Академический Документы

Профессиональный Документы

Культура Документы

Fabrication of Nanowire MOSFETS: Virginia Polytechnic Institute

Загружено:

Mas Mo0 оценок0% нашли этот документ полезным (0 голосов)

11 просмотров14 страницA very simple construction of a nanowire MOSFET is proposed by using Silicon-On-Insulator (SOI) substrates without advanced photolithography.

Исходное описание:

Оригинальное название

Dhillon

Авторское право

© © All Rights Reserved

Доступные форматы

PDF, TXT или читайте онлайн в Scribd

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документA very simple construction of a nanowire MOSFET is proposed by using Silicon-On-Insulator (SOI) substrates without advanced photolithography.

Авторское право:

© All Rights Reserved

Доступные форматы

Скачайте в формате PDF, TXT или читайте онлайн в Scribd

0 оценок0% нашли этот документ полезным (0 голосов)

11 просмотров14 страницFabrication of Nanowire MOSFETS: Virginia Polytechnic Institute

Загружено:

Mas MoA very simple construction of a nanowire MOSFET is proposed by using Silicon-On-Insulator (SOI) substrates without advanced photolithography.

Авторское право:

© All Rights Reserved

Доступные форматы

Скачайте в формате PDF, TXT или читайте онлайн в Scribd

Вы находитесь на странице: 1из 14

Fabrication of Nanowire MOSFETS

Virginia Polytechnic Institute

Mehtab Singh Dhillon

Advisor : Dr. Marius Orlowski

Ideal MOSFET:

Gate electrode wraps all

around a nanowire semiconductor

(a single crystal cylinder of Si or Ge)

Nanowire Mosfets

A very simple construction of a nanowire MOSFET is proposed by using

Silicon-On-Insulator (SOI) substrates without advanced photolithography.

BO

X

Si

Si 100 nm

}

SOI-type

wafer

BO

X

Amount of BOX underetch

During last oxide removal

Si

Si

Si

Source/Drain

Deposition of Si3N4

We deposit Silicon nitride on the silicon wafer

Plasma enhanced chemical vapor deposition machine is used

to form a uniform layer

Inflow of gases

Chamber: plasma deposition

takes place

Wafer is loaded here

Computer control

BO

X

Si

Si

Si3N4

Cleaning of Wafer

RCA cleaning of wafers with hydrogen peroxide to remove the

organic/inorganic impurities

For every use wafer is treated with acetone, propane to remove

other impurities

Nitrogen gas

DI Water

Solvent and Developer

waste collected

HDMS (trimethylsilyl)spin :

Dehydration of wafer at 150 c for 13 minutes

Wafer smoothly coated (30s with 2000 rpm)

Used for adhesion for photoresist

Also silicon dioxide reacts with HDMS to form water repellent

surface thus preventing aqueous developer to penetrate wafer

soft bake the wafer at 100 C

Photoresist spinner

Wafer holder : creates vacuum

Control unit: Set run time; Desired rpm

Photoresist Spin

Positive photoresist (AZ5214E) poured on wafer

Spin for 50s at 2000rpm

Bake for 2 minutes to remove all the solvents

Thickness of resist determined by its viscosity and spin speed

For 2000 rpm we have layer thickness of 1.98 micro meters

Photoresist spinner

BO

X

Si

Si

Si3N4

PR

Mask Aligner: Exposure

Wafer patterned with one micron line mask

Wafer and the mask are aligned and brought close together

Then exposed with UV light. UV light does not penetrate through the

patterned lines but passes through the other open area and thus attacks the

photoresist on wafer

The exposure makes the photoresist soluble in the developer

After exposure wafer baked for 30s at 100 C

Post bake important for one micron lines as they are very thin; baking

makes the photoresist more durable

Longer post bake makes the resist too hard for developer to dissolve

Right balance between exposure time and post bake time is very important

Mask Aligner

BO

X

Si

Si

Si3N4

PR

Moniter screen

Exposure source

Change mask

Function keys:

Edit distance between wafer and

mask gap

Change exposure time

Align the masks with the wafer

Load wafer

Result of Patterning

we successfully pattern the wafer with one micron lines

Trimming of Resist Lines

Trimming is always done in a 2 step process

Vertical trimming using plasma etching

Lateral etching using chemicals like phosphoric acid, BOE(HF with water)

Silicon nitride is etched using phosphoric acid

Silicon dioxide is etched using BOE which is diluted hydrofluoric acid

BO

X

Si

Si

Si3N4

PR

Deep Reactive Ion Etching

Silicon Nitride Trimming

Silicon nitride is trimmed down using the plasma etching

Lateral etching is done using phosphoric acid

vertical etching Lateral etching

We now strip of the Photoresist

BO

X

Si

Si

Si3N4

PR

BO

X

Si

Si

PR

Silicon Nitride

Silicon Trimming

Si

BOX

Si

Si3N4

Si

BOX

Si Si

Silicon vertical etch using plasma Silicon nitride stripped off

100-200 nm

We can etch silicon using the DRIE plasma machine

Вам также может понравиться

- Semiconductor Manufacturing ProcessДокумент51 страницаSemiconductor Manufacturing Processmanoj3e9329100% (1)

- Semiconductor FabricationДокумент20 страницSemiconductor FabricationMahabub HossainОценок пока нет

- Carbide, Nitride and Boride Material Synthesis and ProcessingДокумент674 страницыCarbide, Nitride and Boride Material Synthesis and ProcessingMarcia Gaby Cruz67% (3)

- Vlsi PDFДокумент81 страницаVlsi PDFShruthiОценок пока нет

- Nmos and Cmos FabricationДокумент33 страницыNmos and Cmos FabricationmannsloveОценок пока нет

- Ceramics and Glasses 2Документ51 страницаCeramics and Glasses 2Vinodhan Milo SivavikkramanОценок пока нет

- Glass and Ceramics IndustryДокумент73 страницыGlass and Ceramics IndustryAngelica Joyce Benito0% (1)

- Unit IДокумент37 страницUnit IDINESH KUMAR DRAVIDAMANIОценок пока нет

- 1.photolithography (ECE209) Unit 2Документ23 страницы1.photolithography (ECE209) Unit 2RajaОценок пока нет

- Ic FabricationДокумент29 страницIc FabricationAkvir Kaur100% (1)

- 001 Device FabricationДокумент60 страниц001 Device FabricationSerwan BamerniОценок пока нет

- Fabrication Mod 2Документ16 страницFabrication Mod 2albin shajanОценок пока нет

- Silicon Nitride - Synthesis, Properties and Application (2012)Документ176 страницSilicon Nitride - Synthesis, Properties and Application (2012)Daud BabaОценок пока нет

- Silicon On Insulator TechnologyДокумент32 страницыSilicon On Insulator TechnologyJayanth bemesettyОценок пока нет

- Silicon Manufacturing: LithographyДокумент55 страницSilicon Manufacturing: LithographyParameswaran SubramanianОценок пока нет

- 14356007.a06 001Документ46 страниц14356007.a06 001mido_u3Оценок пока нет

- BioMEMS Chapter 1Документ85 страницBioMEMS Chapter 1Mohanarajan Mohan KumarОценок пока нет

- Unit - IДокумент69 страницUnit - IsaravananОценок пока нет

- Integrated Circuit Fabrication ProcessДокумент14 страницIntegrated Circuit Fabrication ProcessSanthosh DheerajОценок пока нет

- Unit 1 MOS Fabrication TechnologyДокумент86 страницUnit 1 MOS Fabrication TechnologyChinna ChowdaryОценок пока нет

- Integrated Circuit FabricationДокумент3 страницыIntegrated Circuit FabricationCedric MontianoОценок пока нет

- C-1 CMOS Processing FlowДокумент76 страницC-1 CMOS Processing FlowKu Ble YanОценок пока нет

- VLSI Design (EE-402) LithographyДокумент31 страницаVLSI Design (EE-402) LithographyZahidullahОценок пока нет

- Ics and Semiconductor Fabrication ProcessesДокумент83 страницыIcs and Semiconductor Fabrication Processesbadrinarayan2210298Оценок пока нет

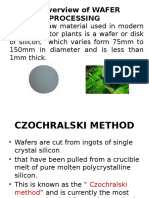

- Wafer ProcessingДокумент24 страницыWafer ProcessingSamson ImmanuelОценок пока нет

- Fabrication Process: Kanada TechnologiesДокумент33 страницыFabrication Process: Kanada TechnologiesKarthigai ValliОценок пока нет

- VLSI Device Isolation TechniquesДокумент24 страницыVLSI Device Isolation Techniquesसुधांशु जनवाड़करОценок пока нет

- Basic Planar ProcessДокумент36 страницBasic Planar ProcessMayank Agarwal75% (4)

- MicromachiningДокумент51 страницаMicromachiningManoj MurthyОценок пока нет

- Module2 - Industrial SafetyДокумент32 страницыModule2 - Industrial SafetyGadde NarendraОценок пока нет

- Fabrikasi ICДокумент47 страницFabrikasi ICNanamaliamОценок пока нет

- Semiconductor Process FlowДокумент48 страницSemiconductor Process Flowgizer74Оценок пока нет

- Process For MicromachingДокумент24 страницыProcess For MicromachingAbcd PqrsОценок пока нет

- Unit Process Steps VlsiДокумент83 страницыUnit Process Steps Vlsis.r.Оценок пока нет

- Chapter 3. CMOS Processing Technology - VLSI - CAD LaboratoryДокумент45 страницChapter 3. CMOS Processing Technology - VLSI - CAD LaboratoryYidnekachwe MekuriaОценок пока нет

- Ic Fabrication Process: Soudip Sinha Roy ECEДокумент51 страницаIc Fabrication Process: Soudip Sinha Roy ECEMayank RajОценок пока нет

- Analog Digital VLSI Design: Discipline/eee/agupta/advd/advd - HTMДокумент78 страницAnalog Digital VLSI Design: Discipline/eee/agupta/advd/advd - HTMhkajaiОценок пока нет

- VLSI Tech Intro 2024Документ89 страницVLSI Tech Intro 2024Jossan EleazarEDENОценок пока нет

- DEC50143 CHAPTER 2 - PART C - EditДокумент49 страницDEC50143 CHAPTER 2 - PART C - Edity meОценок пока нет

- Surface Micromachining: Chang Liu Micro Actuators, Sensors, Systems Group University of Illinois at Urbana-ChampaignДокумент61 страницаSurface Micromachining: Chang Liu Micro Actuators, Sensors, Systems Group University of Illinois at Urbana-ChampaignGuru VelmathiОценок пока нет

- Solar Cell ProjectДокумент32 страницыSolar Cell Projectmathavan333100% (2)

- Unit - I: Vlsi Fabrication TechniquesДокумент64 страницыUnit - I: Vlsi Fabrication TechniquesAnand KumarОценок пока нет

- Cmos Fabrication: - Lithography - Etching - Oxidation - Doping - DepositionДокумент30 страницCmos Fabrication: - Lithography - Etching - Oxidation - Doping - DepositionJames Hyun Wook ParkОценок пока нет

- VLSI DTS Intro SVRE LakshmiNarasaiahДокумент32 страницыVLSI DTS Intro SVRE LakshmiNarasaiahRn HarishОценок пока нет

- CMOS Processing Technology Silicon: A Semiconductor With Resistance Between That of Conductor and AnДокумент18 страницCMOS Processing Technology Silicon: A Semiconductor With Resistance Between That of Conductor and AntmdmurthyОценок пока нет

- IC Fabrication - An IntroductionДокумент37 страницIC Fabrication - An IntroductionramkumarrajaОценок пока нет

- Three CMOS Fabrication VideosДокумент5 страницThree CMOS Fabrication VideosPhola PatulinОценок пока нет

- Fabrication of Silicon DiodeДокумент26 страницFabrication of Silicon Diodeali974424Оценок пока нет

- VLSI Lab Viva Questions and Answers 1Документ21 страницаVLSI Lab Viva Questions and Answers 1anand_duraiswamyОценок пока нет

- IC Fabrication Process: Course: VLSI DesignДокумент14 страницIC Fabrication Process: Course: VLSI DesignDwayne WaltonОценок пока нет

- Soi ProcessДокумент14 страницSoi ProcessMichael CampbellОценок пока нет

- Midterm Exam 1Документ9 страницMidterm Exam 1Hemal ShahporiaОценок пока нет

- Wafer Manufacturing CleaningДокумент25 страницWafer Manufacturing CleaningsrihariОценок пока нет

- BASIC VLSI DESIGN .PptsДокумент32 страницыBASIC VLSI DESIGN .PptsNarayana Rao RevallaОценок пока нет

- Micro Electro Mechanical Systems (MEMS)Документ44 страницыMicro Electro Mechanical Systems (MEMS)Neethu Krishna KОценок пока нет

- Etching PPT3Документ29 страницEtching PPT3FahadОценок пока нет

- Introduction To MOS TechnologiesДокумент15 страницIntroduction To MOS TechnologieslokeshwarrvrjcОценок пока нет

- Semiconductor Fabrication: Presented by P JaswanthДокумент31 страницаSemiconductor Fabrication: Presented by P JaswanthPullepu JaswanthОценок пока нет

- Bulk MicromachiningДокумент14 страницBulk MicromachiningSrilakshmi MОценок пока нет

- Module 5: Fabrication Methods Photolithography: Raja SellappanДокумент24 страницыModule 5: Fabrication Methods Photolithography: Raja SellappanAbhiramОценок пока нет

- A Teacher-Student Conversation On "Cmos Fabrication Process Flow"Документ70 страницA Teacher-Student Conversation On "Cmos Fabrication Process Flow"Calcutta University RPE 2020Оценок пока нет

- Eem413e Lecture-Week4Документ47 страницEem413e Lecture-Week4Furkan AvcıoğluОценок пока нет

- Manufacturing of Microprocessor: Farooq Ahmad ShahДокумент18 страницManufacturing of Microprocessor: Farooq Ahmad ShahCristianCristianHerreraОценок пока нет

- Ceramic Materials for Energy Applications VIОт EverandCeramic Materials for Energy Applications VIHua-Tay LinОценок пока нет

- H. Liu, D. K. Mohata, A. Nidhi, V. Saripalli, V. Narayanan and S. DattaДокумент2 страницыH. Liu, D. K. Mohata, A. Nidhi, V. Saripalli, V. Narayanan and S. DattaMas MoОценок пока нет

- Nanoelectronics and at Imec: More-than-MooreДокумент52 страницыNanoelectronics and at Imec: More-than-MooreMas MoОценок пока нет

- Silicon-Nanowire Mosfets Cmos Compatible Gate-All-Around VerticalДокумент4 страницыSilicon-Nanowire Mosfets Cmos Compatible Gate-All-Around VerticalMas MoОценок пока нет

- Vertical Silicon-Nanowire Formation and Gate-All-Around MOSFETДокумент4 страницыVertical Silicon-Nanowire Formation and Gate-All-Around MOSFETMas MoОценок пока нет

- Silicon Vertically Integrated Nanowire Field Effect TransistorsДокумент5 страницSilicon Vertically Integrated Nanowire Field Effect TransistorsMas MoОценок пока нет

- Logic Gates With A Single Graphene Transistor: Roman Sordan Floriano Traversi Valeria RussoДокумент4 страницыLogic Gates With A Single Graphene Transistor: Roman Sordan Floriano Traversi Valeria RussoMas MoОценок пока нет

- J 1151-2916 2000 tb01182 XДокумент21 страницаJ 1151-2916 2000 tb01182 Xrahil7860Оценок пока нет

- UHTCs Ultra-High Temperature Ceramic MaterialsДокумент9 страницUHTCs Ultra-High Temperature Ceramic MaterialsMelih ÖzdenОценок пока нет

- Review of Journal Bearing Materials and Current TrendsДокумент13 страницReview of Journal Bearing Materials and Current TrendsKamolwan WeerachatsakulОценок пока нет

- Wet EtchДокумент28 страницWet Etchkhalil alhatabОценок пока нет

- Mitutoyo - Trzpienie Pomiarowe, Końcówki I Akcesoria - PRE983017 (4) - 2017 ENДокумент56 страницMitutoyo - Trzpienie Pomiarowe, Końcówki I Akcesoria - PRE983017 (4) - 2017 END.T.Оценок пока нет

- MM 357 - Lecture 1 - Introduction - For ClassДокумент5 страницMM 357 - Lecture 1 - Introduction - For ClassPiyush DivyankarОценок пока нет

- t2 Chem Revision Ex 22 - Answer SchemeДокумент20 страницt2 Chem Revision Ex 22 - Answer SchemeNicholas Ow50% (2)

- Evaluation of Mechanical and Thermal Properties of Al 6360 Alloy Reinforced With Sic ParticulatesДокумент13 страницEvaluation of Mechanical and Thermal Properties of Al 6360 Alloy Reinforced With Sic ParticulatesSripad AОценок пока нет

- Escholarship UC Item 7hd8r1ftДокумент26 страницEscholarship UC Item 7hd8r1ftAvadhoot RajurkarОценок пока нет

- Hybrid Bearing PresentationДокумент10 страницHybrid Bearing PresentationNaunihal KumarОценок пока нет

- Advanced Transmission and Oil System Concepts For Modern Aero-EnginesДокумент8 страницAdvanced Transmission and Oil System Concepts For Modern Aero-EnginessenthilОценок пока нет

- Silicon Nitride Bearing Balls: Standard Specification ForДокумент8 страницSilicon Nitride Bearing Balls: Standard Specification ForDarwin DarmawanОценок пока нет

- Test Rig FrictionДокумент7 страницTest Rig FrictionRiyaz AhmedОценок пока нет

- Hybrid Ceramic Vs Steel Bearings Article 2Документ27 страницHybrid Ceramic Vs Steel Bearings Article 2Yusantya Ahmad FachrizalОценок пока нет

- Patent Application Publication (10) Pub. No.: US 2013/0247388 A1Документ12 страницPatent Application Publication (10) Pub. No.: US 2013/0247388 A1Gregory Mora LlamacponccaОценок пока нет

- Ceramic Materials UTS IДокумент24 страницыCeramic Materials UTS IMaryan Arfa YhudaОценок пока нет

- Mechanical Seals PDFДокумент14 страницMechanical Seals PDFZeeshan SajidОценок пока нет

- 제12주차 Chapter07 박막증착공정Документ8 страниц제12주차 Chapter07 박막증착공정K SiriusОценок пока нет

- Waste Management: Fabio Dal Magro, Haoxin Xu, Gioacchino Nardin, Alessandro RomagnoliДокумент10 страницWaste Management: Fabio Dal Magro, Haoxin Xu, Gioacchino Nardin, Alessandro RomagnoliKARAN KHANNAОценок пока нет

- MHP 100 RevAДокумент3 страницыMHP 100 RevArajesh langojuОценок пока нет

- All Functional Materials For Material EngineeringДокумент27 страницAll Functional Materials For Material Engineeringeddula ganeshОценок пока нет

- 2021 Pricelist Europractice General MPW 8Документ7 страниц2021 Pricelist Europractice General MPW 8Dal BarОценок пока нет

- Ceramics International: Junfeng Chen, Nan Li, Yaowu Wei, Bingqiang Han, Wen YanДокумент9 страницCeramics International: Junfeng Chen, Nan Li, Yaowu Wei, Bingqiang Han, Wen YanJunfeng ChenОценок пока нет

- Dense Si N Coatings With High Friction Coefficient Deposited by High-Velocity Pulsed Plasma SprayingДокумент8 страницDense Si N Coatings With High Friction Coefficient Deposited by High-Velocity Pulsed Plasma SprayingVincenzo PilusoОценок пока нет

- Investigations On Transient Dynamic Response of Functionally Graded MaterialsДокумент5 страницInvestigations On Transient Dynamic Response of Functionally Graded MaterialsInternational Journal of Application or Innovation in Engineering & ManagementОценок пока нет