Академический Документы

Профессиональный Документы

Культура Документы

SPM 1

Загружено:

bekavacs0 оценок0% нашли этот документ полезным (0 голосов)

27 просмотров3 страницыspm1

Оригинальное название

spm1

Авторское право

© © All Rights Reserved

Доступные форматы

PDF, TXT или читайте онлайн в Scribd

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документspm1

Авторское право:

© All Rights Reserved

Доступные форматы

Скачайте в формате PDF, TXT или читайте онлайн в Scribd

0 оценок0% нашли этот документ полезным (0 голосов)

27 просмотров3 страницыSPM 1

Загружено:

bekavacsspm1

Авторское право:

© All Rights Reserved

Доступные форматы

Скачайте в формате PDF, TXT или читайте онлайн в Scribd

Вы находитесь на странице: 1из 3

Performance efficiency monitoring on board

Performance continuously compared with ideal case

Configurable for any vessel

Emissions monitoring and reporting

Data monitored, trended, stored & transmitted to remote office

Trim optimisation by dynamic trim-meter

Typical 3% savings means rapid payback

SeaTechnik Ship Performance Monitor (SPM)

Level 1 Monitoring for all Ship Types

Ship Performance Monitoring

Fuel is the single largest operational cost of running a

vessel.

Fuel costs are rising dramatically, and the key question

occupying ship-owners, ship managers and charterers

alike is; In a competitive market how do we reduce the

running costs of the vessels we operate while maintain-

ing the level of service to our customers?

Trelleborg Marine Sysytems UK has developed the total

solution. For the last 25 years Trelleborg has been at the

forefront of the development and implementation of

Ship Performance Monitoring and Optimisation systems.

Using the latest technology available, computer-based

systems have monitored and controlled the performance

of complex vessels such as multi-engined Ro-Ro ferries

up to LNGCs. Trelleborg Marine Systems has now

developed a family of systems in 3 levels. These range

from a basic package for Ship Performance Monitoring

to the most sophisticated Ship Performance Optimising

systems that assure savings through continuous voyage

planning and automatic propulsion control systems.

The systems are modular in concept to enable all ship

system configurations to be accommodated and for

systems to be upgraded. Interfaces are used to link with

all applicable on-board systems.

The SPM-level 1 provides ship-operators with the tools to

develop and maintain a strategy under the mandatory

SEEMP as well as achieve real savings to remain

competitive.

The three configuration levels are:

Level 1 Monitoring, display & reporting

machinery and hull performance data -

applicable to all ships

Level 2 Monitoring, display & reporting

machinery and hull performance data - Further

savings are achieved by advanced modelling

techniques of sophisticated ship machinery &

cargo arrangements, e.g. LNGCs, bitumen carriers

Level 3 Ship and route specific voyage planning

with automatic propulsion control - Optimum

savings assured from voyage optimisation using

predicted weather and ship modelling

Level 1 - Performance Monitoring and

Reporting

The SeaTechnik SPM L1 system can be installed on any

type of vessel from the conventional single slow speed

main engine to a medium speed CPP or other propulsion

system. It is designed as a cost-effective solution for the

operator who is content with the base level savings and

daily/ voyage reporting for Ship Performance Monitoring.

System Benefits

The benefits of the SeaTechnik Level1 SPM system for

vessel operators are:

Continuous calculation of ship efficiency

Calculation of EEOI

Proactive administration of mandatory SEEMP

and other company specific KPIs

Increased vessel efficiency through continuous

crew awareness of efficiency and potential for

wastage

Data transmission via Ship IT network for onshore

monitoring & reporting for fleet management

teams

Data transmission to SeaTechnik for on-going

analysis and trouble shooting of efficiency issues

Reduced fuel costs up to 3%

Reduces emissions

Rapid Return On Investment (ROI); months not

years

S

w

itch B

o

ard

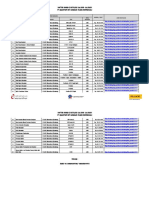

SPM 8853 Main Unit TRM-8420 Trim-meter

INS

T

rim

m

eter

S

P

M

U

n

it

S

P

M

U

n

it

B

o

iler

IA

S

F

u

el

F

u

el

A

u

x

ilia

ry

G

e

n

e

ra

to

rs

M

a

in

E

n

g

in

e

Bridge

FT

FT

F

T

FT

Engine

Control

Room

Engine

Room

TSX-8500 Shaft Power Meter

Taking data inputs from fuel mass flow, shaft power,

draught, trim, auxiliary machinery energy consumption

and output, machinery configuration and water depth as

well as manual estimates of hull fouling, fuel bunker

quality etc, the system continuously calculates machin-

ery and hull efficiency. These are compared with a

baseline model reference.

In this way random external parameters that affect

efficiency reporting can be isolated so that the base

vessel efficiency in operation can be maintained by

adjustment of propulsion power, mode and controllable

factors such as trim.

The Trelleborg Marine Systems UK TSX5 advanced

shaft power meter uses strain gauge technology for

repeatability and accuracy. Power to the water measure-

ment is fundamental to the sucessful application of the

SeaTechnik SPM L1 system.

The SeaTechnik TRM-8450 Dynamic Trimmeter is

another key instrument in optimising vessel perfor-

mance and is recommended for use with all SeaTechnik

SPM L1 applications.

Modular interfaces and network capability enable the

system to be configured to accept any signal, digital or

analogue and link with

Discrete or Integrated Automation Systems (IAS) /

Machinery Systems (MACS)

Discrete or Integrated Navigation Systems (INS) /

Integrated Bridge Systems (IBS)

SeaTechnik instruments

Shipboard management systems for networking,

printing, data storage and data transfer to remote

offices

Trelleborg Marine Systems UK Ltd, Airfield View, Hawarden Industrial Park, Hawarden, Deeside, Flintshire, CH5 3QW, United Kingdom.

Tel: +44 (0)1244 539 635, Fax: +44 (0)1244 539 880, email: sales.seatechnik@trelleborg.com

Trelleborg Marine Systems UK Ltd. 2013

Trelleborg Marine Systems UK has been designing, manufacturing and supporting leading edge marine energy management

and safety systems for over 20 years. With the Head Office located in Northwest UK, a team of experienced service engineers

and performance analysts / specialists provides installation, commissioning and in-service support worldwide. The worldwide

team includes dedicated staff in our Korea and Singapore offices.

A network of experienced sales/technical agents and associates worldwide provides further support, and ongoing technical

training is offered to both customers and associates engineers worldwide.

Service & Support

SEATECHNIK OIL AND GAS TRANSFER TECHNOLOGY | SEATECHNIK VESSEL TECHNOLOGY | SEATECHNIK WORLDWIDE SERVICE

Results can be viewed instantaneously via the SPM

screen in the ECR or wheelhouse enabling corrective

action to be taken as necessary.

All or any parameters, measured or derived can be

trended over time to find the optimum operation point for

certain parameters. These include trim for a given

power, speed and depth.

Measured data can be saved, printed as a snapshot in

time or routine report in a given format.

Savings will always depend on the commitment to apply

corrective action but the SeaTechnik SPM 1 will result in

savings typically exceeding 3% on the best managed

ship. Trelleborg Marine Systems analysis of data, the

development of the ideal ship specific cases and identifi-

cation of optimum operational points will enable these

savings to be regularly and repeatably achieved.

Вам также может понравиться

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeОт EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeРейтинг: 4 из 5 звезд4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreОт EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreРейтинг: 4 из 5 звезд4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItОт EverandNever Split the Difference: Negotiating As If Your Life Depended On ItРейтинг: 4.5 из 5 звезд4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceОт EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceРейтинг: 4 из 5 звезд4/5 (895)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersОт EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersРейтинг: 4.5 из 5 звезд4.5/5 (344)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureОт EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureРейтинг: 4.5 из 5 звезд4.5/5 (474)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)От EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Рейтинг: 4.5 из 5 звезд4.5/5 (120)

- The Emperor of All Maladies: A Biography of CancerОт EverandThe Emperor of All Maladies: A Biography of CancerРейтинг: 4.5 из 5 звезд4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingОт EverandThe Little Book of Hygge: Danish Secrets to Happy LivingРейтинг: 3.5 из 5 звезд3.5/5 (399)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyОт EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyРейтинг: 3.5 из 5 звезд3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)От EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Рейтинг: 4 из 5 звезд4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaОт EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaРейтинг: 4.5 из 5 звезд4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryОт EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryРейтинг: 3.5 из 5 звезд3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnОт EverandTeam of Rivals: The Political Genius of Abraham LincolnРейтинг: 4.5 из 5 звезд4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaОт EverandThe Unwinding: An Inner History of the New AmericaРейтинг: 4 из 5 звезд4/5 (45)

- S7-200 Programmable Controller - Step 7 Micro WinДокумент482 страницыS7-200 Programmable Controller - Step 7 Micro Winapi-3704887100% (2)

- Domtapkeyprov2 Manual en Assembly and Operating Instructions Dom Tapkey Pro v2Документ124 страницыDomtapkeyprov2 Manual en Assembly and Operating Instructions Dom Tapkey Pro v2bekavacsОценок пока нет

- SL00 378Документ7 страницSL00 378bekavacsОценок пока нет

- Kopija Datoteke NMIДокумент1 страницаKopija Datoteke NMIbekavacsОценок пока нет

- SL00 383Документ5 страницSL00 383bekavacsОценок пока нет

- 6.002 Lec2Документ54 страницы6.002 Lec2bekavacsОценок пока нет

- Opisane Funkcije Mitsubishi ProgManual For Beginners ManualДокумент106 страницOpisane Funkcije Mitsubishi ProgManual For Beginners ManualbekavacsОценок пока нет

- Exhaust Emissions From ShipsДокумент10 страницExhaust Emissions From ShipsShanthan Gambino GopalinoОценок пока нет

- A Prognostic Modeling Approach For Predicting Recurring Maintenance For Shipboard Propulsion SystemsДокумент8 страницA Prognostic Modeling Approach For Predicting Recurring Maintenance For Shipboard Propulsion SystemsbekavacsОценок пока нет

- Hulda Winnes - Air Pollution From ShipsДокумент92 страницыHulda Winnes - Air Pollution From ShipsbekavacsОценок пока нет

- NVQ Level 3 in Marine Engineering OperationsДокумент3 страницыNVQ Level 3 in Marine Engineering OperationsbekavacsОценок пока нет

- Fault Detection and Diagnosis of A Gearbox in Marine Propulsion Systems Using Bispectrum Analysis and Artificial Neural NetworksДокумент8 страницFault Detection and Diagnosis of A Gearbox in Marine Propulsion Systems Using Bispectrum Analysis and Artificial Neural NetworksbekavacsОценок пока нет

- Cv388 - en - US - Europass CV Teacher - IrelandДокумент2 страницыCv388 - en - US - Europass CV Teacher - IrelandМарија ЦонићОценок пока нет

- Important MCQ - Materials and ComponentsДокумент8 страницImportant MCQ - Materials and ComponentsarijitlgspОценок пока нет

- Informed RRT : Optimal Sampling-Based Path Planning Focused Via Direct Sampling of An Admissible Ellipsoidal HeuristicДокумент8 страницInformed RRT : Optimal Sampling-Based Path Planning Focused Via Direct Sampling of An Admissible Ellipsoidal HeuristicGuiОценок пока нет

- Function Mit18086Документ3 страницыFunction Mit18086Ria Dwi IzahyantiОценок пока нет

- Comments Resolution Discharge Filter Coalescer Skid - Foundation - Anchor - CVL ReplyДокумент1 страницаComments Resolution Discharge Filter Coalescer Skid - Foundation - Anchor - CVL ReplySana UllahОценок пока нет

- Guide To Better Geotextile Specifying US FABRICSДокумент19 страницGuide To Better Geotextile Specifying US FABRICSOladunni AfolabiОценок пока нет

- Generator Protection 7UM62Документ39 страницGenerator Protection 7UM62Reji Kurian100% (1)

- Make Up Water.r1Документ54 страницыMake Up Water.r1Ranu JanuarОценок пока нет

- Thin-Walled Structures: Jovan Trajkovski, Jasenko Perenda, Robert Kunc TДокумент7 страницThin-Walled Structures: Jovan Trajkovski, Jasenko Perenda, Robert Kunc TMohamed AmineОценок пока нет

- Salsbury: Torque ConvertersДокумент19 страницSalsbury: Torque Convertersvt133primОценок пока нет

- ORMOCERIДокумент6 страницORMOCERIBogdanОценок пока нет

- 7 1 Centripetal Acceleration and Force Problems Answer KeyДокумент7 страниц7 1 Centripetal Acceleration and Force Problems Answer KeyCarlo GarciaОценок пока нет

- Engineering Aplication SДокумент371 страницаEngineering Aplication SLon CarlОценок пока нет

- PP DL Pipe and Fittings PDFДокумент8 страницPP DL Pipe and Fittings PDFakash dabhadeОценок пока нет

- Reinforced - Concrete Design IIДокумент54 страницыReinforced - Concrete Design IIgendadeyu552625Оценок пока нет

- Limits and ContinuityДокумент8 страницLimits and Continuityprince12Оценок пока нет

- Physics 2 Current Ohms - Law Resistance Student PDFДокумент26 страницPhysics 2 Current Ohms - Law Resistance Student PDFRaizha GranadoОценок пока нет

- Wartsila o e W 50df TRДокумент16 страницWartsila o e W 50df TRNoel MejiaОценок пока нет

- Downloaded From Uva-Dare, The Institutional Repository of The University of Amsterdam (Uva)Документ12 страницDownloaded From Uva-Dare, The Institutional Repository of The University of Amsterdam (Uva)Iqioo RedefiniОценок пока нет

- SAMPAG ANCHOR CHANELS CatalogueNo.8 PDFДокумент40 страницSAMPAG ANCHOR CHANELS CatalogueNo.8 PDFKemo TufoОценок пока нет

- Elec Motors Generators Design GuideДокумент18 страницElec Motors Generators Design GuidemiasatoОценок пока нет

- SAMPLE PAPER-AT-2324-C-XII-PASS-AT+PCM-Paper-2Документ24 страницыSAMPLE PAPER-AT-2324-C-XII-PASS-AT+PCM-Paper-2Arijit DasОценок пока нет

- Optical Ground WireДокумент14 страницOptical Ground Wireshubham jaiswalОценок пока нет

- PL Fluke Biomedical (Ekatalog Link) 2018 - 2020Документ2 страницыPL Fluke Biomedical (Ekatalog Link) 2018 - 2020lukas adi nugrohoОценок пока нет

- High Tensile Steel 4340Документ2 страницыHigh Tensile Steel 4340Arun KumarОценок пока нет

- Origin and Nature of Radiation (English)Документ23 страницыOrigin and Nature of Radiation (English)laloooppОценок пока нет

- Leaflet Poly Met 3394 en LowДокумент2 страницыLeaflet Poly Met 3394 en LowCamiloОценок пока нет

- Engineering Geology Assignment 29.11.12Документ4 страницыEngineering Geology Assignment 29.11.12Richard WestonyОценок пока нет

- Notification APSWREIS Teacher PostsДокумент14 страницNotification APSWREIS Teacher PostsRuthvik ReddyОценок пока нет

- 2Nd Experiment "Coagulation - Floculation Analysis Using Jar - Test Method"Документ15 страниц2Nd Experiment "Coagulation - Floculation Analysis Using Jar - Test Method"garum_1Оценок пока нет

- 5 6154457525488977613Документ5 страниц5 6154457525488977613ankith sОценок пока нет