Академический Документы

Профессиональный Документы

Культура Документы

10 - Cargo Pumps

Загружено:

Jamie RiosИсходное описание:

Оригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

10 - Cargo Pumps

Загружено:

Jamie RiosАвторское право:

Доступные форматы

10- Cargo Pumps

10 Cargo pumps

10.1 Classification and selection of pumps

There are a number of different pump types. Each type has its own special quality

and therefore certain advantages and disadvantages. The selection of pumps is

determined by a thorough study of the capacity needs and under which operational

conditions the pump will operate. The following factors are important when you

evaluate these conditions:

Estimated back pressure

Capacity requirement

Capacity range

Requirement for installation and arrangement

Expenses for purchase, installation and maintenance

Availability of parts and service

Suction terms

Characteristics for the liquid to be pumped

Selection of the right pump for a determined purpose qualifies a close co-operation

between the customer and the producer of the pump. The customer has a special

responsibility to clarify all conditions concerning the pump installation, so the

producer can choose the best pump from his product range with the best match.

When you choose a pump you must find out how much the pump needs to deliver

under a specific condition. Definition of capacity range is important. Demand for

capacity or capacity range and expected discharge pressure must be specified. The

capacity requirement is determined by the intended use of the pump. The discharge

pressure is determined by various conditions where the pumps delivery pipeline

design, the capacity of the pump and the liquids characteristics, is the essential.

Alternative installation locations of the pump are limited due to special demands from

Class and Shipping Authorities and also from lack of space.

Purchase and installation cost is important. Future maintenance expenses, availability

of parts and service now and over the next years, are also important and must be

included in the evaluation of alternative pump supplies.

The liquids properties and which other arrangements you have to consider, often

limits the options. Density, viscosity and boiling point are important properties to

consider. The liquid temperature and corrosive properties are important factors when

pump material is selected.

The pumps suction condition is determined from where the pump is located in

relation to the liquid to be pumped. A given suction pipe creates a certain resistance

that will have influence on the pump capacity. The main principle is to minimise

resistance on the suction side by decreasing the suction pipe length, have the largest

diameter possible and few as possible restrictions in form of bends, valves and so on.

The different types of pumps are divided into two main groups, displacement and

kinetic pumps. The displacement pumps displace the liquid by reducing the volume

inside the pump. An example is a piston pump where the piston is moving up and

down inside a cylinder or when the screws revolve inside a screw pump. Kinetic

pumps (kinetic energy is equal to movement energy) increase the liquids velocity

through the pump.

The diagram below gives a brief view of the different available groups and types of

pumps. The diagram would be more comprehensive if the pumps were divided in all

details according to number of rotors, design of pump inlet/outlet and flow

directions.

A kinetic pump like the centrifugal pump increases the liquids velocity in the pump

by means of a rotating impeller. A displacement pump, like the piston pump,

mechanically displaces the liquid in the pump, either by help of a piston or screws.

Resistance on delivery side gives a liquid pressure rise (pump delivery pressure). One

should be aware of this difference for these two pump types.

The pressure rise on a kinetic pump is restricted by the increase in velocity over the

pump, which is controlled by the pump design. All kinetic pumps therefor have a

designed or built-in limitation for maximum discharge pressure. The displacement

pumps limitation depends only on available power and the constructional strength. In

contrast to a kinetic pump, such a pump will operate against resistance with all its

available power. A closed-delivery valve on a displacement pump is damaging. The

same closed delivery valve for a kinetic pump will not bring any immediate danger.

Piston pumps and screw pumps have good suction capacity and are used where

these characteristics are required. The weakness of these pumps is the complex

construction and the relatively low capacity.

Centrifugal pumps are simply constructed with few parts and no valves. There are no

immediate problems if the outlet of the pump is closed. These qualities result in

relative low purchase and servicing costs. Operation at high speed makes the pump

small in proportion compared to the capacity and flexibility in relation to the pumps

location.

The most negative side of using a centrifugal pump is the lack of self-priming

capacity. This weakness is improved by constructional efforts and positioning, which

consolidate the free flow of liquid. Location of a pump, for instance below the liquid

level, can reduce the flow resistance. High viscosity liquids are therefore particularly

difficult to pump due to this condition.

A centrifugal pumps efficiency is high only within a small range. This is the reason it

is especially important to have a clear understanding of what capacity range the

pump will operate under, in connection with the selection of a centrifugal pump.

The differential pressure over each impeller is relatively low. Using so-called

multistage pumps where several impellers are mounted in serial, increase the pumps

capacity to deliver against higher backpressure.

A centrifugal pump will, without a non-return valve on delivery side, give complete

back flow at the time the pump stops. For all operators of centrifugal pumps, this

relationship is important to know

Examples of various pump types

Double-suction split-casing centrifugal pump

10.2 THE EJECTOR

The ejector design is simple and is used for stripping and as bilge pumps in hold and

interbarrier spaces. The ejector has no revolving or reciprocating parts and is thereby

especially easy to maintain.

The propellant (driving water), is forced through a nozzle into a mixer tube. The

velocity of the propellant will naturally increase as it passes through the nozzle. Due

to the propellants velocity and direction, plus the friction force between the

propellant and the liquid, the surrounding liquid will be sucked into the ejectors

mixer tube. The mixer tube is connected to an expanding tube, the diffusor. Here

some of the kinetic energy supplied to the liquid in the mixer tube is transformed

into potential energy. The capacity depends on the friction force between the two

mediums, suction head, delivery head and the propellants velocity. The ejector has

the advantage that it does not lose the suction capacity even if it sucks air or vapour.

The ejectors efficiency is between 30% and 40%. Even if the propellants efficiency

is up to approximately 70%, the total efficiency for the whole ejector system is far

less than compared to a pump system, such as a centrifugal pump. Another

drawback with ejectors is that the propellant is mixed with the pumping liquid. This

implies that if the ejector is to be used in cargo transfer operation, the cargo itself

must be used as propellant liquid.

The ejector is frequently used as a bilge pump in hold spaces. A common

arrangement for a hold space is as follows:

The ejector is usually submerged in a bilge sump and the propellant is normally

supplied from a seawater pump. Onboard gas carriers where the hull is the

secondary barrier, the ejector may also be used to pump cargo from hold space. In

that case, the liquefied cargo itself must be used as a propellant.

Tips

Be aware that the ejector has a limitation on the propellants pressure. Higher

pressure than recommended by the supplier may result in reduced suction capacity.

Start the ejector by opening all valves on delivery side first, and then adjust the

correct propellant pressure. The ejectors suction valves should be opened last, which

will prevent the propellants flow back into the tank that is to be stripped.

Stop the ejector by using the opposite procedure.

As the drawing shows the ejector is positioned 3 meters above the liquid level. The

liquid level in the slop tank is 15 meters above the ejector and the propellant's

pressure is 8 bars. The ejectors capacity can be found by use of the performance

curve for the specific ejector.

In the performance curve the ejector capacity is set as a function of the propellant

pressure. Observe that this curve has curves for different suction lifts. The different

performance curves are marked with different suction lifts. The ejectors suction lift

in this example is 3 meters; this specific curve shall be used.

You can find the capacity of the ejector by drawing a vertical line from 8 bars on the

scale for a delivery head of 15 meters and up to the performance curve with a

suction lift of 3 meters. From this point of intersection, draw a horizontal line to the

left and over to the ejectors capacity side. The found capacity in this case is 600

m3/h.

10.3 The centrifugal pump

10.3.1 The theory of the centrifugal pump

The sketch below indicates a radial section of a rotor-blade wheel for a centrifugal

pump. For plainness, we observe the liquid as an amount of small particles and see

what occurs with one of these on its way through the rotor-blade wheel. We

presume further that the rotor-blade wheel is filled with liquid when this is rotating.

The inlet at the end of the blade will have a precise velocity and direction, marked

ua. The direction is the key to the circle of the point. The size of the vector is given

by the angular velocity of the rotor-blade wheel, w. The connection between the

sizes, can be expressed as:

ua = w x r when w = 2 x p x T

The liquid particle will, at point A, be affected by power, from the blade marked Fua.

The energy works in the same direction as the velocity vector ua. It means that the

particle performs power F that is equal, but in the opposite direction as Fua, which is

toward the blade housing.

When the blade influences a liquid particle, the particle achieves a certain velocity.

The velocity is causing the particles centrifugal force, F, which has a direction

leading straight out from the centre. This force gives the liquid particle certain

acceleration, a., the relation between proportions may be expressed as:

Fsa = m x a or a = Fsa/m

As we see from the sketch, the energy forces Fsa and F1 to produce energy, marked

F.

When the rotor-blade wheel is rotating, the liquid particles will move lengthways

along the blade because of the centrifugal force. Since the blade governs the liquid,

the relative velocity will have the same direction as the blade. The relative velocity

factor will try to accelerate the particle, but the liquids inner friction (viscosity)

resists and reduces the centrifugal force influence. If the only consideration is the

liquids viscosity, the relative velocity will achieve a certain proportion when the inner

friction compensates for the centrifugal acceleration. The system is in balance and a

certain relative liquid velocity is achieved. The relative velocity is a direct expression

of the flow through the rotor-blade wheel (the pump).

The liquid particles are influenced by the relative velocity vector (V) and the blades

velocity vector (U). The resulting velocity vector gives the particles absolute velocity

(C). This vector (C) determines the particles track through the rotor-blade wheel.

In the point D the liquid particles leave the rotor-blade wheel. As a result of the

relative velocity vector (Vd) and the rotor-blade wheels velocity vector (Ud), an

absolute velocity (Cd) has been achieved with direction and proportion.

The blades deflection will determine the relative direction of the liquid that comes

out of the rotor-blade wheel. When it is the blade that set the liquid in motion, you

see that the liquids absolute velocity can never exceed the rotor-blade wheels

peripheral speed.

The rotor-blade wheel sets the liquid in motion; i.e. the liquid is supplied with kinetic

energy, Wk. This energy is transformed to potential energy, Ws, and/or pressure

energy, Wt. The connection between these energy forms may be expressed as:

Kinetic = Potential energy = Pressure energy

or:

Wk = Ws = Wt

If the pump is connected to a high riser, the liquid will stabilise at a certain level. All

kinetic energy is transformed to potential energy. The centrifugal pumps lifting

height, H, is then:

mv2 = mgH

H = v2/2g

The pumps lifting height is dependent on the liquids mass and consequently, the

liquids density.

If a centrifugal pump is running against a closed valve, all the kinetic energy will be

transformed to pressure energy. The pressure after the pump is then:

mv2 = mp/r

p = v2r

Also, the pressure after the pump is proportional with the liquids density.

If we are placing a number of rotor-blade wheels in serial in order to prevent energy

loss. The liquids absolute velocity out of the pump will be to equal to the peripheral

speed. The theoretical maximum lifting height, Ht1, for the pump will be:

Ht1 = Cd2/2g

when Cd = Ud, we will obtain:

Ht1 = Ud2/2g

The volume flow is determined by the liquids density. When the lifting height is at a

minimum, the volume flow will be at a maximum. The theoretical pump

characterisation, QHt1, which emerged, will be linear.

But in our example, we only have one rotor-blade wheel. The liquids absolute

velocity will be less than the peripheral speed. A new pump characterisation, which

has adapted real velocity, is shown on the diagram to you right (marked QHt2).

In all pumps a certain loss will always occur. The friction between the liquid, the

rotor-blade wheel and deflection loss can be empirically set to:

h1 = k1 x Q2

k1 = an invariable determined by the specific rotor-blade wheel.

In addition, it is entrance loss and shock loss, which are theoretically set at:

h2 = k2 x (Q - Qs)2

Out of the above formula: h2 = 0 when Q = Qs

This will occur when the liquids relative velocity into the blade has the same

direction as the inlet blade. The loss curves h1 and h2 give a resultant loss curve, h3.

From the theoretical pump characterisation QH1, 2 and the resultant loss curve, h3,

a theoretical calculated pump curve emerged, marked QH.

10.3.2 The centrifugal pumps mode of operation

A centrifugal pump consists of a rotating impeller inside a pump casing. The liquid

inside the impeller is affected by the blades, and will be lead through the blades

due to the centrifugal force. Energy in forms of kinetic energy (velocity energy) is

added to the liquid. New liquid is constantly lead into the impeller and put into

rotation. A flow through the pump is established.

If the delivery pipeline from the pump is open to the atmosphere and has sufficient

height, the liquid will adjust itself to a precise level given by the energy, which was

added to the liquid through the impeller. Here, all kinetic energy is transformed into

potential energy.

The difference in liquid level is called net delivery head. A pumps delivery head is

dependent on the individual pumps construction. If the level in the tank is lowered,

the liquid level in the delivery pipeline will be correspondingly lower. Net delivery

heads (H1, H2, H3) will be equal for the same pump provided that flow disturbance

does not occur on the pumps suction side.

However, the pumps delivery pressure is dependent on the liquids density and

delivery head. In this case, the liquid is water with a density (r) of 1000 kg/m3 and

the head (H) is 100 meters, the manometer pressure (pm) after the pump will be

read at:

pm = r x g x H = (1000 kg/m3 x 9,81 m/s2 x 100 m)

pm = 981000 Pa = 981 kPa

pm = 9,81 bars

One can see from the previous example that the delivery head of the pump is

obtained from the pump itself, and that the delivery head is independent from the

pumps position or location. It is therefore natural that the centrifugal pumps

capacity always is given as a function of the pumps delivery head.

If you bend the discharge pipe from the previous example, like the illustration below,

the liquid will flow out of the pipe. Only a part of the added energy in the pump will

lift the liquid. The rest of the energy is still in the form of kinetic energy. From the

previous taught experiment, one can predict that the capacity of a centrifugal pump

will be highest at minimal delivery head. The capacity curve (Q-H curve) will, in

practice, follow this assumption, but the curve is not linear due to loss of energy in

the pump.

If you ignore the pipe resistance, the capacity Q in this situation is determined by the

delivery head (H). The delivery head here is the static height or the static

backpressure, which the liquid has to lift.

In a real pipe system, bends and valves will create a resistance due to friction

against free liquid flow. This resistance varies with the velocity and viscosity of the

liquid, and is called the dynamic backpressure. The total pipe resistance, composed

by the static and the dynamic backpressure, is called a system characteristic curve.

The intersection point between the system characteristic curve and the capacity

curve is called the actual operation point.

It was previously mentioned that disturbances on the pumps suction side would

have influence on the capacity.

The conditions on the inlet side are very important for the centrifugal pumps

operation. A centrifugal pump has normally no self-priming qualities, meaning that

the pump is not able to suck liquid from a lower level. Additional vacuum equipment

connected to the pump will, however, improve the pump's self-priming qualities.

When the inlet pipe and impeller is filled with liquid, the pumping process will be able

to continue without this equipment. The liquids viscosity may ensure a continual flow

into the pump. Too high resistance in the inlet pipe will cause the same operational

disturbance. If the flow into the pump is less than the outlet flow, due to too high

pipe resistance and/or too high viscosity, these factors will have considerable

influence on the pumps capacity.

If you start a pump, submerged in water like the sketch indicates, the pump will

have a specific capacity at a specific delivery head. If you gradually lift the pump, the

pump will, at a specific height, have a perceptible reduction in the capacity. When

this occurs, the height of the pump above liquid level is called Net Positive Suction

Head or NPSH.

The explanation of this phenomena is that when the pump is lifted up out off the

water, the pipe length and the resistance at the inlet side increases. The increased

resistance creates constant negative pressure on the inlet side of the pump. The

liquid that accelerates from the centre of the impeller and out to the periphery

increases this negative pressure. When the negative pressure reaches the liquids

saturation pressure, the liquid starts boiling and a large quantity of vapour is created

in the pump. The output from the pump become irregular, and will stop at huge

vapour volumes. We say that the pump cavitates.

A centrifugal pump operates satisfactorily with approximately 2% gas in the liquid.

But cavitation will always cause damage to the pump. The gas bubbles created in the

liquid on the pumps suction side will collapse when the pressure rises inside the

impeller.

The consequences of cavitation are:

Vibrations and noise

Reduced efficiency

Pitting or cavity erosion inside the pump house

As we have observed, the cavitation is destructive and must be avoided or

controlled. To ensure limited or non-generation of vapour one must make sure that

the liquid at the pump inlet has sufficient overpressure to avoid evaporation. The

resistance at the pump inlet side should be made as low as possible. This can be

done by constructing the pipeline as short as possible, limiting the number of bends

and selecting a maximum diameter on the pipeline. The pump should be positioned

at the lowest possible level, and preferably below liquid level at the suction side.

A pumps NPSH is variable and dependent on the flow. When the flow increases, the

negative pressure generated inside the pump increases. A reduction of the flow will

reduce the negative pressure. Reducing the pumps capacity may therefore control

and reduce the cavitation.

A centrifugal pumps capacity is adjusted by throttling the delivery valve. Throttling

increases the pumps discharge pressure (backpressure) which causes reduced

capacity.

The capacity may also be adjusted by changing the revolution on the pump.

Adjustments of the pumps revolution move the capacity curve up or down.

Reduction of the revolution moves the curve parallel downwards, an increase in

revolution, upwards. Note that these relations are valid only if the flow conditions are

unchanged.

10.3.3 The Pump performance diagram

All manufacturers supply a pump performance diagram with the pump delivery. The

curves in the diagram are results from practical tests in the manufacturers workshop

and specifies:

Type of liquid used in the test (generally water)

Number of revolutions

Type and size of impeller

The optimal operation point

The operation point is normally set at the best possible efficiency, simultaneously

within the pumps predicted capacity range.

It is important to be aware that the pumps diagram is made for a special liquid with

specific properties. The capacity curve will be real for all liquids, provided the free

flow to the pump inlet is not restricted due to for example too high viscosity. The

power consumption curve will of course depend on the fluids density.

A pumps condition is of course vital for the curve accuracy. There are a lot of

methods to check the centrifugal pumps condition. Monitoring the pumps delivery

head, capacity, power consumption and development of these is obvious. Detection

of many minor operational disturbances may be difficult and not necessarily

observed. Establishment of routines ensures continuous control of vibrations. Visual

inspection of the pump and regular maintenance is important to prevent break

down.

10.3.4 Example on pump diagram

10.4 The deepwell pump

Cargo discharge pumps onboard gas carriers are generally deepwell pumps. The

deepwell pumps main parts are the pump, shaft, and mechanical seal, coupling and

motor. The pump is located at the lowest level inside the cargo tank pump sump.

The shaft is located in the discharge pipe from the pump to the mechanical seal and

connected to the coupling. The coupling connects the shaft and motor together. On

top of the cargo dome the top unit with an electric or hydraulic motor are located.

Due to the length of the shaft, the pump has a limited rotation speed. This leads to a

reduced delivery head for a single stage pump. The pump is therefore built with

multiple stages. Shaft bearings are located between each stage in the pump unit and

with even intervals along the shaft. These bearings can be made of PTFE

preservative carbon that have self-lubricating qualities.

The top unit consists of an axial bearing, a double mechanical shaft seal, revision

ring and an upper ball bearing.

The axial bearing is a roller bearing that holds the entire weight of the shaft and

impellers. The bearing house is usually

provided with cooling ribs to maintain an acceptable oil temperature. The purpose of

the double mechanical shaft seal is to prevent leakage of cargo into the environment,

and leakage of air into the cargo. The oil in the seal lubricates the seal surfaces, and

quarantee an operation without leak or other problems. If we got a leak in the seal

the oil must not came in contact with the cargo. The revision ring in the mechanical

seal functions normally as a deflector that will lead a leakage of seal oil into a special

chamber. This chamber can be drained.

A second function for the revision ring is to prevent leakage of cargo vapour along

the shaft when renewal of the mechanical seal. If the axial bearing nut is loose, the

shaft will drop down and the revision ring will land on a seat below.

The top carbon shaft bearing, must like the other shaft bearings, be lubricated by the

cargo itself. One can thereby not avoid contact between the cargo and the seal oil in

the top unit. Control of compatibility between the seal oil and actual cargo is

therefore important. The seal oil should not pollute the cargo or generate hazardous

reactions when mixed with the cargo.

10.4.2 General tips for operation of a deepwell pump:

Check pump unit guides clearances inside the cargo tank when possible.

Check for lose bolts and nuts inside the cargo tank when possible.

Always carefully check the cargo tank and sump for rags and other lose objects

before the hatch is closed.

Always check the motors running direction before the coupling is fitted. Wrong

direction may result in shaft damage.

Always regularly check the anti rotation device, if fitted.

Always check lubrication oil level and seal oil level, pressurise before the pump is

started.

Regularly check seal oil and lubrication oil levels when the pump is running.

Always turn the pump before start.

Check and adjust the pumps safety device.

Running of deepwell pump without liquid is the most common reason for

breakdown. Stop the pump when the tank is liquid free, do not force operation of the

pump and do not run the pump against a closed delivery valve for too long a time.

These pumps are operating without vibration and related noise. Stop the pump

immediately if this occurs.

10.4.3 Design of the double mechanical seal

Example of pump parts

10.5 Submerged pumps

Submerged pumps are multistage centrifugal pumps that are often used as discharge

pumps on large LNG and LPG tankers. The motor and pump are submerged down in

the tank sump or as close to the tank bottom as possible. The motor is connected

directly to the pump with a short shaft on this type of pump. The liquid that is

pumped lubricates and cools the pumps bearings. It is therefore essential that the

pump is used only when there is liquid in the tank. The liquid is pumped up through

the tanks discharge pipe and up to the liquid line.This type of pump is equipped with

electrical motor. The cables to the electric motor are either made of copper or

stainless steel. If copper is used in the cable, the cables must be sheathed with

stainless steel to prevent damage on the cable from corrosive cargoes. When

transporting Ammonia, the cable and engine must be sheathed with a thin layer of

stainless steel. It is important that the stainless steel sheathing is kept unbroken, and

we must avoid a sharp bend on the cable to protect the stainless steel sheath. One

must at all times check the resistance of the cable insulation before starting the

pump.

Submerged pumps are also installed as portable pumps. The discharge pipe is then

the steering pipe for the pump. At the bottom of the discharge pipe it is a non-return

valve that opens when pump is lowered and shut when the pump is taken up. Before

opening the discharge pipe it must be gas freed, this is done either with inert gas or

Nitrogen.

10.6 The boster pump

If the backpressure during discharging is too high for the deepwell pump(s), a

booster pump is connected in serial with the deepwell pump(s) to increase the

systems ability to pump against high backpressure. There are normally two booster

pumps installed on deck on gas carriers. The booster pump is normally a centrifugal

pump, installed horizontally or in vertical position. Horizontally installed pumps have

an axial inlet and radial outlet in the same centre line. Vertically installed booster

pumps have radial in and outlet in-line.

The booster pumps onboard gas carriers have mainly an individual and compact

design. They are constructed with focus on reliability, simple maintenance and long

lifetime. The shaft seal, with double mechanical seal with sealing liquid, is similar to

the arrangement of the deepwell pump.

The bearing is lubricated by oil; the liquid lubricates the inner shaft bearings.

The following general regulations are existing for working a booster pump:

Turn the pump shaft regularly when the pump is not used for long periods.

Turn the shaft before starting the pump.

Do never start the pump if the pump is not filled with liquid.

Regularly check the seal oil level.

Never run the pump against the closed delivery valve for more than approximately

30

seconds.

Adjust the flow by throttling the delivery valve, the inlet valves should always be

fully open.

10.7 Parallel operation of centrigal pump

The capacity requirement is many times higher than the performance of one

centrifugal pump. All available pumps are then lined up and run in parallel operation.

The diagram below indicates two equal pumps in parallel operation. We assume a

symmetry pipeline for both pumps.

The pumps capacity curve (1) indicates the relation between the delivery head and

the flow rate for one pump. As both pumps are equal, the pumps individual capacity

curves are represented by the curve marked 1. When equal pumps are run in

parallel the delivery head for the system will be equal the delivery head for one

pump. The capacity will meanwhile increase in proportion to the number of pumps.

If, for example one pump has a capacity of 100 m3/hrs at a head of 100 meters, two

pumps in parallel will supply 200 m3/hrs and three pumps 300 m3 /hrs at the same

head.

If the pumps are of different types or equal pumps are run at different speed, their

individual performance curves will be different. This is no problem provided the

operation point is outside the pumps individual operation point. If, for example the

operation point is altered by increasing the back pressure, this may lead to that one

of the pumps are run without output flow. If this situation occurs and is maintain, the

pump may be damaged.A deepwell pump is special vulnerable in this situation

because these pumps are dependent of a liquid flow through the pump. The only

indication on such condition is that the power consumption no longer is in agreement

with the operation.

If there are no check valves after the pump and the backpressure increases further,

you will have a back flow trough the pump into the cargo tank.

Even though the type of the pump is the same in a parallel operation, variation in

rotational speed, asymmetric piping, variance in opening if valves, cavitation and

variance of the pumps condition, may form the same condition.

10.7.2 Two equal pumps are run in parallel operation.

Two equal pumps are run in parallel operation. The resulting performance curve of

the pumps (1+2) is constructed like previous described. We then see on this actual

pump situation, a pump alone will deliver 120 m3/hrs against a head of 120 meters.

When you start pump number 2, the capacity for the system increases to 140 m3/hrs

against a head of 150 meters. Starting pump number 2 will not double the capacity

because a higher volume flow creates higher dynamic resistance. The systems

capacity will increase if other pumps are started up in parallel operation. The

increase in capacity will however be relatively less for each pump added.

10.8 Serial operation of centrifugal pumps

If the backpressure while discharging is too high and the capacity hence too low, a

booster pump in series with cargo pumps will improve the capacity.

The following illustration shows two cargo pumps run in parallel (1 and 2) in series

with a third booster pump (B). Some ship has a dedicated pump for this purpose,

also-called booster pump.

The systems maximum capacity is the number of pumps in parallel operation, times

maximum capacity for one pump. The maximum head is the maximum head for one

pump (1 or 2), plus maximum head for the booster pump (B).Notice that cargo

pumps no.1 and no.2 must ensure sufficient flow of liquid to the booster pump (B).

One must emphasise that there are made no special demands for a dedicated

booster pumps NPSH-performance. If one of the pumps in parallel stops, there is a

risk that the supply of liquid to the booster pump became too low and will result in

cavitation. If so occur, cavitation can be reduced or stopped by throttling the delivery

valve on the booster pump.

10.8.2 Two equal pumps run in parallel operation.

Two equal pumps run in parallel operation. The capacity is 100 m3/hrs with a head

of 160 meters. The master and chief officer evaluate the operation and decide to line

up for a booster pump in serial with the cargo pumps.

The new capacity is calculated by constructing a new resulting performance curve for

all three pumps, as previous described. The new operation point will appear in the

intersection between the resulting performance curve, and the system characteristic

curve. The capacity will increase to 140 m3/hrs at a head of 340 meters. If the cargo

is propane at a temperature of 20oC, and with a density of 502 kg/m3, the

corresponding delivery pressure will be:

r x g x H = 502 kg/m3 x 9,81 m/s2 x 340 = 167.437 Pa 16,7 bars

10.9 Pressure surge and liquid pressure

When a valve on a liquid line is closed too quickly, the pressure inside the line very

quickly increases to a hazardous high level.

Quick changes to the liquid flow in a pipeline may lead to a pressure surge resulting

in a rupture in the pipeline system. This surge pressure can be recognised by a

knock in the pipeline. This type of pressure peak is generated very quickly in

pipelines, faster than a common safety valve is capable to relieve. The consequence

may be breakdown of the pipeline system and thereby high risk of pollution, fire and

personal injury.

Pressure surge may appear if:

The emergency shutdown valves are activated and closed too quickly.

(ESD/Emergency Shut Down)

Fast closing/opening of manual or remote operated valves.

Fast variation of the volume flow resulting that a non-return valve starts hammering.

When a pump is started or stopped.

The pressure in a cargo transfer system has three components; the hydrostatic

pressure, the cargo tank pressure and the pressure generated by the pump. The

hydrostatic pressure and the cargo tank pressure will mainly be constant and we will

refer to these as static pressure.

If the flow suddenly is varying due to, i.e. too fast valve closure, the moving liquid

that have a specific velocity and mass will hit a wall inside the valve (the valve seat

or the valve flap). The kinetic energy of the moving liquid will immediately convert

into potential energy by compression of the liquid against the valve seat. How fast

the pressure peak is generated depends on the velocity and the density of the

liquid.

A pipeline of 250 meters and 150 mm in diameter is used for water transfer at a

capacity of 400 m3/hrs. The total mass of the moving liquid inside the pipe is 4400

kg and moves with a velocity of 6,3 meters/second. If a valve is closed very fast, the

kinetic energy will convert almost immediately to potential energy. The pressure

surge may reach approximately 40 bars within 0,3 seconds.

If the liquid is a condensed gas or crude oil, vapour may be present. These vapour

bubbles will collapse when the pressure increases. The collapsed bubbles will

generate pressure waves that will also be transmitted through the pipeline system.

In an opposite case where the pressure is decreasing rapidly, a volatile liquid will

start boiling. The above mentioned cases illustrate why it is especially important that

the valves and pumps are cautiously operated so neither dangerous pressure peaks

nor pressure drops are generated.

The enclosed diagram on the next page is from ITC Tanker Safety Guide. It shows a

normal cargo operation and pressure in the pipeline. The maximum pressure is at the

pump outlet. This pressure is the sum of the hydrostatic pressure and the pressure

generated by the pump. Due to friction in the pipeline, the pressure will gradually

decrease toward the cargo manifold. If the ESD valve is activated and the valve is

closed too quickly, the liquid flow will stop quite quickly.

The liquids kinetic energy will convert into potential energy immediately when the

liquid hits the valve seat. A pressure peak is generated and will be transmitted at the

speed of sound (the only way possible) back towards the pump. When the wave of

pressure reaches the pump, some of the pressure will unload through the pump, but

the resistance here will also operate as a wall. The pressure is rebuilt and reflected

back towards the ESD valve again. A new pressure peak is generated with additional

increased pressure. A knock will occur each time a pressure top is generated

against a wall. All personnel that operate valves or pumps must be observant of

these phenomena and of the liquid pressure, which may occur consequently.

The progress and the length of the pressure surge depends on the system. If the

wave of pressure is allowed to move between two valves without pressure relief, a

maximum pressure surge will be generated.

The most vulnerable parts in the system are the shore connections and

loading/discharging arms. The operative personnel normally work nearby the

manifold area. A rupture in this area may easily lead to personnel injury. (Please

note that control of cargo hoses is dealt with in this chapter).

Maintenance and testing of the ESD-valves closing time is the most important of the

above mentioned causes. Closing time of the ESD-valves, which is too short, may

lead to generation of a dangerous pressure surge. Always consult the terminal

representatives about the required pipe line period and ESD time.

10.9.1 Development of pressure surge

The closing time of ESD valves should be as short as possible to prevent overflow

and spillage. But not so fast that a risky pressure surge occurs. Necessary time for a

safe closure of valves can be calculated based on the expected maximum pressure

surge when the pressure wave has passed forward and backward through the

pipeline. The speed of the sound is set to 1320 m/s. If the pipeline is 2 km, the

calculated time for maximum pressure surge at closure of the ESD valve is:

T = (2 x L) / Speed of sound = (2 x 2000 m) / 1320 m/s = 3 s

The maximum pressure surge will occur 3 seconds from closure of the ESD valve.

This time is called a pipeline period. It is assumed that the safe closing time is five

times a pipeline period, so the closing time should at minimum be:

5 x 3s = 15 seconds

10.9.2 Cargo hoses

The cargo hoses are normally the weakest part in a pipeline system transferring

cargo. The responsibility for the cargo hose condition on board lays with the ship. It

is important to be aware of this fact, in case a cargo hose is lent out to a third party

or is used in transferring cargo between ships.

Hoses for cargo should be cleaned and dried before storing. The storage area should

be dry and out of the sun, if you want to take care of the hoses as long as possible.

Poor cleaning and storage is generally the cause of damage and consequently

replacement. A cargo hose prototype is tested with the products, pressure and

temperature for which the hose type is approved. The cargo hoses should be tested

yearly at a pressure that is 1,5 times the maximum working pressure.

The normal procedure for yearly testing is:

The hose is laid out on deck, blinded off and filled with water.

The hose is pressurised with 1,5 times the working pressure.

The hose is checked for leakage.

Electric bonding is checked.

Linear expansion for the hose is measured (measure for strength)

The test result is logged.

If there is no leakage, bonding is okay and the linear expansion is less than the

limitation set by the manufacturer, the hose is approved.

10.10 capacity calculation

All centrifugal pumps are delivered with pump performance diagrams. The diagram is

an important tool for insight in the factors that have influence on operation of

pumps.

Enclosed is a pump curve with a drawn system curve for an actual unloading

situation. The operation point is in the intersection between the pump curve and the

system curve. The system curve is composed of a static- and a dynamic curve. The

static backpressure (H), is corresponding to a level distinction of 20 m between the

liquid in the shore tank and the cargo tank onboard.

The dynamic backpressure is calculated from a stated differential pressure in the

pipeline of 10 mlc at a flow rate of 500 m3/h.

The pipeline resistance is dependent of the flow rate in the pipe, and the dynamic

backpressure (pipe resistance) can be expressed as:

H = c x Q2 (see The Affinity Laws)The constant c, is calculated from above

mentioned expression. The dynamic curve is a result of calculation of the dynamic

backpressure at different flow rates with the same c-value. The system curve is

constructed by adding the static- and the dynamic backpressure at the same flow

rate.

We then see from the diagram, that the pump delivers 80 m3/h at a head of 120

mlc. The pumps delivery pressure is dependent of the density of the liquid pumped.

If the liquid is propylene at a temperature of 44oC, the pumps delivery pressure (p)

will be:

p = r x g x H

= 607,4 kg/m3 x 9,81 m/s2 x 120 m

= 715.031 Pa

= 7,15 Mpa

= 7,15 bars

The cargo tank pressure is 0,2 bars at a temperature of 40oC. Observed delivery

pressure (manometer pressure) is thereby approximately 7 bars.If the backpressure

increases, by for example throttling of the manifold valve, the dynamic backpressure

will increase. An increased dynamic backpressure is visualised by a more steep

system characteristic curve. The operational point will move up along the pump

curve. The pumps delivery head increases and the capacity is reduced. The new

delivery head, and hence the capacity, can be calculated without construction of a

new system curve.If the backpressure increases to 8 bar, the new delivery head will

be:

p = r x g x H

H = p / r x g = 800 000 Pa / 607,4 kg/m3 x 9,81 m/s2 = 134 m

A delivery head of 134 m corresponds to a capacity of approximately 50 m3/h.

10.10.1 An extended capacity calculation

The method of calculation above is a simplified procedure, but gives sufficient means

for most practical calculation. An extended calculation of capacity where one

considerate all factor influencing a pumps working conditions, must necessarily be

more complex.When describing the centrifugal pumps physical relations, it is natural

to focus on the whole systems energies. The systems energy balance is then:

Energy on the suction side + Energy added the pump = Energy after the pump.

In the following example we have a partly filled tank where a submission is working.

The pump is supplying liquid a stated energy, which is lifting the liquid into the tank

and gives is velocity, which creates a flow rate through the pump.

The energy level on the suction is decided by the height of the liquid, and the liquid

pressure. This is expressed as:

(m x g x X) + (m x po/r)

The energy supplied into the pump is expressed as:

m x g x H

where H is the lifting height of the pump.

The liquid is lifted out of the cargo tank. The energy level after the pump is

compound of static energy (liquid are lifted a given value Y), kinetic energy (given

backpressure p2) and velocity energy (velocity of the liquid c2).

The balance of the energy is then:

(m x g x X) + (m x po/r) + m x g x H = (m x g x Y) + (m x p2/r) + 1/2 x m x c22

where the real pump head H is:

H = (p2 - p0)/(r x g) + (y - x)

One can see how the tank pressure and levels affect the simplified calculation of the

lifting height of the pump. When the liquid level in the tank is lowered toward the

end of the unloading, the lifting height increases with hence following reduction in

the capacity. A higher tank pressure gives lower lifting height, and with that larger

capacity.

10.10.2 Affinity equation

The affinity equation is an expression that demonstrates the proportionally relation

between flow rate, lifting height, effect and number of revolutions for a centrifugal

pump. If one of these element changes, this will influence on the rest. The equation

can be used to calculate theoretic consequences of the changes on the existing

centrifugal pump.

10.10.3 Equation 1

The velocity of the liquid from a pump, is an expression for flow rate through the

pump, and can be defined as:

c = Q/A where:

c = velocity of the liquid in m/s

Q = volume flow through the pump in m3/hrs

A = cross section of the pipe in m2

10.10.4 Equation 2

The velocity of the liquid from a pump is dependent from the impellers velocity, the

number of revolutions. Higher number of revolutions of an impeller gives larger

velocity of the liquid, which again gives larger capacity. This is defined as:

Q1/Q2 = c1/c2 = n1/n2 where:

Q1 = Capacity before changes

Q2 = Capacity after changes

c1 = velocity of the liquid before changes

c2 = velocity of the liquid after changes

n1 = revolution of impeller before changes

n2 = revolution of impeller after changes

10.10.5 Equation 3

Lifting head of a pump are given by the following expression:

H = c2/2g where:

H = pump lifting head in mlc

c = velocity of the liquid in m/s

g = gravitation in m/s2

We then se that the pump lifting head is proportional with c2 and equation 2 can be

changed to:

H1/H2 = c12/c22 = n12/n22

10.10.6 Equation 4

The theoretical need of power (P) for a pump is:

P = r x g x Q x H where:

= density of the liquid in kg/m3

Change of the operation of the pump gives the following connections:

P1/P2 = (c1/c2)3 = (n1/n2)3

Peripheral speed (v) for a pumps impeller is:

v = (p x d x n)/60 where:

d = impeller diameter

When the impeller diameter and the peripheral speed is variable the following

equation can be used:

v1/v2 = d1/d2 = n1/n2

When the velocity of the liquid is proportional with impeller speed can we use the

following equation:

c1/c2 = v1/v2 = d1/d2 = n1/n2 = Q1/Q2

or:

Q1/Q2 = (n1 x d1) / (n2 x d2)

10.10.7 Equation 5

Above mentioned expression can be summarised as:

H1/H2 = (c1/c2)2 = (n1 x d1)2 / (n2 x d2)2

where the condition in the alteration of the pump effect is:

P1/P2 = (d1/d2)5 x (n1/n2)3

One shall notice that the three last expression for flow rate, lifting height an effect,

only effect small changes of the rotor-blade wheels diameter.

This is due to that the loss of the pump is not directly proportional with the flow rate.

Large changing of the diameter will give bigger effect of the flow rate, lifting height

an effect.

10.10.8 Equation 6

A combination of equation 4 and 5 can the relation between lifting head and volume

flow give the hydraulic operation of the pump as follows:

H1/H2 = (Q1/Q2)2 = constant or

H = k x Q2

10.11 Displacement pumps

Pumps are very old machines. The first types of pumps (screw pump and piston

pump) are more than two thousand years old.

A pumps purpose in transport of liquids, usually are to pump from a low level to a

higher level. Its purpose can also be to pump a liquid into a tank, which contains

higher pressure than the surroundings. The pump increases the liquids energy. The

increased energy is potential energy; the liquid is transported from a low level to a

higher level. This is the kinetic energy, the liquids flow has increased or as pressure

energy, if the liquid is pumped into a tank with a higher pressure than its

surroundings. As an example, the feed water pump to a boiler is working using these

principles.In addition to the mentioned increase of energy, the pump also has to

maintain the energy, which is lost due to streaming in the system.

As mentioned, kinetic pumps constantly have liquid streaming through the pump

with pressure increasing simultaneously. In displacement pumps, a certain volume of

liquid is branched off and moved from the pumps delivery side. Then a pressure

increase occurs. Screw pumps and piston pumps will be viewed further in this

chapter. A wide range of displacement pumps is available, such as the lamella pump,

ring pump, propeller pump, etc.

10.11.1 Piston pump

The piston pump is used for relatively small amounts of liquid with large delivery

heads. When the piston is pulled upwards, a vacuum occurs inside the pump

housing. The suction valve will then open and liquid streams into the pump. When

the piston is pressed downward the pressure will increase, the suction valve will

close, the delivery valve is set open and the liquid sent out of the pump. The liquid

does not stream in a smooth flow as in a centrifugal pump, but accelerates and slows

alternately. This is of inconvenience with long pipelines. The valve is a weak point.

They are sensitive to liquid pollution and they also increase the resistance against

streaming.

Usually, the piston pump is double acting. Because of the pumps movements, the

pump must have a relatively slow piston speed. The piston pump may sustain almost

unlimited pressure. However, the limitation is the automotive power and the material

strength. The piston pump does not have to be filled with liquid before starting.

Make sure that all the valves on the delivery side are open before starting. The

efficiency of piston pumps is higher than, for instance, centrifugal pumps. The piston

pump is a well-known pump on board an oil tanker. This is the pump, which is used

to pump cargo deposits ashore at the end of the discharging operation. These oil

deposits from cargo tanks, lines and cargo pumps are pumped ashore through a

small diameter line.

10.11.2 Screw pump

The screw pump consists of two screws or more, where one of them is activated.

The screws are placed inside a pump house. A common and well-known screw pump

is the Swedish manufactured so-called IMO pump. This pump consists of one active

screw placed in the middle and two symmetrical side screws. The screws tighten to

each other and to the housing, but have no metallic contact. When the screw

rotates, the threads are filled with liquid. The liquid is displaced by axial through the

pump. In this pump, the side screw rotates in the opposite direction of the middle

screw. These screws are working like an endless piston which constantly moves

forward. The liquid is not exposed to rotation. The pump is self-priming, running

almost soundless and with little exposure for wear and tear when pumping clean

liquids. The screw pumps are used a lot as a lubricating pump, but are also used as a

stripping pump on oil tankers.

Вам также может понравиться

- The Yellow House: A Memoir (2019 National Book Award Winner)От EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Рейтинг: 4 из 5 звезд4/5 (98)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeОт EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeРейтинг: 4 из 5 звезд4/5 (5795)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureОт EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureРейтинг: 4.5 из 5 звезд4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryОт EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryРейтинг: 3.5 из 5 звезд3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceОт EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceРейтинг: 4 из 5 звезд4/5 (895)

- Never Split the Difference: Negotiating As If Your Life Depended On ItОт EverandNever Split the Difference: Negotiating As If Your Life Depended On ItРейтинг: 4.5 из 5 звезд4.5/5 (838)

- The Little Book of Hygge: Danish Secrets to Happy LivingОт EverandThe Little Book of Hygge: Danish Secrets to Happy LivingРейтинг: 3.5 из 5 звезд3.5/5 (400)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersОт EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersРейтинг: 4.5 из 5 звезд4.5/5 (345)

- The Unwinding: An Inner History of the New AmericaОт EverandThe Unwinding: An Inner History of the New AmericaРейтинг: 4 из 5 звезд4/5 (45)

- Team of Rivals: The Political Genius of Abraham LincolnОт EverandTeam of Rivals: The Political Genius of Abraham LincolnРейтинг: 4.5 из 5 звезд4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyОт EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyРейтинг: 3.5 из 5 звезд3.5/5 (2259)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaОт EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaРейтинг: 4.5 из 5 звезд4.5/5 (266)

- The Emperor of All Maladies: A Biography of CancerОт EverandThe Emperor of All Maladies: A Biography of CancerРейтинг: 4.5 из 5 звезд4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreОт EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreРейтинг: 4 из 5 звезд4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)От EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Рейтинг: 4.5 из 5 звезд4.5/5 (121)

- OrcaДокумент8 страницOrcaPranshu MalikОценок пока нет

- Final ReportДокумент118 страницFinal Reportdivmech1988Оценок пока нет

- EIA Envt Impact Assessment Report On Myitsone Dam BurmeseДокумент13 страницEIA Envt Impact Assessment Report On Myitsone Dam BurmesePugh JuttaОценок пока нет

- The Development of Sanitation SystemsДокумент2 страницыThe Development of Sanitation SystemsKhue MinhОценок пока нет

- Plumbing DBR 30%Документ5 страницPlumbing DBR 30%Dolphin Engineering ServicesОценок пока нет

- LabReport4 322 UploadedДокумент12 страницLabReport4 322 UploadedepsilonnaughtОценок пока нет

- Bomba e Motor Sauer DanfossДокумент18 страницBomba e Motor Sauer Danfossalbsalves8645Оценок пока нет

- CANAL (G) Canal Locks Design - ClarkeДокумент8 страницCANAL (G) Canal Locks Design - ClarkeMIKHA2014Оценок пока нет

- Saxon Copperflow Electric-Installermanual PDFДокумент20 страницSaxon Copperflow Electric-Installermanual PDFWayne AshОценок пока нет

- Industrial Training Template BasicsДокумент65 страницIndustrial Training Template BasicsFaiz IbrahimОценок пока нет

- Dams and Reservoirs PDFДокумент6 страницDams and Reservoirs PDFUtpalSahaОценок пока нет

- Specification For Piping FabricationДокумент24 страницыSpecification For Piping FabricationSanjay SenОценок пока нет

- Water - Resource - MGT - HIP WastewaterДокумент9 страницWater - Resource - MGT - HIP WastewaterFekadu100% (1)

- 10 State Standards - Waste Water FacilitiesДокумент178 страниц10 State Standards - Waste Water Facilitiesblin254Оценок пока нет

- PPT-ASHRAE Hong Kong-Fundamentals of Water Systme DesignДокумент64 страницыPPT-ASHRAE Hong Kong-Fundamentals of Water Systme DesignIsso Xue Xue100% (1)

- Engineer's Report DPДокумент1 страницаEngineer's Report DPMICHELLE grace corpuzОценок пока нет

- Centrifugal Pump TestДокумент15 страницCentrifugal Pump TestChayanon AutramontriОценок пока нет

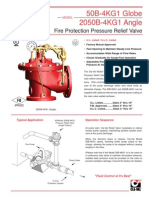

- E 50B 4KG1 - Fire PDFДокумент2 страницыE 50B 4KG1 - Fire PDFdocrafiОценок пока нет

- AC DownloadДокумент5 страницAC DownloadJason RogersОценок пока нет

- ActiveCell Brochure WEBДокумент3 страницыActiveCell Brochure WEBdiane mercadoОценок пока нет

- City of Arcata Wastewater Treatment Facility Improvements Project - Estimated Alternatives Project and Construction CostsДокумент1 страницаCity of Arcata Wastewater Treatment Facility Improvements Project - Estimated Alternatives Project and Construction CostsLiska Feby FitrianiОценок пока нет

- Wastes: Excreta and Sewage DisposalДокумент44 страницыWastes: Excreta and Sewage DisposalMare5Der5Оценок пока нет

- Eu 2-M2-3a-Surname, First NameДокумент3 страницыEu 2-M2-3a-Surname, First NamePoker FaceОценок пока нет

- CDEP Pre-Board - Jan2012 - PlumbingДокумент11 страницCDEP Pre-Board - Jan2012 - PlumbingdizonabigailmaereyesОценок пока нет

- 4.water Supply Distribution & PipesДокумент43 страницы4.water Supply Distribution & PipesAqib Javed SindhuОценок пока нет

- Basic Valve and Testing Method - 1Документ37 страницBasic Valve and Testing Method - 1Fouad OudinaОценок пока нет

- Installation, Commissioning and Maintenance Guidelines: For Electrohydraulic SystemsДокумент0 страницInstallation, Commissioning and Maintenance Guidelines: For Electrohydraulic Systemsanta77100% (1)

- Lavaojos PortatilДокумент16 страницLavaojos PortatilFosting SolanoОценок пока нет

- Annexure III Design of INTAKE WELL 12.01.12 FOR 2045Документ10 страницAnnexure III Design of INTAKE WELL 12.01.12 FOR 2045tapan kumar sen100% (1)

- Buffer Tank Hydraulic SeparatorДокумент4 страницыBuffer Tank Hydraulic SeparatorJohn MoreОценок пока нет