Академический Документы

Профессиональный Документы

Культура Документы

Injection Oilers, Micro Pumps

Загружено:

LLАвторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Injection Oilers, Micro Pumps

Загружено:

LLАвторское право:

Доступные форматы

Metering pumps deliver and meter out lubricants.

This piston pumps are for small delivery rates from 3 to 40 mm

3

.

The lubricants delivery rate is partially adjustable.

Possible applications: spot, brush lubrication:

G Air oiling (assembly tools)

G Greasing of small parts (assembly support)

G Chain lubrication

Main features of magnetic piston pumps

G 26 outlet ports

G Electric drive with AC and DC voltage

G Compact design

Main features of injection oilers, micropumps

G Optimal metering of every lube point regardless of line lengths

and cross sections

G Lubricant supplied from one central reservoir, a standalone

reservoir, also by a central pressurized oil line in the case of

injection oilers

G Metering elements can be actuated individually or in groups

G Splash lubrication through high oil acceleration (injection oiler)

G Fast sequence of pulses:

up to 120 pulses per minute (injection oiler)

up to 180 pulses per minute (micropump)

G Spacesaving design

G Ecofriendly: no oil in the exhaust air

Micropump Grease metering Magnetic piston pump Injection oiler

for minimal quantity metering

Injection Oilers, Micro Pumps

150124US

Quality Management

DIN EN ISO 9001: 2000

Environmental Management

DIN EN ISO 14001

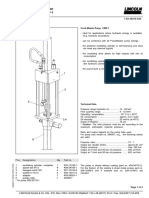

Sectional view of injection oiler

Oiling during production of camshafts

P

S Lubricant Z Compressed air pulse

Injection Oilers, Micro Pumps 150124US 2

The magnetic piston pump is

an electrically actuated posi

tivedisplacement micropump.

A solenoid actuator moves the

delivery piston inside the

pump's body. The return stroke

takes place with spring force.

The oil is fed from a gravity oil

reservoir. Pumps with up to six outlet ports and three different

delivery rates can be chosen from.

Order advice

Pump PE x xx + xxx

Outlets 2 / 4 / 6

Delivery rate 20 / 40 / 60

Voltage

115 V AC 429 / 230 V AC 428 / 24 V DC 924

Order example

Pump with 2 outlets, delivery rate/outlet 40 mm

3

,

voltage 24 V DC, order No. PE 2 40+924

Magnetic piston

pump PE

Technical data

Number of outlet ports . . . . . . . . 2, 4 and 6

Delivery rate/outlet . . . . . . . . . . . . 20, 40 and 60 mm

3

Voltage/ frequency . . . . . . . . . . . . 115 V, 230 V, 50 Hz; 24 V DC

Power . . . . . . . . . . . . . . . . . . . . . . 120 W

Power consumption . . . . . . . . . . . 1 A at 115 V,

0.55 A at 230 V

ON time. . . . . . . . . . . . . . . . . . . . . 40%

Max. frequency. . . . . . . . . . . . . . . 2 Hz

Operating temperature . . . . . . . . +10 to +60 C

Max. delivery pressure . . . . . . . . . 20 bars

with reservoir and

injection nozzles

Example of a

chain lubication unit

Order No. UC.DES.135

Chain lubrication application

A typical application is chain

lubrication. Due to the fre

quency and small delivery rate,

the friction points of a chain

can be targeted directly and

with pinpoint accuracy while

it's running. A proximity sensor

detects the chain studs and

activates the corresponding

control system for the magnet

ic piston pump with the elec

tric input signal.

Injection Oilers, Micro Pumps 150124US 3

Technical data

Ambient temperature: . . . 20 C to +80 C

Actuating medium: . . . . .compressed air (Z),

310 bars,

max. flow 200 l/min

Lubricant: . . . . . . . . . . . .oil at 101100 mm

2

/s

Other media on request.

When grease is used, the priming process must

be supported with priming pressure.

Please inquire!

Adjustment of volume

All injection oilers are set for maximum delivery

volume at the plant. The delivery rate can be

reduced in increments by turning the setting

sleeve counterclockwise.

Max. delivery rate/stroke 30 mm

3

1 full turn to the left: 25 mm

3

2 full turns to the left: 20 mm

3

3 full turns to the left: 15 mm

3

4 full turns to the left: 10 mm

3

5 full turns to the left: 5 mm

3

over 6 full turns to the left: 3 mm

3

The setting sleeve can be set by hand.

It engages 4 times per revolution (which can be

heard and felt) si that intermediate settings are

also possible. The maximum delivery rate is set

again by turning the setting sleeve clockwise to

the stop.

The first startup should take place at the maxi

mum delivery rate.

1

) Ports tapped for solderless tube connection

(for 2.5 mm diam. tubing)

2

) Throughhole ( 6.7) for wall mounting

(M6x30 screws)

Lateral connec

Delivery rate for tube tions for sensor Seal

Version [ccm/stroke] Order No. diam. Z S material Features, application

1port 0.003 0.03 501301000 2.5 no NBR individual use, can be coupled to further

type 501301008 2.5 no FKM (FPM) 1 and 3portinjection oilers.

501301024 4 no NBR Basic unit for injection oilers with reservoir.

501301001 2.5 yes NBR internal oil discharge

501301002 *) 2.5 yes NBR external oil discharge

3port 0.003 0.03 501303000 2.5 no NBR group actuation

type 501303008 2.5 no FKM (FPM) group actuation

501303003 2.5 no NBR individual actuation

501303024 4 no NBR group actuation

*) yes, but internal oil path covered by gasket 818100007

Basic unit for injection oiler

with reservoir and sensor

(combined oiler

Setting sleeves

a Setting sleeve for adjust

ment of quantity and manu

al actuation for additional

triggering of a lube pulse

b Indicator pin for function

display

c Guard cap

NB: direction of rotation

turn to the left

+ turn to the right

Illustration: oiler for group actuation

Injection oiler

1 and 3port types

coupling set

order No. 995900100

(including 2 Orings

WVN5019x3)

threads only

in case of oiler for

individual actuation

Setting sleeves

S = oil feed

P = oil outlet

Z = compressed air port

501303000

Injection Oilers, Micro Pumps 150124US 4

Injection oiler, 1port type

Example 1: Gravity oil layout (group actuation)

Example 2: Gravity oil layout with venting line

(group and individual actuation combined)

Example 3: Configuration of a large system with ring line

(group actuation)

Injection oiler, 3port type

individual actuation

Air flow with individual actuation

Air flow with group actuation

Injection oiler, 3port type

group actuation

S = oil feed

P = oil outlet port

Z = compressed air port

air pulse for

group actuation to the

lube points

screw plug

sealing ring

to the

lube points

priming

pump

air pulses for

individual actuation

air pulses for

group actuation

air pulse for

group actuation

Both control types

can be combined

in any way desired.

S = oil feed

P = oil outlet port

Z = compressed air port

max.

3 bars

Injection Oilers, Micro Pumps 150124US 5

Order No. Seal material

501301011 NBR Mounting position as shown

501301028 FKM (FPM) See page 3 for technical data

501303011 NBR

Reservoir capacity 0.25 liter

Reservoir material PA63T

Further injection oilers can be

hooked up. The individual

metering pumps can in turn be

actuated individually or in

groups. If the lubrication fre

quency has to be scaled down,

the injection oiler can be cou

pled to a counting stage.

We recommend that a venting

line be laid for automatic

venting of the oilconducting

chambers and bores (cf. illus.).

setting

sleeve

compressed

air port

oil outlet port

1

) Port tapped for solderless tube connection

Injection oiler

with reservoir

The injection oiler is combined

with a reservoir of transparent

material when used with only a

few lube points.

Applications

G tool lubrication

ORing

WVN5019x3

ORing

WVN5019x3

venting

line

Automatic venting when coupled

to further injection oilers

501301011

Injection Oilers, Micro Pumps 150124US 6

Grease metering

Applications

G Greasing small parts

(assembly support)

G Selective splash lubrication

of chain friction points

Spring pressure is used to deposit the

lubricant from the grease cartridge. When

the injection oiler is actuated, the adjusted

output is ejected. The proximity switch

monitors the motion of the metering pis

ton.

Large distances can be selectively wetted

with VOGEL spray nozzles (leaflet

150125US). Steel tubing (4 mm) with

a max. length of 500 mm should be used

for this purpose.

The cartridge (order No. MLUB.EP2.DP.2)

is exchangeable; reservoirs for greater

grease demand on request. To suit the

respective application it is possible to

operate the injection oiler with oil or

grease up to NLGI grade 2.

Technical data

Cartridge capacity 80 ccm, grease, NLGI grade 2

Operating temperature . . . . . . . . 20 to +70 C

Mounting position . . . . . . . . . . . . . . . as shown

Injection oiler

Control medium . filtered compressed air 40 m

Actuation pressure . . . . . . . . . . . . . 3 to 10 bars

Delivery rate. 0.0030.03 ccm/stroke, adjustable

Material . . . . . . . . . . . . . . housing: zinc die cast

seal: NBR

Proximity switch

Supply voltage . . . . . . . . . . . . . . 10 to 30 V DC

Rated current . . . . . . . . . . . . . . . . . . . . 400 mA

Type of enclosure . . . . . . . . . . . . . . . . . . . IP 67

Switching indication . . . . . . . . . . . . . . . . . . LED

filler socket

grease level

indicator

G1/4

82

~

3

2

3

72

P pressure port

follower piston

120

9

1

0

0

150

M14x1,5

1

)

Injection oiler with grease

cartridge and monitoring

Order No. 501301094

Order No. BF1.5

(reservoir capacity 1.5 liter)

1

) Port tapped for solderlesse 8 mm diam. tube connection

Order No. 501301056

(reservoir capacity 0.8 liter with WS for min. filling level)

Injection Oilers, Micro Pumps 150124US 7

Micropump

The micropump is a pneumat

ically actuated, miniature pis

ton pump. The compressed air

controlled by a 3/2way valve

actuates the delivery piston,

which discharges the respec

tive output on the basis of its

displacement. The travel of the

stroke, and thus the metering

of the delivery rate, is

increased or decreased with

setting rings.

Care must be taken to make

sure that the compressedair

line leading to the pump is

relieved of pressure after each

actuation so that the delivery

piston can return to its initial

position.

Technical data

Order No. . . . . . . . . . . . . . . . . . . PVR003

metering rate adjustable

from 030 mm

3

Order No. . . . . . . . . . . . . . . . . . . PV003

fixed metering rates with

setting ring:

3; 5; 10 and 30 mm

3

Air pressure. . . . . . . . . . . . . . . . . . 48 bars

Frequency . . . . . . . . . . . . . . . . . . . max. 3 Hz

Operating temperature . . . . . . . . +10 to +70 C

Max. delivery pressure . . . . . . . . . approx. 35 bars

Lubricant . . . . . . . . . . . . . . . . . . . . mineral oils without additives,

max. viscosity 100 mm

2

/s

Oil feed . . . . . . . . . . . . . . . . . . . . gravity oil reservoir

2port type on baseplate

The micropump is specially

designed for minimal quantity

lubrication, and, namely, only

for cases in which oil is to be

sprayed on with compressed

air.

The necessary accessories are

documented in leaflet

150125US.

Baseplate

Number

Order No. of pumps

PV.1641 1

PV.1642 2

PV.1643 3

PV.1644 4

stroke

air port

max. 4 ports

outlet ports M10x1

Willy Vogel AG

Motzener Strasse 35/37

12277 Berlin, Germany

P.O. Box 97044412704 Berlin

Tel. +49 (0) 30 720020

Fax +49 (0) 30 72002111

info@vogelberlin.de

www.vogelag.com

Willy Vogel AG

2. Industriestrasse 4

68766 Hockenheim

Germany

Tel. +49 (0) 6205 270

Fax +49 (0) 6205 27132

info@vogelberlin.de

www.vogelag.com

Vogel France SAS

Rue Robert Amy, B.P. 70130

49404 Saumur cedex

France

Tel. +33 (0) 241 404 200

Fax +33 (0) 241 404 242

info@vogelfrance.com

www.vogelfrance.com

S

u

b

j

e

c

t

t

o

c

h

a

n

g

e

w

i

t

h

o

u

t

n

o

t

i

c

e

!

0

0

0

0

1

1

/

2

0

0

4

Notice!

All products from VOGEL may be used only for their intended purpose.

If operating instructions are supplied together with the products, the provi

sions and information therein of specific relevance to the equipment must

be observed as well.

In particular, we call your attention to the fact that hazardous materials of

any kind, especially the materials classified as hazardous by EC Directive

67/548/EEC, Article 2, Par. 2, may only be filled into VOGEL centralized

lubrication systems and components and delivered and/or distributed with

the same after consultation with and written approval from VOGEL.

All products manufactured by VOGEL are not approved for use in con

junction with gases, liquefied gases, pressurized gases in solution and

fluids with a vapor pressure exceeding normal atmospheric pressure

(1013 mbars) by more than 0.5 bar at their maximum permissible

temperature.

Вам также может понравиться

- Circulating Lubrication Systems (Oil)Документ8 страницCirculating Lubrication Systems (Oil)LLОценок пока нет

- 1 3015 enДокумент20 страниц1 3015 enAbbas AhmedОценок пока нет

- 1 0107 2Документ8 страниц1 0107 2oleg-spbОценок пока нет

- LINCOLN Lubrication Centro - MaticДокумент53 страницыLINCOLN Lubrication Centro - Maticrmartinf2527Оценок пока нет

- Modular Feeder PSG 2Документ22 страницыModular Feeder PSG 2LLОценок пока нет

- Lincoln Sl1 Centro Matic InjectorДокумент5 страницLincoln Sl1 Centro Matic InjectorcakendriОценок пока нет

- Transfer Pump BrochureДокумент12 страницTransfer Pump BrochureRafert RamОценок пока нет

- Grundfos MTS Screw Spindle PumpДокумент68 страницGrundfos MTS Screw Spindle PumpAnonymous lswzqlo100% (1)

- Flow Monitors and Sensors: For Intermittent and Circulating Centralized Lubrication SystemsДокумент8 страницFlow Monitors and Sensors: For Intermittent and Circulating Centralized Lubrication SystemsRogério PereiraОценок пока нет

- Progressive FeedersДокумент16 страницProgressive FeedersLLОценок пока нет

- 1-1108-US - Mechncial Piston PumpsДокумент2 страницы1-1108-US - Mechncial Piston Pumpsli geneОценок пока нет

- Dropsa YoensaДокумент73 страницыDropsa YoensaCAGERIGOОценок пока нет

- 75A 38010 A03 ContiMasterДокумент4 страницы75A 38010 A03 ContiMasterjacklyn ade putra100% (1)

- Catálogo General UPA 50 HZ 2 PARTEДокумент20 страницCatálogo General UPA 50 HZ 2 PARTENao Oi OiОценок пока нет

- AP GBДокумент2 страницыAP GBTitu NicuОценок пока нет

- Samoa Section 2 Pages25 32Документ8 страницSamoa Section 2 Pages25 32Wiki YuanditraОценок пока нет

- GC Tips Tricks-Agilent (Compatibility Mode)Документ43 страницыGC Tips Tricks-Agilent (Compatibility Mode)Sneha PatelОценок пока нет

- PFRДокумент580 страницPFRDavid Carlos Dady100% (6)

- Hatlapa L160 BA - EnglДокумент18 страницHatlapa L160 BA - Engltim kaminskyОценок пока нет

- Accessories Catalogue 17000187 UEL 1Документ12 страницAccessories Catalogue 17000187 UEL 1quiquenuОценок пока нет

- CMB Iso 6020-2Документ63 страницыCMB Iso 6020-2David AlbellaОценок пока нет

- Centro-Matic Automated Lubrication Systems: System ControlsДокумент8 страницCentro-Matic Automated Lubrication Systems: System ControlsAlex Rivera RiveraОценок пока нет

- Anonymous 1-1en PDFДокумент6 страницAnonymous 1-1en PDFAlexander BrewerОценок пока нет

- NAFRA Guaranteed Technical Perticulars Spherical ValveДокумент8 страницNAFRA Guaranteed Technical Perticulars Spherical Valvepavankumar001Оценок пока нет

- 6206 Guide For Selection Installation andДокумент32 страницы6206 Guide For Selection Installation andakbavra80% (5)

- YukenPiston PumpsДокумент146 страницYukenPiston PumpsCahyo DiyantoОценок пока нет

- 14564625Документ2 страницы14564625kisgobeОценок пока нет

- GX35 GX60 GS100 Operating InstructionsДокумент18 страницGX35 GX60 GS100 Operating InstructionsMiguel Jiménez FloresОценок пока нет

- Variable Vane Pumps: 1 P V 2 V 3 - / RA01MC A 1Документ8 страницVariable Vane Pumps: 1 P V 2 V 3 - / RA01MC A 1Dias EliОценок пока нет

- Piston Pump For OilsДокумент2 страницыPiston Pump For Oilsli geneОценок пока нет

- Re 15224Документ12 страницRe 15224Ahmed Abd ElhakeemОценок пока нет

- 6mm To 18mmДокумент15 страниц6mm To 18mmMd.zubairОценок пока нет

- MLP - Mobile Lube Pump: User and Maintenance Manual Warranty InformationДокумент23 страницыMLP - Mobile Lube Pump: User and Maintenance Manual Warranty InformationTimon2005Оценок пока нет

- DC73C12RBU6Документ2 страницыDC73C12RBU6enrimoli1250Оценок пока нет

- Re 15190Документ24 страницыRe 15190Ahmed Abd ElhakeemОценок пока нет

- Fuel Oil Meter ManualДокумент89 страницFuel Oil Meter ManualbouguerraОценок пока нет

- Gunclean Toftejorg T-73 Fixed IM-TE91A450-En3Документ39 страницGunclean Toftejorg T-73 Fixed IM-TE91A450-En3cengiz kutukcuОценок пока нет

- HSN 7461-70Документ11 страницHSN 7461-70codymasterОценок пока нет

- 05-Force Feed Lubrication SystemДокумент34 страницы05-Force Feed Lubrication SystemBookMaggotОценок пока нет

- MMS Product GuideДокумент40 страницMMS Product GuideFelipe VargasОценок пока нет

- HusqvarnaДокумент34 страницыHusqvarnaMakis Ekoytsidis100% (1)

- Piston Distributors, Metering UnitsДокумент12 страницPiston Distributors, Metering UnitsLLОценок пока нет

- All About HidrolicДокумент7 страницAll About Hidrolicpiteng1945100% (3)

- STD Line: Product DescriptionДокумент16 страницSTD Line: Product DescriptionrpmОценок пока нет

- UVN SeriesДокумент3 страницыUVN SeriesgreatharunОценок пока нет

- CenlubДокумент32 страницыCenlubShivakumar PattarОценок пока нет

- Grundfosliterature 722Документ32 страницыGrundfosliterature 722coral18082495Оценок пока нет

- Ta3000 090610 PDFДокумент6 страницTa3000 090610 PDFganipantojaОценок пока нет

- Grundfos LiteratureДокумент36 страницGrundfos Literaturebenjiy80Оценок пока нет

- 177-999 Rev C1Документ32 страницы177-999 Rev C1vallolet_sb5185Оценок пока нет

- TFP910 09 2014Документ20 страницTFP910 09 2014goskleОценок пока нет

- 02E CTP 100 Portable Profi Serie V1Документ4 страницы02E CTP 100 Portable Profi Serie V1bmxmmxОценок пока нет

- Rexworth Hydraulic MotorДокумент28 страницRexworth Hydraulic MotorSorin-Adrian Learschi100% (1)

- Fix Displacement MotorДокумент28 страницFix Displacement MotorIan MuhammadОценок пока нет

- Force Feed Lubricator SystemДокумент34 страницыForce Feed Lubricator SystemMOHANОценок пока нет

- Lincoln Pump 215 230 PumpsДокумент3 страницыLincoln Pump 215 230 PumpsWuchizyaОценок пока нет

- Imo ACGДокумент16 страницImo ACGMiguel Ponce100% (1)

- C12Документ98 страницC12Marcos Astete EgoavilОценок пока нет

- Installation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitОт EverandInstallation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitОценок пока нет

- Iso-Iec 14515-1Документ327 страницIso-Iec 14515-1LLОценок пока нет

- Iso-Iec 9075-5Документ261 страницаIso-Iec 9075-5LLОценок пока нет

- Methane Air Diluent, ASME ICE 98 PaperДокумент5 страницMethane Air Diluent, ASME ICE 98 PaperLLОценок пока нет

- Iso-Iec 9075-4Документ170 страницIso-Iec 9075-4LLОценок пока нет

- Audio Codecs Mpeg 4 Aac Ieee Coding SchemesДокумент199 страницAudio Codecs Mpeg 4 Aac Ieee Coding SchemesFacundo VignoloОценок пока нет

- ISO-IEC 11172-3 BДокумент37 страницISO-IEC 11172-3 BLLОценок пока нет

- S 025022 eДокумент32 страницыS 025022 ejawad chraibiОценок пока нет

- CMM Paper - Analyzing The Conceptual Relationship Between Iso Iec 15504 (Software Process AssessmДокумент11 страницCMM Paper - Analyzing The Conceptual Relationship Between Iso Iec 15504 (Software Process AssessmAlessandro BaffaОценок пока нет

- Mam71 Prod Ref GuideДокумент167 страницMam71 Prod Ref Guidee305050Оценок пока нет

- Ingersoll CAT-009 HoleM TechДокумент30 страницIngersoll CAT-009 HoleM TechLLОценок пока нет

- Ebook - HardWare - RFID ISO 18000-6 SCS PDFДокумент58 страницEbook - HardWare - RFID ISO 18000-6 SCS PDFjorge gomezОценок пока нет

- Ilchmann GMBH EДокумент6 страницIlchmann GMBH ELLОценок пока нет

- FACOM - Hand Tools - 2004Документ899 страницFACOM - Hand Tools - 2004Евгений АнатольевичОценок пока нет

- KVR UkДокумент4 страницыKVR UkLLОценок пока нет

- GBSP 47Документ3 страницыGBSP 47LLОценок пока нет

- Goodyear Hydraulics Adapters Catalog PDFДокумент165 страницGoodyear Hydraulics Adapters Catalog PDFpsolutions.franciscoОценок пока нет

- Master Gears UsaДокумент6 страницMaster Gears UsaLLОценок пока нет

- l0820300 Stacker Reclaimer ChainsДокумент2 страницыl0820300 Stacker Reclaimer ChainsLLОценок пока нет

- IEEE1068 Repair & Rewinding of MotorsДокумент28 страницIEEE1068 Repair & Rewinding of MotorsjojeecaresОценок пока нет

- Material Grades EN PDFДокумент30 страницMaterial Grades EN PDFnechitamariusОценок пока нет

- Lubrication Guide - Ultrasonic Condition-Based LubricationДокумент7 страницLubrication Guide - Ultrasonic Condition-Based LubricationLLОценок пока нет

- Hardox Uk 400Документ2 страницыHardox Uk 400Jackson VuОценок пока нет

- Falk Metric Key KeywayДокумент2 страницыFalk Metric Key KeywayMAXОценок пока нет

- Price List - Fluke Precision Measurements - End Users - October 2006Документ29 страницPrice List - Fluke Precision Measurements - End Users - October 2006LLОценок пока нет

- Standard - Manual - Low - Voltage - EN Rev G Web PDFДокумент26 страницStandard - Manual - Low - Voltage - EN Rev G Web PDFTuấn Anh CaoОценок пока нет

- Motor Donot Just Fail... Do They - A Guide To Preventing FailureДокумент70 страницMotor Donot Just Fail... Do They - A Guide To Preventing FailuresurawutwijarnОценок пока нет

- FACOM - Hand Tools - 2004Документ899 страницFACOM - Hand Tools - 2004Евгений АнатольевичОценок пока нет

- Heat LineДокумент1 страницаHeat LineLLОценок пока нет

- Motor Bearings - ABBДокумент8 страницMotor Bearings - ABBhozipek5599100% (1)

- Motor Bearings - ABBДокумент8 страницMotor Bearings - ABBhozipek5599100% (1)

- Pumps & System September 2015Документ132 страницыPumps & System September 2015Arif ShahzadОценок пока нет

- Bearing Mounting - SKF Drive Up MethodДокумент5 страницBearing Mounting - SKF Drive Up Methodkuruvillaj2217Оценок пока нет

- GAPS Guidelines: Analyzing Water SuppliesДокумент6 страницGAPS Guidelines: Analyzing Water Suppliesasad khanОценок пока нет

- ERI Pumps LДокумент4 страницыERI Pumps LMauro VergaraОценок пока нет

- Veco Engineering Ltd. Equipment Data Sheet: Centrifugal FanДокумент9 страницVeco Engineering Ltd. Equipment Data Sheet: Centrifugal Fanwado11Оценок пока нет

- Two Way Aqua Hand Pump: Gokul K GДокумент6 страницTwo Way Aqua Hand Pump: Gokul K GDevendrasinh PadhiyarОценок пока нет

- Operator's ManualДокумент102 страницыOperator's ManualJulliana SilvaОценок пока нет

- Appendix A: A.1. Three Phase SeparatorДокумент48 страницAppendix A: A.1. Three Phase SeparatorNhaaaeyОценок пока нет

- Mitho Steam Wash ManualДокумент28 страницMitho Steam Wash ManualedgarcooОценок пока нет

- SciCan Statim 2000 S, G4 Autoclave - Service ManualДокумент275 страницSciCan Statim 2000 S, G4 Autoclave - Service ManualXat DeviceОценок пока нет

- Lit gx200 DataДокумент4 страницыLit gx200 DataPatrick BrilhanteОценок пока нет

- SW2020 Users Manual V10Документ81 страницаSW2020 Users Manual V10Antonio Antonio100% (2)

- Waukesha Cherry Burrell 95 03095 Pumps PD MDL Series UsДокумент58 страницWaukesha Cherry Burrell 95 03095 Pumps PD MDL Series UsGrupo CruzОценок пока нет

- ISO10816 Charts - VibsensДокумент12 страницISO10816 Charts - VibsensJoe Smith100% (1)

- Applications Shaft SealДокумент23 страницыApplications Shaft SealMandisa Sinenhlanhla NduliОценок пока нет

- Engine Oil Pump - Disassemble: ShutdownДокумент3 страницыEngine Oil Pump - Disassemble: ShutdownLuis TepezanoОценок пока нет

- Brosur Heart-Lung Machine + Heater Cooler Unit + Hemofiltration SetДокумент22 страницыBrosur Heart-Lung Machine + Heater Cooler Unit + Hemofiltration SetadefcesyoОценок пока нет

- Cat 330dДокумент2 страницыCat 330dShahreyar KhanОценок пока нет

- EC054 5 Solenoids PumpДокумент28 страницEC054 5 Solenoids PumpAnh Đại MaiОценок пока нет

- Calpeda NGДокумент5 страницCalpeda NG2009tamerОценок пока нет

- Punch List-Electrochlorination Plant-1 (ENVITECH) PDFДокумент3 страницыPunch List-Electrochlorination Plant-1 (ENVITECH) PDFJoni EfwanОценок пока нет

- Power Transformer Design, Manufacturing and TestingДокумент19 страницPower Transformer Design, Manufacturing and TestingAbd ALRahmanОценок пока нет

- Ash Handling System Operetaion and Maintenance InstructionДокумент162 страницыAsh Handling System Operetaion and Maintenance InstructionHari PrasadОценок пока нет

- 2013 ESP Workshop Summary of PresentationsДокумент28 страниц2013 ESP Workshop Summary of PresentationsScott YoungОценок пока нет

- NEWDOSE Dosing Pump CatalogДокумент4 страницыNEWDOSE Dosing Pump CatalogvpcharaОценок пока нет

- D60 FD70 CA20 Harvest Header Flex Draper Combine Adapter: Technical ManualДокумент558 страницD60 FD70 CA20 Harvest Header Flex Draper Combine Adapter: Technical Manualguilherme paludoОценок пока нет

- Goulds Pumps O & MДокумент52 страницыGoulds Pumps O & Msatishbabuyadav100% (1)

- Week13 Turbomachine IДокумент24 страницыWeek13 Turbomachine IMuhammad imranОценок пока нет

- Booster Pump 4L.s@15m - 99614306 - HYDRO - MULTIE - 2 - CRE1002Документ3 страницыBooster Pump 4L.s@15m - 99614306 - HYDRO - MULTIE - 2 - CRE1002tuiОценок пока нет