Академический Документы

Профессиональный Документы

Культура Документы

Multistage Flow-Shop Scheduling With Weighted Jobs: DR Neeru Chaudhary

Загружено:

inventionjournals0 оценок0% нашли этот документ полезным (0 голосов)

13 просмотров4 страницыInternational Journal of Mathematics and Statistics Invention (IJMSI) is an international journal intended for professionals and researchers in all fields of computer science and electronics. IJMSI publishes research articles and reviews within the whole field Mathematics and Statistics, new teaching methods, assessment, validation and the impact of new technologies and it will continue to provide information on the latest trends and developments in this ever-expanding subject. The publications of papers are selected through double peer reviewed to ensure originality, relevance, and readability. The articles published in our journal can be accessed online.

Оригинальное название

g 02402054057

Авторское право

© © All Rights Reserved

Доступные форматы

PDF, TXT или читайте онлайн в Scribd

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документInternational Journal of Mathematics and Statistics Invention (IJMSI) is an international journal intended for professionals and researchers in all fields of computer science and electronics. IJMSI publishes research articles and reviews within the whole field Mathematics and Statistics, new teaching methods, assessment, validation and the impact of new technologies and it will continue to provide information on the latest trends and developments in this ever-expanding subject. The publications of papers are selected through double peer reviewed to ensure originality, relevance, and readability. The articles published in our journal can be accessed online.

Авторское право:

© All Rights Reserved

Доступные форматы

Скачайте в формате PDF, TXT или читайте онлайн в Scribd

0 оценок0% нашли этот документ полезным (0 голосов)

13 просмотров4 страницыMultistage Flow-Shop Scheduling With Weighted Jobs: DR Neeru Chaudhary

Загружено:

inventionjournalsInternational Journal of Mathematics and Statistics Invention (IJMSI) is an international journal intended for professionals and researchers in all fields of computer science and electronics. IJMSI publishes research articles and reviews within the whole field Mathematics and Statistics, new teaching methods, assessment, validation and the impact of new technologies and it will continue to provide information on the latest trends and developments in this ever-expanding subject. The publications of papers are selected through double peer reviewed to ensure originality, relevance, and readability. The articles published in our journal can be accessed online.

Авторское право:

© All Rights Reserved

Доступные форматы

Скачайте в формате PDF, TXT или читайте онлайн в Scribd

Вы находитесь на странице: 1из 4

International Journal of Mathematics and Statistics Invention (IJMSI)

E-ISSN: 2321 4767 P-ISSN: 2321 - 4759

www.ijmsi.org Volume 2 Issue 4 || April. 2014 || PP-54-57

www.ijmsi.org 54 | P a g e

Multistage Flow-Shop Scheduling With Weighted Jobs

Dr Neeru Chaudhary

Assistant professor

Dewan V S Group of institutions, Meerut

ABSTRACT: There are so many techniques to attempt multistage flow shop scheduling problem.

A few of techniques may be described as critical path method. Branch-Bound algorithms method of adjacent

pair wise job inter change hemistich method, and Guatts method etc. This paper develops multistage scheduling

with weight of job. The weight of a job shows the relative priority over some other job in a schedule of job.

Higher the weight a job has become more important in comparison with other job in the operating schedule. An

idle Waiting time operation Oiw is Recently introduced by Maggu and Das (1980) in scheduling Theory

operation techniques is an easy approach in economical and computational senses to solve equipment job for

job block multistage flew shop scheduling problem.

The scheduling problem arise when inventory costs for jobs are involved. There Are two types of

scheduling problems: weighted and simple. Further the Scheduling problem involving weight of jobs is

referred to as weighted Scheduling problems whereas the scheduling problem does not involve weight

Of job is called simple or un weighted scheduling problem.

The Paper presents the heuristic approach for multistage flow shop weighted Scheduling problem in the

reference of Maggu (1982) study. In the multistage flow shop problem each job consists of several tasks which

require processing by district

Resources but there is a common route for all jobs. Recently Miyzaak in(1980) and Maggu in (1982) have

studied flow shop scheduling problem in which computational algorithm for the optimal or near optimal

solution of the problem are described. Improving local search heuristics for some scheduling problem

have given by P.Bruker J.Hurnik and F.Werever in (1997) and weighted flow tome bounds for scheduling

identical processor is given by S.Webster in (1995). Scheduling identical parallel machine to minimize total

weighted completion time is given by H.Belouadah and C.N Posts in 1994.

KEYWORDS: Multistage flow shop scheduling, Branch-Bound algorithms, weighted.

I. MATHMATICAL ANALYSIS

Flow shop model with weights can be stated as follow:-

1- Let n be the no of job processed and ith job in the arbitrarily sequence S can Be denoted by ji where

(i=1,2,3,n) all jobs become avaolable for Processing at time t=0.

2- The manufacture system consists of different machine which are numbered According to order of

production stage. Let Mj be the jth machine in the.

System where (j=1,2,3). Each machine can only process one job at a time and each job can only

processed by one machine at any time.

3- Every job is completed through the same production ordering that is

M1 M2

4- Let Mij denote the processing time of job ji on Mj set up times for operation Are sequences independent and

are include in the processing time. Handling Times are assumed to be neglected.

5- Fj (i) devote the partial flow time of ji counted form the starting time of first Job j1 on M1 to be the

completion time of J1 on M1 in particular, Fm (i) is Called as flow time a f ji.

6- The same job sequence occurs in each machine, in other words no passing is Allowed in the shop.

7- Each job is assigned weight Wi according to its importance.

8- The performance measure is weighted mean flow time define by n

Fw { Wi Fm(i)}/Wi

i=1

9- nFw express the total weighted flow time.

Heuristic algorithm for optimal or near optimal solution, the heuristic approach m is given by into following

steps.

Multistage Flow-Shop Scheduling With Weighted Jobs

www.ijmsi.org 55 | P a g e

Step1- Find Min (Mij) for every i=1,2,3n j=1,2

Step2- (i) if Min (Mij) = Mi1 then

J

M11 =Mi1-Wi

M12 = Mi2

` (ii) if Min (Mij) = Mi2 then

Mi1 = Mi1

Mi2 = Mi2 +wi

Step3- Formulate a new problem as below

Job Machine A Machine B

(i) M1 M2

Mi1/wi Mi2/wi

1 M11/w1 M12/w1

2 M21/w2 M22/w2

3 M31/w3 M32/w3

- - -

- - -

N Mn1/wn Mn2/wn

Step4- Apply Johnsons (1994) procedure to find optimal solution for

Reduce problem in step 3.

Step5- One of the sequence thus obtained in step 4 is either optimal or

Near to optimal for the original problem minimizing the weighted

Mean flow time.

2. Numerical illustration

we will silve our problem one by one as according Maggu and Miyazaki consider

7 job 2- machine flow shop scheduling problem with weight as in the

Following table:

Job Machine M1 Machine M2 Weights

i Mi1 Mi2 Wi

1 4 7 3

2 6 11 5

3 10 14 6

4 15 19 4

5 24 21 1

6 26 22 2

7 30 25 8

Table 1.1

Find optimal and near optimal scheduling minimizing the weighted mean flow time

By step 1 we find

Min (Mi) I = 1,2,3,4,5,6

J = 1,2

Min (M11,M12) = Min (4,7) = 4

M11 = M11-w1

4 - 3 = 1

M12 = M12 = 7

Min (M12,M22) = Min (6,11) = 6

M21 = 6 - 5 = 1

M22 = M22 = 11

Multistage Flow-Shop Scheduling With Weighted Jobs

www.ijmsi.org 56 | P a g e

Min ( M31 , M32) = Min (10 , 14) = 10

M31 = 10 - 6 = 4

M32 = M32 = 14

Min ( Min 41 , M42) = Min ( 15 , 19) = 15

M41 = 15 4 = 11

By Step 2

Min ( M51 , M52) = Min ( 24 , 21) = 21

M52 = 21 + 1 = 22

M51 =M51 = 24

Min ( M61,M62) = ( 62 , 22) = 22

M62 = 22+2 =24

M61 = M61 = 26

Min ( M71, M72) = Min (30 , 25) = 25

M72 =25 + 8 = 33

M71 = M71 = 30

By Step 3 - Formulation a new problem as below:

.

Table 1.2

By Step 4- with the help of Johnson (1954) method the reduce problem gives us the optimal

schedule. 2.1.3.4.7.5.6.

Now the weighted mean flow time for this sequence 2,1,3,4,7,5,6

Table 1.3

Here F2(1) = 6 , F2 (2) = 17 , F2 (3) = 24 , F2 (4) = 38

F2 (5) = 65 , F2 (6) = 90 , F2 (7) = 115

Fw = wiFi

wi

(i) 3x6 + 5x17 + 6x24 + 4x38 + 1x38 + 2x90 + 8x115

3 + 5 + 6 + 4 + 1 + 2 + 8

(ii) 18 + 85 + 144 + 152 + 65 + 180 + 920

29

=1564

29 = 53.93

Job Mavhine Machine

i M1 M2

1 1/3 7/2

2 1/5 11/5

3 4/6 = 2/3 14/6=7/2

4 11/4 19/4

5 24/1=24 22/1=22

6 26/2=13 24/2=12

7 30/8=15/4 33/8

Job Machine Machine

(i) M1 M2

In - out In - out

2 0-6 6 - 17

1 6-10 17 - 24

3 10-20 24 38

4 20-35 38 - 57

7 35-65 65 90

5 65-89 90 111

6 89-115 115 - 140

Multistage Flow-Shop Scheduling With Weighted Jobs

www.ijmsi.org 57 | P a g e

Now this schedule 2,1,3,4,7,5,6 is near optimal to the schedule 1,2,3,4,5,6,7

Which gives weighted mean flow time as?

1492

29 = 51.44

II. CONCLUSION

The model presented in the section is near to real time of left communication Our study provides a

guideline to be system based on optimal continue policy.

REFERENCES:

[1]. 1980 Maggu P.L. and Das G. On 2xn sequencing problem with transportation times of jobs,pure app. Maths,Sci.vol 12,PP.1-6

[2]. 1981 Maggu P.L. Two machine maximum flow shop problem with breakdown of machine j. ind. Soc. Statist. , opers. Res,

Vol2 PP 124.

[3]. 1990 Hucthison j and V.L Chang Optimal no delay job shop schedules, inter. J .prod. Res. Vol. 28 PP 245-257

[4]. 1992 Bagga P.C. A new procedure for finding the lower bonds in nx3 flow shop problem joms vol .pp 289-292.

[5]. 1993 Singh T.P. Heuristic algorithm for awaited job nx2 flow shop problem including transportation time and breakdown

interval proceduing .IST AM PP 186-191.

[6]. 2002 Stefford and Tseng F. Two model for a flow shop sequencing problems. European journals of operation research 142(2),

282 293.

Вам также может понравиться

- Economic and Financial Modelling with EViews: A Guide for Students and ProfessionalsОт EverandEconomic and Financial Modelling with EViews: A Guide for Students and ProfessionalsОценок пока нет

- Unit - 3 Assignment ProblemsДокумент23 страницыUnit - 3 Assignment ProblemsIsha NatuОценок пока нет

- Integer Optimization and its Computation in Emergency ManagementОт EverandInteger Optimization and its Computation in Emergency ManagementОценок пока нет

- Scheduling NotesДокумент26 страницScheduling NotesIshpreet SinghОценок пока нет

- Renuka 2Документ10 страницRenuka 2Rasan BoparaiОценок пока нет

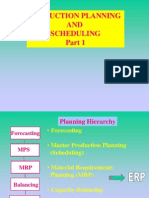

- Production Planning and ControlДокумент27 страницProduction Planning and Controlsagar09Оценок пока нет

- Two MachineДокумент5 страницTwo MachineIAEME PublicationОценок пока нет

- KMB 206 OR Unit - 4Документ21 страницаKMB 206 OR Unit - 4Prashant SharmaОценок пока нет

- Lecture-3 Flow Shop 3 MC Problem 23aug22Документ40 страницLecture-3 Flow Shop 3 MC Problem 23aug22motted groupОценок пока нет

- Or Notes (Unit Iv)Документ24 страницыOr Notes (Unit Iv)Vinayak Mishra100% (1)

- Operation Research HandbookДокумент18 страницOperation Research HandbookEshwar TejaОценок пока нет

- Job Shop SchedulingДокумент28 страницJob Shop Schedulinganmol6237Оценок пока нет

- QTM (Unit - 4)Документ7 страницQTM (Unit - 4)Arkhitekton DesignОценок пока нет

- Operations Research: Department of MathematicsДокумент9 страницOperations Research: Department of MathematicsAhmad Zia YaqoobiОценок пока нет

- Scheduling Jobs in Parallel Machines To Minimise Total TardinessДокумент44 страницыScheduling Jobs in Parallel Machines To Minimise Total TardinessSaurabh SrivastavaОценок пока нет

- Lecture-2 Flow Shop Scheduling Johnson's Method 22aug22Документ29 страницLecture-2 Flow Shop Scheduling Johnson's Method 22aug22motted groupОценок пока нет

- Selection of Job Shop Scheduling Problem Using Fuzzy Linguistic VariablesДокумент5 страницSelection of Job Shop Scheduling Problem Using Fuzzy Linguistic VariablesSTATPERSON PUBLISHING CORPORATIONОценок пока нет

- Sequencing (Models) : Job Sequencing What Is Best Sequence: Based On ObjectiveДокумент57 страницSequencing (Models) : Job Sequencing What Is Best Sequence: Based On Objectivemanendra chopraОценок пока нет

- IOSR JournalsДокумент6 страницIOSR JournalsInternational Organization of Scientific Research (IOSR)Оценок пока нет

- Bsor Project Application of Job Shop SchedulingДокумент47 страницBsor Project Application of Job Shop SchedulingAditya SapraОценок пока нет

- N Jobs and M - Machine ProblemДокумент9 страницN Jobs and M - Machine ProblemHarsha KasaragodОценок пока нет

- Manufactring Mangement Project 2Документ10 страницManufactring Mangement Project 2Hazem ElbannaОценок пока нет

- Chapter 7 Scheduling1Документ39 страницChapter 7 Scheduling1daftpunk915Оценок пока нет

- Op Scheduling Lesson 8Документ36 страницOp Scheduling Lesson 8Balraj AnandОценок пока нет

- SequencingДокумент16 страницSequencingSundaramali Govindaswamy GОценок пока нет

- Presentation ON Production Scheduling: Presented By:-Pooja Hemangi Kiran AnuradhaДокумент23 страницыPresentation ON Production Scheduling: Presented By:-Pooja Hemangi Kiran AnuradhaShailaja RaghavendraОценок пока нет

- A Modified Activity Selection Algorithm With New Parameter: Minimum MakespanДокумент4 страницыA Modified Activity Selection Algorithm With New Parameter: Minimum MakespanyetsedawОценок пока нет

- Ecc 501 Cat 1 2020 2021Документ4 страницыEcc 501 Cat 1 2020 2021Clara KeruboОценок пока нет

- Flow Shop Scheduling: Chapter ContentsДокумент33 страницыFlow Shop Scheduling: Chapter ContentsRajendra Prasad DashОценок пока нет

- Solving Sequencing Problem On Neutrosophic SetДокумент4 страницыSolving Sequencing Problem On Neutrosophic SetScience DirectОценок пока нет

- Production Planning and ControlДокумент45 страницProduction Planning and Controlsagar09Оценок пока нет

- Shop Environment of FMSДокумент21 страницаShop Environment of FMSharshgupta2988Оценок пока нет

- Schedule Chapter5 V2Документ18 страницSchedule Chapter5 V2ミンОценок пока нет

- Operations Research VII SEMESTER (18ME735) Module - 5: Department of Collegiate and Technical EducationДокумент29 страницOperations Research VII SEMESTER (18ME735) Module - 5: Department of Collegiate and Technical Educationjhansi lakshmiОценок пока нет

- SEQUENCINGДокумент34 страницыSEQUENCINGmayureshk776Оценок пока нет

- Jobshop and MLДокумент12 страницJobshop and MLMahmoud ZhiouaОценок пока нет

- Production Planning and ControlДокумент18 страницProduction Planning and Controlsagar09100% (2)

- Chapter-4 AP - FormattedДокумент25 страницChapter-4 AP - FormattedMaxy GiuliОценок пока нет

- Job Shop SchedulingДокумент6 страницJob Shop Schedulingrtikole100% (2)

- Chapter 5: Job Shop Scheduling: Phan Nguyen Ky Phuc April 8, 2020Документ18 страницChapter 5: Job Shop Scheduling: Phan Nguyen Ky Phuc April 8, 2020ManhОценок пока нет

- Journal On SequenceДокумент8 страницJournal On SequenceDevaraj AstroОценок пока нет

- Mixed-Integer Programming Models For Flowshop Scheduling Problems Minimizing The Total Earliness and TardinessДокумент14 страницMixed-Integer Programming Models For Flowshop Scheduling Problems Minimizing The Total Earliness and TardinessPugazhenthi RajagopalОценок пока нет

- Solving The Permutation Flow Shop Problem With Makespan Criterion Using GridsДокумент12 страницSolving The Permutation Flow Shop Problem With Makespan Criterion Using Gridsferronatto11Оценок пока нет

- Heuristics Job Shop PDFДокумент7 страницHeuristics Job Shop PDFPratikJagtapОценок пока нет

- Single Machine Scheduling With Time Dependent Learning EffectДокумент18 страницSingle Machine Scheduling With Time Dependent Learning EffectPradipta PatraОценок пока нет

- Unit - II: Sequencing Problems Johnson's RuleДокумент30 страницUnit - II: Sequencing Problems Johnson's RuleRakib KhanОценок пока нет

- A Variable Capacity Parallel Machine Scheduling ProblemДокумент7 страницA Variable Capacity Parallel Machine Scheduling Problemieom2012Оценок пока нет

- GA Job SchedullingДокумент6 страницGA Job Schedullingbudi2326Оценок пока нет

- Production and Operations Management Systems: Chapter 6: Scheduling Sushil K. Gupta Martin K. Starr 2014Документ69 страницProduction and Operations Management Systems: Chapter 6: Scheduling Sushil K. Gupta Martin K. Starr 2014IdrisОценок пока нет

- Production SchedulingДокумент5 страницProduction SchedulingElbert Leo AstilleroОценок пока нет

- Daa Module 1Документ23 страницыDaa Module 1Abhishek DubeyОценок пока нет

- Sequencing ProblemДокумент32 страницыSequencing ProblemSanjal DesaiОценок пока нет

- Some Efficient Heuristic Methods For The Flow Shop Sequencing ProblemДокумент21 страницаSome Efficient Heuristic Methods For The Flow Shop Sequencing ProblemDeba SahooОценок пока нет

- Pom Imp QuestionsДокумент7 страницPom Imp QuestionsramsastryОценок пока нет

- 5.2 Processing N Jobs K MachinesДокумент15 страниц5.2 Processing N Jobs K MachinesPreethiОценок пока нет

- Scheduling & Sequencing Njobs 2 Machines 2012Документ80 страницScheduling & Sequencing Njobs 2 Machines 2012gay mojicaОценок пока нет

- M4L3 LNДокумент9 страницM4L3 LNswapna44Оценок пока нет

- Final Year Project Presentation For End Semester On Some Aspects of Line Balancing On Assembly LineДокумент70 страницFinal Year Project Presentation For End Semester On Some Aspects of Line Balancing On Assembly LineBob AbrahamОценок пока нет

- Scheduling ExamplesДокумент28 страницScheduling ExamplesHirenkumar ShahОценок пока нет

- Effects of Online Marketing On The Behaviour of Consumers in Selected Online Companies in Owerri, Imo State - NigeriaДокумент12 страницEffects of Online Marketing On The Behaviour of Consumers in Selected Online Companies in Owerri, Imo State - Nigeriainventionjournals100% (1)

- Inter-Caste or Inter-Religious Marriages and Honour Related Violence in IndiaДокумент5 страницInter-Caste or Inter-Religious Marriages and Honour Related Violence in IndiainventionjournalsОценок пока нет

- Student Engagement: A Comparative Analysis of Traditional and Nontradional Students Attending Historically Black Colleges and UniversitiesДокумент12 страницStudent Engagement: A Comparative Analysis of Traditional and Nontradional Students Attending Historically Black Colleges and Universitiesinventionjournals100% (1)

- A Critical Survey of The MahabhartaДокумент2 страницыA Critical Survey of The MahabhartainventionjournalsОценок пока нет

- Non-Linear Analysis of Steel Frames Subjected To Seismic ForceДокумент12 страницNon-Linear Analysis of Steel Frames Subjected To Seismic ForceinventionjournalsОценок пока нет

- Effect of P-Delta Due To Different Eccentricities in Tall StructuresДокумент8 страницEffect of P-Delta Due To Different Eccentricities in Tall StructuresinventionjournalsОценок пока нет

- Immobilization and Death of Bacteria by Flora Seal Microbial SealantДокумент6 страницImmobilization and Death of Bacteria by Flora Seal Microbial SealantinventionjournalsОценок пока нет

- Inter-Caste or Inter-Religious Marriages and Honour Related Violence in IndiaДокумент5 страницInter-Caste or Inter-Religious Marriages and Honour Related Violence in IndiainventionjournalsОценок пока нет

- Caste Based Discrimination and Socio Economic Status of Dalit in NepalДокумент9 страницCaste Based Discrimination and Socio Economic Status of Dalit in NepalTirtha BiswokarmaОценок пока нет

- Summer Internship Project: ON Performance Appraisal Effectiveness IN Hindalco Flat Rolled Product, HirakudДокумент92 страницыSummer Internship Project: ON Performance Appraisal Effectiveness IN Hindalco Flat Rolled Product, HirakudUmrah NaushadОценок пока нет

- 6 Prosiding ICM2E 2017Документ434 страницы6 Prosiding ICM2E 2017Andinuralfia syahrirОценок пока нет

- Final ProgrammeДокумент240 страницFinal Programmethe_szabikaОценок пока нет

- TugasFilsS32019.AnthoniSulthanHarahap.450326 (Pencegahan Misconduct)Документ7 страницTugasFilsS32019.AnthoniSulthanHarahap.450326 (Pencegahan Misconduct)Anthoni SulthanОценок пока нет

- Chapter 2 - Theoretical FrameworkДокумент25 страницChapter 2 - Theoretical FrameworkRomano GabrilloОценок пока нет

- Transfer Pricing: Strategies, Practices, and Tax MinimizationДокумент52 страницыTransfer Pricing: Strategies, Practices, and Tax MinimizationAnnisa NabilaОценок пока нет

- DbrvogardensДокумент180 страницDbrvogardensHalil İbrahim ŞimşekОценок пока нет

- Garima Chaudhary Report On Export Clusters of IndiaДокумент20 страницGarima Chaudhary Report On Export Clusters of Indiasiddhant.18062003Оценок пока нет

- Report 1Документ11 страницReport 1manswi joshiОценок пока нет

- A Study On Performance of Sarva Shiksha Abhiyan in IndiaДокумент3 страницыA Study On Performance of Sarva Shiksha Abhiyan in IndiaAditya ShrivastavaОценок пока нет

- Human Resourse PlaningДокумент49 страницHuman Resourse PlaningarrpitОценок пока нет

- Navila Loreal & DoveДокумент42 страницыNavila Loreal & DovePrashant SinghОценок пока нет

- EPFL - Prezentare UniversitateДокумент42 страницыEPFL - Prezentare UniversitateMelania DulameaОценок пока нет

- A Batteryless Remote Control For Volvo, Results of A Feasibility StudyДокумент9 страницA Batteryless Remote Control For Volvo, Results of A Feasibility StudyShouvik DasОценок пока нет

- Pornography and Sexual Aggression: Can Meta-Analysis Find A Link?Документ10 страницPornography and Sexual Aggression: Can Meta-Analysis Find A Link?scottbrodieОценок пока нет

- Coronado Manabay Edited For Final Script Research AДокумент12 страницCoronado Manabay Edited For Final Script Research Ajc coronadoОценок пока нет

- Toronto Youth Cabinet Newcomer Consultation ReportДокумент15 страницToronto Youth Cabinet Newcomer Consultation ReportAudra WilliamsОценок пока нет

- DLL Practical Research 2 12 q1 q2Документ13 страницDLL Practical Research 2 12 q1 q2Asia MinalangОценок пока нет

- A Study On Satisfaction Level of Employees With Special ReferenceДокумент52 страницыA Study On Satisfaction Level of Employees With Special ReferenceVasu Devan67% (6)

- Corporate Stereotyping of Women at Work PlaceДокумент15 страницCorporate Stereotyping of Women at Work PlaceGlobal Research and Development Services100% (1)

- New Rich Text DocumentДокумент4 страницыNew Rich Text DocumentManikandan KОценок пока нет

- Videocon by Etanshu (1mainДокумент75 страницVideocon by Etanshu (1mainoutlanderlordОценок пока нет

- Assessing ChangeДокумент65 страницAssessing ChangeNCVOОценок пока нет

- CTU Portal - Applied Managerial Finance FINC6151Документ1 страницаCTU Portal - Applied Managerial Finance FINC6151Legend WritersОценок пока нет

- Mailman PetitionДокумент9 страницMailman PetitionColumbia Daily SpectatorОценок пока нет

- Master of Theology Thesis TopicsДокумент6 страницMaster of Theology Thesis Topicsafabggede100% (2)

- Differentiation of Terms: ConceptsДокумент3 страницыDifferentiation of Terms: ConceptsmikalynneОценок пока нет

- Customer PerceptionДокумент81 страницаCustomer PerceptionShywin James100% (1)

- Studi Efektifitas Bank Sampah Dalam Pengelolaan Sampah Berbasis MasyarakatДокумент11 страницStudi Efektifitas Bank Sampah Dalam Pengelolaan Sampah Berbasis MasyarakatKhasrilОценок пока нет

- Summary and Interpretation of Reality TransurfingОт EverandSummary and Interpretation of Reality TransurfingРейтинг: 5 из 5 звезд5/5 (5)

- Knocking on Heaven's Door: How Physics and Scientific Thinking Illuminate the Universe and the Modern WorldОт EverandKnocking on Heaven's Door: How Physics and Scientific Thinking Illuminate the Universe and the Modern WorldРейтинг: 3.5 из 5 звезд3.5/5 (64)

- Dark Matter and the Dinosaurs: The Astounding Interconnectedness of the UniverseОт EverandDark Matter and the Dinosaurs: The Astounding Interconnectedness of the UniverseРейтинг: 3.5 из 5 звезд3.5/5 (69)

- A Beginner's Guide to Constructing the Universe: The Mathematical Archetypes of Nature, Art, and ScienceОт EverandA Beginner's Guide to Constructing the Universe: The Mathematical Archetypes of Nature, Art, and ScienceРейтинг: 4 из 5 звезд4/5 (51)

- Bedeviled: A Shadow History of Demons in ScienceОт EverandBedeviled: A Shadow History of Demons in ScienceРейтинг: 5 из 5 звезд5/5 (5)

- Quantum Physics: What Everyone Needs to KnowОт EverandQuantum Physics: What Everyone Needs to KnowРейтинг: 4.5 из 5 звезд4.5/5 (49)

- The End of Everything: (Astrophysically Speaking)От EverandThe End of Everything: (Astrophysically Speaking)Рейтинг: 4.5 из 5 звезд4.5/5 (157)

- A Natural History of Color: The Science Behind What We See and How We See itОт EverandA Natural History of Color: The Science Behind What We See and How We See itРейтинг: 4 из 5 звезд4/5 (13)

- A Brief History of Time: From the Big Bang to Black HolesОт EverandA Brief History of Time: From the Big Bang to Black HolesРейтинг: 4 из 5 звезд4/5 (2193)

- Midnight in Chernobyl: The Story of the World's Greatest Nuclear DisasterОт EverandMidnight in Chernobyl: The Story of the World's Greatest Nuclear DisasterРейтинг: 4.5 из 5 звезд4.5/5 (410)

- Infinite Powers: How Calculus Reveals the Secrets of the UniverseОт EverandInfinite Powers: How Calculus Reveals the Secrets of the UniverseРейтинг: 4.5 из 5 звезд4.5/5 (126)

- The Beginning of Infinity: Explanations That Transform the WorldОт EverandThe Beginning of Infinity: Explanations That Transform the WorldРейтинг: 5 из 5 звезд5/5 (60)

- Quantum Spirituality: Science, Gnostic Mysticism, and Connecting with Source ConsciousnessОт EverandQuantum Spirituality: Science, Gnostic Mysticism, and Connecting with Source ConsciousnessРейтинг: 4 из 5 звезд4/5 (6)

- Lost in Math: How Beauty Leads Physics AstrayОт EverandLost in Math: How Beauty Leads Physics AstrayРейтинг: 4.5 из 5 звезд4.5/5 (125)

- Packing for Mars: The Curious Science of Life in the VoidОт EverandPacking for Mars: The Curious Science of Life in the VoidРейтинг: 4 из 5 звезд4/5 (1396)

- Mastering Logical Fallacies: The Definitive Guide to Flawless Rhetoric and Bulletproof LogicОт EverandMastering Logical Fallacies: The Definitive Guide to Flawless Rhetoric and Bulletproof LogicРейтинг: 4 из 5 звезд4/5 (91)

- The 60 Minute Quantum Physics Book: Science Made Easy For Beginners Without Math And In Plain Simple EnglishОт EverandThe 60 Minute Quantum Physics Book: Science Made Easy For Beginners Without Math And In Plain Simple EnglishРейтинг: 4.5 из 5 звезд4.5/5 (4)

- The Magick of Physics: Uncovering the Fantastical Phenomena in Everyday LifeОт EverandThe Magick of Physics: Uncovering the Fantastical Phenomena in Everyday LifeОценок пока нет

- The Power of Eight: Harnessing the Miraculous Energies of a Small Group to Heal Others, Your Life, and the WorldОт EverandThe Power of Eight: Harnessing the Miraculous Energies of a Small Group to Heal Others, Your Life, and the WorldРейтинг: 4.5 из 5 звезд4.5/5 (54)

- Hyperspace: A Scientific Odyssey Through Parallel Universes, Time Warps, and the 10th DimensionОт EverandHyperspace: A Scientific Odyssey Through Parallel Universes, Time Warps, and the 10th DimensionРейтинг: 4.5 из 5 звезд4.5/5 (3)

- The Tao of Physics: An Exploration of the Parallels between Modern Physics and Eastern MysticismОт EverandThe Tao of Physics: An Exploration of the Parallels between Modern Physics and Eastern MysticismРейтинг: 4 из 5 звезд4/5 (500)