Академический Документы

Профессиональный Документы

Культура Документы

HOW To DO Capsmill Cycle Time Reduction Cadcam

Загружено:

rajualagОригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

HOW To DO Capsmill Cycle Time Reduction Cadcam

Загружено:

rajualagАвторское право:

Доступные форматы

CAPSmill

TM

Software for cycle time reduction and programming

For CNC Machining Centers

CAPSmill cuts your costs

Reduce cycle time

Specially designed to generate minimal cycle time programs

Reduce machine downtime

For dry runs, program entry, program editing and correction

Reduce part rejections

During tryouts

Reduce programming time

First-time-right programs, fast

Reduce tool cost

Efficient and appropriate tool paths

Reduce damage to machine

Eliminate accidents, spindle overuse

Reduce documentation time

Shop documents generated automatically

Reduce skill level of programmer

Does not need an engineer - a machinist can do the programming

Draw part and blank shapes

How CAPSmill works

Cycle time OK?

No

Yes

Define machining operations

Check tool path

Edit machining parameters

Check cycle time, spindle usage

Generate NC program

Generate shop documents

DNC to machine

Conversational software

Reduce programming time

Reduce skill level of programmer

No CNC programming knowledge needed just machining knowledge.

Training time is typically 2 4 hours.

Reduce cycle time

Reduce tool cost

Reduce skill level of programmer

Automatic cutting parameters selection

Eliminates a big cause of low cycle times poor FS selection.

Reduces tool wear caused by poor FS selection.

Reduce cycle time

Reduce tool cost

Reduce programming time

Reduce skill level of programmer

Wide variety of operations with unique tool paths

Eliminates a big cause of low cycle times inefficient tool paths.

Improves tool life because of proper usage.

Tool selection expert system

Reduce machine downtime

Reduce programming time

Reduce skill level of programmer

Suggests appropriate tools based on operation being performed.

Spindle direction is automatically decided eliminates a big cause of errors.

Eliminates dry run to check for such errors.

Tools database

Reduce machine downtime

Reduce skill level of programmer

Extensive library of tools commonly used in machining.

Can be configured by the user.

Tools can be classified according to manufacturer.

Automatic tool gouge prevention

Reduce cycle time

Reduce machine downtime

Reduce tool cost

Reduce damage to machine

Reduce skill level of programmer

Tool removes only whatever material it can, does not gouge into part.

Reduces cycle time - you can use roughing tools to the maximum.

Cycle time calculation

Reduce cycle time

Reduce documentation time

Reduce skill level of programmer

Extremely accurate cycle time less than 1 % error.

Try out many process options, decide on the one with least cycle time.

Generates printable cycle time sheet.

Spindle power graph

Reduce cycle time

Reduce damage to machine

Check if you are using the available spindle power to the maximum.

Check if you are over-using the spindle.

Highly effective tool path simulation

Reduce machine downtime

Reduce part rejections

Reduce damage to machine

Variety of simulation options - Zoom, pan, single block, tool-wise, auto

Dynamic tool position and parameter display.

Eliminates dry run, rejections and accidents.

Efficient, fully documented programs

Reduce programming time

Reduce machine downtime

Reduce skill level of programmer

Easy to understand because of extensive comments

Has canned cycles, nose radius compensation commands

No editing required on machine.

Build your own machine-specific program format, easily.

DNC

Reduce machine downtime

Inbuilt DNC eliminates program entry time

CAD for milling

Reduce programming time

Reduce skill level of programmer

Special functions for quick definition of parts

Can import part and raw material shapes from CAD software

Machining expert

Reduce programming time

Reduce skill level of programmer

Quick reference for machining data

Diagnostics for machining problems

Tutorials

Reduce skill level of programmer

Cover all aspects of the software

Enable you to learn the software yourself, in 2 to 4 hours.

Shop floor documentation automatic

Reduce machine downtime

Reduce documentation time

Reduce skill level of programmer

Use in shop floor, file away for future reference.

Tools list can be given to operator for tool setting

Tool layout sheet - graphical details of each operation.

Eliminates errors in information flow to shop floor.

Generic postprocessor

Reduce machine downtime

Reduce programming time

Reduce skill level of programmer

Makes posts to suit your machine and style of programming.

Conversational, very easy to use.

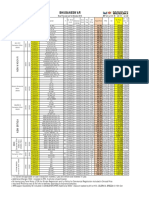

Benefit Features that enable the benefit

Reduce cycle time

Auto FS selection, Unique tool paths,

Tool selection expert, Cycle time calculation, Spindle power graph

Reduce machine downtime

Tool path simulation, Tools database,

Tool selection expert, Auto documentation, DNC

Reduce part rejections

Tool path simulation,

Tool selection expert, Auto FS selection

Reduce programming time

Conversational screens, Tool selection expert,

Auto tool gouge prevention, Tools database, Auto FS selection

Reduce tool cost Auto FS selection, Unique tool paths, Tool selection expert

Reduce damage to machine

Auto tool gouge prevention, To ol selection expert,

Tool path simulation, Spindle power graph, Auto FS selection

Reduce documentation time Auto documentation

Reduce skill level of programmer

Conversational screens, Auto FS selection, Tools database,

Unique tool paths, Tool selection expert, Cycle time calculation, Auto documentation,

Tutorials

Summary of features and benefits

CADEM used by top companies

CADEM endorsed by OEMs

Premier CNC machine manufacturers

For more information, contact

sales@cadem.com

Cadem Technologies Pvt.Ltd.

264/75, 36th cross, 8th Block Jayanagar,

Bangalore 560 070, INDIA

T: +91 80 2663 4767

F: +91 80 2244 2732

www.cadem.com

Thank you

Copyright 1997 2009 Cadem Technologies Pvt. Ltd.

Вам также может понравиться

- WP02 Kick Off SlideДокумент45 страницWP02 Kick Off SlideMacmacBentedos LitonManiego100% (1)

- NC CNC Machine ToolДокумент50 страницNC CNC Machine ToolShoaib MultaniОценок пока нет

- Stereo Lithography PresentationДокумент28 страницStereo Lithography PresentationJayanth RajОценок пока нет

- Additive Manufacturing Methods and Modelling ApproachesДокумент17 страницAdditive Manufacturing Methods and Modelling ApproachesBianca EndoОценок пока нет

- Laser Beam Machining: Done By: MuradДокумент15 страницLaser Beam Machining: Done By: MuradAl Mutiry MuardОценок пока нет

- Surface Roughness MeasurementДокумент30 страницSurface Roughness MeasurementHarish KumarОценок пока нет

- Natural Stone Test Methods - Determination of Uniaxial Compressive StrengthДокумент20 страницNatural Stone Test Methods - Determination of Uniaxial Compressive Strengthanjana100% (1)

- Twin-Scroll TurbochargerДокумент24 страницыTwin-Scroll TurbochargerJih Yan LaiОценок пока нет

- Final Copy With Page SetupДокумент37 страницFinal Copy With Page SetupPankajDhobleОценок пока нет

- Manual Operacion Cargadora Daewoo M200 V, M200 VTCДокумент200 страницManual Operacion Cargadora Daewoo M200 V, M200 VTCJovita Uvijindia100% (2)

- RPT - 20 - 08 - LomДокумент27 страницRPT - 20 - 08 - LomfamilyumaОценок пока нет

- 3D Printing Introduction and Types PDFДокумент83 страницы3D Printing Introduction and Types PDFŤhåŕüñ Kūmæř GøwđОценок пока нет

- Chapter 1 - Introduction - 2020 - Industrial Ventilation Design GuidebookДокумент14 страницChapter 1 - Introduction - 2020 - Industrial Ventilation Design GuidebookRichard100% (1)

- Questionnaire PMДокумент97 страницQuestionnaire PMapi-3781101100% (8)

- Mini Review On Desiging of Press Tools For Sheet Metal PartsДокумент11 страницMini Review On Desiging of Press Tools For Sheet Metal Partsdhananjaya_eeeОценок пока нет

- Twin MG 6690Документ234 страницыTwin MG 6690Calos Enrque75% (4)

- 11.en 10025-2Документ34 страницы11.en 10025-2Akash GhuleОценок пока нет

- 07 Final Rapid Prototype ReportДокумент16 страниц07 Final Rapid Prototype ReportpallaviОценок пока нет

- Guide to Load Analysis for Durability in Vehicle EngineeringОт EverandGuide to Load Analysis for Durability in Vehicle EngineeringP. JohannessonРейтинг: 4 из 5 звезд4/5 (1)

- Report On Digital Switching SystemДокумент20 страницReport On Digital Switching SystemKurban UbulОценок пока нет

- 16M Sebp4108-18-01-All PDFДокумент1 033 страницы16M Sebp4108-18-01-All PDFMarvin Melendez VanegasОценок пока нет

- Environmentally Conscious, &: DesignДокумент26 страницEnvironmentally Conscious, &: Designleila hanjani hanantoОценок пока нет

- Selective Laser SinteringДокумент5 страницSelective Laser Sinteringmanoharanpark_433315Оценок пока нет

- A Report On Organization Study at MRF LTD Kottayam by Subin Surendran OrganisationДокумент72 страницыA Report On Organization Study at MRF LTD Kottayam by Subin Surendran OrganisationBhavaniОценок пока нет

- Water LevelДокумент25 страницWater LevelPradeep Kumar RoutrayОценок пока нет

- Advanced Welding 2 PDFДокумент7 страницAdvanced Welding 2 PDFhalumsonaОценок пока нет

- Solid Freeform FabricationДокумент24 страницыSolid Freeform FabricationpsenthilpkumarОценок пока нет

- Tolerances: ENDG105 Class 7.1Документ43 страницыTolerances: ENDG105 Class 7.1nedunchiОценок пока нет

- Nanotechnology For Cancer TreatmentДокумент32 страницыNanotechnology For Cancer TreatmentJatin IsherОценок пока нет

- Computer Aided Process Planning-IIДокумент46 страницComputer Aided Process Planning-IIPrabha KaranОценок пока нет

- Geometric TolerancesДокумент23 страницыGeometric TolerancesSameer shaikhОценок пока нет

- Static and Dynamic Analysis of HCR Spur Gear Drive UsingДокумент54 страницыStatic and Dynamic Analysis of HCR Spur Gear Drive Usingjr-parshanthОценок пока нет

- Turning and Drilling PPT MFG Chapter23 FinalДокумент78 страницTurning and Drilling PPT MFG Chapter23 FinalRavichandran GОценок пока нет

- GSM Based RobotДокумент232 страницыGSM Based RobotTanvi KhuranaОценок пока нет

- Soil Moisture Sensor Based Solar Water PumpДокумент10 страницSoil Moisture Sensor Based Solar Water PumpJilly ArasuОценок пока нет

- Tool Engineering and Design Design of SiДокумент23 страницыTool Engineering and Design Design of Simulugeta assefaОценок пока нет

- CNC Machining Designing For SpeedДокумент9 страницCNC Machining Designing For SpeedjaimeОценок пока нет

- Design and Fabrication of Multi-Spindle MachineДокумент6 страницDesign and Fabrication of Multi-Spindle MachineIJIRSTОценок пока нет

- Mechatronic System DesignДокумент34 страницыMechatronic System Designgreen_way26Оценок пока нет

- Hybrid Additive ManufacturingДокумент9 страницHybrid Additive ManufacturingAbhishek KaleОценок пока нет

- Plastic Design Guide - Part Design, Material Selection, Processing ConditionsДокумент5 страницPlastic Design Guide - Part Design, Material Selection, Processing ConditionsAdithya SjОценок пока нет

- Powerinspect Manual CmmsДокумент2 страницыPowerinspect Manual CmmsFelipe Cordeiro100% (1)

- Selection &optimization of Spot Welding Process Parameters Using Taguchi MethodДокумент40 страницSelection &optimization of Spot Welding Process Parameters Using Taguchi MethodBabuli KumarОценок пока нет

- 3-Day Workshop On Press Tool DesignДокумент1 страница3-Day Workshop On Press Tool DesignPrasannakumar ShankarОценок пока нет

- Brochure Book Additive Manufacturing FinalДокумент5 страницBrochure Book Additive Manufacturing FinalsreeshpsОценок пока нет

- 15me835 PLCM Module 2Документ17 страниц15me835 PLCM Module 2prashanth prabhuОценок пока нет

- Design and Analysis of PROTECTED FLANGE COUPLING Solidworks 2016 and ANSYS WorkbenchДокумент27 страницDesign and Analysis of PROTECTED FLANGE COUPLING Solidworks 2016 and ANSYS Workbenchamu100% (1)

- Rapid Prototyping 212me2301Документ20 страницRapid Prototyping 212me2301Abhishek SinghОценок пока нет

- For Wood Cutter MachineДокумент19 страницFor Wood Cutter MachineRahul Rajput100% (1)

- Preparing For The Solid Edge Professional Certification ExamДокумент29 страницPreparing For The Solid Edge Professional Certification ExamAnderson PereiraОценок пока нет

- Different Types of Manufacturing Processes, Their Advantages, Disadvantages and Ideal Applications Blog - MechGuruДокумент4 страницыDifferent Types of Manufacturing Processes, Their Advantages, Disadvantages and Ideal Applications Blog - MechGuruvsdeepakchandra0% (1)

- Design Considerations With Powder MetallurgyДокумент15 страницDesign Considerations With Powder MetallurgyTagaytayan MaritesОценок пока нет

- Rapid PrototypingДокумент23 страницыRapid PrototypingRAIHAN SHAIKHОценок пока нет

- Recent Trends in ManufacturingДокумент13 страницRecent Trends in ManufacturingAmbarish100% (2)

- Additive Manufacturing: Case Study: Generative Design of A Bracket, Part 1Документ35 страницAdditive Manufacturing: Case Study: Generative Design of A Bracket, Part 1Ali Raza JuttОценок пока нет

- Industrial AutomationДокумент33 страницыIndustrial Automationbhuvanesh85Оценок пока нет

- Additive Manufacturing Notes PDFДокумент14 страницAdditive Manufacturing Notes PDFVishal Thakur0% (1)

- Nontraditional Manufacturing ProcessesДокумент157 страницNontraditional Manufacturing ProcessesKiran AsknaniОценок пока нет

- FRP Pultrusion CatalogДокумент6 страницFRP Pultrusion CatalogMani MaranОценок пока нет

- Additive Manufacturing Course Guide Run17 CourseSchedДокумент14 страницAdditive Manufacturing Course Guide Run17 CourseSchedAbdullah Amir MughalОценок пока нет

- Design and Fabrication of Pneumatic Sheet Metal CuДокумент3 страницыDesign and Fabrication of Pneumatic Sheet Metal CuMohammed Abdul KaleemОценок пока нет

- Powder Metallurgy - Chapter 16Документ43 страницыPowder Metallurgy - Chapter 16xharpreetxОценок пока нет

- NX Design Brochure W 3 - tcm73-4285Документ16 страницNX Design Brochure W 3 - tcm73-4285r0n41dОценок пока нет

- Lecture 13 Guidelines For Process SelectionДокумент23 страницыLecture 13 Guidelines For Process Selectionshanur begulajiОценок пока нет

- Introduction To Manufacturing TechnologyДокумент29 страницIntroduction To Manufacturing TechnologySahil SundaОценок пока нет

- Thesis Dewangan SДокумент244 страницыThesis Dewangan SShiba Narayan SahuОценок пока нет

- Organization Study ReportДокумент44 страницыOrganization Study ReportGovind ChowdharyОценок пока нет

- Design For Manufacture And Assembly A Complete Guide - 2020 EditionОт EverandDesign For Manufacture And Assembly A Complete Guide - 2020 EditionОценок пока нет

- Cylinder Hyd SealДокумент72 страницыCylinder Hyd SealrajualagОценок пока нет

- Cutting Force CaluДокумент9 страницCutting Force CalurajualagОценок пока нет

- Mathematical Elements For Computer Graphics 1Документ75 страницMathematical Elements For Computer Graphics 1furyfox19100% (3)

- Cadem VtuДокумент12 страницCadem VturajualagОценок пока нет

- Amf6926d 1x EnglishДокумент2 страницыAmf6926d 1x EnglishrajualagОценок пока нет

- Mechatronics IntroДокумент2 страницыMechatronics IntrorajualagОценок пока нет

- Unit7 Nan PDFДокумент56 страницUnit7 Nan PDFAnonymous L7XrxpeI1zОценок пока нет

- Carbon Nanotubes PresentationДокумент11 страницCarbon Nanotubes PresentationrajualagОценок пока нет

- Long Play Version of SM 911Документ6 страницLong Play Version of SM 911dОценок пока нет

- SPP Operating Manual PDF273201695332Документ9 страницSPP Operating Manual PDF273201695332ask101Оценок пока нет

- FI750 User ManualДокумент36 страницFI750 User ManualEnrrique Vega MecatronicОценок пока нет

- Air Vacuum ValvesДокумент4 страницыAir Vacuum ValvesmariuspiОценок пока нет

- Lovely Professional UniversityДокумент19 страницLovely Professional UniversitySukhvinder Singh DhimanОценок пока нет

- Case Study - Nguyen Hoang Exim Co. - QualityДокумент2 страницыCase Study - Nguyen Hoang Exim Co. - Qualitysusmitabiswas0% (1)

- Arduino Info SoftwareSerialRS485ExampleДокумент8 страницArduino Info SoftwareSerialRS485ExampleindoramaОценок пока нет

- R307 Fingerprint Module User ManualДокумент24 страницыR307 Fingerprint Module User ManualHide AnakbangsaОценок пока нет

- Security Evaluation of SCTP: Bachelor ThesisДокумент61 страницаSecurity Evaluation of SCTP: Bachelor ThesisGábor NémethОценок пока нет

- 175 012200 PDFДокумент2 страницы175 012200 PDFAbu Anas M.SalaheldinОценок пока нет

- Alloy Cross Reference Table PDFДокумент4 страницыAlloy Cross Reference Table PDFChad MitchellОценок пока нет

- Trimline UT20006Документ22 страницыTrimline UT20006ashumovОценок пока нет

- MEM 603 MINI Project Assessment - Noriah Sept 2017-Mac2018Документ4 страницыMEM 603 MINI Project Assessment - Noriah Sept 2017-Mac2018Farrina AzizОценок пока нет

- Norma A751Документ5 страницNorma A751Dionisio Hidalgo SanchezОценок пока нет

- Zarandas MongooseДокумент12 страницZarandas MongooseLuis Alfredo Gregorio RivasОценок пока нет

- Digital Stiffness TesterДокумент1 страницаDigital Stiffness TesterProduction SHVPMОценок пока нет

- VLAN Ip SubnetДокумент3 страницыVLAN Ip SubnetVane Duarte GonzalezОценок пока нет

- Dealer Price List Oct 2019Документ2 страницыDealer Price List Oct 2019Pranab Kumar NayakОценок пока нет

- HPE ProLiant DL380 Gen10 Server UKDoC HSTNS-5200-a50005003enwДокумент3 страницыHPE ProLiant DL380 Gen10 Server UKDoC HSTNS-5200-a50005003enwhesmaileeОценок пока нет

- CT101 IntroductionToNetworkingДокумент39 страницCT101 IntroductionToNetworking2begeniusОценок пока нет