Академический Документы

Профессиональный Документы

Культура Документы

Final Report

Загружено:

DharminSavaliyaИсходное описание:

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Final Report

Загружено:

DharminSavaliyaАвторское право:

Доступные форматы

1

CHAPTER 1

INTRODUCTION

1.1 Story of quality and 5S concept

During the time of World War II, it virtually destroyed the production capability of Europe

and Asia. On the contrary, the United States (U.S) production capability greatly expanded

since their major emphasis was on quantity and not quality production. However, as poor

as it was in quality, the U.S still produced the best in the world compared to other nations.

In late 1940s, Dr. W. Edwards Deming, a U.S quality control expert began working with

the Japanese and continued doing so periodically for several years.

The Japanese developed the quality circle concept during the early 1960 and 20 years later,

the concept had expanded to more than a million organizations. At the same time, Dr.

Genichi Taguchi, a Japanese quality expert, introduced new statistical concept that was

invaluable in improving process and product quality. Due to this improvement, Japanese

industry ultimately has developed in various technologies all over the world. Following in

their footsteps, U.S made some drastic changes in strengthening their power in the global

age. Example of their improvement is:-

Ford Motor Company decided to do things differently following the Japanese. From the

beginning all the disciplines from design through assembly to marketing came on stream in

unison. All of the relevant disciplines therefore interacted and contributed from the

beginning. The plant was modernized and Ford personnel visited assembly plants,

manufacturing facilities, major suppliers. The Ford employee was also asked what they

would like to see in a new car (Waterman, 1987).

Besides all kinds of quality improvement techniques developed, one of the most famous is

the 5S concept developed by the Japanese. (Osada, 1991) developed the original concept of

5-S in the early 1980s. 5S is the acronym for five Japanese words. They are:- (a) Seiri (b)

Seiton (c) Seiso (d) Seiketsu (e) Shitsuke

2

Respectively, Osada refers to the 5Ss as the five keys to a total quality environment. The

Japanese have been widely practicing 5-S technique and believe it can help in all aspects of

life.

1.2 DISCOVERY OF 5S:

Thirty to forty years ago researchers started studying the secret of success of

Japanese manufacturing companies

5S turned out to be the most impressive "secret"

The factories were so well organized that abnormal situations were readily apparent

Equipment were so clean and well maintained that any problem such as a loose bolt

or leaking oil could be easily seen

This passion of cleanliness and orderliness became a hallmark of Japanese

organizations

1.3 Background of the problem:

Satisfying the customer, through making a good product is the main objective of every

manufacturing company. In competition, company is not only to provide cost effective

products but also good in quality as well, which satisfy the demand. Fail to check the level

of their quality consistently will have a consequence on the continuation of the product. It

is necessary for the company to have the suitable quality management methods that fits to

the needs, types of product and its activities. This study is based on a case study in a

manufacturing

3

1.4 Objectives:

Improve housekeeping

Make every individual responsible for housekeeping

Beautify by simple means

Productivity improvement by saving time, space etc.

4

CHAPTER 2

WHAT IS 5S AND METHODOLOGY

2.1 What is 5S?

5S is a systematic approach for improvement of quality and safety by organizing a

Workplace. It is a methodology which advocates;

What should be kept

Where should be kept

How should be kept

5S is a Japanese concept of housekeeping having reference to five Japanese words starting

with letter S. Figure S.1 illustrates these words with their English equivalent words and

for what these words stand for?

5 S Japanese English

1 S Seiri Sort out unnecessary items in the workplace and discard them.

2 S Seiton Arrange necessary items in good order.

3 S Seiso Clean your workplace thoroughly so that there is no dust on floors, machines and

equipment.

4 S Seiketsu Maintain high standards of housekeeping at workplace at all times.

5 S Shitsuke Train people to follow good housekeeping disciplines.

TABLE. 2.1: MEANING OF 5S

5

2.1.1 The First S Sorting

Meaning: -Distinguish between necessary and unnecessary

items and eliminate the unnecessary items

Activity: - Establish a criteria for eliminating unwanted items

-Eliminate unwanted items either by disposing them or

by relocating them.

Success: - Area saved or percentage of space available

Indicator

2.1.1.1 PROCESS:

Separating the needed from the not needed and discard the not needed

Eliminate not-needed items and perform an initial cleaning

Establish criteria/handling of items

The list should include raw material, finished product, tools, tackles, dust bin,

facilities like chair, table, bins etc. nothing should be left unlisted.

Make a list of all the items in the department.

Identify not-needed items.

Appropriate authority should decide which items can be disposed of and which

items need to be kept in the department.

Move not-needed items to holding area

Conduct an initial cleaning

Items marked for disposal should be disposed off in a safe manner.

6

2.1.1.2 Identifying unnecessary:

1. Parts & Work in Process (WIP)

Things fallen back behind the machine or rolled under it

Broken items inside the machine

Things under the racks/ platform

Extra WIP

Stock of rejected items

Items accumulated over period for rework

Material awaiting disposal decision

Material brought for some trial, still lying even after trial

Small qty. of material no longer in use

2. Tools, Tooling, Measuring devices

Old jigs, tools not in use are lying

Modified tools, tooling for trial, are lying after trial

Worn out items like bushes, liners, toggles etc. lying

Broken tools, bits, etc. may be lying

Measuring equipment not required for the operation

being performed , is lying

3. Contingency Parts

Many times storage place for contingency parts become a last refuge for broken

parts, surplus items and things nobody is likely to use

4. Shelves and Lockers

Shelves and lockers tends to collect things that nobody ever uses, like surplus,

broken items etc.

5. Passages and Corners

Dust, material not required seem to gather in corner

6. Besides Pillars and under the stairs

These places tend to collect junk, spittoon etc.

7

7. Walls and Bulletin Boards

Old out dated notices which have lost their relevance

Posters or bulletins on wall

Dust, remains of torn notices, cell tape pieces

8. Floor, Pits, Partitions

Defective parts

Protection caps, covers

Packing material

Hardware items , small items

Even tools, tooling

Items dropped on the floor are never picked

9. Computer Hard Disk

Many unwanted, outdated, temporary files pile up

Dealing with papers

How to reduce papers on your table ?

1. Make a single pile of papers

2. Go through them and sort in following categories

a) Immediate action

b) Low priority

c) Pending

d) Reading material

e) For information

4 D Principle

DO

DELEGATE

DELAY

DUMP

8

2.1.2 The Second S Set in Order

Meaning: -To determine type of storage and layout that will ensure easy

accessibility for everyone.

Activity: -Functional storage

- Creating place for everything and putting everything in its

Place

Success: -Time saved in searching

Indicator - Time saved in material handling

2.1.2.1 PROCESS:

A place for everything and everything in its place, clean and ready to use

Arrange workplace for safety and efficiency

After disposing unwanted material, provide appropriate place for every item that

has to be kept in the department.

Identify key equipment and supplies

Determine location for each item

While providing the place the ergonomic factors and safety aspects have also to be

considered

Place for movement of men and material should also be provided.

Place should be distinctly identified and marked.

9

2.1.2.2 How to achieve Systematic Arrangement?

1. Decide where things belong

2. Decide how things should be put away

3. Obey the Put away rules

1. Decide where things belong

- Standardize Nomenclature

- Determine an analytical method of storage

- Name & locations to everything. Label both item and location

- Store material functionally

- Prevent mistakes with coding by shapes & color

2. Decide how things should be put away

- Follow first in first out rule

- If two identical items are to be located, then store them separately, color code them.

3. Obey the rules

- Put the things back to their location after their use

2.1.2.3 Area of activity:

1. Outlining and Placement Marks

- Mark boundaries of dept., aisles, Machines

- Follow straight line, right angle rule

- Nothing shall be kept outside the boundaries

2. Stands and shelves

- Keep only required number of stands and shelves

- Standardize height, size

- Provide casters where necessary so that it can be moved

10

3. Wires and Ducts

- Color code

- When there are multiple connections - bundle the wires, label them and make sure

that they are in straight line /right angle and firmly anchored

4. Machine-tools & Tools

- Put the tools in the order you need them

- Location of the tool should be such that it can be put away with one hand

- Try to eliminate some hand tools by permanently attaching it to the bolt head

5. Blades, Dies, Other important consumables

- Store them in the protected place

- Maintain these things regularly by applying rust preventive, oiling etc.

6. WIP- Work in Process

- Designate a place for each component/part

- Decide on how much quantity to be stored

- Ensure that there is no damage to good part during transit, they do not get rusty and

they are not mislabeled

7. Oils

- Reduce number of oils used (Standardize)

- Color code for oil

- Safety aspects - fire prevention, pollution, leak, spillage

8. Instrumentation & Measuring Devices

- Label them, show direction of flow

11

FIG. 2.1: Implementation of first and second S

BEFORE AFTER

12

2.1.3 The Third S Systematic Cleaning

Meaning: Cleaning trash, filth, dust and other foreign matter.

Activity: - Keep workplace spotlessly clean

- Inspection while cleaning

- Finding minor problems with cleaning inspection

Success: - Reduction in machine down time

Indicator - Reduction in no. of accidents

2.1.3.1 PROCESS:

Cleaning for Inspection

Perform daily cleaning and inspection to understand work conditions

- Clean everything including material, floor, containers, walls, windows etc.

- Identify points to check for performance

- Determine acceptable performance

- Determine visual indicators/controls

- Mark equipment/controls

- If necessary painting also should be done.

- While painting follow color codes wherever applicable.

- Insist on regular cleaning at the end of the work

13

FIG. 2.2: Cleaning and Inspection

14

2.1.3.2 Cleaning-Inspection points for most equipment

1. Cleaning

- Grime, clogging, dust balls, rust, leakage etc.

2. Oils

- No oil, Low oil, leakage, filter clogging, dirty oil, dirty or bent oil lines, clogged

drainage, oil spillage, worn& torn ports etc.

3. Tightening

Loose bolts, welding detachment, loose parts, vibration or bumping noise, friction

4. Heat

Oil tanks, motors, heater, axles, control panels, washing/ cleaning water, bearing, wiring

etc.

5. Breakage Cracks

Breakage, cracks, dent on sliding parts, handle has come off, broken switches, wire joints

come off, wires are broken or crack, crack dial of various pre. gauges, meters etc.

2.1.3.3 Function wise Cleaning check list of equipment

1. Pneumatics

- Compressed Air lines, air valves, connections, meters, filters, reservoirs etc.

2. Hydraulics

- Hydraulic oil tank, oil valves, filters, pumps, hoses, gauges, cylinders etc.

3. Mechanical & Power Train

- Motor fan, fan belt, couplings, Joints, pulleys, chains, pump bearings etc.

15

4. Electrical

- Control panel, lamps, light, switch, sensors, wiring, ducts, fuses etc.

5. Tooling

- Tools, fixtures, gauges, die, measuring instruments, etc.

6. Equipment Specific

- Furnaces, rollers, CNC machines, etc.

16

2.1.3 The Fourth S Standardizing

Meaning: Setting up standards / Norms for a neat, clean, workplace and

details of how to maintain the norm (Procedure)

Activity: - Innovative visual management

- Color coding

- Early detection of problem and early action

Success: -Increase in 5S indicator

Indicator

2.1.4.1 PROCESS:

Developing Common Methods for Consistency

- Make abnormal conditions noticeable and document agreements

- Document agreements and checks

- Establish/document standard methods across similar work areas

- Document new standard methods

- Maintain high standards of housekeeping at workplace at all times.

- Ensure that people keep the items at designated place after its use.

- If possible, design the system such that if something is missing from the place, it is

easily highlighted

- Regularizing 5S activities so that abnormalities are revealed

- Make it easy for everyone to identify the state of normal or abnormal condition

- For maintaining previous 3S, deploy

17

2.1.4.2 Visual management:

- It has been estimated by scientific study that 60% of all human activities starts with

sight

- 5S is easy to do once. It is consistency that is difficult. That is why Visual

- Management is so important, so that everybody will know that there is some

problem.

What visual control communicates?

It grabs one or more of our senses in order to

- Alert us to an abnormality

- Help us recover quickly

- Promote adherence and prevention

- Enable successful self management

Some methods for visual communication:

- Color coding

- Use of Labels

- Danger alerts

- Indication where things should be put

- Directional arrows/ marks

- Transparent covers

- Performance indicators

Some methods for visual communication Labels

- Precision management labels

- Inspection labels

- Temperature labels

- Responsibility labels

18

Points to remember in making visual control tools

- Make them easy to see from distance

- Put the display on the things

- Everyone can tell what is right and what is wrong

- Anybody can follow them and make necessary corrections easily

- Work place should look brighter & orderly

Some everyday visual management examples

- Traffic signal

- Zebra crossing

- In car - Petrol indicator

- Speed indicator

- Direction arrows

- Electric danger sign etc.

19

FIG. 2.3: EXAMPLES OF VISUAL COMMUNICATION

20

2.1.5 The Fifth S Sustaining

Meaning: -Every one sticks to the rule and makes it a habit

Activity: - Participation of everyone in developing good habits

- Regular audits and aiming for higher level

Success: -High employee morale

Indicator -Involvement of all people

2.1.5.1 PROCESS:

Holding the Gains and Improving

Maintain the gains from other 5S activities and improve

- Determine 5S Level of Achievement

- Perform routine checks

- Analyze results of routine checks

- Measure progress and plan for continuous improvement

Train people to follow good housekeeping discipline.

- Train people in 5 S, housekeeping etc.

- Lead by example.

- Maintain discipline in every aspect

We need everyone to maintain 5S guidelines.

To maintain DISCIPLINE, we need to practice and repeat until it becomes a way of

life.

Discipline is the Core of 5S

Discipline means making a steady habit of properly maintaining correct procedure.

21

Time and effort involved in establishing proper arrangement and orderliness will be

in vain if we do not have discipline to maintain it.

It shall be my constant effort to maintain my workplace in good order.

22

Before After

FIG. 2.4: AFTER SUCCESSFUL IMPLEMENTATION OF 5S

23

CHAPTER 3

ORGANIZATION IN INDUSTRY FOR 5S

3.1 Organization:

- Coordinators at department level

- Coordinator at each area level

- Training for all

- Audit each area and make action check list

- Implement actions

- Audit and evaluation on continuous basis

24

FIG. 3.1: Five S Communication Board

25

CHAPTER 4

IMPLEMENTATION AND ISSUES

4.1 Role of individuals

Role of top management in 5 S implementation

- Play the role of mentor

- Initiate the 5S program

- Provide resources

- Appreciate the efforts

Role of middle and line management in 5 S implantation

- Play the role of facilitator

- Take initiative in his area of work

- Train the people in 5S

- Give the feedback

Role of employees in 5 S implementation

- Participate actively.

- Give suggestions.

- Respect the opinion of others.

- Be a good team player, and

- Maintain discipline

26

4.2 Getting Started

Planning launches your 5S activity

Evaluating tells you what you need to do

Preparing gets you ready for implementation

4.2.1Planning for Implementation

- Assemble a 5S Lead team

- Define the work area 5S boundaries

- Assign work group members to their 5S areas

- Install a 5S communication board

- Determine 5S targets, activities, and schedule

- Review/finalize plans with work group and site leadership

4.2.2 Preparing for Implementation

- Obtain existing standards for color-coding and signage

- Decide on 5S color-coding and signage standards

- Prepare for Sorting

- Prepare for Simplifying

- Prepare for Systematic Cleaning

- Prepare for Standardizing

- Prepare for Sustaining

4.2.3 Summary: Implementing Five Ss

- Share 5S Overview

- Choose work area implementation group

- Determine implementation targets, activities, and schedules

- Document current situation

- Apply 5Ss

- Document improvements

- Determine new improvement goals and action steps

27

4.2.4 Issues and Concerns

- Communicating across shifts

- Disposing of, or moving, personal items

- Making time available

- Following agreements consistently

- Maintaining the gains

- Giving rewards and recognition

- Integrating 5S with other improvement activities

28

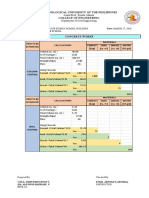

TABLE. 4.1: 5S ACHIVEMENT LEVELS

29

CHAPTER 5

ADVANTAGES OF 5S

ADVANTAGES OF 5S:

- If tools and materials are conveniently located in uncluttered work areas

- Operators spend less time looking for items

- This leads to higher workstation efficiency, a fundamental goal in mass

production

- A clean and tidy workplace leads to greater wellbeing and increased

motivation

- Company image improves

- Health and Safety is ensured

- Machine maintenance

- Quality

- Productivity

- Lean Manufacturing

- Results in a place easier to manage

- Smooth working no obstruction

- No deviation, no problems

- Everyone knows where the things are supposed to be

- Time saving

- Quick retrieval

- Accidents & mistakes minimized

- Increases space

- Creates workplace ownership

- Foundation of all QC tools

- Continuous quality improvement

- Kindergarten of quality tools & techniques

- Visual management system

30

- Visual control to see the abnormalities

- Simple signals that provide an understanding of the condition (normal/

abnormal)

- A look at the process reveals its direction (right/wrong)

31

CHAPTER 8

REFERENCES

- Development Of 5S Practice Checklist For Manu. Ind. (Proceedings of the world

congress on Engineering 2009 Vol 1- ISBN: 978-988-17012-5-1, (WCE 2009, July

1-, 2009, London U.K.)

- The Use Of 5S as Sustainable Practices in Manu. Small and Medium- Sized

Enterprises ( From: Global Conference on Operations and Supply Chain

Management(GCOM 2012) Proceeding- ISBN: 978-967-5705-06-9)

- Implementation Of 5S Practices in the manufacturing Companies: A case Study

(From: American Journal Of Applied Sciences 7(8): 1182-1189, 2010 ISBN

1546-9329)

- http://en.mwikipedia.org/wiki/5S_(methodology)

- www.isixsigma.com/dictionary/5s

- www.siliconfareast.com/5S.htm

- www.slideshare.net/anurag.aries/what-is-5-s

- www.japanintecultural.com/en/news/default.aspx?newsid=93

- wiki.answers.com/Q/what_is_5s_concept

- www.scribed.com/mobile/doc/52007715

- scholar.google.co.in/scholar?hl=en&q=5s+Japanese+concept&btng

Вам также может понравиться

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeОт EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeРейтинг: 4 из 5 звезд4/5 (5794)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceОт EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceРейтинг: 4 из 5 звезд4/5 (895)

- The Yellow House: A Memoir (2019 National Book Award Winner)От EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Рейтинг: 4 из 5 звезд4/5 (98)

- The Little Book of Hygge: Danish Secrets to Happy LivingОт EverandThe Little Book of Hygge: Danish Secrets to Happy LivingРейтинг: 3.5 из 5 звезд3.5/5 (400)

- The Emperor of All Maladies: A Biography of CancerОт EverandThe Emperor of All Maladies: A Biography of CancerРейтинг: 4.5 из 5 звезд4.5/5 (271)

- Never Split the Difference: Negotiating As If Your Life Depended On ItОт EverandNever Split the Difference: Negotiating As If Your Life Depended On ItРейтинг: 4.5 из 5 звезд4.5/5 (838)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyОт EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyРейтинг: 3.5 из 5 звезд3.5/5 (2259)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureОт EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureРейтинг: 4.5 из 5 звезд4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryОт EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryРейтинг: 3.5 из 5 звезд3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnОт EverandTeam of Rivals: The Political Genius of Abraham LincolnРейтинг: 4.5 из 5 звезд4.5/5 (234)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaОт EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaРейтинг: 4.5 из 5 звезд4.5/5 (266)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersОт EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersРейтинг: 4.5 из 5 звезд4.5/5 (345)

- The Unwinding: An Inner History of the New AmericaОт EverandThe Unwinding: An Inner History of the New AmericaРейтинг: 4 из 5 звезд4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreОт EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreРейтинг: 4 из 5 звезд4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)От EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Рейтинг: 4.5 из 5 звезд4.5/5 (121)

- Switch 3COM 2952Документ4 страницыSwitch 3COM 2952Fabio de OliveiraОценок пока нет

- HydacДокумент4 страницыHydacmarkoОценок пока нет

- Lab 1 Level 0 Illumination Lux MeterДокумент4 страницыLab 1 Level 0 Illumination Lux MeterTaufiq Al IlhamОценок пока нет

- Instruction Manual: Fundus CameraДокумент37 страницInstruction Manual: Fundus Camerashakil ahmadОценок пока нет

- What Is A StartupДокумент3 страницыWhat Is A StartupArun SoniОценок пока нет

- Mac Mini: User's GuideДокумент106 страницMac Mini: User's GuideLouis WilliamsОценок пока нет

- Module 5Документ80 страницModule 5Big Brown BeastОценок пока нет

- Unit 2Документ17 страницUnit 2PRASATH RОценок пока нет

- Fundamentals V3F18: The LWD Is Adjusted With The User Interface. AdjustmentДокумент1 страницаFundamentals V3F18: The LWD Is Adjusted With The User Interface. AdjustmentOsman ElmaradnyОценок пока нет

- 2 Concrete Works CompuДокумент14 страниц2 Concrete Works CompuALFONSO RAPHAEL SIAОценок пока нет

- DB 0032400 enДокумент2 страницыDB 0032400 enMihai BancuОценок пока нет

- Huawei Parameter Strategy: Security LevelДокумент22 страницыHuawei Parameter Strategy: Security Leveloshwa_ishОценок пока нет

- Q1 Module 7 - Topic7Документ2 страницыQ1 Module 7 - Topic7Kristel Ann MontianoОценок пока нет

- RBS 6000 Commissioning Procedure - PA1Документ17 страницRBS 6000 Commissioning Procedure - PA1He Ro90% (10)

- Export Import Between SQL TablesДокумент5 страницExport Import Between SQL TablesSantiago Alcaraz MartinezОценок пока нет

- To Study On Marketing Strategies of SamsungДокумент64 страницыTo Study On Marketing Strategies of SamsungVaibhav Shah MangalamjobsОценок пока нет

- Batangas State University College of Engineering, Architecture & Fine ArtsДокумент20 страницBatangas State University College of Engineering, Architecture & Fine ArtsJezreel GamboaОценок пока нет

- Harvey Gulf International Marine: Competency ProfileДокумент5 страницHarvey Gulf International Marine: Competency ProfileAntonio SerranoОценок пока нет

- Short Questions... DbmsДокумент10 страницShort Questions... DbmsMuhammad Jamal ShahОценок пока нет

- TSP071 BNV Cctalk Protocol Manual V2 (1) .4Документ47 страницTSP071 BNV Cctalk Protocol Manual V2 (1) .4nost winОценок пока нет

- ElectrecityДокумент2 страницыElectrecityMarchli AhmedОценок пока нет

- Ad Notam Display Frame Unit: Product HighlightsДокумент5 страницAd Notam Display Frame Unit: Product HighlightsVishal SuryawaniОценок пока нет

- PUMP MMTV Vertical Mixed Flow Multistage Pump With CanisterДокумент3 страницыPUMP MMTV Vertical Mixed Flow Multistage Pump With Canisterarondaniel ocampoОценок пока нет

- Strategic Management Term PaperДокумент18 страницStrategic Management Term PaperOchena RajkonnaОценок пока нет

- 08 - IP SubnettingДокумент20 страниц08 - IP Subnettingkndnew guadeОценок пока нет

- Documenting Software Architectures: Views and Beyond: June 2002Документ3 страницыDocumenting Software Architectures: Views and Beyond: June 2002Ioan AdascaliteiОценок пока нет

- Bugreport Lime - Global QKQ1.200830.002 2021 05 04 22 36 45 Dumpstate - Log 30853Документ30 страницBugreport Lime - Global QKQ1.200830.002 2021 05 04 22 36 45 Dumpstate - Log 30853Blackgouest 1043Оценок пока нет

- Company Report FS Work Draft !!!Документ26 страницCompany Report FS Work Draft !!!tsehay seidОценок пока нет

- How To Grow Audience On TikTokДокумент2 страницыHow To Grow Audience On TikTokIrene TayongОценок пока нет

- Caterpillar 785c 789c Off Highway Trucks Service TrainingДокумент20 страницCaterpillar 785c 789c Off Highway Trucks Service Trainingjames100% (46)