6

5

8-in ...........T1 MK1 FBS .................. T111 Steerable ........................... 36

6

5

8-in ...........T1XL MK1 FBS ............. T111XP Steerable...................... 38

6

5

8-in ...........T1 MK2 FBS .................. T112 Steerable ........................... 40

6

5

8-in ...........T1XL MK2 FBS ............. T112XP Steerable...................... 42

6

5

8-in ...........TSH MK2 FBS ............... T112HF Steerable ...................... 44

6

5

8-in ...........T1 MK3 FBS .................. T113 Steerable ........................... 46

6

5

8-in ...........T1XL MK3 FBS ............. T113XP Steerable...................... 48

6

5

8-in ...........TSH MK3 FBS ............... T113HF Steerable ...................... 50

6

5

8-in ...........T2 MK1 FBS .................. T121 Steerable ........................... 52

6

5

8-in ...........T2 MK2 FBS .................. T122 Steerable ........................... 54

7

1

4-in ...........T1 MK1 FBS .................. T111 Steerable ........................... 56

7

1

4-in ...........T2 MK1 FBS .................. T121 Steerable ........................... 58

7

1

4-in ...........T3 MK1 FBS .................. T131 Steerable ........................... 60

9

1

2-in ...........T1 MK1 FBS .................. T111 Steerable ........................... 62

9

1

2-in ...........T1 MK2 FBS .................. T112 Steerable ........................... 64

9

1

2-in ...........TSH MK2 FBS ............... T112HF Steerable ...................... 66

9

1

2-in ...........TSH MK3 FBS ............... T113HF Steerable ...................... 68

9

1

2-in ...........T2H MK2 FBS ............... T122HF Steerable ...................... 70

9

1

2-in ...........T2H MK3 FBS ............... T123HF Steerable ...................... 72

9

1

2-in ...........T2 MK1 FBS .................. T121 Steerable ........................... 74

9

1

2-in ...........T2 MK2 FBS .................. T122 Steerable ........................... 76

Neyrfor Delta Series ...........................................................................79

Tool Size Old Nomenclature New Nomenclature

4

3

4-in ...........NA ................................... D211 Steerable .......................... 80

4

3

4-in ...........T1XL MK1 FBS ............. D211XP Steerable ..................... 82

Contents

Neyrfor Delta Series, continued

Tool Size Old Nomenclature New Nomenclature

4

3

4-in ...........T1 MK2 FBS .................. D212 Steerable .......................... 84

4

3

4-in ...........T1XL MK2 FBS ............. D212XP Steerable ..................... 86

4

3

4-in ...........T1 MK3 FBS .................. D213 Steerable .......................... 88

6

5

8-in ...........T1 MK1 FBS .................. D211 Steerable .......................... 90

6

5

8-in ...........T1XL MK1 FBS ............. D211XP Steerable ..................... 92

6

5

8-in ...........T1 MK2 FBS .................. D212 Steerable .......................... 94

6

5

8-in ...........T1XL MK2 FBS ............. D212XP Steerable ..................... 96

6

5

8-in ...........TSH MK2 FBS ............... D212HF Steerable ..................... 98

Appendix .............................................................................................101

Neyrfor Nomenclature .......................................................................... 102

Turbodrill Approximate Shipping Weights........................................ 103

Mud Quality Guidelines ......................................................................... 104

Neyrfor Turbodrill Specifications ....................................................... 105

Hole Curvature Calculation .................................................................. 106

Radius of Curvature Calculation ......................................................... 106

Triplex Pump Output .............................................................................. 106

Total Flow AreaComparison of Values ......................................... 107

Buoyancy and Drilling Fluid Density .................................................. 107

Drilling Fluid Density .............................................................................. 108

Weights of 31-ft Drill Collars ................................................................ 110

Heavy-Weight Drillpipe Properties .................................................... 112

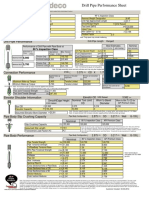

Drillpipe Properties ................................................................................ 112

Rotary-Shouldered Connection Interchange List ........................... 113

Engineering Formulae ........................................................................... 114

Neyrfor LC3

Turbodrill

Locking

Clutch

1

N

e

y

r

f

o

r

L

C

3

T

u

r

b

o

d

r

i

l

l

L

o

c

k

i

n

g

C

L

u

t

c

h

Turbodrill Handbook

2

Neyrfor LC3

Turbodrill Locking Clutch

Drilling environments that induce bit sticking can certainly benefit from

using the Neyrfor LC3* turbodrill locking clutch system. When added to

a Neyrfor Traditional or Neyrfor Delta series configuration, it assists in

freeing the bit if it becomes stuck during drilling or reaming. The clutch

engages when the turbodrill drive shaft stops or the rpm is below that of

the rotary string speed. Accordingly, the string along with the turbodrill

housing and the resulting connected output drive shaft linked together

by the locking clutch allows the operators to apply string torque directly

to the bit by the LC3* clutch system from the top drive or rotary table.

Once the bit has become free, the clutch disengages and normal drilling

operations can be resumed.

Bit type and directional well applications are evaluated on a per well basis.

LC3 Performance Improvements

Material Changes1,400% Improvement in Fracture Toughness

Design Modification25% Improvement in Drilling Mode Wear

Optimized placement to be run with both Neyrfor Traditional and

Neyrfor Delta series turbodrills100% Improvement in Reliability

while Drilling Directional Wells.

N

e

y

r

f

o

r

L

C

3

T

u

r

b

o

d

r

i

l

l

L

o

c

k

i

n

g

C

L

u

t

c

h

Turbodrill Handbook 3

Locking clutch pawl engaged to outer housing transmits torque

through the string from the rotary table or top drive.

Locking clutch pawl in drilling mode.

Neyrfor TTT

Thru-Tubing

Turbodrills

5

N

e

y

r

f

o

r

T

T

T

T

h

r

u

-

T

u

b

i

n

g

T

u

r

b

o

d

r

i

l

l

s

Turbodrill Handbook

6

Neyrfor TTT

2 7/8 in 2-Phase Flow Summary

Tool Specifications

Type TTT T1-FBS T2-FBS

Size, in 2

7

8 2

7

8 2

7

8

Length, ft 15.9 21.5 32.3

Operational Data

Dual-phase flow

Fluid, galUS/min 25 25 25

Gas, scf/min 820 850 655

Operating torque, ft.lbf 48 46 92

Stall torque, ft.lbf 96 92 118

Operating speed, rpm 2,500+ 2,500+ 2,000+

Pressure drop, psi 595 570 720

Notes:

1. Calculations based on approximately 20% water + 80%

nitrogen (dual, or two-phase) fluid system at inlet greater

or lesser % of gas is possible depending on operator

requirements and application conditions

2. For the purposes of modeling, bottomhole conditions shown

are for bottomhole pressure of 1,000 psi and bottomhole

temperature of 425F

3. Turbodrill mechanical power output modeling based on

achieving a minimum 3.0 hp/in2, 2 7/8-in tool with 3-in bit

4. Please consult your local Schlumberger office for individual

application modeling and turbodrill system customization

N

e

y

r

f

o

r

T

T

T

T

h

r

u

-

T

u

b

i

n

g

T

u

r

b

o

d

r

i

l

l

Turbodrill Handbook 7

TTT

section

8

Neyrfor TTT

2

7

8-in TTT MK2

TOOL SUMMARY

Tool Specifications

Turbine section diameter 2.875 in [73.03 mm]

(A) Overall length 15.92 ft [4.85 m]

(B) Bit to center of stabilizer B 0.4 ft [0.1 m]

(C) Bit to bend NA [NA]

(D) Bit to center of stabilizer D NA [NA]

Top connection 2

3

8 in PAC box 2

3

8 in PAC box

Bit connection 2

3

8 PAC pin 2

3

8 PAC pin

Total tool weight 284 lbm [128.8 kg]

Bend settings NA NA

Recommended bit sizes 3

1

4 in to 4

3

4 in [83 mm to 102 mm]

Operational Data

RPM range/revolution per gallon 1,450 to 2,800 rpm 23.0 rev/gal

Pressure drop range 1,200 to 2,500 psi 1,200 to 2,500 psi

Max. power output 71 hp [53 kw]

Max. stall torque 399 ft-lbf [541 nm]

Turbodrill

power

output,

hp

Flow rate, gpm

60 65 70 75 80 85 90 95 100 105 110 115 120 125

60 65 70 75 80 85 90 95 100 105 110 115 120 125

80

70

60

50

40

30

20

10

0

10 ppg

12 ppg

14 ppg

16 ppg

Turbodrill

pressure

drop,

psi

Flow rate, gpm

3,000

2,500

2,000

1,500

1,000

500

0

10 ppg

12 ppg

14 ppg

16 ppg

N

e

y

r

f

o

r

T

T

T

T

h

r

u

-

T

u

b

i

n

g

T

u

r

b

o

d

r

i

l

l

Turbodrill Handbook 9

A

B

TTT

section

9 Turbodrill Handbook

A

B

TTT

section

Neyrfor

Traditional

Series

N

e

y

r

f

o

r

T

r

a

d

i

t

i

o

n

a

l

S

e

r

i

e

s

Turbodrill Handbook 11

2

7

8-in T112 Steerable

2

7

8-in T1 Mk2 FBS

TOOL SUMMARY

Tool Specifications

Turbine section diameter 2.875 in [73.03 mm]

(A) Overall length 21.5 ft [6.55 m]

(B) Bit to center of stabilizer B 10.8 ft [3.29 m]

(C) Bit to bend 3.1 ft [0.94 m]

(D) Bit to center of stabilizer D 0.4 ft [0.1 m]

Top connection 2

3

8 in PAC box 2

3

8 in PAC box

Bit connection 2

3

8 in PAC pin or

2

3

8 in API Reg Pin

2

3

8 in PAC pin or

2

3

8 in API Reg Pin

Total tool weight 392 lbm [177.8 kg]

Bend settings 0 to 2.0 0 to 2.0

Recommended bit sizes 3

1

4 in to 4

3

4 in [83 mm to 102 mm]

Operational Data

RPM range/revolution per gallon 1,600 to 2,900 rpm 23.0 rev/gal

Pressure drop range 1,100 to 2,700 psi 1,100 to 2,700 psi

Max. power output 76 hp [57 kw]

Max. stall torque 327 ft-lbf [443 nm]

Turbodrill

power

output,

hp

60 65 70 75 80 85 90 95 100 105

Flow rate, gpm

110 115 120 125 130 135

60 65 70 75 80 85 90 95 100 105 110 115 120 125 130 135

80

70

60

50

40

30

20

10

0

10 ppg

12 ppg

14 ppg

16 ppg

Turbodrill

pressure

drop,

psi

Flow rate, gpm

3,000

2,500

2,000

1,500

1,000

500

0

10 ppg

12 ppg

14 ppg

16 ppg

Build rate

capabilities,

/100

0 10 20 30 40 50 60 70 80 90

Hole angle,

25

20

15

10

5

0

1.0

2.0

12

N

e

y

r

f

o

r

T

r

a

d

i

t

i

o

n

a

l

S

e

r

i

e

s

13 Turbodrill Handbook

A

B

C

D

Power

section

Bearing

section

2

7

8-in T122 Steerable

2

7

8-in T2 Mk2 FBS

TOOL SUMMARY

Tool Specifications

Turbine section diameter 2.875 in [73.03 mm]

(A) Overall length 32.3 ft [9.85 m]

(B) Bit to center of stabilizer B 21.6 ft [6.58 m]

(C) Bit to center of stabilizer C 10.8 ft [3.29 m]

(D) Bit to Bend 3.1 ft [0.94 m]

(E) Bit to center of stabilizer E 0.4 ft [0.1 m]

Top connection 2

3

8-in PAC Box 2

3

8-in PAC Box

Bit connection 2

3

8 in PAC pin or

2

3

8 in API Reg Pin

2

3

8 in PAC pin or

2

3

8 in API Reg Pin

Total tool weight 590 lbm [267.6 kg]

Bend settings 0 to 2.0 0 to 2.0

Recommended bit sizes 3

1

4 in to 4

3

4 in [83 mm to 102 mm]

Operational Data

RPM range/revolution per gallon 1,330 to 2,400 rpm 23.0 rev/gal

Pressure drop range 1,350 to 2,720 psi 1,350 to 2,720 psi

Max. power output 75 hp [56 kw]

Max. stall torque 329 ft-lbf [446 nm]

Turbodrill

power

output,

hp

Flow rate, gpm

40 50 55 60 65 45 70 75 80 85 90 95 100 105 110

40 50 55 60 65 45 70 75 80 85 90 95 100 105 110

80

70

60

50

40

30

20

10

0

10 ppg

12 ppg

14 ppg

16 ppg

Turbodrill

pressure

drop,

psi

Flow rate, gpm

3,000

2,500

2,000

1,500

1,000

500

0

10 ppg

12 ppg

14 ppg

16 ppg

Build rate

capabilities,

/100

0 10 20 30 40 50 60 70 90 80

Hole angle,

25

20

15

10

5

0

1.00

2.00

14

Turbodrill Handbook

N

e

y

r

f

o

r

T

r

a

d

i

t

i

o

n

a

l

S

e

r

i

e

s

15

A

B

C

E

Power

section

Bearing

section

D

3

3

8-in T112 Steerable

3

3

8-in T1 MK2 FBS

TOOL SUMMARY

Tool Specifications

Turbine section diameter 3.375 in [85.73 mm]

(A) Overall length 20.3 ft [6.19 m]

(B) Bit to center of stabilizer B 9.7 ft [2.96 m]

(C) Bit to bend 3.0 ft [0.91 m]

(D) Bit to center of stabilizer D 0.4 ft [0.1 m]

Top connection 2

3

8 IF box 2

3

8 IF box

Bit connection 2

3

8 API Reg pin 2

3

8 API Reg pin

Total tool weight 546 lbm [247.7 kg]

Bend settings 0 to 1.5 0 to 1.5

Recommended bit sizes 3

3

4 in to 5

3

8 in [95 mm to 137 mm]

Operational Data

RPM range/revolution per gallon 1,500 to 2,460 rpm 14.83 rev/gal

Pressure drop range 1,400 to 2,850 psi 1,400 to 2,850 psi

Max. power output 106 hp [79 kw]

Max. stall torque 531 ft-lbf [720 nm]

Turbodrill

power

output,

hp

Flow rate, gpm

95 105 115 125 135 145 155 165 175

95 105 115 125 135 145 155 165 175

120

100

80

60

40

20

0

10 ppg

12 ppg

14 ppg

16 ppg

Turbodrill

pressure

drop,

psi

Flow rate, gpm

3,000

2,500

2,000

1,500

1,000

500

0

10 ppg

12 ppg

14 ppg

16 ppg

Build rate

capabilities,

/100

0 10 20 30 40 50 60 70 80 90

Hole angle,

20

15

10

5

0

0.75

1.00

1.25

16

Turbodrill Handbook

N

e

y

r

f

o

r

T

r

a

d

i

t

i

o

n

a

l

S

e

r

i

e

s

17

A

B

C

D

Power

section

Bearing

section

3

3

8-in T122 Steerable

3

3

8-in T2 MK2 FBS

TOOL SUMMARY

Tool Specifications

Turbine section diameter 3.375 in [85.73 mm]

(A) Overall length 32.1 ft [9.78 m]

(B) Bit to center of stabilizer B 21.5 ft [6.55 m]

(C) Bit to center of stabilizer C 9.7 ft [2.96 m]

(D) Bit to bend 3.0 ft [0.91 m]

(E) Bit to center of stabilizer E 0.4 ft [0.1 m]

Top connection 2

3

8 IF box 2

3

8 IF box

Bit connection 2

3

8 API Reg pin 2

3

8 API Reg pin

Total tool weight 867 lbm [393.3kg]

Bend settings 0 to 1.5 0 to 1.5

Recommended bit sizes 3

3

4 in to 5

3

8 in [95 mm to 137 mm]

Operational Data

RPM range/revolution per gallon 1,200 to 2,000 rpm 14.83 rev/gal

Pressure drop range 1,730 to 3,000 psi 1,730 to 3,000 psi

Max. power output 106 hp [79 kw]

Max. stall torque 563 ft-lbf [763 nm]

Turbodrill

power

output,

hp

Flow rate, gpm

70 75 80 85 90 95 100 105 120 125 110 130 135 140

70 75 80 85 90 95 100 105 120 125 110 130 135 140

120

100

80

60

40

20

0

10 ppg

12 ppg

14 ppg

16 ppg

Turbodrill

pressure

drop,

psi

Flow rate, gpm

3,500

3,000

2,500

2,000

1,500

1,000

500

0

10 ppg

12 ppg

14 ppg

16 ppg

Build rate

capabilities,

/100

0 10 20 30 40 50 60 70 80 90

Hole angle,

20

15

10

5

0

1.00

1.50

18

N

e

y

r

f

o

r

T

r

a

d

i

t

i

o

n

a

l

S

e

r

i

e

s

19 Turbodrill Handbook

A

B

C

E

Power

section

Bearing

section

D

4

3

4-in T111 Steerable

4

3

4-in T1 MK1 FBS

TOOL SUMMARY

Tool Specifications

Turbine section diameter 4.75 in [120.65 mm]

(A) Overall length 30.2 ft [9.20 m]

(B) Bit to center of stabilizer B 13.1 ft [4.02 m]

(C) Bit to bend 5.63 ft [1.72 m]

(D) Bit to center of stabilizer D 0.6 ft [0.2 m]

Top connection 3

1

2 IF box 3

1

2 IF box

Bit connection 3

1

2 API Reg pin 3

1

2 API Reg pin

Total tool weight 1,537 lbm [697.2 kg]

Bend settings 0 to 1.5 0 to 1.5

Recommended bit sizes 5

5

8 in to 6

3

4 in [143 mm to 171 mm]

Operational Data

RPM range/revolution per gallon 1,200 to 2,050 rpm 7.44 rev/gal

Pressure drop range 1,150 to 3,000 psi 1,150 to 3,000 psi

Max. power output 212 hp [152 kw]

Max. stall torque 1,270 ft-lbf [1,722 nm]

20

Turbodrill

power

output,

hp

Flow rate, gpm

150 170 190 210 230 250 270 290

150 170 190 210 230 250 270 290

210

190

170

150

130

110

90

10 ppg

12 ppg

14 ppg

16 ppg

Turbodrill

pressure

drop,

psi

Flow rate, gpm

3,000

2,500

2,000

1,500

1,000

10 ppg

12 ppg

14 ppg

16 ppg

Build rate

capabilities,

/100

0 10 20 30 40 50 60 70 90 80

Hole angle,

14

12

10

8

6

4

2

0

1.00

1.25

1.50

Turbodrill Handbook

N

e

y

r

f

o

r

T

r

a

d

i

t

i

o

n

a

l

S

e

r

i

e

s

21

A

B

C

D

Power

section

Bearing

section

4

3

4-in T111XP Steerable

4

3

4-in XL MK1 FBS

TOOL SUMMARY

Tool Specifications

Turbine section diameter 4.75 in [120.65 mm]

(A) Overall length 36.3 ft [11.17 m]

(B) Bit to center of stabilizer B 13.1 ft [4.02 m]

(C) Bit to bend 5.63 ft [1.72 m]

(D) Bit to center of stabilizer D 0.6 ft [0.2 m]

Top connection 3

1

2 IF box 3

1

2 IF box

Bit connection 3

1

2 API Reg pin 3

1

2 API Reg pin

Total tool weight 1,662 lbm [753.9 kg]

Bend settings 0 to 1.5 0 to 1.5

Recommended bit sizes 5

5

8 in to 6

3

4 in [143 mm to 171 mm]

Operational Data

RPM range/revolution per gallon 1,070 to 1,870 rpm 7.44 rev/gal

Pressure drop range 1,200 to 3,000 psi 1,200 to 3,000 psi

Max. power output 217 hp [162 kw]

Max. stall torque 1,318 ft-lbf [1,787 nm]

22

Turbodrill

power

output,

hp

Flow rate, gpm

150 160 170 180 190 200 210 220 230 240 250

150 160 170 180 190 200 210 220 230 240 250

210

190

170

150

130

110

90

10 ppg

12 ppg

14 ppg

16 ppg

Turbodrill

pressure

drop,

psi

Flow rate, gpm

3,500

3,000

2,500

2,000

1,500

1,000

10 ppg

12 ppg

14 ppg

16 ppg

Build rate

capabilities,

/100

0 10 20 30 40 50 60 70 90 80

Hole angle,

14

12

10

8

6

4

2

0

1.00

1.25

1.50

Turbodrill Handbook

N

e

y

r

f

o

r

T

r

a

d

i

t

i

o

n

a

l

S

e

r

i

e

s

23

A

B

C

D

Power

section

Bearing

section

4

3

4-in T112 Steerable

4

3

4-in T1 MK2 FBS

TOOL SUMMARY

Tool Specifications

Turbine section diameter 4.75 in [120.65 mm]

(A) Overall length 30.20 ft [9.20 m]

(B) Bit to center of stabilizer B 13.10 ft [4.02 m]

(C) Bit to bend 5.63 ft [1.72 m]

(D) Bit to center of stabilizer D 0.60 ft [0.20 m]

Top connection 3

1

2 IF box 3

1

2 IF box

Bit connection 3

1

2 API Reg pin 3

1

2 API Reg pin

Total tool weight 1,552 lbm [704.0 kg]

Bend settings 0 to 1.5 0 to 1.5

Recommended bit sizes 5

5

8 in to 6

3

4 in [143 mm to 171 mm]

Operational Data

RPM range/revolution per gallon 860 to 1,600 rpm 6.357 rev/gal

Pressure drop range 1,250 to 3,000 psi 1,250 to 3,000 psi

Max. power output 197 hp [147 kw]

Max. stall torque 1,405 ft-lbf [1,905 nm]

24

Turbodrill

power

output,

hp

Flow rate, gpm

150 170 190 210 230 250 270

150 170 190 210 230 250 270

200

180

160

140

120

100

80

10 ppg

12 ppg

14 ppg

16 ppg

Turbodrill

pressure

drop,

psi

Flow rate, gpm

3,500

3,000

2,500

2,000

1,500

1,000

10 ppg

12 ppg

14 ppg

16 ppg

Build rate

capabilities,

/100

0 10 20 30 40 50 60 70 90 80

Hole angle,

14

12

10

8

6

4

2

0

1.00

1.25

1.50

Turbodrill Handbook

N

e

y

r

f

o

r

T

r

a

d

i

t

i

o

n

a

l

S

e

r

i

e

s

25

A

B

C

D

Power

section

Bearing

section

4

3

4-in T112XP Steerable

4

3

4-in XL MK2 FBS

TOOL SUMMARY

Tool Specifications

Turbine section diameter 4.75 in [120.65 mm]

(A) Overall length 36.3 ft [11.17 m]

(B) Bit to center of stabilizer B 13.1 ft [4.02 m]

(C) Bit to bend 5.63 ft [1.72 m]

(D) Bit to center of stabilizer D 0.6 ft [0.2 m]

Top connection 3

1

2 IF box 3

1

2 IF box

Bit connection 3

1

2 API Reg pin 4

1

2 API Reg pin

Total tool weight 1,684 lbm [763.8 kg]

Bend settings 0 to 1.5 0 to 1.5

Recommended bit sizes 5

5

8 in to 6

3

4 in [143 mm to 171 mm]

Operational Data

RPM range/revolution per gallon 760 to 1,420 rpm 6.357 rev/gal

Pressure drop range 1,400 to 3,000 psi 1,400 to 3,000 psii

Max. power output 191 hp [142 kw]

Max. stall torque 1,491 ft-lbf [2,022 nm]

26

Turbodrill

power

output,

hp

Flow rate, gpm

150 130 140 170 160 190 180 210 220 200 230

150 130 140 170 160 190 180 210 220 200 230

200

180

160

140

120

100

80

10 ppg

12 ppg

14 ppg

16 ppg

Turbodrill

pressure

drop,

psi

Flow rate, gpm

3,500

3,000

2,500

2,000

1,500

1,000

10 ppg

12 ppg

14 ppg

16 ppg

Build rate

capabilities,

/100

0 10 20 30 40 50 60 70 90 80

Hole angle,

14

12

10

8

6

4

2

0

1.00

1.25

1.50

Turbodrill Handbook

N

e

y

r

f

o

r

T

r

a

d

i

t

i

o

n

a

l

S

e

r

i

e

s

27

A

B

C

D

Power

section

Bearing

section

4

3

4-in T113 Steerable

4

3

4-in T1 MK3 FBS

TOOL SUMMARY

Tool Specifications

Turbine section diameter 4.75 in [120.65 mm]

(A) Overall length 30.2 ft [9.20 m]

(B) Bit to center of stabilizer B 13.1 ft [4.02 m]

(C) Bit to bend 5.63 ft [1.72 m]

(D) Bit to center of stabilizer D 0.6 ft [0.2 m]

Top connection 3

1

2 IF box 3

1

2 IF box

Bit connection 3

1

2 API Reg pin 3

1

2 API Reg pin

Total tool weight 1,549 lbm [702.6 kg]

Bend settings 0 to 1.5 0 to 1.5

Recommended bit sizes 5

5

8 in to 6

3

4 in [143 mm to 171 mm]

Operational Data

RPM range/revolution per gallon 950 to 1,660 rpm 7.785 rev/gal

Pressure drop range 1,250 to 3,000 psi 1,250 to 3,000 psi

Max. power output 155 hp [116 kw]

Max. stall torque 916 ft-lbf [1,242 nm]

28

Turbodrill

power

output,

hp

Flow rate, gpm

140 120 100 160 180 200 220 240

140 120 100 160 180 200 220 240

160

140

120

100

80

10 ppg

12 ppg

14 ppg

16 ppg

Turbodrill

pressure

drop,

psi

Flow rate, gpm

3,500

3,000

2,500

2,000

1,500

10 ppg

12 ppg

14 ppg

16 ppg

Build rate

capabilities,

/100

0 10 20 30 40 50 60 70 90 80

Hole angle,

14

12

10

8

6

4

2

0

1.00

1.25

1.50

Turbodrill Handbook

N

e

y

r

f

o

r

T

r

a

d

i

t

i

o

n

a

l

S

e

r

i

e

s

29

A

B

C

D

Power

section

Bearing

section

4

3

4-in T113XP Steerable

4

3

4-in XL MK3 FBS

TOOL SUMMARY

Tool Specifications

Turbine section diameter 4.75 in [120.65 mm]

(A) Overall length 36.3 ft [11.17 m]

(B) Bit to center of stabilizer B 13.1 ft [4.02 m]

(C) Bit to bend 5.63 ft [1.72 m]

(D) Bit to center of stabilizer D 0.6 ft [0.2 m]

Top connection 3

1

2 IF box 3

1

2 IF box

Bit connection 3

1

2 API Reg pin 3

1

2 API Reg pin

Total tool weight 1,709 lbm [775.2 kg]

Bend settings 0 to 1.5 0 to 1.5

Recommended bit sizes 5

5

8 in to 6

3

4 in [143 mm to 171 mm]

Operational Data

RPM range/revolution per gallon 840 to 1,480 rpm 7.785 rev/gal

Pressure drop range 1,300 to 3,000 psi 1,300 to 3,000 psi

Max. power output 156 hp [116kw]

Max. stall torque 1,189 ft-lbf [1,612 nm]

30

Turbodrill

power

output,

hp

Flow rate, gpm

130 120 110 100 140 150 160 170 190 180 200

130 120 110 100 140 150 160 170 190 180 200

160

140

120

100

80

10 ppg

12 ppg

14 ppg

16 ppg

Turbodrill

pressure

drop,

psi

Flow rate, gpm

3,500

3,000

2,500

2,000

1,500

10 ppg

12 ppg

14 ppg

16 ppg

Build rate

capabilities,

/100

0 10 20 30 40 50 60 70 90 80

Hole angle,

14

12

10

8

6

4

2

0

1.00

1.25

1.50

Turbodrill Handbook

N

e

y

r

f

o

r

T

r

a

d

i

t

i

o

n

a

l

S

e

r

i

e

s

31

A

B

C

D

Power

section

Bearing

section

4

3

4-in T121 Steerable

4

3

4-in T2 MK1 FBS

TOOL SUMMARY

Tool Specifications

Turbine section diameter 4.75 in [120.65 mm]

(A) Overall length 47.5 ft [14.48 m]

(B) Bit to center of stabilizer B 29.3 ft [8.93 m]

(C) Bit to center of stabilizer C 13.1 ft [4.02 m]

(D) Bit to bend 5.63 ft [1.72 m]

(E) Bit to center of stabilizer E 0.6 ft [0.2 m]

Top connection 3

1

2 IF box 3

1

2 IF box

Bit connection 3

1

2 API Reg pin 3

1

2 API Reg pin

Total tool weight 2,397 lbm [1,087.3 kg]

Bend settings 0 to 1.5 0 to 1.5

Recommended bit sizes 5

5

8 in to 6

3

4 in [143 mm to 171 mm]

Operational Data

RPM range/revolution per gallon 1,010 to 1,710 rpm 7.44 rev/gal

Pressure drop range 1,380 to 3,000 psi 1,380 to 3,000 psi

Max. power output 214 hp [160 kw]

Max. stall torque 1,387 ft-lbf [1,881 nm]

Turbodrill

power

output,

hp

Flow rate, gpm

120 130 140 150 160 170 180 190 200 210 220 230 240

120 130 140 150 160 170 180 190 200 210 220 230 240

250

200

150

100

50

0

10 ppg

12 ppg

14 ppg

16 ppg

Turbodrill

pressure

drop,

psi

Flow rate, gpm

3,500

3,000

2,500

2,000

1,500

1,000

500

0

10 ppg

12 ppg

14 ppg

16 ppg

Build rate

capabilities,

/100

0 10 20 30 40 50 60 70 90 80

Hole angle,

14

12

10

8

6

4

2

0

1.00

1.25

1.50

32

Turbodrill Handbook

N

e

y

r

f

o

r

T

r

a

d

i

t

i

o

n

a

l

S

e

r

i

e

s

33

A

B

C

E

Power

section

Bearing

section

D

4

3

4-in T122 Steerable

4

3

4-in T2 MK2 FBS

TOOL SUMMARY

Tool Specifications

Turbine section diameter 4.75 in [120.65mm]

(A) Overall length 47.5 ft [14.48 m]

(B) Bit to center of stabilizer B 29.3 ft [8.93 m]

(C) Bit to center of stabilizer C 13.1 ft [4.02 m]

(D) Bit to bend 5.63 ft [1.72 m]

(E) Bit to center of stabilizer E 0.6 ft [0.2 m]

Top connection 3

1

2 IF box 3

1

2 IF box

Bit connection 3

1

2 API Reg pin 3

1

2 API Reg pin

Total tool weight 2,437 lbm [1,105.4 kg]

Bend settings 0 to 1.5 0 to 1.5

Recommended bit sizes 5

5

8 in to 6

3

4 in [143 mm to 171 mm]

Operational Data

RPM range/revolution per gallon 690 to 1,300 rpm 6.357 rev/gal

Pressure drop range 1,530 to 3,000 psi 1,530 to 3,000 psi

Max. power output 190 hp [142 kw]

Max. stall torque 1,457 ft-lbf [1,975 nm]

Turbodrill

power

output,

hp

Flow rate, gpm

80 90 100 110 120 130 140 150 160 170 180 190 200 210 220 230 240

80 90 100 110 120 130 140 150 160 170 180 190 200 210 220 230 240

200

150

100

50

0

10 ppg

12 ppg

14 ppg

16 ppg

Turbodrill

pressure

drop,

psi

Flow rate, gpm

3,500

3,000

2,500

2,000

1,500

1,000

500

0

10 ppg

12 ppg

14 ppg

16 ppg

Build rate

capabilities,

/100

0 10 20 30 40 50 60 70 90 80

Hole angle,

14

12

10

8

6

4

2

0

1.00

1.25

1.50

34

Turbodrill Handbook

N

e

y

r

f

o

r

T

r

a

d

i

t

i

o

n

a

l

S

e

r

i

e

s

35

A

B

C

E

Power

section

Bearing

section

D

6

5

8-in T111 Steerable

6

5

8-in T1 MK1 FBS

TOOL SUMMARY

Tool Specifications

Turbine section diameter 6.625 in [168.28 mm]

(A) Overall length 32.79 ft [10.0 m]

(B) Bit to center of stabilizer B 15.69 ft [4.78 m]

(C) Bit to bend 5.7 ft [1.74 m]

(D) Bit to center of stabilizer D 0.77 ft [0.24 m]

Top connection 4

1

2 IF box 4

1

2 IF box

Bit connection 4

1

2 API Reg pin 4

1

2 API Reg pin

Total tool weight 3,099 lbm [1,405.7 kg]

Bend settings 0 to 1.5 0 to 1.5

Recommended bit sizes 7

1

2 in to 9

7

8 in [191 mm to 251 mm]

Operational Data

RPM range/revolution per gallon 980 to 1,580 rpm 2.604 rev/gal

Pressure drop range 980 to 2,200 psi 980 to 2,200 psi

Max. power output 367 hp [274 kw]

Max. stall torque 2,721ft-lbf [3,689 nm]

Turbodrill

power

output,

hp

Flow rate, gpm

300 350 400 450 500 550 600 650

300 350 400 450 500 550 600 650

400

350

300

250

200

150

100

50

0

10 ppg

12 ppg

14 ppg

16 ppg

Turbodrill

pressure

drop,

psi

Flow rate, gpm

2,500

2,000

1,500

1,000

500

0

10 ppg

12 ppg

14 ppg

16 ppg

Build rate

capabilities,

/100

0 10 20 30 40 50 60 70 80

Hole angle,

10

8

6

4

2

0

0.75

1.00

1.25

36

Turbodrill Handbook

N

e

y

r

f

o

r

T

r

a

d

i

t

i

o

n

a

l

S

e

r

i

e

s

37

A

B

C

D

Power

section

Bearing

section

6

5

8-in T111XP Steerable

6

5

8-in T1XL MK1 FBS

TOOL SUMMARY

Tool Specifications

Turbine section diameter 6.625 in [168.28 mm]

(A) Overall length 39.35 ft [11.99 m]

(B) Bit to center of stabilizer B 15.69 ft [4.78 m]

(C) Bit to bend 5.7 ft [1.74 m]

(D) Bit to center of stabilizer D 0.77 ft [0.24 m]

Top connection 4

1

2 IF box 4

1

2 IF box

Bit connection 4

1

2 API Reg pin 4

1

2 API Reg pin

Total tool weight 3,716 lbm [1,430.6 kg]

Bend settings 0 to 1.5 0 to 1.5

Recommended bit sizes 7

1

2 in to 9

7

8 in [191 mm to 251 mm]

Operational Data

RPM range/revolution per gallon 850 to 1,380 rpm 2.604 rev/gal

Pressure drop range 1,130 to 2,580 psi 1,130 to 2,580 psi

Max. power output 375 hp [280 kw]

Max. stall torque 3,334 ft-lbf [4,520 nm]

Turbodrill

power

output,

hp

Flow rate, gpm

250 300 350 400 450 500 550 600

250 300 350 400 450 500 550 600

400

350

300

250

200

150

100

50

0

10 ppg

12 ppg

14 ppg

16 ppg

Turbodrill

pressure

drop,

psi

Flow rate, gpm

3,000

2,500

2,000

1,500

1,000

500

0

10 ppg

12 ppg

14 ppg

16 ppg

Build rate

capabilities,

/100

0 10 20 30 40 50 60 70 80

Hole angle,

10

8

6

4

2

0

0.75

1.00

1.25

38

Turbodrill Handbook

N

e

y

r

f

o

r

T

r

a

d

i

t

i

o

n

a

l

S

e

r

i

e

s

39

A

B

C

D

Power

section

Bearing

section

6

5

8-in T112 Steerable

6

5

8-in T1 MK2 FBS

TOOL SUMMARY

Tool Specifications

Turbine section diameter 6.625 in [168.28 mm]

(A) Overall length 32.79 ft [10.0 m]

(B) Bit to center of stabilizer B 15.69 ft [4.78 m]

(C) Bit to bend 5.7 ft [1.74 m]

(D) Bit to center of stabilizer D 0.77 ft [0.24 m]

Top connection 4

1

2 IF box 4

1

2 IF box

Bit connection 4

1

2 API Reg pin 4

1

2 API Reg pin

Total tool weight 3,135 lbm [1,422.0 kg]

Bend settings 0 to 1.5 0 to 1.5

Recommended bit sizes 7

1

2 in to 9

7

8 in [191 mm to 251 mm]

Operational Data

RPM range/revolution per gallon 760 to 1,350 rpm 2.222 rev/gal

Pressure drop range 960 to 2,210 psi 960 to 2,210 psi

Max. power output 328 hp [245 kw]

Max. stall torque 3,047 ft-lbf [4,131 nm]

Turbodrill

power

output,

hp

Flow rate, gpm

300 350 400 450 500 550 600 650

300 350 400 450 500 550 600 650

350

300

250

200

150

100

50

0

10 ppg

12 ppg

14 ppg

16 ppg

Turbodrill

pressure

drop,

psi

Flow rate, gpm

2,500

2,000

1,500

1,000

500

0

10 ppg

12 ppg

14 ppg

16 ppg

Build rate

capabilities,

/100

0 10 20 30 40 50 60 70 80

Hole angle,

10

8

6

4

2

0

0.75

1.00

1.25

40

Turbodrill Handbook

N

e

y

r

f

o

r

T

r

a

d

i

t

i

o

n

a

l

S

e

r

i

e

s

41

A

B

C

D

Power

section

Bearing

section

6

5

8-in T112XP Steerable

6

5

8-in T1XL MK2 FBS

TOOL SUMMARY

Tool Specifications

Turbine section diameter 6.625 in [168.28 mm]

(A) Overall length 39.35 ft [11.99 m]

(B) Bit to center of stabilizer B 15.69 ft [4.78 m]

(C) Bit to bend 5.7 ft [1.74 m]

(D) Bit to center of stabilizer D 0.77 ft [0.24 m]

Top connection 4

1

2 IF box 4

1

2 IF box

Bit connection 4

1

2 API Reg pin 4

1

2 API Reg pin

Total tool weight 3,716 lbm [1,430.6 kg]

Bend settings 0 to 1.5 0 to 1.5

Recommended bit sizes 7

1

2 in to 9

7

8 in [191 mm to 251 mm]

Operational Data

RPM range/revolution per gallon 645 to 1,138 rpm 2.222 rev/gal

Pressure drop range 1,265 to 2,550 psi 1,265 to 2,550 psi

Max. power output 321 hp [239 kw]

Max. stall torque 3,582 ft-lbf [4,857 nm]

42

Turbodrill

power

output,

hp

Flow rate, gpm

300 350 400 450 500 550

300 350 400 450 500 550

400

350

300

250

200

150

100

10 ppg

12 ppg

14 ppg

16 ppg

Turbodrill

pressure

drop,

psi

Flow rate, gpm

3,000

2,500

2,000

1,500

1,000

10 ppg

12 ppg

14 ppg

16 ppg

Build rate

capabilities,

/100

0 10 20 30 40 50 60 70 80

Hole angle,

10

8

6

4

2

0

0.75

1.00

1.25

Turbodrill Handbook

N

e

y

r

f

o

r

T

r

a

d

i

t

i

o

n

a

l

S

e

r

i

e

s

43

A

B

C

D

Power

section

Bearing

section

6

5

8-in T112HF Steerable

6

5

8-in TSH MK2 FBS

TOOL SUMMARY

Tool Specifications

Turbine section diameter 6.625 in [168.28 mm]

(A) Overall length 38.56 ft [11.76 m]

(B) Bit to center of stabilizer B 15.69 ft [4.78 m]

(C) Bit to bend 5.7 ft [1.74 m]

(D) Bit to center of stabilizer D 0.77 ft [0.24 m]

Top connection 4

1

2 IF box 4

1

2 IF box

Bit connection 4

1

2 API Reg pin 4

1

2 API Reg pin

Total tool weight 3,750 lbm [1,701.0 kg]

Bend settings 0 to 1.5 0 to 1.5

Recommended bit sizes 7

1

2 in to 9

7

8 in [191 mm to 251 mm]

Operational Data

RPM range/revolution per gallon 690 to 1,550 rpm 2.22 rev/gal

Pressure drop range 1,050 to 3,200 psi 1,050 to 3,200 psi

Max. power output 595 hp [444 kw]

Max. stall torque 4,142 ft-lbf [5,616 nm]

44

Turbodrill

power

output,

hp

Flow rate, gpm

300 350 400 450 500 550 600 650 700

300 350 400 450 500 550 600 650 700

700

600

500

400

300

200

100

10 ppg

12 ppg

14 ppg

16 ppg

Turbodrill

pressure

drop,

psi

Flow rate, gpm

3,500

3,000

2,500

2,000

1,500

1,000

10 ppg

12 ppg

14 ppg

16 ppg

Build rate

capabilities,

/100

0 10 20 30 40 50 60 70 80

Hole angle,

10

8

6

4

2

0

0.75

1.00

1.25

Turbodrill Handbook

N

e

y

r

f

o

r

T

r

a

d

i

t

i

o

n

a

l

S

e

r

i

e

s

45

A

B

C

D

Power

section

Bearing

section

6

5

8-in T113 Steerable

6

5

8-in T1 MK3 FBS

TOOL SUMMARY

Tool Specifications

Turbine section diameter 6.625 in [168.28 mm]

(A) Overall length 32.79 ft [10.0 m]

(B) Bit to center of stabilizer B 15.69 ft [4.78 m]

(C) Bit to bend 5.7 ft [1.74 m]

(D) Bit to center of stabilizer D 0.77 ft [0.24 m]

Top connection 4

1

2 IF box 4

1

2 IF box

Bit connection 4

1

2 API Reg pin 4

1

2 API Reg pin

Total tool weight 3,154 lbm [1,430.6 kg]

Bend settings 0 to 1.5 0 to 1.5

Recommended bit sizes 7

1

2 in to 9

7

8 in [191 mm to 251 mm]

Operational Data

RPM range/revolution per gallon 720 to 1,320 rpm 3.23 rev/gal

Pressure drop range 1,382 to 2,157 psi 1,382 to 2,157 psi

Max. power output 215 hp [160 kw]

Max. stall torque 2,101 ft-lbf [3,689 nm]

46

Turbodrill

power

output,

hp

Flow rate, gpm

330 310 290 270 250 350 370 390 410 430 450

330 310 290 270 250 350 370 390 410 430 450

240

210

180

150

10 ppg

12 ppg

14 ppg

16 ppg

Turbodrill

pressure

drop,

psi

Flow rate, gpm

2,500

2,000

1,900

1,600

1,300

1,000

10 ppg

12 ppg

14 ppg

16 ppg

Build rate

capabilities,

/100

0 10 20 30 40 50 60 70 80

Hole angle,

10

8

6

4

2

0

0.75

1.00

1.25

Turbodrill Handbook

N

e

y

r

f

o

r

T

r

a

d

i

t

i

o

n

a

l

S

e

r

i

e

s

47

A

B

C

D

Power

section

Bearing

section

6

5

8-in T113XP Steerable

6

5

8-in T1XL MK3 FBS

TOOL SUMMARY

Tool Specifications

Turbine section diameter 6.625 in [168.28 mm]

(A) Overall length 39.35 ft [11.99 m]

(B) Bit to center of stabilizer B 15.69 ft [4.78 m]

(C) Bit to bend 5.7 ft [1.74 m]

(D) Bit to center of stabilizer D 0.77 ft [0.24 m]

Top connection 4

1

2 IF box 4

1

2 IF box

Bit connection 4

1

2 API Reg pin 4

1

2 API Reg pin

Total tool weight

Bend settings 0 to 1.5 0 to 1.5

Recommended bit sizes 7

1

2 in to 9

7

8 in [191 mm to 251 mm]

Operational Data

RPM range/revolution per gallon 680 to 1,140 rpm 3.23 rev/gal

Pressure drop range 1,619 to 2,537 psi 1,619 to 2,537 psi

Max. power output 217 hp [162 kw]

Max. stall torque 2,464 ft-lbf [3,341 nm]

48

Turbodrill

power

output,

hp

Flow rate, gpm

280 260 240 220 200 300 320 340

280 260 240 220 200 300 320 340

240

210

180

150

10 ppg

12 ppg

14 ppg

16 ppg

Turbodrill

pressure

drop,

psi

Flow rate, gpm

2,700

2,400

2,100

1,800

1,500

10 ppg

12 ppg

14 ppg

16 ppg

Build rate

capabilities,

/100

0 10 20 30 40 50 60 70 80

Hole angle,

10

8

6

4

2

0

0.75

1.00

1.25

Turbodrill Handbook

N

e

y

r

f

o

r

T

r

a

d

i

t

i

o

n

a

l

S

e

r

i

e

s

49

A

B

C

D

Power

section

Bearing

section

6

5

8-in T113HF Steerable

6

5

8-in TSH MK3 FBS

TOOL SUMMARY

Tool Specifications

Turbine section diameter 6.625 in [168.28 mm]

(A) Overall length 38.56 ft [11.76 m]

(B) Bit to center of stabilizer B 15.69 ft [4.78 m]

(C) Bit to bend 5.7 ft [1.74 m]

(D) Bit to center of stabilizer D 0.77 ft [0.24 m]

Top connection 4

1

2 IF box 4

1

2 IF box

Bit connection 4

1

2 API Reg pin 4

1

2 API Reg pin

Total tool weight 3,750 lbm [1,701.0 kg]

Bend settings 0 to 1.5 0 to 1.5

Recommended bit sizes 7

1

2 in to 9

7

8 in [191 mm to 251 mm]

Operational Data

RPM range/revolution per gallon 730 to 1,480 rpm 3.23 rev/gal

Pressure drop range 1,549 to 3,169 psi 1,549 to 3,169 psi

Max. power output 387 hp [289 kw]

Max. stall torque 2,858 ft-lbf [3,875 nm]

50

Turbodrill

power

output,

hp

Flow rate, gpm

250 300 350 400 450 500

250 300 350 400 450 500

400

350

300

250

200

100

10 ppg

12 ppg

14 ppg

16 ppg

Turbodrill

pressure

drop,

psi

Flow rate, gpm

3,500

3,000

2,500

2,000

1,500

1,000

10 ppg

12 ppg

14 ppg

16 ppg

Build rate

capabilities,

/100

0 10 20 30 40 50 60 70 80

Hole angle,

10

8

6

4

2

0

0.75

1.00

1.25

Turbodrill Handbook

N

e

y

r

f

o

r

T

r

a

d

i

t

i

o

n

a

l

S

e

r

i

e

s

51

A

B

C

D

Power

section

Bearing

section

52

6

5

8-in T121 Steerable

6

5

8-in T2 MK1 FBS

TOOL SUMMARY

Tool Specifications

Turbine section diameter 6.625 in [168.28 mm]

(A) Overall length 49.71 ft [15.16m]

(B) Bit to center of stabilizer B 32.62 ft [9.94 m]

(C) Bit to center of stabilizer C 15.69 ft [4.78 m]

(D) Bit to bend 5.7 ft [1.74 m]

(E) Bit to center of stabilizer E 0.77 ft [0.24 m]

Top connection 4

1

2 IF box 4

1

2 IF box

Bit connection 4

1

2 API Reg pin 4

1

2 API Reg pin

Total tool weight 4,833 lbm [2,192 kg]

Bend settings 0 to 1.5 0 to 1.5

Recommended bit sizes 7

1

2 in to 9

7

8 in [191 mm to 251 mm]

Operational Data

RPM range/revolution per gallon 790 to 1,300 rpm 2.604 rev/gal

Pressure drop range 1,368 to 2,664 psi 1,368 to 2,664 psi

Max. power output 359 hp [268 kw]

Max. stall torque 3,581 ft-lbf [4,855 nm]

Turbodrill

power

output,

hp

Flow rate, gpm

300 360 380 340 320 400 420 440 460 480 500

300 360 380 340 320 400 420 440 460 480 500

450

400

350

300

250

200

150

10 ppg

12 ppg

14 ppg

16 ppg

Turbodrill

pressure

drop,

psi

Flow rate, gpm

3,000

2,500

2,000

1,500

1,000

10 ppg

12 ppg

14 ppg

16 ppg

Build rate

capabilities,

/100

0 10 20 30 40 50 60 70 90 80

Hole angle,

10

8

6

4

2

0

0.75

1.00

1.25

Turbodrill Handbook

N

e

y

r

f

o

r

T

r

a

d

i

t

i

o

n

a

l

S

e

r

i

e

s

53

A

B

C

E

Power

section

Bearing

section

D

6

5

8-in T122 Steerable

6

5

8-in T2 MK2 FBS

TOOL SUMMARY

Tool Specifications

Turbine section diameter 6.625 in [168.28 mm]

(A) Overall length 49.71 ft [15.16m]

(B) Bit to center of stabilizer B 32.62 ft [9.94 m]

(C) Bit to center of stabilizer C 15.69 ft [4.78 m]

(D) Bit to bend 5.7 ft [1.74 m]

(E) Bit to center of stabilizer E 0.77 ft [0.24 m]

Top connection 4

1

2 IF box 4

1

2 IF box

Bit connection 4

1

2 API Reg pin 4

1

2 API Reg pin

Total tool weight 4,905 lbm [2,224.9 kg]

Bend settings 0 to 1.5 0 to 1.5

Recommended bit sizes 7

1

2 in to 9

7

8 in [191 mm to 251 mm]

Operational Data

RPM range/revolution per gallon 600 to 1,090 rpm 2.222 rev/gal

Pressure drop range 1,351 to 2,747 psi 1,351 to 2,747 psi

Max. power output 324 hp [242 kw]

Max. stall torque 3,845 ft-lbf [5,213 nm]

54

Turbodrill

power

output,

hp

Flow rate, gpm

250 300 350 400 450 500

250 300 350 400 450 500

400

350

300

250

200

150

10 ppg

12 ppg

14 ppg

16 ppg

Turbodrill

pressure

drop,

psi

Flow rate, gpm

3,500

3,000

2,500

2,000

1,500

1,000

10 ppg

12 ppg

14 ppg

16 ppg

Build rate

capabilities,

/100

0 10 20 30 40 50 60 70 80

Hole angle,

10

8

6

4

2

0

0.75

1.00

1.25

Turbodrill Handbook

N

e

y

r

f

o

r

T

r

a

d

i

t

i

o

n

a

l

S

e

r

i

e

s

55

A

B

C

E

Power

section

Bearing

section

D

7

1

4-in T111 Steerable

7

1

4-in T1 MK1 FBS

TOOL SUMMARY

Tool Specifications

Turbine section diameter 7.25 in [184.15 mm]

(A) Overall length 32.6 ft [9.94 m]

(B) Bit to center of stabilizer B 16.9 ft [1.89 m]

(C) Bit to bend 6.2 ft [1.89 m]

(D) Bit to center of stabilizer D 1.0 ft [0.3 m]

Top connection 4

1

2 IF box 4

1

2 IF box

Bit connection 4

1

2 API Reg pin 4

1

2 API Reg pin

Total tool weight 3,670 lbm [1,664.7 kg]

Bend settings 0 to 1.5 0 to 1.5

Recommended bit sizes 8

3

8 in to 10

5

8 in [213 mm to 270 mm]

Operational Data

RPM range/revolution per gallon 765 to 1,430 rpm 1.85 rev/gal

Pressure drop range 915 to 2,351 psi 915 to 2,351 psi

Max. power output 474 hp [353 kw]

Max. stall torque 3,679 ft-lbf [4,988 nm]

56

Turbodrill

power

output,

hp

Flow rate, gpm

450 500 550 600 650 700 750

450 500 550 600 650 700 750

500

400

300

200

100

10 ppg

12 ppg

14 ppg

16 ppg

Turbodrill

pressure

drop,

psi

Flow rate, gpm

2,500

2,200

1,900

1,600

1,300

1,000

10 ppg

12 ppg

14 ppg

16 ppg

Build rate

capabilities,

/100

0 10 20 30 40 50 60 70 80

Hole angle,

6

5

4

3

2

1

0

0.5

1.00

Turbodrill Handbook

N

e

y

r

f

o

r

T

r

a

d

i

t

i

o

n

a

l

S

e

r

i

e

s

57

A

B

C

D

Power

section

Bearing

section

7

1

4-in T121 Steerable

7

1

4-in T2 MK1 FBS

TOOL SUMMARY

Tool Specifications

Turbine section diameter 7.25 in [184.15 mm]

(A) Overall length 48.1 ft [9.88 m]

(B) Bit to center of stabilizer B 32.4 ft [5.15 m]

(C) Bit to center of stabilizer C 16.9 ft [5.15 m]

(D) Bit to bend 6.2 ft [1.89 m]

(E) Bit to center of stabilizer E 1.0 ft [0.3 m]

Top connection 4

1

2 IF box 4

1

2 IF box

Bit connection 4

1

2 API Reg pin 4

1

2 API Reg pin

Total tool weight 5,500 lbm [2,494.8 kg]

Bend settings 0 to 1.5 0 to 1.5

Recommended bit sizes 8

3

8 in to 10

5

8 in [213 mm to 270 mm]

Operational Data

RPM range/revolution per gallon 640 to 1,200 rpm 1.85 rev/gal

Pressure drop range 1,065 to 3,035 psi 1,065 to 3,035 psi

Max. power output 522 hp [389 kw]

Max. stall torque 4,769 ft-lbf [6,466 nm]

58

Turbodrill

power

output,

hp

Flow rate, gpm

350 400 450 500 550 600 650

350 400 450 500 550 600 650

600

500

400

300

200

100

10 ppg

12 ppg

14 ppg

16 ppg

Turbodrill

pressure

drop,

psi

Flow rate, gpm

3,500

3,000

2,500

2,000

1,500

1,000

10 ppg

12 ppg

14 ppg

16 ppg

Build rate

capabilities,

/100

0 10 20 30 40 50 60 70 80

Hole angle,

6

5

4

3

2

1

0

0.5

1.00

Turbodrill Handbook

N

e

y

r

f

o

r

T

r

a

d

i

t

i

o

n

a

l

S

e

r

i

e

s

59

A

B

C

E

Power

section

Bearing

section

D

7

1

4-in T131 Steerable

7

1

4-in T3 MK1 FBS

TOOL SUMMARY

Tool Specifications

Turbine section diameter 7.25 in [184.15 mm]

(A) Overall length 63.6 ft [19.39 m]

(B) Bit to center of stabilizer B 47.9 ft [14.60 m]

(C) Bit to center of stabilizer C 32.4 ft [9.88 m]

(D) Bit to center of stabilizer D 16.9 ft [5.15 m]

(E) Bit to bend 6.2 ft [1.89 m]

(F) Bit to center of stabilizer F 1.0 ft [0.3 m]

Top connection 4

1

2 IF box 4

1

2 IF box

Bit connection 4

1

2 API Reg pin 4

1

2 API Reg pin

Total tool weight 7,300 lbm [3,311.2 kg]

Bend settings 0 to 1.5 0 to 1.5

Recommended bit sizes 8

3

8 in to 10

5

8 in [213 mm to 270 mm]

Operational Data

RPM range/revolution per gallon 565 to 1,000 rpm 1.85 rev/gal

Pressure drop range 1,200 to 3,410 psi 1,200 to 3,410 psi

Max. power output 521 hp [382 kw]

Max. stall torque 5,672 ft-lbf [7,690 nm]

60

Turbodrill

power

output,

hp

Flow rate, gpm

300 350 400 450 500 550 600

300 350 400 450 500 550 600

600

500

400

300

200

100

10 ppg

12 ppg

14 ppg

16 ppg

Turbodrill

pressure

drop,

psi

Flow rate, gpm

3,500

3,000

2,500

2,000

1,500

1,000

10 ppg

12 ppg

14 ppg

16 ppg

Build rate

capabilities,

/100

0 10 20 30 40 50 60 70 80

Hole angle,

6

5

4

3

2

0

0.5

1.00

Turbodrill Handbook

N

e

y

r

f

o

r

T

r

a

d

i

t

i

o

n

a

l

S

e

r

i

e

s

61

A

B

C

F

Power

section

Bearing

section

D

E

9

1

2-in T111 Steerable

9

1

2-in T1 MK1 FBS

TOOL SUMMARY

Tool Specifications

Turbine section diameter 9.5 in [241.30 mm]

(A) Overall length 37.9 ft [11.55 m]

(B) Bit to center of stabilizer B 18.4 ft [5.61m]

(C) Bit to bend 6.8 ft [2.07 m]

(D) Bit to center of stabilizer D 1.0 ft [0.3 m]

Top connection 7

5

8 API Reg box 7

5

8 API Reg box

Bit connection 6

5

8 or 7

5

8 API Reg pin 6

5

8 or 7

5

8 API Reg pin

Total tool weight 7,620 lbm [3,546.4 kg]

Bend settings 0 to 1.5 0 to 1.5

Recommended bit sizes 12 in to 17

1

2 in [305 mm to 445 mm]

Operational Data

RPM range/revolution per gallon 570 to 950 rpm 1.095 rev/gal

Pressure drop range 920 to 1,817 psi 920 to 1,817 psi

Max. power output 439 hp [327 kw]

Max. stall torque 5,054 ft-lbf [6,852 nm]

62

Turbodrill

power

output,

hp

Flow rate, gpm

600 650 700 750 800 850 900

600 650 700 750 800 850 900

450

400

350

300

250

200

10 ppg

12 ppg

14 ppg

16 ppg

Turbodrill

pressure

drop,

psi

Flow rate, gpm

2,000

1,800

1,600

1,400

1,200

1,000

10 ppg

12 ppg

14 ppg

16 ppg

Build rate

capabilities,

/100

0 10 20 30 40 50 60 70 80 90

Hole angle,

8

7

6

5

4

3

2

1

0

0.75

1.00

1.25

Turbodrill Handbook

N

e

y

r

f

o

r

T

r

a

d

i

t

i

o

n

a

l

S

e

r

i

e

s

63

A

B

C

D

Power

section

Bearing

section

9

1

2-in T112 Steerable

9

1

2-in T1 MK2 FBS

TOOL SUMMARY

Tool Specifications

Turbine section diameter 9.5 in [241.30 mm]

(A) Overall length 37.9 ft [11.55 m]

(B) Bit to center of stabilizer B 18.4 ft [5.61 m]

(C) Bit to bend 6.8 ft [2.07 m]

(D) Bit to center of stabilizer D 1.0 ft [0.3 m]

Top connection 7

5

8 API Reg box 7

5

8 API Reg box

Bit connection 6

5

8 or 7

5

8 API Reg pin 6

5

8 or 7

5

8 API Reg pin

Total tool weight 7,770 lbm [3,524.4 kg]

Bend settings 0 to 1.5 0 to 1.5

Recommended bit sizes 12 in to 17

1

2 in [305 mm to 445 mm]

Operational Data

RPM range/revolution per gallon 450 to 790 rpm 0.980 rev/gal

Pressure drop range 975 to 2,094 psi 975 to 2,094 psi

Max. power output 409 hp [305 kw]

Max. stall torque 5,638 ft-lbf [7,644 nm]

64

Turbodrill

power

output,

hp

Flow rate, gpm

500 550 600 650 700 750 800 850

500 550 600 650 700 750 800 850

450

400

350

300

250

200

10 ppg

12 ppg

14 ppg

16 ppg

Turbodrill

pressure

drop,

psi

Flow rate, gpm

2,200

2,000

1,800

1,600

1,400

1,200

1,000

10 ppg

12 ppg

14 ppg

16 ppg

Build rate

capabilities,

/100

0 10 20 30 40 50 60 70 90 80

Hole angle,

8

7

6

5

4

3

2

0

0.75

1.00

1.25

Turbodrill Handbook

N

e

y

r

f

o

r

T

r

a

d

i

t

i

o

n

a

l

S

e

r

i

e

s

65

A

B

C

D

Power

section

Bearing

section

9

1

2-in T112HF Steerable

9

1

2-in TSH MK2 FBS

TOOL SUMMARY

Tool Specifications

Turbine section diameter 9.5 in [241.30 mm]

(A) Overall length 44.4 ft [13.5m]

(B) Bit to center of stabilizer B 18.4 ft [5.61 m]

(C) Bit to bend 6.8 ft [2.07 m]

(D) Bit to center of stabilizer D 1.0 ft [0.3 m]

Top connection 7

5

8 API Reg box 7

5

8 API Reg box

Bit connection 6

5

8 or 7

5

8 API Reg pin 6

5

8 or 7

5

8 API Reg pin

Total tool weight 8,988 lbm [4,076.9 kg]

Bend settings 0 to 1.5 0 to 1.5

Recommended bit sizes 12 in to 17

1

2 in [305 mm to 445 mm]

Operational Data

RPM range/revolution per gallon 425 to 1,156 rpm 0.980 rev/gal

Pressure drop range 1,271 to 4,480 psi 1,271 to 4,480 psi

Max. power output 1,279 hp [953 kw]

Max. stall torque 13,107 ft-lbf [17,770 nm]

66

Turbodrill

power

output,

hp

Flow rate, gpm

400 500 600 700 800 900 1,000 1,100 1,200

400 500 600 700 800 900 1,000 1,100 1,200

1,400

1,200

1,000

800

600

400

200

10 ppg

12 ppg

14 ppg

16 ppg

Turbodrill

pressure

drop,

psi

Flow rate, gpm

4,500

4,000

3,500

3,000

2,500

2,000

1,500

1,000

10 ppg

12 ppg

14 ppg

16 ppg

Build rate

capabilities,

/100

0 10 20 30 40 50 60 70 90 80

Hole angle,

8

7

6

5

4

3

2

0

0.75

1.00

1.25

Turbodrill Handbook

N

e

y

r

f

o

r

T

r

a

d

i

t

i

o

n

a

l

S

e

r

i

e

s

67

A

B

C

D

Power

section

Bearing

section

9

1

2-in T113HF Steerable

9

1

2-in TSH MK3 FBS

TOOL SUMMARY

Tool Specifications

Turbine section diameter 9.5 in [241.30 mm]

(A) Overall length 44.4 ft [13.5 m]

(B) Bit to center of stabilizer B 18.4 ft [5.61m]

(C) Bit to bend 6.8 ft [2.07 m]

(D) Bit to center of stabilizer D 1.0 ft [0.3 m]

Top connection 7

5

8 API Reg box 7

5

8 API Reg box

Bit connection 6

5

8 or 7