Академический Документы

Профессиональный Документы

Культура Документы

Atkinson Tractor Service Shop Manual Unit 2 - Transmission

Загружено:

David KellyАвторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Atkinson Tractor Service Shop Manual Unit 2 - Transmission

Загружено:

David KellyАвторское право:

Доступные форматы

I

Unit: _2 ___ _

Section : 3

SERVICE SHOP MANUAL Page :

-----

I Date : October, 1969

UNIT 2 - TRANSI'v11SSION

SECTION 3

DAVID BROVVN 10-550 GEARBOX

INDEX OF CONTENTS

Technical Data

Gearbox-Technical Description ..

Lubrication

Routine Maintenance ..

Unit Replacement

Unit Overhaul (Refer to David Brown publication) ..

Forward Control Unit-Lubrication

Routine Maintenance

Unit Replacement

Unit Overhaul ..

Range Change-Technical Description ..

Control Valve-Technical Description ..

Routine Maintenance ..

Unit Replacement

Unit Overhaul

Operating Cylinder-Technical Description ..

Routine Maintenance

Unit Replacement

Unit Overhaul

Page

2

3

4

4

4

4

4

5

5

6

7

8

8

8

.. 10

. . 11

.. 11

.. 11

U nit ~ . _ . ~ _ ~ _ .. _._J

Section : 3

Page: 2

~ I

SERVICE SHOP MANUAL

Date. October, 1969 .

TECHNICAL DATA

Ratios

Gears

Model

Type

Mainshaft 1 st speed gear

Mainshaft, reverse speed gear

Mainshaft 2nd speed gear

Mainshaft, 3rd speed gear

Mainshaft, 4th speed gear

Mainshaft 5th speed gear

Primary Shaft

Layshaft 1 st speed gear

Layshaft 2nd speed gear

Layshaft 3rd speed gear

Layshaft, reverse speed gear . .

Layshaft, 4th speed gear

Layshaft 5th speed gear

Layshaft twin range driving gear

Reverse shaft, driving and PTO gear

Bearings

Clutch Withdrawal

Primary Shaft-I nner

Outer

Mainshaf -Centre

Rear . .

Layshaft-Front Inner ..

Front Outer . .

Centre . .

Rear

Reverse Shaft-Front

Rear

Mainshaft gears (except reverse)

Mainshaft 5th speed gear and Reverse shaft

driving gear

David Brown 10-550

10-speed constant mesh with two reverse speeds

and air operated splitter control (Twin Range)

Gears

1 st

2nd

3rd

4th

5th

Reverse

No. of teeth

53

53

46

37

27

20

22

15

22

30

28

39

45

38

38

High

range

6100 :1

3610 :1

2130:1

1 196 :1

0768 :1

6220 :1

Type of Gear

Helical

Spur

Helical

Helical

Helical

Spur

Helical

Helical

Helical

Helical

Spur

Helical

Spur

Helical

Spur

Single row ball type

Single row roller type

Single row ball type

Single row roller type

Single row ball type

Single row roller type

Single row ball type

Single row roller type

Single row roller type

Single row roller type

Single row roller type

Double row needle roller type

Low

range

795 :1

470 :1

278 :1

156 :1

100 :1

808 :1

Single row needle roller thrust type bearings.

I ~ _ n i t ___ 2

i Section: 3

SERVICE SHOP MANUAL

I-page: 3

Oil Seals

Primary Shaft

Mainshaft (coupling flange)

Speedomete r Gear Chart

Spring loaded single-lip type

Spring loaded double-lip type

Date : October, 1969

.1

Note : Rev/min based on Dunlop highway unless otherwise stated.

Reduction gears to suit 4:1 speedo gears.

TYRE SIZE RPM

900 x 20 523

10 x 225

10 x 20 503

0225

11 x 20 492

Range Change

Control Valve

Operating Cylinder

Stroke

Selector Shaft Springs

Number

Free length

MAKE GEARS

Dunlop Driving

Driven

Dunlop Driving

Highway Driven

I

Dunlop Driving

Driven

Length when loaded with 6151b (28 kg) . .

TECHNICAL DESCRIPTION

The gearbox has five forward speeds and one

reverse with twin range auxiliary gears mounted at

the front end, providing ten forward and two reverse

speeds. The twin range section is air operated by

push/pull cable mounted on the change speed lever

and operates an air cylinder mounted on top of the

gearbox casing through a control valve to select

either the High or Low range gear ratios.

All gears operate in constant mesh, engagement

being by sliding clutches. The mainshaft gears

revovle on needle roller bearing assemblies with

support bushes located on the mainshaft for 3rd, 4th

and 5th speed gears, while the needle rollers of 1 st

and 2nd gear rotates directly on the mainshaft.

The mainshaft is supported on a ball bearing at

the rear end, and a roller bearing at the front end,

the outer race of which is circlip located in the casing.

The layshaft is supported by roller bearings at the

rear end and in the centre, while the front end is

supported by a roller and ball bearing. The 1st and

2nd speed layshaft gears are an integral part of the

layshaft, while the remaining gears apart from the

AXLE

578 701

23166-23 23164-21

23164-21 23166-23

23166-23 23164-21

23164-21 23166-23

23167-24 23164-21

23163-20 23166-23

Clayton Dewandre

Clayton Dewandre

RATIOS

-----

795 917

23162-19 23161-18

23168-25 23169-26

23163-20 23161-18

23167-24 23169-26

23163-20 23161-18

23167-24 23169-26

1047 to 1089 in (2659 to 2766 mm)

4

1 -h in (3334 mm)

1 t in (2858 mm)

twin range driving gear are key located on the shaft.

The twin range driving gear is supported on the

layshaft by a bush and is in constant mesh with the

primary shaft gear.

The cast aluminium gearbox casing is in two

halves to facilitate easy servicing and oil leakage

from the casing at the input and output ends is

prevented by oil seals.

Provision is made for the fitting of power take-off

units which can either be driven from the reverse

shaft driving and PTO gear or from the rear end of

the layshaft. A blanking plate or cover is fitted to the

casing when these are not fitted.

An efficient drum type clutch stop is fitted on the

primary shaft and this is easily adjusted by means of

a large bakelite knob located on the O/S of the bell

housing. Instructions for adjusting the clutch stop

are given in the Atkinson Operators Handbook.

A standard forward control change speed unit is

fitted with a universal jointed change speed rod. A

spring resistance must be overcome when moving

the change speed to the 1 st and 2nd gate and reverse

position.

Unit : 2

-J

----

Section : 3

I

Page: 4

SERVICE SHOP MANUAL

Date: October. 1969

- - - -- - -------------------------------

LUBRICATION

For the lubrication periods and correct lubricants

refer to Lubricants and Fluids and the Lubri-

cation Chart in Unit 0 of this manual.

ROUTINE MAINTENANCE

First 1 500 Mile (2400 I(m) of a New

Vehicle or the Fitment of a Service

Exchange or Overhaul Unit

1. Check all mounting nuts for tightness.

2. Check the security of the range change

operating cylinder and control valve.

3. Check that the change speed forward control

is securely mounted.

4. Ensure that the gearbox breather is not blocked.

Monthly or Every 5000 Mile (8000 km)

1. Check gearbox for oil leakage and rectify if

necessary.

2. Check all nuts and bolts for tightness including

change speed forward control.

3. Carry out operating and air leakage tests on

rang'e change control valve and operating

cylinder.

4. Ensure that the gearbox breather is not blocked.

UNIT REPLACEMENT

To Remove and Refit the Gearbox

To Remove

1. Drain the oil frc ..... the gearbox preferably when

warm and free flowing.

Replace the drain plug when the oil has stopped

flowing.

2. Remove the propeller shaft.

3. Disconnect the wiring from the speed a drive

unit.

4. Disconnect the change speed operating shaft

from the gearbox coupling flange and discon-

nect power take-ofts if fitted .

5. Disconnect the clutch operating rod from the

clutch operating lever.

6. Disconnect the air pipes from the twin range

operating cylinder.

7. Suitably support the engine at the rear end and

remove the rear engine and gearbox mounting

crossmember.

8. Take the weight of the gearbox on suitable

lifting gear and remove the clutch bell housing

bolts.

9. Withdraw the gearbox from the flywheel

housing and lower to the ground. ensuring that

the gearbox primary shaft is clear of the clutch

assembly.

To Refit

I n general refitting the gearbox is a reversal of the

removal procedure. ensuring that the following points

are carefully noted.

1. Check that the clutch driven plate is centralised

correctly. see section 1 of this unit.

2. Sparingly lubricate the primary shaft with high

melting point g,ease.

3. On no account allow the gearbox to hang on

the clutch driven plate assembly when entering

the splines. or driven plate distortion will take

place leading to eventual clutch failure.

4. When the gearbox has been refitted. adjust the

clutch pedal free play and the clutch stop as

described in Section 1, Unit 3 of this manual.

5. Refill the gearbox with the correct lubricant as

shown in Section 5, Lubricants and Fluids,

Unit 0 of this manual.

UNIT OVERHAUL

For unit overhaul refer to the appropriate David

Brown Service Manual.

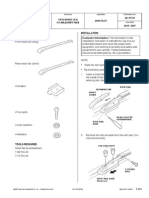

FORWARD CONTROL UNIT (Refer to Fig. 1)

The change speed forward control unit is mounted

on a bracket attached to the engine crankcase and

consists of a lever assembly the lower wnd of which

locates in a lever (15) attached to the forward control

operating shaft (12) by a locating screw (18) . The

shaft (12) is located in the housing (16) by two dry

wrapped bushes (14) which are a press fit in the

bosses of the housing and is connected to the control

rod by a muft coupling (10) . Dirt andforeign matter

is prevented from entering the housing via the

operating shaft by PVC bc;>ots (13) which are

positioned over the shaft as shown in Fig 1.

The lever assembly (3) is located in the top cover

by a conical spring (7) which locates over a damper

(9) and spring loads a spherical seating (6) against

the swivel ball of the change speed lever.

LUBRICATION

The unit is lubricated on assembly and needs no

further lubrication until unit overhaul.

ROUTINE MAINTENANCE

Monthly or Every 5000 Mile (8000 km)

1. Check mounting securing nuts and tighten if

necessary.

2. Check for play and/or wear in selector shaft

universal joints and service if necessary.

3. Check for excessive wear in operating shaft

bushes and replace if excessive wear is evident.

4. Inspect the operating shaft boots for deteriora-

tion and replace if necessary.

Unit: 2

Section : 3

SERVICE SHOP MANUAL

Page: 5

Date: October, 1969

._.

FIG. 1. SECTION VIEWS OF FORWARD CONTROL.

1. Knob. 7. Spring.

2. Locking ring. 8. Screw.

3. Lever assembly. 9. Damper.

4. Cap. 10. Muff coupling.

5. Cover. 11. Bolt.

6. Spherical seating. 12. Shaft.

UNIT REPLACEMENT

To Remove

1. Detach the change speed lever draught excluder

from the cab floor and release the jubilee clip

from the lever.

2. Disconnect the range change cable from the

change speed lever.

3. Remove one nut and bolt from the muff coup-

ling to disengage the operating shaft from the

control rod.

4. Remove the four setscrews which secure the

top cover to the forward control housing and

withdraw the change speed lever assembly

complete with top cover and draught excluder

up through the cab floor.

5. Remove the spherical seating, spring and

damper from the top of the housing.

6. Remove the nuts and shakeproof washers from

the housing studs and withdraw the housing

from the mounting bracket, lowering it down-

wards between the engine and chassis frame.

13.

14.

15.

16.

17.

18.

Boot. 19. Washer.

Bush. 20. Stud.

Lever. 21. Nut.

Housing. 22. Washer.

Locating screw. 23. Nut.

Locating screw.

To Refit

Refitting is a reversal of the removal procedure

ensuring that the change speed lever engages

correctly in operating shaft lever.

UNIT OVERHAUL

To Dismantle

With the forward control unit removed from the

chassis and already dismantled into two halves,

dismantle the housing assembly as follows :-

1. Remove the PVC boots from the operating

shaft and housing.

2. Remove the locking wire from operating shaft

lever locating screw and remove the screw.

3. Withdraw the operating shaft from the housing

and collect the lever. To dismantle the lever

assembly, draw off the change speed lever

knob (1) and locking ring (2) and withdraw the

lever assembly (3) from the top cover (5)

draught excluder, and cap (4).

Jnit : 2

)ection : 3

'age: 6

SERVICE SHOP MANUAL

)ate . October, 1 969

4

1

2

"t

3

J

1

~

FIG. 2. SCHEMATIC LAYOUT OF AIR OPERATED RANGE CHANGE UNITS.

1. Pressure regulator valve.

2. Supply from auxiliary reservoirs

3. Pipe connections on chassis frame.

Cleansing and Inspection of Dismantled Parts

1. Wash all metal parts in a suitable cleaning

solvent and blow dry with dry compresse.d air.

2. Inspect the operating shaft bushes for wear

and replace if necessary.

3. Inspect the operating shaft and lever for wear

and/or damage and replace if necessary.

4. Inspect the change speed lever for wear and/or

damage and replace if necessary.

5. Inspect the conical spring and spherical seat

for damage and/or distortion and replace if

necessary.

6. Inspect the top cover change speed lever

location for wear and replace if necessary.

7. It is recommended at unit overhaul that the

rubber damper and PVC cap and boots are

automatically replaced with new parts.

8. Inspect all nuts, bolts and studs of damaged

threads and replace if necessary.

To Re-Assemble

1 . Assemble the change speed lever to the top

cover and refit the PVC cap (4). draught

excluder, locking ring (2) and press on the lever

knob (1) .

2. If previously removed press new bushes (14)

into the housing (16).

4. Operating cable.

5. Control valve.

6. Operating cylinder on gearbox.

3. Position the lever (15) in the housing and refit

the operating shaft (12) . Secure the lever to

the operating shaft with the locating screw,

which should be securely tightened and wire

locked in posit!on.

4. Refit the PVC boots (13) and wire in position

on the housing shaft.

5. At this stage further assembly cannot be carried

out until the housing assembly has.been refitted

to the vehicle.

RANGE CHANGE

TECHNICAL DESCRIPTION

The equipment illustrated schematically in Fig. 2

is designed to operate the gearbox range change,

using compressed air supplied by the vehicle braking

system through the pressure regulator valve, which

is fitted in the air line between the auxiliary reservoirs

and control valve to protect the braking system in

the event of air leakage occuring in the gear shift

system.

The control valve is actuated by a push/pull cable

and is mounted on the rear right-hand side of the

engine. The main purpose of the valve is to control

the operating cylinder, which is mounted on the

gearbox casing, by admitting compressed air to one

end of the cylinder and exhausting the other end to

atmosphere. Operation of the valve reverses the

porting to the cylinder causing an opposite force to

be apglied to the gear shift parts in the cylinder and

gearbox.

Unit : 2

Section: 3

~

SERVICE SHOP MANUAL

Page: 7

CONTROL VALVE

TECHNICAL DESCRIPTION

The body of the unit has four ports for air line

connections, and houses two spring-loaded inlet

exhaust valves. The valves are identical, and consist

of rubber faced metal discs lightly sprung against

removable seats. A cover plate, bolted to the body,

retains the valve springs and valve seat retaining

springs. Two tubular exhaust stems project into a

top cover, and are inter-connected by means of a

beam spring to ensure synchronous operation. The

cover has a short exhaust tube which should be

fitted with a filter or breather pipe to prevent ingress

of foreign matter. The operating cable, from a hand

control knob, passes through a compression screw

fitted in the cover, and is secured to a valve actuating

toggle mechanism.

The cover has two bosses, tapped *-20 UNC-2B,

for mounting purposes.

When the control cable and trunnion are moved

either up or down, the operating levers acting about

FIG. 3. THE CONTROL VALVE.

1. Air supply port. 2. Air delivery port.

3. Cable connection port.

Date : October, 1969

the pivot pin, extend the two springs between the

poppet lever plate and trunnion pin until they reach

an 'over-centre' position. At this point, the springs

suddenly contract, moving the plate to operate the

valves.

The design of the unit is such that when one valve

is open to pass compressed air, the other is open to

exhaust through the hollow stem. Compressed air

enters the unit through the inlet port and p3sses to

the interconnected valve chambers. In the illustration,

Fig. 4, the right-hand exhaust stem is closed against

the valve disc which is held off its seat allowing

compressed air to pass to the right-hand shift-

cylinder air line.

The left-hand valve disc is seated, tha exhaust stem

being lifted clear by the beam spring. Exhaust air

from gear shift cylinder passes through the stem, top

cover and exhaust port.

When the toggle mechanism is operated, the right-

hand disc valve seats and air is exhausted from the

air line. The left-hand exhaust stem closes on the

disc, pushing it off its seat allowing compressed air

to pass to the left-hand gear shift cylinder air line.

FIG. 4. SECTION VIEW OF CONTROL VALVE

1. Trunnion.

2. Toggle mechanism.

3. Beam spring.

4. Supply port.

5. Valve chambers.

6. Valve discs.

7. Valve seat.

B. Plugged pori.

9. Delivery ports to

operating cylinder.

10. Exhaust stem.

11. Exhaust port.

Unit: 2

Section: 3

8 Page:

---I

Date: October, 1969 I

SERVICE SHOP MANUAL

ROUTINE MAINTENANCE

Monthly or Every 5000 Mile (8000 I<m)

1. Check the mounting bolts and air line con-

nections at the valve for looseness and tighten

if necessary.

2. Remove exhaust port filter and clear thoroughly

in paraffin-blow dry with compressed air and

refit.

Yearly or Every 50000 Mile (80000 I<m)

1. Dismantle the control valve, thoroughly clean

all parts and inspect for wear and damage.

Repair or replace all worn or damaged parts,

or replace the complete valve with a Service

Exchange Unit.

UNIT REPLACEMENT

To Remove the Valve

1. Release all air pressure from the system.

2. Brush away dirt from the unit, particularly at

the air line connections and in the mounting

area.

3. Note the respective positions of the air line

connections to ensure cormct replacement.

Disconnect the three air lines at the valve and

plug the open ends to prevent dirt entering.

FIG. 5. CONTROL VALVE MOUNTED ON ENGINE

1. Air supply pipe. 4. Oelivery pipe.

2. Exhaust filler. 5. Oelivery pipe.

3. Operating cable.

4. Remove the two mounting bolts and detach

the unit from its mounting. Slacken the cable

fixing grub screws in the trunnion Fig. 6,

unscrew the compression screw and remove

the unit from the vehicle.

To Replace the Valve

1. Reconnect the operating cable to the trunnion

in the top cover and tighten the compression

screw.

2. Hold the unit in its mounting position and

replace and tighten the two mounting bolts.

3. Reconnect the air lines as originally fitted.

4. Check the 'snap over' position of the trunnion

as detailed on page 9.

UNIT OVERHAUL

(Refer to Fig. 6.)

To Dismantle the Valve

1. Remove grease and dirt from the exterior of the

valve by scraping if necessary, followed by

cleaning with solvent brush.

2. Remove the three cheese-headed screws and

spring washers and detach the top cover and

joint.

3. Unhook and remove the two valve actuating

tension springs.

4. Examine the ends of the poppet lever plate pin,

and drive out from the unserrated end. Take

care not to damage the two mounting lugs.

Remove the cable trunnion and pin assembly,

two operating levers and poppet lever plate.

5. Unscrew and remove the beam spring locating

screw and withdraw the two exhaust stems

and beam springs.

6. Invert the unit, remove the six setscrews and

spring washers and detach the cover plate and

joint. Withdraw the springs, valve discs and

seats.

7. Remove the two valve stem rubber a-rings in

the body. .

8. Remove the valve seat rubber a-rings.

Cleaning and Inspection of Dismantled Parts

1. Wash all parts in cleaning solvent and blow dry

with compressed air.

2. Carefully examine the body, lop cover and

cover plate for cracks and damage and the

the exhaust stem bores in the body for scores

and excessive wear. Examine the exhaust stems

for wear and scores, and the exhaust seat ends

for wear and pitting. The stems should be a

neat sliding fit in the body. Inspect the valve

disc seats for wear and nicks and the disc and

seat springs for corrosion and distortion.

3. Examine the toggle mechanism parts for exces-

sive wear and the springs and beam spring for

corrosion.

SERVICE SHOP MANUAL

To Re-Assemble the Valve

1. Renew the rubber faced valve discs, O-rings,

joints and all parts found to be defective during

'Inspection'.

2. Lubricate the bores in the body, the exhaust

stems, springs etc, by lightly smearing with

Valvoline X-All grease.

3. Fit new O- rings on the valve seats and in the

exhaust stem bores in the body.

4. Invert the body, press the two valve seats into

position and insert two new valve discs. Each

disc has a small hole in the rubber facing. Fit

the discs with holes facing the valve seats.

I nsert the fou r springs. Position the cover

plate with a new joint and secure with spring

washers and setscrews. Hold the beam spring

in position between the exhaust stems and

insert the stems into the body. Replace and

tighten the locating screw.

5. Assemble the toggle mechanism as shown in

Fig. 4 with the rounded ends of the operating

beams on each side of the trunnion and the

pin to the left of the trunnion centre line. Hold

the lever plate and operating beams in place

and press the pin into position, plain end first.

taking care not to damage the mounting lugs.

Ensure that the ends of the pin are flush with

the mounting lugs. Attach the tension springs

to the trunnion pin and lever plate.

6. Assemble top cover to body as ori]inally fitted,

with joint, replacing spring washers and cheese-

headed screws and tighten.

CHECK AFTER RE-ASSEMBLY

Move the cable trunnion up and down several

times by hand to ensure that the toggle mechanism

moves freely and that the 'over centre' action actuates

the valves without any signs of lag or binding.

Check the 'snap over' position of the cable

trunnion.

'Snap over' must occur when the cable trunnion

is not less than tin (32 mm) from the valve body

in one direction and not less than -t in (32 mm)

from the top cover in the other direction.

FIG. 6. EXPLODED VIEW OF CONTROL VALVE.

1. Cover plate. 14. Beam spring.

2. Setscrew. 15. Screw.

3. Spring washer. 16. Poppet lever plate.

4. Spring. 17. Spring.

5. Spring. lB. Operating lever.

6. Valve. 19. Trunnion and pin.

7. Valve seat. 20. Grubscrew.

8. D-ring. 21. Joint.

9. D-ring. 22. Cover.

10. J oint. 23. Spring washer.

11. Body. 24. Screw.

12. Pivot pin. 25. Compression screw.

13. Stem.

Unit: 2

Section : 3

Page: 9

Date : October, 1969

."

co

-

-------------,---

Unit: 2

Section : 3

Page: 10

Date

SERVICE SHOP MANUAL

1

FIG. 7 SECTION VIEW OF OPERATING CYLINDER

1 . . Breather. 4. O-rings.

2. Piston. 5. Spring.

3. Seals. 6. Piston rod.

OPERATING CYLINDER

TECHNICAL DESCRIPTION

The operating cylinder has an integral body and

mounting flange and an end-cover with a tapped

hole for a breather. The cylinder body has two ports

for air line connections and is sealed at each end to

prevent the escape of air. The cylinder contains a

FIG. 8. THE OPERATING CYLINDER.

1. Piston shaft.

2. Cylinder body.

3. End cover.

4. Breather.

5. Air supply- port.

exhaust.

7. Piston shaft. 10. O-ring.

8. Cylinder body. 11. End cover.

9. Circlip.

piston assembly consisting mainly of a double-

acting piston, a piston rod, a compression spring and

a piston shaft slotted at one end to engage a gear

selector lever in the gearbox. -The piston has two

rubber seals and is extended on one side to form a

guide tube in a bearing in the end-cover.

The piston assembly is designed to minimise shock

loads on the gear shift components in the gearbox.

Should the shift cylinder be operated when the

gearbox meshing parts cannot engage, the spring

is compressed and expands to move the piston shaft

when the meshing parts are in alignment.

When the control valve is operated, air under

pressure is simultaneously admitted to one end of the

cylinder, and exhausted from the other end to

atmosphere. The air pressure, acting through the

piston and piston rod, compresses the shaft spring

and applies a force to the gear shift parts in the

gearbox.

These conditions continue until the control valve

is again operated to change the gear ratio, when the

inlet/exhaust porting to the cylinder is reversed,

causing the piston to move in the opposite direction,

again compressing the spring and applying a force

to the gear shift parts.

Unit: 2

Section : 3

SERVICE SHOP MANUAL

Page : 11

---------- - - - -- ---

ROUTINE MAINTENANCE

Monthly or Every 5000 Mile (8000 km)

1. Brush away 10::Jse dirt from the breather con-

nection in the end-cover and remove the

breather. Pour a few drops of light mineral-base

oil into the cover and refit the breather.

2. Check the air line connections, end-cover set-

screws and mounting bolts for looseness, and

tighten if necessary.

Yearly or 50000 Mile (80000 I(m)

Dismantle the unit thoroughly clean all the parts

and inspect for wear and damage. Repair or replace

all worn or damaged parts, or replace the operating

cylinder with a service exchange unit.

UNIT REPLACEMENT

To Remove the Cylinder

1. Release all air pressure from the system. Note

the respective positions of the air lines on the

cylinder to ensure correct replacement.

2. Brush away dirt from the air line connections,

and the mounting flange.

3. Disconnect the air lines and plug the open ends

to prevent dirt entering.

4. Remove the mounting bolts and spring washers,

and detach the unit from the gearbox.

To Refit the Cylinder

1. Use a new joint secure the unit to the gearbox

casing with the two bolts and spring washers.

Ensure that the gear shift lever correctly engages

in the groove of the piston shaft.

2. Reconnect the air I ines as originally fitted.

UNIT OVERHAUL

(Refer to Fig. 10)

To Dismantle the Cylinder

1. Remove grease and dirt from the exterior of the

unit, by scraping if necessary, followed by

cleaning with solvent and brush.

2. Mark the end-cover relative to the cylinder to

ensure correct re-assembly.

3. Remove four setscrew together with spring

washers and detach the end cover with joint.

4. Withdraw the piston and shaft assembly. Hold

the piston by the flats provided, and unscrew

the cap nut inside the piston extension with a

1

9

6 in A/F hexagon box spanner. Remove the

piston, nut and copper washer.

Date: October, 1 969

FIG. 9. OPERATING CYLINDER MOUNTED

ON GEARBOX CASING

1. Gearbox casing. 4. Air supply-exhaust pipe.

2. Operating cylinder. 5. Air supply-exhaust pipe.

3. Breather.

5. Hold the hexagon locknut on the piston rod and

unscrew the tab locknut.

6. Grip the threaded end of the piston rod in the

protected jaws of a vice, and tighten the hex-

agon locknut a few turns against the spacer

tube. Remove the circlip, inside the piston shaft,

and withdraw the piston rod assembly.

7. Unscrew the nut taking care, as it is subjected

to a spring load of 10-15 lb. Withdraw the

spacer tubes, stop washers and spring.

8. Remove the rubber seals and a-rings.

Cleaning and Inspection of Dismantled Parts

1. Clean all components in cleaning solvent and

blow dry with compressed air.

2. Examine the body and end-cover for cracks

and damage, and the cylinder bore for excessive

wear. Renew if worn or damaged.

3. Inspect the piston for scores, cracks and

damage, and the piston shaft for scores and for

wear at the slotted end and circlip groove.

4. Inspect the springs for corrosoin and distortion,

and the spacer tubes, stop washers, piston rod

and circlip for wear and damage.

Unit: 2

Section: 3 I

Page: 12 I

~ a t ; ~ October, 1969--1

SERVICE SHOP MANUAL

FIG. 10. EXPLODED VIEW OF OPERATING CYLINDER

1. Cylinder body. 6. Setscrew.

2. O-rings. 7. Spring. washer.

3. Joint. 8. Cap nut.

4. End cover. 9. Copper washer.

5. Breather. 10. Piston.

To Re-Assemble the Cylinder

1. Renew the copper washer, rubber piston seals,

a -rings and all parts found to be defective

during 'Inspection'.

2. Lubricate the cylinder bore, piston and piston

extension, piston shaft and bore, and all other

moving parts by lightly smearing with Valvoline

X-All grease.

3. Install new a-rings in the cylinder and end-

cover and two new seals on the piston. Fit seals

back to end.

Assemble the piston rod parts in this order:

stop washer, long spacer, spring, stop washer,

short spacer. Use a modified G-clamp or

similar tool to compress the spring, and screw

the locknut on the end of the rod.

4. Tighten the nut until the outer faces of the stop

washers are 35 in (88'9 mm) apart approxi-

mately. Insert the assembly into the piston shaft

,'Inri fit the circlio.

11. Piston seals. 16. Stop washer.

12. Tab locknut. 17. Long spacer.

13. Locknut. 18. Spring.

14. Circlip.

19. Piston rod.

15. Short spacer. 20. Piston shaft.

5. Grip the threaded end of the piston rod in the

protected jaws of a vice,' and slacken off the

nut and adjust until it just touches the short

spacer. Insert the chamfered end of the piston

shaft into the flanged end of the cylinder and

screw the tab locknut . on the rod and tighten

against the nut.

6. Insert the end of the rod into the piston, ensuring

that the locknut tabs engage the cast slots in

the piston. Position a new copper washer and

screw down the cap nut. but do not tighten.

To ensure correct alignment, slide the as.5embly

into the cylinder, and tighten the cap nut.

Partially withdraw the assembly, and holding

the piston by the flats provided, finally tighte n

the cap nut. (Torque 100-110 Ib in).

7. Use a new joint and install the end-cover as

originally fitted, replace spring washers and

setscrews and secure. (Torque 50-601b in) .

Move the piston assembly through its stroke

several times to ensure freedom from excessive

friction and/or binding.

---------------------- ---

Unit : 2

Section: 4

SERVICE SHOP MANUAL Page :

Date: April, 1969

UNIT 2 - TRANSMISSION

.SECTION 4

PROPELLER SHAFT

INDEX OF CONTENTS

Page

Technical Description 3

Lubrication .. 4

Routine Maintenance 4

Unit replacement-To Remove . . 4

To Refit 4

Unit Overhaul-To Dismantle 5

Cleaning and Inspection of Dismantled Parts 5

To Re-assemble 7

Unit: 2

Section: 4

SERVICE SHOP MANUAL

Page : 3

TECHNICAL DESCRIPTION

On two axle and rear steer chassis a single

. propeller shaft is used. The shaft is of tubular con-

struction with 1 700 Series companion flanges at

each end.

The propeller shaft incorporates needle roller

bearing universal joints at each end, the forward end

has a sliding slip joint to allow for elongation when

running while the opposite end is fixed.

The flange and sleeve jokes are assembled on a

trunnion journal with four needle roller bearing

assemblies. The needle roller bearings, are self

contained being assembled in a hardened bearing

race. This bearing race is retained and located by a

Date : April, 1969

bearing cap, which in turn is held by a lock strap and

setscrews. Lubricant from the centre of the trunnion

journal fills the grease reservoirs in each arm, then

passes through a small hole direct to the needle roller

bearings.

The bearings are protected against lubricant

leakage and the ingress of foreign matter by a

bearing seal and retainer.

A relief valve positioned between two of the

trunnion arms prevents damage to the seals through

over lubrication or the use of high pressure equipment

and serves as an indicator to show when the joint is

completely filled. A lubricator is also provided in the

slip joint for spline lubrication, leakage being

prevented by a cork washer and dust cap. No relief

valve is fitted to the slip joint.

16

FIG. 1. SECTION VIEW OF PROPELLER SHAFT UNIVERSAL JOINT.

1. Flange yoke. 5. Locking plate. 9. Closing washer. 13. Dust cap.

2. Bearing assembly. 6. Bearing seal. 10. Sleeve yoke. 14. Cork or felt washer.

3. Journal. 7. Seal retainer. 11. Lubricator. 15. Steel washer.

4. Bearing cap. 8. Lubricator 12. Slip stub shaft. 16. Tube and yoke assembly.

Unit: 2

Section : 4

Page: 4

SERVICE SHOP MANUAL

Date : April, 1969

LUBRICATION

For lubrication times refer to the Lubrication

Chart at the end of Unit O.

It is recommended that high pressure lubrication

equipment is not used for lubrication of universal

joints, as it is possible for the grease to be expelled

from the relief valve before it reaches the needle

roller bearings. The trunnion seals can also be

damaged with the use of high pressure equipment.

It is therefore recommended that a hand-operated

grease gun only is used for this operation.

Never over lubricate to the extent that excessive

grease is flung from the joints on to the chassis frame

and body. Always wipe off any surplus grease which

expels from the relief valve after lubrication is

complete.

UNIT REPLACEMENT

To Remove

1. The propeller shaft can be removed by either

removing the shaft complete with both universal

joints or by disconnecting the front end at the

sliding slip joint.

2. Support the propeller shaft near the sliding

joint and remove the nuts and bolts from the

companion flange at the sliding splined end.

3. Slide the splined sleeve yoke backwards about

half an inch to disengage the pilot flange and

allow the front end of the shaft to be lowered

on to a suitable support.

4. Remove all the nuts and bolts from the com-

panion flange at the fixed joint end and lower

ROUTINE MAINTENANCE the shaft carefully to the ground.

Monthly or Every 5000 Mile (8000 I(m)

1. Check the tightness of all nuts and bolts.

2. Check for wear on universal joint needle roller

bearings by lifting the joints, either by hand, or

by the use of a length of wood suitably sup-

ported under the joints.

3. Inspect for circumferential movement of the

propeller shaft relative to the flange yoke by

attempting to turn the shaft in the opposite

direction to the companion flange. If movement

is present this indicates that wear has taken

place on the needle roller bearings, or the

splines of the slip joint.

Fault Finding

If there is excessive noise and/or vibration from

the transmission check the propeller shafts for :

1. Misalignment or out of balance due to incorrect

assembly on the vehicle.

2. Wo, n or damaged needle roller bearings.

3. Loose flange yoke bolts.

4. Bent propeller shaft "tube due to accident

damage.

5. I nsufficient lubrication.

5. If the propeller shaft is being removed by

disconnecting the sliding slip joint, remove the

nuts and bolts from the fixed joint end and

slide the shaft forwards to disengage the rear

companion flange pilot flange. Suitably sup-

port the propeller shaft and before unscrewing

the sliding spline dust cap check that the

relative position of the trunnion journals to each

other if the propeller shaft tube and sleeve

yoke are not stamped with alignment arrows.

To Replace

1. Before refitting the shaft ensure that the

mounting faces of the companion flanges are

clean and free from burrs and/or damage.

2. Mount the rear companion flange on the rear

axle companion flange ensuring that it beds

evenly all round and secure with the nuts and

bolts. New self-locking nuts should always be

used and the bolts should be fitted with the

threads towards the universal joints.

3. Mount the front end of the shaft onto the gear-

box companion flange, again ensuring that it

beds evenly all round and secure using new

self-locking nuts. Tighten the nuts securely and

evenly.

4. Screw up the slip joint dust cap as far as

possible by hand.

Unit : 2

Section: 4

SERVICE SHOP MANUAL

Page: 5

5. If the propeller shaft was disconnected at the

slip joint during removal , it should be refitted

with the arrows on the sleeve yoke and tube in

correct alignment to preserve the balance of the

propeller shaft before the rear companion flange

is bolted in place and the dust cap should be

screwed on to the sleeve yoke as far as possible

by hand.

6. Lubricate the universal joints and slip joint

using a hand grease gun only with the correct

lubricant as specified in Lubricants and

Fluids, Unit 0 of this manual.

UNIT OVERHAUL (Refer to Fig. 4)

To Dismantle

1. Unscrew the dust cap (13) and pull back the

steel washer ( 12) and cork washer (11) . This

will allow the splined sleeve yoke assembly (9)

to be withdrawn from the shaft (14).

2. Bend back the locking plate (3) tabs and

remove the bearing cap bolts (4) and bearing

cap (2) .

3. Support the flange yoke (1) and the splined

sleeve yoke (9) on two wooden blocks.

4. Using a soft nose drift drive out the bottom

bearing (5) which is a light drive fit in the yoke

trunnion. Repeat the operation for the opposite

bearing using a soft nose drift on the end of the

spider journal (8), taking care to support the

two halves of the joint.

5. The splined sleeve yoke (9) can now be

removed and the bearings in the flange yoke

trunnion t apped out in a similar manner.

Cleaning and Inspection of Dismantled Parts

1. Wash all metal parts in a suitable cleaning fluid

and blow dry with compressed air.

2. Discard the journal gasket (6) and cork washer

(11) together with the locking plates (3) and

automatically replace with new parts.

3. The parts most likely to show signs of wear

after long service are the bearing races and

spider journals. If there is distortion, looseness

or load markings in these parts they must be

replaced completely. It is essential that the

bearing races are a light drive fit in the yoke

trunnion.

o

Date April, 1969

FIG. 2. TAPPING BEARING RACE FROM INSIDE WITH

A SMALL DIAMETER BAR.

FIG. 3. DRIVING OUT LOWER BEARING RACE

ASSEMBLY.

....

....

'-e. 0

I'

o 2

Alternative Circlip Fitting,

1,

o

y

&1

11

co

FIG. 4, EXPLODED VIEW OF TYPICAL PROPELLER SHAFT UNIVERSAL JOINT.

1. Flange yoke. 5. Needle bearing 8. Journal. 12. Steel washer.

2. Bearing cap. assembly. 9. Sleeve yoke. 13. Dust cap.

3. Locking plate. 6. Bearing seal. 10. Lubricator. 14. Tube and yoke assembly.

4. Bolt, bearing cap. 7. Seal retainer. 11. Cork or felt washer.

0 ""0

Q) , Q)

- CO

co co

}>

-g.

to

O'l

to

O'l

(I)

m

:rJ

<

-

n

m

(I)

:E:

o

-a

s

2

c:

r-

Ul

co

0'

::J

@

C

::J

;::;'

N

Unit : 2

Section : 4

SERVICE SHOP MANUAL

Page : 7

Date : April, 1969

-- --------

4. If wear has taken place in the yoke cross holes

the yokes must be replaced. In the case of wear

of the holes in the fixed yoke, it should be

replaced with a complete tubular shaft assembly

5. Other parts likely to show signs of wear are the

splined sleeve yoke and/or the splined stub

shaft. A total of 0 004 in (0102 mm) cir-

cumerential movement, measures on the out-

side of the spline should not be exceeded.

6. Unit packages are available for overhauling

universal joints and contain items 3, 5 and 8 as

shown in Fig. LI,. of this section.

To Re-assemble

1. See that all drilled holes in the journals are

clean and clear.

2. Grease the needle rollers and assembly in the

bearing races.

3. Renew the journal seals (6) and fit the

retainers (7) and seals (6) on the journal

trunnion. The journal shoulders should be

smeared with shellac prior to fitting the

retainers to obtain a good oil seal. Use a tubular

drift, as shown in Fig. 5 to ensure that the

seals and retainers fit down on the trunnion

shoulders.

4. Insert the journal trunnion in the yokes. Tap the

bearings into position at the opposite ends of

the journal trunnion in turn, with a soft nose

drift. It is essential that the slot in the top of the

bearing race is in line with the bearing cap screw

holes.

5. Refit the bearing caps, locking plates and bolts.

6. If the joint appears to bind, tap the lugs lightly

with a wooden mallet, which will relieve any

pressure of the bearing race on the end of the

journal trunnion arm.

7. When replacing the sliding joint on the shaft,

ensure that the lugs on the flange and sleeve

yoke are in line. This can also be checked by

observing that the arrows stamped on the

sleeve yoke and slip stub shaft are in alignment.

Screw the dust dap over the cork and steel

washers as far as possible by hand.

8. Refill the joints and sleeve yoke with grease

through the lubricators provided.

FIG. 5. REPLACING OIL SEAL AND RETAINER ON

JOURNAL.

FIG. 6. REFITTING SPLINED SLEEVE YOKE.

Вам также может понравиться

- Catalogue of Ploughs Manufactured by R. Hornsby & Sons Ltd - Spittlegate Iron Works, Grantham, EnglandОт EverandCatalogue of Ploughs Manufactured by R. Hornsby & Sons Ltd - Spittlegate Iron Works, Grantham, EnglandОценок пока нет

- 1971-1972 ALSPORT Snowmobile ManualДокумент4 страницы1971-1972 ALSPORT Snowmobile ManualtimmckennaОценок пока нет

- Cub Cadet Parts Manual For Model 2155 Tractor SN 326006 and UpДокумент87 страницCub Cadet Parts Manual For Model 2155 Tractor SN 326006 and UpfogdartОценок пока нет

- TPCD1350E4Документ370 страницTPCD1350E4Andrei BaiОценок пока нет

- MTD Mulch Kit Operators Manual Model OEM-190-116Документ0 страницMTD Mulch Kit Operators Manual Model OEM-190-116b0beiiiОценок пока нет

- WheelHorse 36 Inch Tiller Manual Models 79271, 99271, 9861915Документ20 страницWheelHorse 36 Inch Tiller Manual Models 79271, 99271, 9861915Kevins Small Engine and Tractor Service100% (3)

- Spare Parts and Accessories 2014 StigaДокумент25 страницSpare Parts and Accessories 2014 Stigadavorin59Оценок пока нет

- GXV160H213Z1V402VerV PDFДокумент92 страницыGXV160H213Z1V402VerV PDFLupin GonzalezОценок пока нет

- Zenith PDFДокумент9 страницZenith PDFhansolosnahОценок пока нет

- Fiat S P AДокумент17 страницFiat S P Aapi-281175594Оценок пока нет

- Acme A349 Service ManualДокумент34 страницыAcme A349 Service ManualCristian DavidОценок пока нет

- Atkinson Tractor Service Shop Manual Unit 1 - Engine and Ancilliary EquipmentДокумент26 страницAtkinson Tractor Service Shop Manual Unit 1 - Engine and Ancilliary EquipmentDavid Kelly100% (1)

- Wheel Horse Mower Parts ManualДокумент26 страницWheel Horse Mower Parts ManualastroltravlerОценок пока нет

- 1974 Ski DooДокумент292 страницы1974 Ski DooVincent RoyОценок пока нет

- SCZ Cheetah Manual Book 03363Документ87 страницSCZ Cheetah Manual Book 03363rob sullivan100% (1)

- Wheel Horse LubricationДокумент82 страницыWheel Horse LubricationPrestonPowell100% (2)

- 51 DD 9 Baa 676 AbДокумент30 страниц51 DD 9 Baa 676 AbLuis MurilloОценок пока нет

- 8x8 HDi-HD Parts Manual 8X8HDi-2012 2013-06-12 From Serial No 34521Документ26 страниц8x8 HDi-HD Parts Manual 8X8HDi-2012 2013-06-12 From Serial No 34521Mikael LarssonОценок пока нет

- Catalogo de Palas Retro Terex - pdf1231185670 PDFДокумент8 страницCatalogo de Palas Retro Terex - pdf1231185670 PDFRobinson GuanemeОценок пока нет

- Rezervni Dijelovi Za Traktore TafeДокумент20 страницRezervni Dijelovi Za Traktore TafeMilos BogicevicОценок пока нет

- D4EДокумент11 страницD4EMantenimiento U.C.O.100% (1)

- Alouette Models, 1967-1976Документ5 страницAlouette Models, 1967-1976Paul MartinОценок пока нет

- Carburettor Weber DMTR Servicing and AdjustmentДокумент4 страницыCarburettor Weber DMTR Servicing and Adjustmentgeorgemesfin@gmailОценок пока нет

- Lancia Scorpion Tecnhnical TipsДокумент11 страницLancia Scorpion Tecnhnical Tipsphantom fiatОценок пока нет

- Type2 1200 1600 Shop Manual PDFДокумент258 страницType2 1200 1600 Shop Manual PDFYenni Katherine Jaimes GallardoОценок пока нет

- WheelHorse Heavy Duty Front Spindle and Wheel Kit 8-10504R1Документ3 страницыWheelHorse Heavy Duty Front Spindle and Wheel Kit 8-10504R1Kevins Small Engine and Tractor ServiceОценок пока нет

- J160 6th Gear ReplacementДокумент6 страницJ160 6th Gear ReplacementdensasОценок пока нет

- Wheel Horse by YearДокумент14 страницWheel Horse by YearNeil SmallwoodОценок пока нет

- Yamaha XT 350 E EC (Modell 1992) Microfiche, EnglischДокумент57 страницYamaha XT 350 E EC (Modell 1992) Microfiche, EnglischchavchirОценок пока нет

- WheelHorse Hydraulic Lift Accessory 8-4113Документ4 страницыWheelHorse Hydraulic Lift Accessory 8-4113Kevins Small Engine and Tractor ServiceОценок пока нет

- WheelhorseTractor 1978 B C D SeriesServiceManual 810063RlДокумент70 страницWheelhorseTractor 1978 B C D SeriesServiceManual 810063RlJamesОценок пока нет

- IPL, Poulan, PE155H38LT, 96011019700, 2006-05, TractorДокумент16 страницIPL, Poulan, PE155H38LT, 96011019700, 2006-05, TractorPaolo BertorelloОценок пока нет

- Triumph Service Bulletin 1965Документ59 страницTriumph Service Bulletin 1965tr_freundeОценок пока нет

- Prima P1-P2 Workshop Manual English Iss1Документ59 страницPrima P1-P2 Workshop Manual English Iss1José LuisОценок пока нет

- Power Shuttle - Pinion Cage, Output Shaft, and Control ValveДокумент4 страницыPower Shuttle - Pinion Cage, Output Shaft, and Control ValveLuis f. C100% (1)

- Wheel Horse GT Series 36 Inch 42 Inch 48 Inch Mower Decks Owners ManualДокумент7 страницWheel Horse GT Series 36 Inch 42 Inch 48 Inch Mower Decks Owners ManualKevins Small Engine and Tractor Service83% (6)

- Pioneer SA-620 AmpДокумент31 страницаPioneer SA-620 Ampngoc_hungОценок пока нет

- Taro 2l Engine ManualДокумент158 страницTaro 2l Engine ManualAlexandru CraiovanОценок пока нет

- 21 3214220 en OMДокумент182 страницы21 3214220 en OMarbi carakaОценок пока нет

- Park Compact 16 13-6103-19Документ2 страницыPark Compact 16 13-6103-19Oana OanaОценок пока нет

- 1T /2T /2T /2T /3T /3T /3.5T /6T /6T /9T /10T: Site DumpersДокумент12 страниц1T /2T /2T /2T /3T /3T /3.5T /6T /6T /9T /10T: Site DumpersRobert HughesОценок пока нет

- Agt Tractor Broshure English enДокумент6 страницAgt Tractor Broshure English enLuciusОценок пока нет

- Ford Old TimersДокумент25 страницFord Old TimersJan-Erik Kaald HusbyОценок пока нет

- 2002 SWOPMANcompleteДокумент36 страниц2002 SWOPMANcompleteBen TottaОценок пока нет

- SK Codes of Practice GasesДокумент50 страницSK Codes of Practice GaseseimrehОценок пока нет

- Mu Gasgas 2t Ec 19 Eng - r02Документ77 страницMu Gasgas 2t Ec 19 Eng - r02νικος σκαλκοςОценок пока нет

- Czereśnie ZaplaczeДокумент37 страницCzereśnie ZaplaczeMaciej BorzeckiОценок пока нет

- Motor E15 para Wood MizerДокумент40 страницMotor E15 para Wood MizerCesar Edgardo Lopez PortilloОценок пока нет

- Jinma20 30a PDFДокумент73 страницыJinma20 30a PDFMark OОценок пока нет

- Parts Manual 267-H 3317-774Документ60 страницParts Manual 267-H 3317-774jjmustoОценок пока нет

- ACME AL-ALN Engine Carburetor Replacement PDFДокумент5 страницACME AL-ALN Engine Carburetor Replacement PDFDezső LőcseiОценок пока нет

- Honda Pilot Roof Rack CrossbarsДокумент2 страницыHonda Pilot Roof Rack Crossbarsgohchuansin100% (1)

- SubaruEA81 ServiceManualДокумент94 страницыSubaruEA81 ServiceManualdlskmphОценок пока нет

- TrackДокумент16 страницTrackOscar Coaquira FelicianoОценок пока нет

- 4 Stroke VinoДокумент298 страниц4 Stroke VinoFeiming HuangОценок пока нет

- Argo Operators Manual (2010 Models) v1Документ76 страницArgo Operators Manual (2010 Models) v1Fred BohnОценок пока нет

- Caja de Cambios EATON FS6209Документ145 страницCaja de Cambios EATON FS62097sergio950% (2)

- SB1208 - ZF As Tronic - Clutch Component LubricationДокумент12 страницSB1208 - ZF As Tronic - Clutch Component LubricationCarlos José FariaОценок пока нет

- 1A Motorkapitlet Diesel Motor VerkstadsmanualДокумент35 страниц1A Motorkapitlet Diesel Motor Verkstadsmanualgdrakas42100% (1)

- Soal BudgetingДокумент2 страницыSoal BudgetingnoortiaОценок пока нет

- Nissan Case AnalysisДокумент3 страницыNissan Case AnalysisVivek VvkОценок пока нет

- Consumables Accessories TVH PDFДокумент504 страницыConsumables Accessories TVH PDFAndreyna Brea100% (1)

- Prepare 1 Page Reaction Paper About The Requirements in Registering A Motor Vehicle For Private and For HireДокумент1 страницаPrepare 1 Page Reaction Paper About The Requirements in Registering A Motor Vehicle For Private and For Hiretricia onaОценок пока нет

- Work Zone Traffic Management Guide Version 1.1 - Release NoteДокумент2 страницыWork Zone Traffic Management Guide Version 1.1 - Release Notefreanne_0527100% (2)

- Mintzberg 5pДокумент5 страницMintzberg 5ptkurasa100% (1)

- MeetingДокумент3 страницыMeetingJanking Madriaga IОценок пока нет

- Tracked Artillery SystemsДокумент1 страницаTracked Artillery SystemsnuedelОценок пока нет

- Specs 1979 Mitsubishi Lancer 1400 Van ELДокумент4 страницыSpecs 1979 Mitsubishi Lancer 1400 Van ELPriyantha GalgepitiyaОценок пока нет

- Memorandum of AssociationДокумент8 страницMemorandum of AssociationSohail AnjumОценок пока нет

- Towing and Impounding FAQДокумент4 страницыTowing and Impounding FAQGeorge JR BagsaoОценок пока нет

- Company Profile of PT. Suryaraya Rubberindo IndustriesДокумент8 страницCompany Profile of PT. Suryaraya Rubberindo IndustriesZubair KhanОценок пока нет

- As 4177.2-2004 Caravan and Light Trailer Towing Components 50 MM TowballsДокумент7 страницAs 4177.2-2004 Caravan and Light Trailer Towing Components 50 MM TowballsSAI Global - APACОценок пока нет

- Country Wing Auto-Mobile GarageДокумент25 страницCountry Wing Auto-Mobile GarageDmitry PigulОценок пока нет

- Industrial Visit Maruti Suzuki in GurgaonДокумент20 страницIndustrial Visit Maruti Suzuki in Gurgaonnitin garg100% (1)

- BW7249 Uhb800-CamДокумент218 страницBW7249 Uhb800-CamKeith McCann100% (1)

- Introduction To Universal Gear ShavingДокумент48 страницIntroduction To Universal Gear ShavingNagesh KamannaОценок пока нет

- Ravineet Singh Marwah - Head of International Business DevelopmentДокумент4 страницыRavineet Singh Marwah - Head of International Business DevelopmentRavineet Singh MarwahОценок пока нет

- Mass Customization at BMW: Presented By: MOHAMED KHALEK Nirmal Joseph Loan NguyenДокумент35 страницMass Customization at BMW: Presented By: MOHAMED KHALEK Nirmal Joseph Loan NguyenfraОценок пока нет

- MICHELIN+CROSSCLIMATEDOSSIER DE PRESSE UK LightДокумент12 страницMICHELIN+CROSSCLIMATEDOSSIER DE PRESSE UK Lightlui lopezОценок пока нет

- Us 912ds+Rail+Brochure SCRДокумент2 страницыUs 912ds+Rail+Brochure SCREnginerdouglasОценок пока нет

- Pressure Sensor HistoryДокумент38 страницPressure Sensor HistoryBrian McMorris100% (3)

- Fab Evap Temp SensorДокумент8 страницFab Evap Temp SensordobrosavkeОценок пока нет

- Why Is It Six SigmaДокумент4 страницыWhy Is It Six SigmaRMVОценок пока нет

- Financial Ratio Analysis of Indus MotorsДокумент31 страницаFinancial Ratio Analysis of Indus MotorsAli Husanen100% (1)

- RD in The EUДокумент85 страницRD in The EUmhldcnОценок пока нет

- 03-04 l4 Engine Vibration in Gear 04-024Документ4 страницы03-04 l4 Engine Vibration in Gear 04-024Vincent HardyОценок пока нет

- Techspec qj331 2013 PDFДокумент2 страницыTechspec qj331 2013 PDFSebastian Pardo Figueroa DianderasОценок пока нет

- Industry Analysis of Auto Ancillaries IndustryДокумент45 страницIndustry Analysis of Auto Ancillaries IndustryAbdullah Saghir Ahmad100% (1)

- New CatalagueДокумент9 страницNew CatalagueOrchaliusОценок пока нет