Академический Документы

Профессиональный Документы

Культура Документы

Kecap Ikan BI

Загружено:

Purnama WIrawanАвторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Kecap Ikan BI

Загружено:

Purnama WIrawanАвторское право:

Доступные форматы

Turkish Journal of Fisheries and Aquatic Sciences 10: 169-172 (2010)

www.trjfas.org

ISSN 1303-2712

DOI: 10.4194/trjfas.2010.0202

Published by Central Fisheries Research Institute (CFRI) Trabzon, Turkey

in cooperation with J apan International Cooperation Agency (J ICA), J apan

Utilization of Gambusia (Affinis affinis) For Fish Sauce Production

Introduction

Many fermented fish products are prepared in

different parts of the world and the method of

processing depends upon various factors, viz.,

availability of raw materials, consumers preference

and the climatic conditions of the region (Al-Jedah et

al., 2000). In addition, fish sauce is a product that can

be made cheaply from various fish raw materials,

which are not normally used for food. Also, it is a

brown, liquid seasoning commonly used in most parts

of Southeast Asia; it is called by different names in

different countries and it contains a mixture of amino

acids and other protein degradation products (Ijong

and Ohta, 1995; Ruiz-Capills et al., 2000; Gildberg,

2001; Sanceda et al., 2001; Aquerreta et al., 2001;

Fukami et al., 2002; Ichimura et al., 2003). Although

fermented fish sauce itself may not be directly used

for a physiological functional food because of its high

concentration of sodium chloride, the sauce may be

useful as a source of biologically active substances,

traditional food supplements in the diet, are widely

used in the world as condiments, as flavoring,

material, and sometimes as a substitute for soy-bean

sauce (Watanabe et al., 2004). It was concluded that

summer capelin may be successfully utilized for the

production of fish sauce without added enzymes.

Capelin harvested during the summer season was

Sayed Mekawy Ibrahim

1

1

National Institute of Oceanography and Fisheries (NIOF), Fish Processing Technology Lab., Cairo, Egypt.

* Corresponding Author: Tel.: +02.42188008 ; Fax: + 02.42185320;

E-mail: ibrahim_niof@yahoo.com

Received 18 February 2008

Accepted 01 December 2009

Abstract

Fish sauce made from Gambusia (Affinis affinis) is evaluted in this study. Whole gambusia samples were carefully

washed, well mixed with 25% (w/w) salt and incubated at room temperature for five months (from January up to the end of

May, 2006). Salted fish was manually drained using cheese cloth to separate supernatant liquor to keep out salted fish. The

fish sauce obtained was composed of 65.97% moisture, 12.37% crude protein, 1.56% lipid, 19.33% ash and 9.08% sodium

chloride content. In addition, the pH value was 6.08 and the nonessential amino acids (3,864 mg/100 ml) were higher than the

essential amino acids (AAs) ones (2,172 mg/100 ml). Based on the biochemical criteria, nutritional value as well as microbial

aspects indicated that gambusia fish could be successfully utilized for fish sauce production as value added fish product.

Keywords: Gambusia (Affinis affinis), fish sauce, biochemical criteria, nutritional value, microbial aspects.

Sivrisinek Balnn (Affinis affinis) Balk Sosu retimi in Kullanm

zet

almann amac, sivrisinek balndan (Affinis affinis) balk sosunun retilmesi ve bunun besinsel deerlendirmesinin

belirlenmesidir. Sivrisinek balna ait rnekler dikkatlice ykanm, %25 (w/w) tuz ile iyice kartrlm ve be ay boyunca

(2006 yl Ocak ayndan Mays aynn sonuna kadar) oda scaklnda tutulmutur. Tuzlu baln bulunduu kapta oluan suyu

uzaklatrmak iin tlbent kullanlm ve elle szme yaplmtr. Elde edilen balk sosu; %65,97 nem, %12,37 ham protein,

%1,56 lipid, %19,33 kl ve %9,08 sodyum klorr iermektedir. pH deeri 6,08 ve esansiyel olmayan amino asitler (3.864

mg/100 ml) esansiyel amino asitlerden (AA) (2.172 mg/100 ml) daha yksek bulunmutur. Biyokimyasal kritere gre besin

deeri ve mikrobiyal durumu gz nne alndnda, sivrisinek balnn katma deerli balk rn olarak balk sosu retimi

iin baarl bir ekilde kullanlabilir.

Anahtar Kelimeler: Sivrisinek bal (Affinis affinis), balk sosu, biyokimyasal kriterler, besin deeri, mikrobiyal etki.

170 S. M. Ibrahim / Turk. J. Fish. Aquat. Sci. 10: 169-172 (2010)

more suitable as a raw material than capelin harvested

during the winter season, due to higher proteolytic

activity. Reduced salt content in processing may help

increase the fermentation rate as well as improve

nutritional properties by reducing the sodium content

(Hjalmarsson et al., 2007). The Gambusia fish is a

small freshwater species and it is not normally used

for human consumption. Therefore, the main

objectives of this work were to utilize Gambusia

(Affinis affinis) as by-catch for sauce production, also

to set a standard for proximal analysis and nutritional

value for fish sauce produced as value added fish

product for Egyptian consumers.

Materials and Methods

Fresh raw Gambusia Affinis affinis (5.281.75

cm length and 1.630.88 g weight) were obtained

from El-Qanatir EL-Khairia Fish Research Station,

National Institute of Oceanography and Fisheries

(NIOF) during harvesting season of 2005. The

samples were well mixed with 25% (w/w) finally

refined sodium chloride (Bono salt, Saltines Co.) by

gloved hands. They were packed in polyethylene

bags, tightly sealed and put into screw capshard

plastic containers. After that, all containers were

incubated at room temperature for 150 days (from

January to the end of May, 2006). After that, salted

fish was manually drained using cheese cloth to

separate fish sauce to keep out salted fish.

Analytical Methods

The moisture, crude protein (TNx6.25), total

lipid and ash content were analyzed using standard

methods (AOAC, 1995). pH value (pocket-sized pH

meter), total volatile base nitrogen (TVB-N) content

and Thiobarbituric acid (TBA) number were

determined (Pearson, 1976). Trimethylamine nitrogen

(TMA-N) was measured (AOAC, 1995). Individual

amino acids were determined using reverse phase

HPLC; hydrolysis, derivatization and analysis were

performed according to the Pico-Tag method

(Millipore Co-operative, 1987). Tryptophan was not

determined. Values of amino acids were expressed as

(mg/100 ml). For microbiological analysis, 10 g of

sample were transferred aseptically to 90 ml of sterile

0.1% (w/v) peptone water. Serial decimal dilutions in

0.1% peptone water were prepared and triplicate 1ml

of appropriate dilutions was poured on selective agar

plates. Plate count agar (PCA, Oxoid) for total

bacterial count (mesophilic bacteria), PCA (Oxoid)

contained 10% salt for halophilic bacteria count and

Potato-Dextrose Agar (PDA, Oxoid) for yeasts and

molds count were incubated at 37C for 48 hrs (FAO,

1979).

Microbiological results were converted into log

10

CFU/ml.

Statistical Analysis

Then results (triplicate determinations) of

chemical composition, biochemical criteria and

microbial aspects were expressed as means SE

(using SPSS 10).

Results

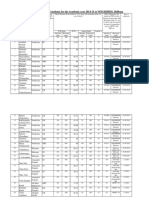

Proximal Analysis

Table 1 shows the compositional parameters of

raw gambusia. Proximal analysis of whole gambusia

samples (on wet weight basis) had the content of

73.42% moisture, 14.59% crude protein, 6.56% lipid

and 4.81% ash.

Fish Sauce

Proximal analysis of fish sauce was (on wet wt.

basis) composed of 65.97% moisture, 12.37% crude

protein, 1.56% lipid, 19.33% ash and 9.08% sodium

chloride content as shown in Table 2.

Biochemical Criteria

The values of pH, TVB, TMA and TBA of

gambusia sauce are shown in table (3). The pH value

of fish sauce was 6.08. On the other hand, TVBN

and TMA-N contents were 107.80 and 0.75 mg /100

ml, respectively. Concerning TBA, value was 1.55 mg

Malonaldhyde/1000 ml sauce Table 3.

Table 1. Proximal analysis (Mean SE) of whole

gambosia fish

% Constituent

73.420.05 Moisture

14.590.62 Crude protein

6.560.79 Lipid

4.810.13 Ash

Table 2. Proximal analysis (Mean SE) of fish sauce

% Constituent

65.970.09 Moisture

12.370.77 Crude protein

1.560.31 Lipid

19.330.08 Ash

9.081.03 Sod. chloride

Table 3. Biochemical criteria (Mean SE) of fish sauce

Value Criterion

6.080.02 pH

107.803.95 TVB-N (mg /100 ml)

0.750.40 TMA-N(mg /100 ml)

1.550.16 TBA (mg MA/1000 ml)

S. M. Ibrahim / Turk. J. Fish. Aquat. Sci. 10: 169-172 (2010) 171

Amino Acids (AAs) Composition

Amino acids (AAs) composition of Gambusia

sauce is shown in Table 4. Total AAS was 6,036 mg

/100 ml; 2,172 mg/100 g as essential AAS and 3,864

mg/100 ml nonessential AAS.

Microbiological Aspects

On the other hand, microbiological count of

TBC, HBC and yeasts and molds were 2.0, 2.30 and

2.10 log

10

cfu/ g sauce, respectively (Table 5).

Discussion

The compositional parameters of raw Gambusia

(Table 1) are quite similar of male capelin-by

products except ash content (2.3%) used for fish sauce

production (Gildberg, 2001). A great variety of raw

materials can be used for sauce production provided

that the content of proteolysis enzymes is sufficient to

give efficient solubilization and protein hydrolysis.

Most frequently fish sauce is made from small pelagic

species like anchovies and sardines (Amano, 1962;

Lee, 1990; Saisithi, 1994).

On the other hand, the results of chemical

composition of fish sauce (Table 2) are in agreement

with those reported by Cho et al. (2000); Park et al.

(2001) who reported that the range of chemical

composition of fish sauce was 61.40-79.20%

moisture, 0.9-13.70% crude protein and 18.20-

25.80% ash content.

The value (6.08) of pH in this study (Table 3)

was slightly increased compared to those (4.66-5.91)

reported by Cho et al. (2000) and Aquerreta et al.

(2001) and it is in agreement with those reported by

Ijong and Ohta (1995), Cho et al. (1999), and Park et

al. (2001). The high pH value of sauce may reflect

bacterial activity during fermentation and probably as

a consequence of the accumulation of basic

compounds (Aquerreta et al., 2001). Concerning

TVB, content was laid in range 14.1-338.6 mg TVB-

N /100 ml which were reported by Aquerreta et al.

(2001), Ruiz-Capillas et al. (2000). The content of

TVB-N might be attributable to the rate of hydrolysis

of fish muscles by fish enzymes and microbial

activity during fermentation under the lower salt

concentration (Ijong and Ohta, 1995). Whereas the

content of TMA (Table 3) was lower than (2.6360.5

mg/100 ml) found by Oh, (1999) and Ruiz-Capillas et

al. (2000). In addition, TBA figures in this work are

lower than those (13.8-66.5 MA/kg) found by Chang

et al. (1994) and Aquerreta et al. (2001).

AAs are major contributors to the palatability of

fish sauce and which derived as result breakdown of

fish proteins as affected by enzymes action. In

general, AAs composition in this work depends

mainly on the amount of salt added and fish source

used for sauce production. The nonessential amino

acids 3,864 mg/100 (nonessentials) are higher than

2,172 mg/100g (essentials). The results obtained are

in disagreement with those reported by Ijong and

Ohta (1995) and Shih et al. (2003) who reported that

the essential amino acids were higher than the

nonessential AAs.

Furthermore, the results of microbial load in

Table 5 were confirmed with Dissaraphong et al.

(2006) who reported that microbial microbial load of

fish sauce decreased with increase fermentation

period, possibly caused by high concentration of salt.

They added to halophilic bacteria counts decreased

gradually during fermentation and were lower than 1

log CFU/ml after 4 and 5 months, respectively

compared with the count of halophilic bacteria in

Table 5. Those micro-organisms might contribute to

the hydrolysis of proteins as well the flavor

development of the fish sauce obtained.

In conclusion, fish sauce contains an important

content of protein and essential amino acids and it is

safe for human consumption as well. Therefore, fish

gambusia can be utilized as raw material for fish

sauce production.

References

A.O.A.C. 1995. Official Methods of Analysis, 16th ed.

Association of Official Analytical Chemists

International, Arlington, Virginia, USA.

AL-Jedah, J.H., Ali, M.Z. and Robinson, P.K. 2000. The

inhibitory action of spices against pathogens that

Table 4. Amino acids composition (mg/100 ml) of fish

sauce

mg

/100ml

Amino acids

mg

/100ml

Amino acids

1248

965

441

*n.d.

679

179

260

92

Nonessential

Aspartic

Glutamic

Cystine

Tryptophan

Serine

Praline

Glycine

Alanine

63

129

142

556

211

29

241

214

111

476

Essential:

lysine

Therionine

Valine

Methionine

Arginine

Isolucine

Leucine

Phenylalanine

Histidine

Tyrosine

3864 Total (b) 2172 Total (a)

6036 Grand (a + b)

*n.d: not determined

Table 5. Microbiological aspects (log

10

cfu/ml) of fish sauce

log

10

CFU /ml Microbiological aspects

2.00.06 Plat count agar (PCA)

2.300.11 Halophilic bacteria (HB)

2.100.02 Yeasts and molds

172 S. M. Ibrahim / Turk. J. Fish. Aquat. Sci. 10: 169-172 (2010)

might be capable of growth in a fish sauce

(mehiawah) from the Middle East. International J.

Food Microbiology, 57(1/2): 129-133.

Amano, K. 1962. The influence of fermentation on the

nutritive value of fish with special reference to

fermented fish products of South-East Asia. In: E.

Heen and R. Kreuzer (Eds.), Fish Nutrition, Fishing

News Books, London, 180 pp.

Aquerreta, Y., Astiasaran, I. and Bello, J. 2001. Use of

exogenous enzymes to elaborate the Roman fish

sauce garum. J. of the Science of Food and

Agriculture, 82(1): 107112.

Chang, C.M., Ohsima, T. and Koizumi, C. 1994. Changes in

the composition of free amino acids, organic acids,

and ripening of "hatahata-zushi", a fermented fish

product of sandfish (Arctoscopus japonicus) and

boiled rice. Journal of the Science of Food and

Agriculture, 66: 7582.

Cho, Y.J., Im, Y.S., Lee, K.W., Kim, G.B. and Choi, Y.J.

1999. Changes of components in salt-fermented

northern sand lance, Ammodytes personatus sauce

during fermentation. J. of the Korean fisheries

Society, 32(6): 693698.

Cho, Y.J., Im, Y.S., Park, H.Y. and Choi, Y.J. 2000.

Quality characteristics of Southeast Asian salt-

fermented fish sauces. J. of the Korean Fisheries

Society, 33(2): 98-102.

Dissaraphong, S., Benjakul, S., Visessanguan, W. and

Kishimura, H. 2006. The influence of storage

conditions of tuna viscera before fermentation on the

chemical, physical and microbiological changes in

fish sauce during fermentation. Bioresource

Technology, 97: 20322040.

FAO 1979. Manuals of food quality control, 4-Rev.1-

Microbiological Analysis, Food and Agriculture

Organization of the United Nations, Rome, 14 pp.

Fukami, K., Ishiyama, S., Yaguramaki, H., Masuzaw, T.,

Nabeta, Y., Endo, K. and Shimoda, M. 2002.

Identification of distinctive volatile compounds in fish

sauce. J. Agric. Food Chem., (50): 5412-5416.

Gildberg, A. 2001. Utilisation of male Arctic Capelin and

Atlantic cod intestines for fish sauce production-

evaluation of fermentation conditions. Bioresource

Technol., 76: 119123.

Hjalmarsson, G.H., Park, J.W. and Kristbergsson, K. 2007.

Seasonal effects on the physicochemical

characteristics of fish sauce made from capelin

(Mallotus villosus). Food Chemistry, 103: 495504.

Ichimura, T., Hu, J., Quaaita, D. and Mayymas, S. 2003.

Angoiotensin.1-Converting enzyme inhibitory activity

and insulin secretion stimulative activity of fermented

sauce. J. Bioscience and Bioengineering, 96(5): 496

499.

Ijong, F.G. and Ohta, Y. 1995. Amino acid composition of

bakasang, a traditional fermented fish sauce from

Indonisia. Lebensm. Wiss. U.Technol., 28: 236-237.

Lee, C.H. 1990. Fish fermentation technology- a review. In:

P.J.A. Reilly, R.W.H. Parry, L.E. Barile, (Eds.) post

harvest technology, preservation and quality of fish in

South-East Asia, Echanis Press, Manila: 1-13.

Millipore Co-Operative 1987. Liquid Chromatographic

Analysis of Amino Acid in Foods Using a

Modification of the PICO.

Oh, K.S. 1999. Quality characteristics of salt-fermented and

sandlance sauce. Anchovy sauce. J. Korean Fish. Soc.,

32(3): 252255.

Park, J.N., Fukumoto, Y., Fujita, E., Tanaka, T., Washio, T.,

Otsuka, S., Shimizu, T., Watanabe, K. and Abe, H.

2001. Chemical Composition of Fish Sauces Produced

in Southeast and East Asian Countries. Journal of

food composition and analysis, 14: 113125.

Pearson, D. 1976. The Chemical Analysis of Food.

Churchilli, New York, London: 374410.

Ruiz-Capillas, C., Gillyon, C.M. and Horner, W.F.A. 2000.

Determination of volatile basic nitrogen and

trimethylamine nitrogen in fish sauce by flow

injection analysis. Eur. Food Res. Technol., 210: 434

436.

Saisthi, P. 1994. Traditional fermented fish: fish sauce

production. In: A.M. Martin, (Ed.), Fisheries

Processing: Biotechnological Application, Chapman

and Hall, London: 111131.

Sanceda, N.G., Suzuki, E. and Kuratal, T. 2001.

Development of normal and branched chain volatile

fatty acids during the fermentation process in the

manufacture of fish sauce. Journal of the Science of

Food and Agriculture, 81: 10131018.

Shih, I.L., Chenb, L.G., Yu T.S., Chang, W.T. and Wang,

S.L. 2003. Microbial reclamation of fish processing

wastes for the production of fish sauce. Enzyme and

Microbial Technology, 33: 154162.

Watanabe, F., Michihata, T., Takenaka, S., Kittaka-Katsura,

H., Enomoto, T., Miyamoto, E. and Adachi, S. 2004.

Purification and characterization of corrinoid

compounds from Japanese fish sauce. J. Liquid

chromatography& Related Technologies, 27(13):

21132119.

Вам также может понравиться

- Assalamualaikum WR WBДокумент1 страницаAssalamualaikum WR WBPurnama WIrawanОценок пока нет

- SKIMMINGДокумент7 страницSKIMMINGPurnama WIrawanОценок пока нет

- Purnama Wirawan. 2018. "Документ2 страницыPurnama Wirawan. 2018. "Purnama WIrawanОценок пока нет

- Contoh Proposal PDPДокумент31 страницаContoh Proposal PDPPurnama WIrawan100% (1)

- Beauty and the Beast: A Tale of Love Conquering AllДокумент3 страницыBeauty and the Beast: A Tale of Love Conquering AllRudi SaragihОценок пока нет

- Relationship Between Knowledge, Attitudes and Use of Communal Toilets in Fishermen VillageДокумент1 страницаRelationship Between Knowledge, Attitudes and Use of Communal Toilets in Fishermen VillagePurnama WIrawanОценок пока нет

- Quality Assessment of A Nigerian Marine Fish, Mullet (Liza Falcipinnis) Under Different Storage ConditionsДокумент8 страницQuality Assessment of A Nigerian Marine Fish, Mullet (Liza Falcipinnis) Under Different Storage ConditionsPurnama WIrawanОценок пока нет

- Bab 4.protectedДокумент3 страницыBab 4.protectedPurnama WIrawanОценок пока нет

- Higher Algebra - Hall & KnightДокумент593 страницыHigher Algebra - Hall & KnightRam Gollamudi100% (2)

- Bekasam Bahasa InggrisДокумент6 страницBekasam Bahasa InggrisPurnama WIrawanОценок пока нет

- Worksheet Bio Me SДокумент2 страницыWorksheet Bio Me SPurnama WIrawanОценок пока нет

- Higher Algebra - Hall & KnightДокумент593 страницыHigher Algebra - Hall & KnightRam Gollamudi100% (2)

- Higher Algebra - Hall & KnightДокумент593 страницыHigher Algebra - Hall & KnightRam Gollamudi100% (2)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeОт EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeРейтинг: 4 из 5 звезд4/5 (5784)

- The Little Book of Hygge: Danish Secrets to Happy LivingОт EverandThe Little Book of Hygge: Danish Secrets to Happy LivingРейтинг: 3.5 из 5 звезд3.5/5 (399)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceОт EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceРейтинг: 4 из 5 звезд4/5 (890)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureОт EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureРейтинг: 4.5 из 5 звезд4.5/5 (474)

- The Yellow House: A Memoir (2019 National Book Award Winner)От EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Рейтинг: 4 из 5 звезд4/5 (98)

- Team of Rivals: The Political Genius of Abraham LincolnОт EverandTeam of Rivals: The Political Genius of Abraham LincolnРейтинг: 4.5 из 5 звезд4.5/5 (234)

- Never Split the Difference: Negotiating As If Your Life Depended On ItОт EverandNever Split the Difference: Negotiating As If Your Life Depended On ItРейтинг: 4.5 из 5 звезд4.5/5 (838)

- The Emperor of All Maladies: A Biography of CancerОт EverandThe Emperor of All Maladies: A Biography of CancerРейтинг: 4.5 из 5 звезд4.5/5 (271)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryОт EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryРейтинг: 3.5 из 5 звезд3.5/5 (231)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaОт EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaРейтинг: 4.5 из 5 звезд4.5/5 (265)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersОт EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersРейтинг: 4.5 из 5 звезд4.5/5 (344)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyОт EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyРейтинг: 3.5 из 5 звезд3.5/5 (2219)

- The Unwinding: An Inner History of the New AmericaОт EverandThe Unwinding: An Inner History of the New AmericaРейтинг: 4 из 5 звезд4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreОт EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreРейтинг: 4 из 5 звезд4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)От EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Рейтинг: 4.5 из 5 звезд4.5/5 (119)

- Getting HSE Right A Guide For BP Managers 2001Документ62 страницыGetting HSE Right A Guide For BP Managers 2001Muhammad Labib Subhani0% (1)

- Practitioner Review of Treatments for AutismДокумент18 страницPractitioner Review of Treatments for AutismAlexandra AddaОценок пока нет

- Social Welfare Administrartion McqsДокумент2 страницыSocial Welfare Administrartion McqsAbd ur Rehman Vlogs & VideosОценок пока нет

- Admission For 1st Year MBBS Students For The Academic Year 2014-2015Документ10 страницAdmission For 1st Year MBBS Students For The Academic Year 2014-2015Guma KipaОценок пока нет

- A Harmonious Smile: Biological CostsДокумент12 страницA Harmonious Smile: Biological Costsjsjs kaknsbsОценок пока нет

- WORKPLACE TB POLICYДокумент4 страницыWORKPLACE TB POLICYGigi CabanaОценок пока нет

- Pregnancy Calendar For DogsДокумент3 страницыPregnancy Calendar For DogsVina Esther FiguraОценок пока нет

- Local Conceptual LiteratureДокумент3 страницыLocal Conceptual LiteratureNatasha Althea Basada LegaspiОценок пока нет

- Ecological PyramidsДокумент19 страницEcological Pyramidsnandhinidish100% (1)

- B29061KДокумент13 страницB29061KMeethuanОценок пока нет

- Bcspca Factsheet Life of An Egg Laying Hen PDFДокумент2 страницыBcspca Factsheet Life of An Egg Laying Hen PDFAnonymous 2OMEDZeqCDОценок пока нет

- Curriculum Map Grade 9 Health: T (N .) M U T C C S P S C S A A R I C V Quarter 1Документ5 страницCurriculum Map Grade 9 Health: T (N .) M U T C C S P S C S A A R I C V Quarter 1joan niniОценок пока нет

- Dat IatДокумент4 страницыDat Iatscribd birdОценок пока нет

- Chemotherapy-Induced Neuropathic PainДокумент7 страницChemotherapy-Induced Neuropathic Paintita_leo2Оценок пока нет

- Hazards of Dietary Supplement Use: Anthony E. Johnson, MD Chad A. Haley, MD John A. Ward, PHDДокумент10 страницHazards of Dietary Supplement Use: Anthony E. Johnson, MD Chad A. Haley, MD John A. Ward, PHDJean CotteОценок пока нет

- Common Diseases of Leafy GreensДокумент6 страницCommon Diseases of Leafy GreensAgung PurnomoОценок пока нет

- Hypertension Drugs Cheat Sheet: by ViaДокумент3 страницыHypertension Drugs Cheat Sheet: by ViaGulzaib KhokharОценок пока нет

- Teenage PregnancyДокумент12 страницTeenage PregnancyJoemel Baui85% (13)

- Influence of Social Capital On HealthДокумент11 страницInfluence of Social Capital On HealthHobi's Important BusinesseuОценок пока нет

- Environmental Hazards For The Nurse As A Worker - Nursing Health, & Environment - NCBI Bookshelf PDFДокумент6 страницEnvironmental Hazards For The Nurse As A Worker - Nursing Health, & Environment - NCBI Bookshelf PDFAgung Wicaksana100% (1)

- Roberts Race Gender DystopiaДокумент23 страницыRoberts Race Gender DystopiaBlythe TomОценок пока нет

- The Tocqueville Review/La Revue Tocqueville, Vol. XXVII, N° 2 - 2006Документ16 страницThe Tocqueville Review/La Revue Tocqueville, Vol. XXVII, N° 2 - 2006Valente EnacheОценок пока нет

- MicroMaxx 3.3 UG ENG P06435-02B e 1 - 1Документ200 страницMicroMaxx 3.3 UG ENG P06435-02B e 1 - 1Waheed MidoОценок пока нет

- Guidelines For Good Distribution Practices For Drugs, Cosmetics, Medical Devices and Household Chemical SubstancesДокумент4 страницыGuidelines For Good Distribution Practices For Drugs, Cosmetics, Medical Devices and Household Chemical SubstancessboaduappiahОценок пока нет

- PancreatoblastomaДокумент16 страницPancreatoblastomaDr Farman AliОценок пока нет

- "PASS" Principles For Predictable PDFДокумент10 страниц"PASS" Principles For Predictable PDFkishan bordaОценок пока нет

- Everything You Need to Know About Prenatal CareДокумент5 страницEverything You Need to Know About Prenatal Carelaura fernandiaОценок пока нет

- BDD Fact SheetДокумент2 страницыBDD Fact SheetKeen ZeahОценок пока нет

- Ageism PowerpointДокумент11 страницAgeism Powerpointapi-254132646Оценок пока нет

- Autism Case Report on 3-Year-Old MaleДокумент24 страницыAutism Case Report on 3-Year-Old MaleMichael John CanoyОценок пока нет