Академический Документы

Профессиональный Документы

Культура Документы

KL-21B Fiber Cleaver Manual

Загружено:

Claudiu Radu0 оценок0% нашли этот документ полезным (0 голосов)

217 просмотров3 страницыKL-21B Optical fiber cleaver Instruction manual Usage and safety regulation: l Before using, please read this manual carefully; l Be cautious use in case harm; l Do not touch the blade with hand when use or repair.

Исходное описание:

Авторское право

© © All Rights Reserved

Доступные форматы

PDF, TXT или читайте онлайн в Scribd

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документKL-21B Optical fiber cleaver Instruction manual Usage and safety regulation: l Before using, please read this manual carefully; l Be cautious use in case harm; l Do not touch the blade with hand when use or repair.

Авторское право:

© All Rights Reserved

Доступные форматы

Скачайте в формате PDF, TXT или читайте онлайн в Scribd

0 оценок0% нашли этот документ полезным (0 голосов)

217 просмотров3 страницыKL-21B Fiber Cleaver Manual

Загружено:

Claudiu RaduKL-21B Optical fiber cleaver Instruction manual Usage and safety regulation: l Before using, please read this manual carefully; l Be cautious use in case harm; l Do not touch the blade with hand when use or repair.

Авторское право:

© All Rights Reserved

Доступные форматы

Скачайте в формате PDF, TXT или читайте онлайн в Scribd

Вы находитесь на странице: 1из 3

Nanjing Jilong Optical Communication Co., Ltd.

KL-21B Optical Fiber Cleaver

Instruction Manual

Usage and safety regulation:

l Before using KL-21B fiber cleaver, please read this manual carefully;

l Be cautious to use KL-21B in case harm;

l Do not touch the blade with hand when use or repair KL-21B;

l Do not take down or oil KL-21B;

l Keep KL-21B away from humid and dusty environment.

I. Technical specifications:

Applicable range Single Core silex-fiber

Coating Diameter 0.25mm !0.9mm

Fiber Diameter 125"m

Cleave Length 9~16mm(0.25) 10~16(0.9)

Dimension 59mm(W)*55mm(D)*49mm(H)

Weight 255g

Cleaving Angle #0.5$

Blade Life 12000 times

II. Operation procedure:

1. Facing the blade shelf and open the big pressboard and small pressboard. (See figure 1).

2. Use the stripper to strip the coating of fiber, reserve 30-40mm bare fiber, use pledget

which is dipped by absolute alcohol to cover and clean the fiber, avoid using the same

pledget twice.

3. Align the stripped fiber with calibration and put it into V-groove and make sure that the

bare fiber is sticking out of the rubber pad exactly in a straight line.

4. Close the pressboard and push the blade shelf to another side to cut the fiber.

5. hold the cleaver with left hand ,open the big pressboard with right hand and clean the

fiber chip.

6. Use left hand to hold the fiber and open the small pressboard with right hand, remove the

cleaved fiber carefully without touching the end face.

III. Maintenance:

1. Clean the pressboard and blade:

Usually use cotton with anhydrous alcohol to clean the rubber surface of big

pressboard, edge of blade and the rubber pad.

2. Blade height adjustment:

Usually dont need to adjust the blade height, please operating as following steps when

KL-21B does not work well:

a. Push the blade shelf to another side to make the screw II align the aperture on the

bottom of cleaver, then release screw II with wrench.

b. Revolve the adjust axle in the middle of blade shelf deasil slightly (See figure 2).

Nanjing Jilong Optical Communication Co., Ltd.

c. Lock screw II and I tightly. (Screw II fix adjust axle and screw I fix blade).

d. Repeat above steps till blade is in proper position.

3. Blade position adjustment:

a. Release screw I on the blade shelf. (See figure 2)

b. KL-21B cleaver revolves 45 degree, insert sharp thing into operation aperture and

revolve the blade to make blade on the point of 1-12 or 1-16.

c. Press the blade with finger and lock screw I tightly.

4. Blade adjustment:

a. If KL-21B could not cut the fiber very well:

The blade is on low position and please adjusts the blade height as above steps.

b. If the fiber has breakage and there is adumbration on the end-surface of fiber or too

large fiber angle:

The blade is on high position and please adjusts the blade height as above steps.

c. If there is large oblique angle when blade is on low or high position.

There is adumbration on the end-surface and please observe from another direction.

d. Please contact us if above methods could not ameliorate the cleaving quality.

5. Blade reusing:

Blade is regularly round, any point of it can cut for 1000 times theoretically, thus any

point between 1-12 or 1-16 can be chosen for cutting.

When all the points of 1-12 or 1-16 have been used, adjust the blade to a higher

position referring to Blade height adjustment to reuse the blade for another circle.

6. Blade replacement

a. Release screw II and I, pull out the adjust axle (see figure 2).

b. Release the screw of blade shelf, lean down the cleaver 45 degree and put the new

blade into blade shelf.

c. Push the adjust axle into the central aperture or revolve adjust axle with screwdriver

and then align position 1 up to lock the screw.

d. Put the coating fiber in the0.9 groove to adjust blade height, revolve adjust axle to

make blade touch the fiber, then adjust half calibration to proper position and lock

screw I and II tightly.

Figure 1

Big pressboard

V-groove

Screw II for lock

Screw III for adjust

Small pressboard

Blade

Blade shelf

Nanjing Jilong Optical Communication Co., Ltd.

Figure 2 Figure 3

Screw I

Spare screw

Spare wrench

Вам также может понравиться

- Rope and Harness Work on the Farm - With Information on Rope Construction and Various Knots Used on the FarmОт EverandRope and Harness Work on the Farm - With Information on Rope Construction and Various Knots Used on the FarmОценок пока нет

- Computerized Quilting Machine ManualДокумент33 страницыComputerized Quilting Machine Manualvalter craccoОценок пока нет

- Cambridge Rocking Microtome ManualДокумент11 страницCambridge Rocking Microtome Manualjaava53100% (3)

- Operation On LJT-4D HLC Paper Tube Winder MachineДокумент15 страницOperation On LJT-4D HLC Paper Tube Winder MachineYonas MuluОценок пока нет

- Afinibot A31 User Manual 2-24-17Документ26 страницAfinibot A31 User Manual 2-24-17ghfjkrrОценок пока нет

- Cornely FD Manual - Operating Instructions for Lockstitch MachineДокумент34 страницыCornely FD Manual - Operating Instructions for Lockstitch MachineAquacypressОценок пока нет

- AO 820 Microtome PDFДокумент8 страницAO 820 Microtome PDFalmutazimОценок пока нет

- GT2_Tensiometer_Assembly_ManualДокумент21 страницаGT2_Tensiometer_Assembly_ManualZeic EngenhariaОценок пока нет

- FC-6 Operation ManualДокумент4 страницыFC-6 Operation ManualbigdrsmithОценок пока нет

- Manual Plotter COLETECHДокумент16 страницManual Plotter COLETECHJuan Carlos CosmeОценок пока нет

- Conector LC Light Crimp - ManualДокумент8 страницConector LC Light Crimp - ManualTirso W. RodríguezОценок пока нет

- Highlead GC24618, - 1Документ55 страницHighlead GC24618, - 1Hristo Stoichkov Rosmel RicraОценок пока нет

- TL 02006 Z Q Head ManualДокумент9 страницTL 02006 Z Q Head ManualMagno AguiarОценок пока нет

- Circular Machine Practical TrainingДокумент70 страницCircular Machine Practical TrainingLiyew WorkieОценок пока нет

- Barudan Technical Sewing Head Maintenance ManualДокумент65 страницBarudan Technical Sewing Head Maintenance ManualMartinandKimberly RayОценок пока нет

- How To Terminate Coaxial CableДокумент16 страницHow To Terminate Coaxial CableghostdreamОценок пока нет

- American Beauty 175 Zig Zag Automatic Sewing Machine InstructionsДокумент27 страницAmerican Beauty 175 Zig Zag Automatic Sewing Machine InstructionsiliiexpugnansОценок пока нет

- TL02007 ZQ-Hook Timing GuideДокумент5 страницTL02007 ZQ-Hook Timing GuideAhmed KamelОценок пока нет

- Sewing Machine Service ManualДокумент40 страницSewing Machine Service ManualRamon Johnson100% (2)

- Installation Directions For The Rotary HookДокумент5 страницInstallation Directions For The Rotary HookjoecentroneОценок пока нет

- Fi - SCST Multimode Singlemode Connector - II PDFДокумент4 страницыFi - SCST Multimode Singlemode Connector - II PDFmirkofedorОценок пока нет

- E4fd3fdc524cДокумент12 страницE4fd3fdc524canilr008Оценок пока нет

- Eo Folding GuitarДокумент7 страницEo Folding GuitarAnonymous w0egAgMouGОценок пока нет

- Cannular Technical Guide Seam SpecificationДокумент16 страницCannular Technical Guide Seam SpecificationRobert HeSОценок пока нет

- Singer 20 U ManualДокумент40 страницSinger 20 U Manualjapa_ps67% (6)

- WheelHorse Snow Thrower Completing Package Manual 6-9111Документ4 страницыWheelHorse Snow Thrower Completing Package Manual 6-9111Kevins Small Engine and Tractor ServiceОценок пока нет

- Lynx-Cleaver-Operating-InstructionsДокумент2 страницыLynx-Cleaver-Operating-InstructionsMANCO MANKONYОценок пока нет

- FABRIC MANUFACTURE Two Marks Question With AnswerДокумент12 страницFABRIC MANUFACTURE Two Marks Question With AnswervasineyОценок пока нет

- PEAK Sidewall Cutter Data ManualДокумент13 страницPEAK Sidewall Cutter Data ManualRizky WahyuОценок пока нет

- Multi-Start ThreadingДокумент7 страницMulti-Start ThreadingWeyih ReganОценок пока нет

- Strain Gauge InstallationДокумент5 страницStrain Gauge InstallationAnonymous UoHUagОценок пока нет

- Redback Operations ManualДокумент11 страницRedback Operations ManualDon BraithwaiteОценок пока нет

- Akses Manual Mesin BarudanДокумент45 страницAkses Manual Mesin BarudanSektor VОценок пока нет

- PW-552TBL Carton Sealing Machine ManualДокумент52 страницыPW-552TBL Carton Sealing Machine ManualTeguh HariyadiОценок пока нет

- Ig Gabions May 2015Документ2 страницыIg Gabions May 2015LynxОценок пока нет

- Expert 24 User ManualДокумент38 страницExpert 24 User ManualDonwBIMOSAОценок пока нет

- Magic BowДокумент13 страницMagic BowSteve Dowell80% (5)

- White 628 Sewing Machine Instruction ManualДокумент27 страницWhite 628 Sewing Machine Instruction ManualiliiexpugnansОценок пока нет

- Confidence 7463 69Документ59 страницConfidence 7463 69Makiniando sas75% (4)

- Thread a Knot in ThreadДокумент3 страницыThread a Knot in ThreadVlade NaumovskiОценок пока нет

- HZL-25Z: Service ManualДокумент35 страницHZL-25Z: Service Manualhowardbsewinn.comОценок пока нет

- Kauo Heng 323D 323DJ 323DTJ Operation ManualДокумент57 страницKauo Heng 323D 323DJ 323DTJ Operation ManualVictor Colucci ManfriniОценок пока нет

- American Beauty Zig Zag 1300 Deluxe - ManualДокумент32 страницыAmerican Beauty Zig Zag 1300 Deluxe - ManualJust4Him0% (1)

- China Patcher Users Manual71719 PDFДокумент13 страницChina Patcher Users Manual71719 PDFeric pacha60% (5)

- Bonding NotesДокумент6 страницBonding NotesDerek YoungОценок пока нет

- Procedure For Backlash Adjusting On Slewing Ring To PitchДокумент3 страницыProcedure For Backlash Adjusting On Slewing Ring To PitchVasanth KumarОценок пока нет

- CN Maintenance Practices IIДокумент10 страницCN Maintenance Practices IIavijayakumar_1964Оценок пока нет

- HP 280 Color Ribbon Hot Printing Machine ManualДокумент7 страницHP 280 Color Ribbon Hot Printing Machine ManualWhosee AmmaОценок пока нет

- Leica Microtome RM 2145Документ16 страницLeica Microtome RM 2145Mathurin Edmond WolaeОценок пока нет

- Manual 120726 Imc5050 Carton SealerДокумент9 страницManual 120726 Imc5050 Carton SealerTheodora StefanОценок пока нет

- Light CrimpДокумент19 страницLight CrimpAlejandro PerezОценок пока нет

- Phu Luc Cable of Drain Solution Instructions V1 - 10082017w32Документ8 страницPhu Luc Cable of Drain Solution Instructions V1 - 10082017w32KHOA NGUYEN DANGОценок пока нет

- Vinyl Cutter Instructions - ALL LANGUAGESДокумент52 страницыVinyl Cutter Instructions - ALL LANGUAGESaaron muñoz salgadoОценок пока нет

- 2007 PIA-Sewing-WSДокумент16 страниц2007 PIA-Sewing-WSMike CryerОценок пока нет

- How To Build A Preformed Vine Robot Main Version 0618Документ25 страницHow To Build A Preformed Vine Robot Main Version 0618Nguyen Khanh LinhОценок пока нет

- Intermediate +: Model 450Документ16 страницIntermediate +: Model 450Djordje TasicОценок пока нет

- Instruction Manual: Effortless Heavy Duty 2-Hole PunchДокумент4 страницыInstruction Manual: Effortless Heavy Duty 2-Hole Punchgustavo Pérez MonteroОценок пока нет

- Expert 52 ManualДокумент58 страницExpert 52 ManualDiana ArghirОценок пока нет

- Install Printhead CI-500/1000Документ2 страницыInstall Printhead CI-500/1000Brad BartonОценок пока нет

- LG Arun Gse2Документ15 страницLG Arun Gse2Claudiu RaduОценок пока нет

- 396081830t&a Software User ManualДокумент203 страницы396081830t&a Software User ManualClaudiu RaduОценок пока нет

- Manual Programare Ramcom AV20Документ98 страницManual Programare Ramcom AV20Florian Dan100% (4)

- KL-280 Splicer201111Документ40 страницKL-280 Splicer201111Claudiu RaduОценок пока нет

- Service Manual Air ConditionerSAMSUNGДокумент47 страницService Manual Air ConditionerSAMSUNGClaudiu Radu100% (1)

- Crow ST Runner 4-8 Zones Quick Setup Diagrams V1.2Документ32 страницыCrow ST Runner 4-8 Zones Quick Setup Diagrams V1.2Armindo Silva100% (1)

- KL-21B Fiber Cleaver ManualДокумент3 страницыKL-21B Fiber Cleaver ManualClaudiu RaduОценок пока нет

- KL-280 Splicer201111Документ40 страницKL-280 Splicer201111Claudiu RaduОценок пока нет

- Liwin V7-1 enДокумент24 страницыLiwin V7-1 enClaudiu Radu100% (1)

- LG Multi F 3828a20097w 1Документ254 страницыLG Multi F 3828a20097w 1Claudiu RaduОценок пока нет

- Multi FcondenserДокумент68 страницMulti FcondenserClaudiu RaduОценок пока нет

- Manual Programare Ramcom AV20Документ98 страницManual Programare Ramcom AV20Florian Dan100% (4)

- Tekmar 1773 - 2Документ16 страницTekmar 1773 - 2Claudiu RaduОценок пока нет

- Devi 330Документ8 страницDevi 330Claudiu RaduОценок пока нет

- Devi 330Документ8 страницDevi 330Claudiu RaduОценок пока нет

- Installation ManualДокумент90 страницInstallation Manualdestiner_1871Оценок пока нет

- Module 3 ITДокумент20 страницModule 3 ITfokusОценок пока нет

- Pricelist ICUДокумент9 страницPricelist ICURSU BungsuОценок пока нет

- Gorman-Rupp Pump Manual Installation Operation MaintenanceДокумент40 страницGorman-Rupp Pump Manual Installation Operation MaintenanceFranco bucciarelliОценок пока нет

- Protection Relay: JD-5 Integrated Protector MotorДокумент3 страницыProtection Relay: JD-5 Integrated Protector Motorzaki amОценок пока нет

- Flyer Misalignment Switch SLS EX - en PDFДокумент4 страницыFlyer Misalignment Switch SLS EX - en PDFLazar MihailОценок пока нет

- User Manual E300: High-Fidelity Sound Motorcycle LntercomДокумент32 страницыUser Manual E300: High-Fidelity Sound Motorcycle LntercomZS MotorОценок пока нет

- Dia MisДокумент8 страницDia MisLim Zi XuanОценок пока нет

- 2d - Guidance On Safe Use of TelehandlersДокумент5 страниц2d - Guidance On Safe Use of TelehandlersmohammudpОценок пока нет

- DEH-80PRS Installation ManualДокумент24 страницыDEH-80PRS Installation ManualmozardiroqueОценок пока нет

- E04-X02 - 1 Dry Type Dist. & Power Trans Data SheetДокумент2 страницыE04-X02 - 1 Dry Type Dist. & Power Trans Data SheetMuhammad IrfanОценок пока нет

- VME MinogaДокумент199 страницVME MinogaFakhri DzulfiqarОценок пока нет

- C2500cbe PM en 16Документ77 страницC2500cbe PM en 16Виталий100% (1)

- Remote-operated source-changeover electrical diagramsДокумент36 страницRemote-operated source-changeover electrical diagramsromancyyОценок пока нет

- Telco sp2000 Datasheet en v3 PDFДокумент6 страницTelco sp2000 Datasheet en v3 PDFHELLOGREGОценок пока нет

- 5sy4301 5Документ23 страницы5sy4301 5Nur AsidikОценок пока нет

- 400 12x4earboxДокумент11 страниц400 12x4earboxMrAlbert2009Оценок пока нет

- Overdoor Light C/W Sounder: NC806CSДокумент3 страницыOverdoor Light C/W Sounder: NC806CSPriesilia PresleyОценок пока нет

- Diff Erential Pressure Gauge - Switch Model 106D: ApplicationsДокумент5 страницDiff Erential Pressure Gauge - Switch Model 106D: ApplicationsB P REDDYОценок пока нет

- Section 90 - Cab - Chapter 3Документ36 страницSection 90 - Cab - Chapter 3Esteban MunaresОценок пока нет

- Utimec LF 600 Transmixer engine bonnet parts listДокумент73 страницыUtimec LF 600 Transmixer engine bonnet parts listalexis aguirre espejo100% (1)

- Factory Redwood Furniture Sdn. Bhd. Fire Extinguisher Monthly ChecklistДокумент13 страницFactory Redwood Furniture Sdn. Bhd. Fire Extinguisher Monthly ChecklistHelo DixonОценок пока нет

- Building Automation SystemДокумент19 страницBuilding Automation SystemAzizi AwangОценок пока нет

- Service Manual: RMP-2860sДокумент51 страницаService Manual: RMP-2860sspeedyeduОценок пока нет

- Hotsale Bulan Feb 21Документ188 страницHotsale Bulan Feb 21Towaf YusufОценок пока нет

- Sulcoflex Trifocal Technical Data SheetДокумент2 страницыSulcoflex Trifocal Technical Data SheetAli SanchezОценок пока нет

- Sri986 Electro-Pneumatic Positioner: Quick Guide QG EVE0102 (En)Документ6 страницSri986 Electro-Pneumatic Positioner: Quick Guide QG EVE0102 (En)herysyam1980Оценок пока нет

- Parallel Clamp Plans: Build Your Own Adjustable Woodworking ClampsДокумент19 страницParallel Clamp Plans: Build Your Own Adjustable Woodworking ClampsMartin MartinezОценок пока нет

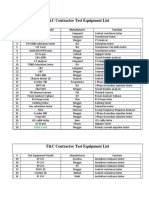

- T&C Contractor Test Equipment ListДокумент2 страницыT&C Contractor Test Equipment Listahmed tarekОценок пока нет

- Sumitomo F-70 KompressorДокумент46 страницSumitomo F-70 Kompressors.noerthemannОценок пока нет

- Re66218 - 2013-12 Lt12 Bloco Freio RexrothДокумент16 страницRe66218 - 2013-12 Lt12 Bloco Freio RexrothEmerson BatistaОценок пока нет