Академический Документы

Профессиональный Документы

Культура Документы

Economic and Physical Optimization of Hydraulic Fracturing

Загружено:

José TimanáИсходное описание:

Оригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Economic and Physical Optimization of Hydraulic Fracturing

Загружено:

José TimanáАвторское право:

Доступные форматы

SPE 111793

Economic and Physical Optimization of Hydraulic Fracturing

Marongiu-Porcu, M./University of Houston, Economides, M.J./University of Houston, Holditch, S.A./e!as A"M

University

#o$yright %&&', Society of Petroleum Engineers

his $a$er (as $re$ared for $resentation at the %&&' SPE )nternational Sym$osium and E!hi*ition on +ormation ,amage #ontrol held in -afayette, -ouisiana, U.S.A. ./0.1 February 2008.

his $a$er (as selected for $resentation *y an SPE $rogram committee follo(ing revie( of information contained in an a*stract su*mitted *y the author2s3. #ontents of the $a$er have not *een

revie(ed *y the Society of Petroleum Engineers and are su*4ect to correction *y the author2s3. he material does not necessarily reflect any $osition of the Society of Petroleum Engineers, its

officers, or mem*ers. Electronic re$roduction, distri*ution, or storage of any $art of this $a$er (ithout the (ritten consent of the Society of Petroleum Engineers is $rohi*ited. Permission to

re$roduce in $rint is restricted to an a*stract of not more than /&& (ords5 illustrations may not *e co$ied. he a*stract must contain cons$icuous ac6no(ledgment of SPE co$yright.

Abstract

Optimization has taken several different hues in all areas of engineering. Hydraulic fracturing, as applied to petroleum wells,

has had its share. In the past, and before the maturing of high-permeability fracturing and the tip screen out techniques, this

well stimulation procedure was limited to low-permeability reservoirs and unrestricted fracturing. In such cases, the fracture

length would be an appropriate design optimization variable against an economic criterion, e.g., the et !resent "alue

#!"$. %his involved the balancing of incremental future revenue against the cost of e&ecution. 'lso interesting are

parametric studies, allowing the variation of e&ecution variables and the detection of differences in their respective design

!". (uch differences would be useful in decisions to measure a variable or stay within reasonable assumptions. %he

emergence of higher-permeability fracturing and the )nified *racture +esign #)*+$ concept allowed two important notions.

*irst, there is no difference between low and high-permeability reservoirs in terms of benefiting for fracturing. ,ust e&ecution

issues need to be resolved. (econd, and more important, for any mass of proppant to be in-ected in any well, there e&ists only

one fracture geometry that would ma&imize production. %his geometry, consisting of length and propped width #with height

as a parasitic variable$ can be readily determined and, if placed, it will provide the ma&imum productivity inde&. 'll other

configurations would result in lower productivity values. %his is physical optimization.

In this paper we combine the two. the economic and physical. *or each proppant mass we first optimize the fracture

physically and then we apply the !" criterion. /e perform a series of parametric studies for a range of reservoirs and we

use economic variables that differ in various parts of the world. /e show how to determine the optimum fracture size. /e

then show how fracture treatments may be attractive in certain reservoirs in mature areas but not attractive elsewhere. /e

also show that for a diversified company, given the choice, few successful fractures in high-permeability reservoirs are far

preferable to fracturing large numbers of wells in lower permeability fields, although the latter can be made economically

attractive only through hydraulic fracturing.

ntroduction

'rguably, with the e&ception of some rare locations or companies, the petroleum industry has finally reached the stage where

hydraulic fracturing is no longer considered as a stimulation technique e&clusively suitable for low permeability formations.

%his took a couple of decades, at least, following the development of the tip screenout #%(O$ and the voluminous body of

work in places such as the 0ulf of 1e&ico and 2ussia.

3etter yet, fracturing is now viewed as an integral part of well and reservoir management and a mainstay of production

engineering rather than a choice of last resort for depleted or ine&plicably underperforming wells. *racturing has

continuously e&panded until it has become the completion of choice for all types of wells but, particularly, for gas wells.

%he choice to develop a field either with conventional completions or through the application of hydraulic fracturing has a

big impact on the number of wells to be drilled and on the in-fill plan of a field. %he tremendous advantage in fracturing most

wells is now largely accepted4 even near water or gas contacts, considered the bane of fracturing. High permeability

fracturing is finding application because it offers controlled fracture e&tent and limits drawdown.

' proper design and e&ecution of a fracturing treatment involves several disciplines such as reservoir, production and

completion engineering, requires a background in rock mechanics and fluid dynamics, is constrained by the physical limits of

% SPE ...78/

the materials and equipment used as well as by the operational issues, and last but not least must satisfy certain economic

criteria.

In such a comple& multi-sub-ect environment, it is not a trivial e&ercise to determine 5optimum6 conditions for the design,

the e&ecution and the post-treatment behavior of the well. 7learly, what represents an optimum condition from a certain

standpoint may not be as favorable from other aspects.

(ince the introduction of the 8conomides and "alk9

:

)nified *racturing +esign approach, the design of fracturing

treatments has generally headed towards the ma&imization of the well productivity #quantified by a Dimensionless

Productivity Index JD$. 'nother clearly important approach is the ma&imization of the revenues according to certain

economic criteria #for instance, the et !resent "alue$.

%he goal of this work is to show how the )*+ approach can be used to achieve a dual physical and economic

optimization, in virtually any reservoir type and under most realistic constrains that arise from e&ecution issues. /e will see

later on that the optimization procedure presented is consistent and systematic, and makes use of the output parameters

coming from the physical optimization as input for the selected economic criterion.

%he central idea of the )*+ technique is to select the appropriate optimum compromise between propped fracture length

and width, for a given proppant volume and depending on the properties of the reservoir and the selected proppant.

8conomides and "alk9

:

introduced the concept of the dimensionless Proppant Number #Np$ #which is the ratio of the fracture

volume and the reservoir drainage volume, ad-usted by the reservoir permeability and the proppant pack permeability, and

completely independent from fracture geometry$, and then they found that for a given value of Np there is an optimal

Dimensionless Fracture Conductivity #CfD$, at which the dimensionless productivity inde& JD is ma&imized. %he optimized

and specific dimensionless fracture conductivity leads also to the unique optimal fracture geometry #width and length$. /ide

and short fractures result for high-permeability reservoirs while narrow and long fractures result for low-permeability

reservoirs.

'n essential element of field e&ecution to obtain the indicated geometries is the tip screen out #%(O$ technique, which

allows the arrest of the lateral growth in order to increase the width of the fracture.

%his method has already been used in a wide range of real field applications with e&cellent results. 8ven more, in some

very progressive areas this design approach has been used to 5push the limits6 of today;s practices in hydraulic fracturing.

8conomides, +emarchos et al.

<-=

showed, for e&le, how relevant the mass of proppant is for the ma&imization of the

productivity inde&. +iyashev and 8conomides

>

presented field case studies of almost a thousand hydraulic fracture treatments

in /estern (iberia, providing a very valuable e&perimental support for the )*+ approach.

/ang et al.

?

considered the ad-ustments required to handle fluid flow impairments such as gas condensate accumulation

in the fracture face, while 2omero et al.

@

in their publication accounted for other two types of flow impediments, fracture face

damage and damage at the fracture-wellbore interface #57hoke (kin6, firstly introduced by 1ukher-ee and 8conomides

A

$.

/ang and 8conomides

B

showed how the )*+ approach can be applied to gas wells, especially in high-permeability

reservoirs, where fracturing is the most appropriate way to slash non-+arcy effects. Copez-Hernandez et al.

D

applied the

methodology to compensate for non-+arcy effects in the fracture.

/ei and 8conomides

:E

presented the applications of the )*+ technique to horizontal wells with multiple fractures for

both oil and gas reservoirs, +aal and 8conomides

::

further adapted the )*+ technique to in-fill drilling and to transversally

multi-fractured horizontal wells by considering non-square drainage areas and the sliced-partition of the drainage area along

the horizontal drain, and +emarchos et al.

:<

presented a set of field-proven procedures to optimally implement the )*+

technique during the sequence of operations required for a multi-fracturing treatment on an horizontal well.

Economic Optimization

%he cru& of hydraulic fracturing is production enhancement, meaning accelerating production in a depleting drainage. %he

question of course is whether this acceleration of the production, compared to a non-fractured well and assessed through their

respective present values of the revenue streams #one for a fractured well and another for a n-fractured well$ can be balanced

against the costs of the treatment.

In addition to the increase in production, an evaluation of the economics of a hydraulic fracturing treatment must consider

many factors, including treatment costs, additional reserves that may be produced before the well reaches its economic limit

and reservoir, risks associated to mechanical problems that could cause the treatment to be unsuccessful.

/hile there are other criteria for assessing economic attractiveness or lack thereof, for the purposes of this work, we will

use the et !resent "alue as the criterion for the optimization and the evaluation of the desirability of the specific hydraulic

fracture treatment.

%he !" criterion has been already selected by several researchers to monetize the incremental production obtained after

a fracturing treatment, but it has never been associated to a rigorous physical optimization such as the )*+ approach. o

matter how sophisticated the model used to predict fracture propagation and performance the economic optimization requires

a trial-and error process to determine the optimum treatment design from a set of the calculated physical designs.

*or instance, 3ritt

:=

used the !" to 5show a process by which the optimum fracture length and fracture conductivity can

be determined for wells in moderate-permeability oil reservoirs under primary depletion and secondary recovery processes6.

"eatch

:>

presented a comprehensive overview of the economics of fracturing and critiqued the methods of design

SPE ...78/ /

optimization. /arembourg et al.

:?

presented an outline of a design optimization process with the proper identification of

critical treatment variables. 'nderson and !hillips

:@

used the concept of the !" to calculate the appropriate amount of

proppant.

' particularly relevant work in this study was presented by 3alen et al.

:A

, who developed a comprehensive engineering

methodology. %heir procedure involved.

- the determination of optimal pumping parameters and ma&imum proppant coverage for a given hydraulic penetration4

- linking the reservoir deliverability, well producing systems and the optimized fracture geometry4

- economic analysis performed to calculate the !" for various design options.

/e will see later in this paper how the uniqueness of the solutions to the optimization problem provided by the )*+

approach greatly simplifies and makes straightforward the e&ecution of !" calculations for fracturing treatments.

0enerating the optimum fracture geometry will lead to the ma&imum well productivity, which is the physical optimization.

3ut all of that can be done within an economic optimization where the !" can be ma&imized and selecting the proppant

mass as the crucial parameter for the sensitivity analysis.

!"nchmar#ing $"ll P"rformanc" %ith th" &nifi"d Fractur" '"sign Approach

%he main implications and consequences arising from this concept were e&plicitly stated in earlier publications, referenced

above. *or a specified mass of proppant of a known permeability to be in-ected in a well within a drainage in a reservoir also

of a known permeability there e&ists only one dimensionless fracture conductivity at which the JD becomes ma&imum. %his

has been called the optimum conductivity. (maller and larger values of this conductivity lead to smaller JD;s. %he !roppant

umber becomes then a very important quantity in designing optimized fracture treatments because it provides the indicated

fracture dimensions as targets before the actual e&ecution design is considered. %his makes the fracture e&ecution subservient

to production enhancement which is a significant departure from past industry practices.

It is important to show how the )*+ approach can 5push the limits6 of fracture design for ma&imum production or

in-ection enhancement. %he issues of using more proppant of better permeability and how it affects the JD will be addressed.

One of the clear messages is that the better the proppant the larger the indicated treatment should be and not the opposite as

very conservative past practices have suggested.

(imilar findings have already been shown with a large set of parametric studies presented by 8conomides et al.

<-=

, as well

as in a field case study of almost a thousand hydraulic fracture treatments in /estern (iberia in which +iyashev and

8conomides

>

provided a substantial e&perimental confirmation to the concept.

A Parametric Study for the Maximization of the JD

%hree reservoir permeabilities were selected for the parametric studies. ? md, ?E md and ?EE md. In order to reflect the

differences in the rock stiffness from low to high permeability formations, three different plane strain moduli #E$ were

assigned to the three formations.

%hree different proppants were used for the study. ' <EF>E mesh sand #kf G @E,EEE md$, a <EF>E mesh manufactured

proppant #kf G <EE,EEE md$ and an BF:< mesh ceramic bau&ite #kf G BEE,EEE md$.

' limit of :,EEE psi was put as a constraint for the net pressure, which affects directly the surface treating pressure and

can have an effect also on the #unwanted$ fracture height migration. However, in practice, this value can be higher or lower

depending on the geological confinement of the reservoir. ' second physical constraint was to force the fracture width to be

at least = times the proppant diameter, in order to prevent the proppant to bridge and determine an involuntary screenout.

*inally, an in-ection time of no more than <> hours was used as third physical constraint.

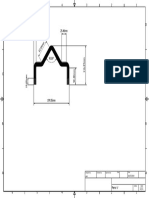

In *igure : the JD;s obtained from the designs pushing the limits of the physical constrains are plotted. %hese results

should be considered as target benchmarks, representing the best performance that could be achievable with the best-in-class

materials and techniques, currently known in the industry.

*rom a strictly physical point of view, the optimization of the well performance via ma&imization of the JD is -ust a matter

of how much one can 5push the limits6 of designs. o matter what the reservoir permeability is, the higher the proppant pack

permeability the higher the productivity inde& would be4 the larger the mass of proppant in-ected the higher the productivity

inde& would be, as well.

't this point it begins to be clear why the )*+ approach needs to be coupled with an economic optimization. %he

physical optimization of the fracture, for a given proppant mass and satisfying the imposed physical constraints, provides a

blue-print to follow on the field during the treatment in order to ma&imize the JD. 3ut this is not sufficient because an

economic optimization is warranted. )sing the !" criterion, the optimal amount of proppant at which the revenues coming

from the enhanced production minus the investment necessary to perform the fracturing treatment are ma&imized, is

determined.

9 SPE ...78/

(urbul"nc" in )atural *as $"lls and &nifi"d Fractur" '"sign Applications

%his section e&plains how the )*+ approach can be applied to a potentially high-rate natural gas well. In this case, the

effective proppant pack permeability that is a very important quantity in fracture design will have to be ad-usted downwards

because of turbulence effects. %he trouble is that the ad-ustment depends on the e&pected rate itself. 8conomides et al.

:B

presented a trial and error procedure combining the )*+ method with the 0idley

:D

ad-ustment to the proppant pack

permeability and the 7ooke

<E

correlations for flow in fractures.

' calculation was performed to illustrate this iterative

approach to fracture design for gas wells and even more

important, to show the effects that fracturing has on the reduction

of turbulence, perhaps as important a role as stimulation itself.

%able : summarizes the important variables for this e&ercise. '

range of permeability from E.E? to :EE md is used.

%o present the results in a convenient way, the folds of

increase between fractured and unfractured case are used. %he

first results are shown in *igure <, and in addition to the gas well,

also the folds of increase for an oil well are presented. 's the

reservoir permeability increases, for the oil well the folds of

production increase over a non-fractured well will decline. In the

e&le shown in *igure <, for E.: md the folds of increase are

over :E, whereas at :EE md the folds of increase approach <.

Figure 1: Pushing the limits: maximum JD theoretically achievable with the materials and constrains considered.

able 1: !esign variable values

!roppant mass for #two wings$, lbm <EE,EEE

(p gravity of proppant material #waterG:$ <.@?

!orosity of proppant pack E.=B

!roppant pack permeability, md :?E,EEE

1a& proppant diameter, Dpmax, inch E.E=:

!ermeable #leakoff$ thickness, ft ?E

/ell radius, ft E.>

/ell drainage area, acres =<E

!re-treatment skin factor E

*racture height, ft :EE

In-ection rate, bpm =E

2heology, !" #lbfFftH<$IsHnJ E.E:B

2heology, n! E.>?

Ceakoff coeff. in permeable layer, ftFmin

E.?

E.EE>

!oisson ratio, E.=B

2eservoir pressure, psi >,EEE

3ottom-hole flowing pressure, psi :,?EE

2eservoir temperature, K* :<E

0as viscosity, cp E.E:?

0as deviation factor ##$ E.D:E

0as specific gravity #$$ E.A:

7ooke;s constant #a$ :.?>

7ooke;s constant #b$ ::E,>AE

SPE ...78/ 1

%he most important conclusion from *igure < is the shape of the curve of the folds of increase for the gas wells. 't low

permeabilities, the gas trends are similar to those in oil, folds of increase decline as permeability increases. 3ut as

permeability increases, the trends diverge. a fractured gas well performs far better than a non-fractured high-permeability

well because of the considerable reduction in turbulence effects that adversely affect well performance and dominate radial

flow. %he obvious conclusion is that although fracturing is very attractive in oil wells, its attractiveness declines relatively in

higher permeabilities. 3ut in gas wells, fracturing becomes imperative at any permeability. It is fair to say that any gas well

above ? md will be greatly handicapped if not hydraulically fractured.

In *igure < as the effective permeability of the proppant decreases with increasing production rate, the theoretical width

of the fracture in a gas well would tend towards highly unrealistic value. /hen a limit of :,EEE psi was put as a constraint for

the net pressure, i.e., the calculations were arrested at the moment at which the value of :,EEE psi was achieved4 then the

width of the actual fracture is reduced and unavoidably the fracture length had to be increased #starting from the ? md

reservoir$. %he results are shown in *igure =.

E

<

>

@

B

:E

:<

:>

:@

E.E: E.: : :E :EE

"eservoir Permeability k # md

F

$

%

o

f

J

D

&

F

r

a

c

'

(

o

)

F

r

a

c

*

"ertical 0as /ell "ertical Oil /ell

Figure +: Folds of increase between fractured and unfractured wells. Fracture width is as wide as determined from

the o,timum values of JD and CfD.

: SPE ...78/

%he potential folds of increase will be significantly affected and trend downwards by the necessity to keep fracture width

within realistic values #and the ensuing net pressure during e&ecution$. %his effect is remedied readily if high-quality

proppant is used. %he reduced required width also reduces the net pressure, so, much larger treatments can be e&ecuted, or #as

in the case under analysis$ a less drastic departure from the optimum geometry is required in order to fulfill the limits

imposed on the net pressure. In both cases, higher JD values are e&pected. *igure > shows the shift in folds of increase by

using a much better quality proppant with proppant-pack permeability of ?EE,EEE md.

E

<

>

@

B

:E

:<

:>

:@

E.E: E.: : :E :EE

"eservoir Permeability k # md

F

$

%

o

f

J

D

&

F

r

a

c

'

(

o

)

F

r

a

c

*

"ertical Oil /ell "ertical 0as /ell '+,)(%8+ "ertical 0as /ell not ad-usted

Figure -: Folds of increase between fractured and unfractured wells. Fracture width is now

constrained in order to fulfill the condition of net ,ressure less than 1#... ,si.

E

<

>

@

B

:E

:<

:>

:@

:B

E.E: E.: : :E :EE

"eservoir Permeability k # md

F

$

%

o

f

J

D

&

F

r

a

c

'

(

o

)

F

r

a

c

*

"ertical Oil /ell "ertical 0as /ell '+,)(%8+ "ertical 0as /ell not ad-usted

Figure /: Folds of increase between fractured and unfractured wells. Fracture width is

still constrained in order to fulfill the condition of net ,ressure less than 1#... ,si# but

this time the ,ro,,ant ,ac0 ,ermeability is 1..#... md.

SPE ...78/ 7

%he crucial message from the calculations presented here is that hydraulic fracturing should be adopted as standard

completion for virtually any gas well. *racturing for gas wells not only leads to stimulation but, in addition, it reduces

turbulence effects which dominate a large range of natural gas wells.

Optimization of the design with the )*+ approach, modified to account for the reduction of the proppant pack

permeability, may be affected by physical limits, such net pressure during e&ecution. However, the selection of high-quality,

high-permeability proppant may allow the design of fracture geometries much closer to the desirable benchmarks as

determined by 5pushing the limits6 of fracture design.

Hydraulic Fractur" P"rformanc" in rr"gular 'rainag" +onfigurations

In this paper, until now hydraulic fracturing has been presented and treated as production enhancement for a single well.

8ven more relevant is the deployment of hydraulically fractured wells for reservoir e&ploitation strategies. In such situation

many issues need to be addressed such as well positioning, configuration and spacing. %he orientation of a fracture in a well

in relation to those of other fractured wells plays a significant role in optimizing rate and recovery.

'fter a well is fractured the flow patterns will change with linear flow replacing radial flow for an unfractured well.

+epending on the length of the fracture in relation to the drainage there may be linear flow permanently. /hen the fracture is

not e&tended enough to fully intersect the reservoir, after the initial linear flow regime period, pseudo-radial flow may

emerge. 's the level of stimulation increases so does the duration and magnitude of linear flow, with a corresponding

decrease in radial flow. %his behavior is very significant, since it shows that the linear shape of the hydraulic fracture

suggests rectangular drainage area in a reservoir e&ploitation strategy.

%he key point here is to recognize that multiple fracturing treatments will no longer drain square drainage areas but

elongated ones, whose aspect ratio depends on the number of infield wells. 3ecause the equations and calculation algorithms

for the )*+ were all derived for square drainage areas, it is necessary to present the generalization of the )*+ approach for

irregular #not-square$ drainage areas. %hen, a calculation scheme for combining infield drilling with fracturing for gas wells

will be presented.

%he adaptation of the )*+ model to non-square drainage areas, and more interestingly, to the sliced-partition of a given

drainage area for infield drilling applications, was presented by +aal and 8conomides

::

.%hey used a direct boundary element

method to generate new analytical correlations for the JD and the CfD.

%he tracking of the problem starts with an initial

square reservoir with dimensions xe and ye and a

hydraulically fractured well positioned in the center

#and the x direction is assumed to be the fracture

propagation direction$. %hen other fractured wells are

added to the same drainage area, by placing them in

the center of rectangular portions obtained by slicing

the square with respect to the y direction. In other

words, if we define the aspect ratio as the ratio

between the y and x dimension, the partition

considered would result in progressively smaller and

smaller aspect ratios, as shown in *igure ?.

3ecause the original definition for the !roppant

umber is only valid for a square reservoir, then for a

rectangular reservoir

% y x &

e e res

#:$

and

e

e

fD x

e f

e f

e e

f f

res

p f

p

y

x

C I

x x

x x

% y kx

'%x k

k&

& k

N

<

> <

#<$

8quation < generalizes now the e&pression of the Np for rectangular reservoirs, by adopting the reciprocal of the aspect a

ratio, xe(ye. +aal and 8conomides

::

have found that for !roppant umbers less than E.:, the optimum value of CfD is :.@ #as

for square drainage areas$ also for rectangular areas. %hus, the correlations for the calculation of the JD and the CfD are still

suitable, with the condition that an equivalent !roppant umber Npe is used

Figure 1: As,ect ratio decrease with increasing the number of

,artitions.

' SPE ...78/

BB . =E

)

p pe

C

N N

#=$

where C) is the classic +ietz shape factor

<:

, tabulated in %able < for a range of aspect ratios.

%he introduction of a new function is necessary because the 7inco-Cey and (amaniego

<A,<B

f-function #valid for radial flow

and used by 8conomides and "alk9

:

in their original formulation of the )*+ model$ does not apply for NpLE.:. %his is

because of the transition from pseudo-radial to linear behavior for large values of Np, until the limit condition in which the

fracture fully penetrates the drainage area, and the linear flow regime is completely developed.

%his new function, called F-function, is intended to describe the optimum fracture behavior of any value Np L E.:. +aal

and 8conomides

::

redefined the )*+ model with this new set of correlations

'

+ +

+ + +

<

+ +

E.: If

J J J

: E <? E and E.: If

:E

A . > D . = == . D

<

= <

<

p

opt opt

opt opt opt

eD p

eD

eD eD

opt

N

u c u b a

du cu bu a

. y . N

y

y y

F #>$

( )

: . E ,

: . E ,

: . E

:EE

:EE

fD p

fD eD

fD"opt

C N

C y

C +

#?$

opt p

D

F N

J

+

$ ln# ? . E @= . E

:

ma& ,

#@$

where the parameters uopt , yeD and CfD*.+ are defined as

$ ln#

,opt fD opt

C u

#A$

e

e

eD

x

y

y

#B$

'

+

>

E.: <? . E If ? < . E >.?

E.<? : If @ . :

: . E ,

eD eD

eD

fD

y y

y

C

#D$

and the constants appearing in 8quation ? are presented in %ables = and >.

able +: !ietz sha,e factors

ye(xe E.:E E.< E.<? E.= E.> E.? E.@ E.A E.B E.D :

C) E.E<? <.=@ ?.=B D.EE :@.:A <:.B> <?.BE <B.=@ <D.BD =E.@@ =E.BB

SPE ...78/ 8

In the range of large !roppant umbers

there is always an inversion point for any

curve JD"max vs. Np at which the JD"max of a

rectangle #ye,xe$ surpasses that of a square

#ye-xe$. *igure @ presents this trend, several

aspect ratios are plotted.

Interestingly, all the inversion points are

also inflection points of the optimum curves.

this means that when the linear behavior starts

to dominate the flow regime #i.e. for larger and

larger fracture sizes$, the rectangular drainage

configuration would lead to higher JD;s than

the ones achievable for square drainage.

Forecast of a (atural 2as 3ell Performance and "ecovery

*or this case study the reservoir variables presented on %able ? and four different configurations shown in *igure A

#representing respectively, one and four unfractured wells and one and four fractured wells, partitioning the drainage

accordingly$ are considered. 'n abandonment pressure of :,AEE psi is assumed.

able -: F)function4s constants

ye(xe - + *.. *./ *.0/ *.0 *.+

) :A.< :A.> <:.> =B.= =?.E =E.@

1 @?.? ??.? ?>.= >@.E ?D.E BD.@

C ?<.? ?=.= ?@.= A:.: AE.E AE.<

D :@.D :@.D :@.D :?.B> :@.= :A.B

able /: F)function4s ,rime constants

*or any ye(xe

a! :E

b! =@

c! ==

E.:

:

:E

E.: : :E :EE

N

p

J

D

"

m

a

x

yeF&eG: yeF&eGE.? yeF&eGE.<? yeF&eGE.< yeF&eGE.:

Figure 5: vs. Np for different as,ect ratios. &from !aal and

6conomides

11

*

able 1: Main design variable values

!roppant mass for #two wings$, lbm <EE,EEE

(p gravity of proppant material #waterG:$ <.@?

!orosity of proppant pack E.=B

!roppant pack permeability, md :?E,EEE

!ermeable #leakoff$ thickness, ft ?E

2eservoir permeability, md :

/ell radius, ft E.>

/ell drainage area, acres =<E

*racture height, ft :EE

2eservoir pressure, psi >,EEE

3ottom-hole flowing pressure, psi :,?EE

2eservoir temperature, K* :<E

0as specific gravity #$$ E.A:

Figure 7: Four different drainage configurations

for the case study.

.& SPE ...78/

%he cumulative production from a gas reservoir under the simple fluid e&pansion mechanism can be written as

$

$i

i i i p

1

1

2 2 2 2 2

#:E$

where 2i and 2 are the initial and current gas-in-place within a drainage area and 1$i and 1$ are the corresponding

formation volume factors.

7oupling 8q. :E with a suitable gas well I!2 e&pression, a forecast of well performance versus time can be developed

readily, by discretizing the depletion in a number of interval #acceptable precision is obtained for :EE-psi steps$, determining

the corresponding amount of gas produced for the p considered, determining the e&pected gas flow rate from the I!2, and

then obtaining the time interval of the considered p.

*or the two unfractured configurations #one and four wells$, the (wift and Miel

<>

model which accounts for non-+arcy

effects is appropriate

,

_

+ +

$

'

e

$

'f

$

D3 s

r

r

4 #

k% p p

3

>A< . E

ln :><>

$ #

< <

#::$

*or the two fractured configurations #one well centered and four placed in the center of each of four slices$, the I!2 to be

used is the classic pseudosteady state, in which the JD is determined with the )*+ methodology that accounts for the

reduction in the proppant pack permeability generated by turbulence

D

$

'f

$

J

4 #

k% p p

3

:><>

$ #

< <

#:<$

/henever the value of the reservoir permeability or the drainage area are such that transient flow regime is not negligible

and lasts for a relevant period before the boundaries are felt, the )*+ methodology needs to be modified, in order to account

for the production under transient flow regime #i.e., for the reservoir considered in this case study, the transient times would

be circa <=E days for the single well, =<E acres, and circa @E days for the quarter slice, BE acres$.

%he key problem in this circumstance is that the JD determined with the )*+ methodology for gas wells is pressure-

dependent. in other words, higher drawdown corresponds to higher gas flow rate. %he proper JD to consider in 8q. :: cannot

be the one corresponding to the initial reservoir pressure, but must be determined in correspondence to the reservoir pressure

at which the pseudosteady state flow regime would begin. %o solve this problem, in practice, an iterative algorithm is

required, and the functional steps are summarized below.

:$ 'ssume a value for the skin factor that would result from the fracturing treatment. ' good initial value for this skin

factor is -?4

<$ +etermine the duration of the transient flow regime period using well known e&pressions #for instance, see

8conomides et al.

<?

$4

=$ 7alculate the cumulative gas production 2p during the transient flow period #properly discretized$ using 8q. :E4

>$ Obtain real !"% data or calculate the values of the compressibility factor #4

?$ 7alculate the value of the formation factor from equation :E and the coresponding group

# p F

4

@$ +etermine the average reservoir pressure

p

4

A$ 7alculate the JD"5ax, the CfD"6pt and the optimal fracture geometry #xf and '$ using the usual )*+ correlations and

methodology, eventually accounting for the proppant pack permeability reduction andFor the effects of irregular

drainage areas4

B$ 7alculate the value of the pseudo-skin f-function, and then the resulting skin factor for the value of CfD"6pt determined

in point A4

D$ %he procedure is iterated by assuming ad each new step a new skin factor, until the skin factor assumed in point :

and the one calculated in point B are close enough.

SPE ...78/ ..

It is imperative to note that this

procedure, based on the 7inco-Cey and

(amaniego pseudo-skin function and its

relationship with the CfD and the fracture

length xf, is suitable for any !roppant umber

and any drainage area geometry. %he reason

is that during the transient flow regime, by

definition, the boundaries are not felt, and the

system can be appro&imated by pseudo-radial

infinite acting behavior, and thus the use of

the 7inco-Cey and (amaniego pseudo-skin

function, valid only in radial flow, is

acceptable.

*igures B and D show the resulting

forecasts of total production rates and

cumulative recovery for the four

configurations considered in this case study.

ote the thick dots shown in each curve

in *igures B and D, indicating respectively the

gas flow rate and the cumulative volume at

the beginning of the pseudosteady state flow

regime. %he enhancement of production

obtained combining infield drilling and

hydraulic fracturing is impressive. 's we will

see in the ne&t section, this provides a huge

boost to pro-ect economics and its net present

value.

*rom *igure D we can infer that the time

to ultimate recovery from the four fractured

wells configuration would be about <.> years

#BB@ days$, while the same recovery would

take more than =E years from a single

unfractured well. %he four unfractured wells case would reach the abandonment pressure in about A years and the single

fractured well case would do it in about D.D years.

%he calculation presented here makes the )*+ a comprehensive tool able to describe well production enhancement from

the startup until the abandonment, for any type of reservoir and under any type of production mechanism. /ith these

capabilities, the outputs generated by the production forecasts can be employed for the determination of net present values

calculations or any preferred economic criterion. %he ne&t section aims to show how these economic calculations can be

performed and how the important information needed for production economics can be determined.

Economic Optimization of Hydraulic Fracturing

)p to this point, the robustness and uniqueness of the solutions to the optimization problem provided by the )*+

methodology has been shown. (tarting from the theory of )*+ we have then e&tended its suitability in virtually any reservoir

type and under realistic constrains that arise from e&ecution issues. /e have seen how to run the )*+ model to benchmark

well performances, to ameliorate production impairments because of turbulence, especially in gas reservoirs, to optimize

reservoir e&ploitation and cumulative field recovery and to account for irregular drainage geometries.

It is clear that, no matter what circumstance one deals with, the )*+ method allows the determination of the optimum

fracture geometry that will lead to the ma&imum well productivity inde& #JD"max$. !roduction forecasts can be run, based on

analytical material balance models coupled with suitable I!2 equations that reflect the well productivity through the )*+-

derived JD. (uch production forecasts represent important results from the )*+-based physical optimization, and in turn they

are suitable for straightforward implementation of an economic criterion that assesses the acceleration of production that is

achievable with hydraulic fracture treatments against the necessary investment.

%he criterion selected for the optimization and the evaluation of the hydraulically fractured well performances in this

work is the et !resent "alue, widely acknowledged and applied for screening and evaluating the portfolio of investments

#well stimulation operations in our case$.

%he first step for any !" calculation is to select reasonable economic and logistical variables that reflect reasonable

estimates #based on e&perience andFor observed behavior in similar situations$. In the calculations shown here two different

geographic scenarios are considered. one a mature and well developed petroleum producing province such as the )nited

(tates, and a far less mature with considerable logistical difficulties that can be found in a number of places in the world

#from now on, it will be referred to simply as 5Overseas6$. %he differences between the tow places deal with the discount rate

E

:E,EEE

<E,EEE

=E,EEE

>E,EEE

?E,EEE

@E,EEE

AE,EEE

BE,EEE

E =@? A=E :,ED? :,>@E :,B<? <,:DE <,??? <,D<E =,<B? =,@?E

time, d

q

,

1

s

c

f

F

d

: *ractured /ell > *ractured /ells : )nfractured /ell > )nfractured /ells

Figure 8: Production rate forecast for drainage in case study.

E

=

@

D

:<

:?

:B

E :,EEE <,EEE =,EEE >,EEE ?,EEE @,EEE A,EEE B,EEE D,EEE :E,EEE ::,EEE

time, d

0

p

,

3

s

c

f

: *ractured /ell > *ractured /ells : )nfractured /ell > )nfractured /ells

Figure 9: :umulative recovery forecast for drainage in case study.

.% SPE ...78/

i as well as the initial investment. %he impact of these variables on the attractiveness of fracturing will be evaluated. In

general, Overseass investments would boost the 5risk factor6, as a result of comple& logistics and even geopolitical

uncertainties, delicate international contracts, etc. and this, in turn, would suggest a substantially higher discount rate i.

'nother typical characteristic of many Overseass regions is the considerably higher capital e&penditures required for the

construction of wells, facilities, pipelines and so on. In this e&pensive environment, fracturing e&ecution costs are much

larger without the benefit of 5massification6, a key feature of the fracturing industry in the )(.

%he annual revenue stream 7n is given by

( ) ( ) ( )

t o r 8 8 n

f f f & 7 : : : N #:=$

where &8 is the cumulative volume of

hydrocarbons produced in the reference

year #in barrels or in 1scf$, 98 is the

unitary revenue for the produced

hydrocarbon #in NFbarrels or in NF1scf$, fr

is the fraction of gross cash flow due to

the lease owners andFor to the foreign

nation governments as royalties, fo is the

fraction of gross cash flow to be allocated

as operative e&penditures and ft is the

fraction of gross cash flow due as ta&es in

the relative fiscal regime.

%able @ presents all the economic

parameters and their selected values in the

two scenarios )(' and Overseas4 the

working interest and net revenue interest

are reported additionally #both of them

selected as :EEO in both scenarios$.

%able A shows in detail the capital

investment for hydraulically fractured

wells. 'ssuming hydraulic fracturing as

the standard completion method for any

new well, construction costs #drilling and

completion$ and stimulation costs will be

considered as capital e&penditures for the

two scenarios )(' and Overseas.

%wo e&le of !" calculations are presented in the following sections. %he first considers a set of four different well

pattern configurations that could e&ploit a reservoir with a given drainage area, and aims to find the optimal configuration for

which the !" would be ma&imized. %he second e&le considers one hydraulically fractured well centered in a given

drainage area, and the purpose is to select the proppant mass to be in-ected during the fracturing treatment for which the !"

is ma&imized. It is worth to emphasize that the performance of each well configuration considered will be already at the

physical optimum, as determined via the )*+ methodology.

(P; of !ifferent !rainage :onfigurations <sing Fractured and <nfractured 3ells

*or this e&ercise the four different configurations already presented in *igure A are re-considered here for the economic

calculation. ' gas reservoir is used for the calculations. It must be re-emphasized that the comparisons presented in this and

subsequent calculations in this work are for aggressive and optimized production engineering decisions and, especially, for

hydraulic fracturing, the presumption is that the e&ecution follows the physical optimization as described by the )*+

methodology. 3adly or ad-hoc designed fracturing treatments may lead to different conclusions.

%he reservoir parameters in %able ? are used. *urthermore, an abandonment pressure of :,AEE psi is assumed #starting

from an initial reservoir pressure of >,EEE psi$, and the fracture optimization with the )*+ method has been performed for a

proppant mass of <EE,EEE lbm of <EF>E ceramic proppant #:?E,EEE md of proppant pack permeability$. %he reservoir

permeability is equal to : md.

able 5: "e=uired in,uts for the (P; calculations

6conomic

Parameters <SA $verseas

+iscount date year E year E

+iscount rate, i :EO <?O

2evenue for produced

gas, NF1scf

A #no escalation applied$ A #no escalation applied$

2evenue for produced

oil, NFbarrel

@E #no escalation applied$ @E #no escalation applied$

/orking interest :EEO :EEO

et revenue interest :EEO :EEO

7ape&, I, N 2ef. %able @-< 2ef. %able @-<

Ope&, fo, N E.< of annual revenue E.< of annual revenue

2oyalties, fr, N E.< of annual revenue -

%a&es, ft, N E.? of annual revenue E.A? of annual revenue

able 7: :a,ital investment considered for the (P; calculations

:a,ital 6x,enditure <SA $verseas

/ell construction #drilling P completion$, N :,EEE,EEE =,EEE,EEE

!umping charges , N @E,EEE :EE,EEE

1obFdemob, N >E,EEE DE,EEE

!roppant #<EF>E ceramic, :?E,EEE md$ cost, NFlbm :.? <.?

*racturing fluids #Q-linked gel$ cost, NFgal E.> E.B

SPE ...78/ ./

(tarting from the production

forecasts obtained for these four

configurations #see *igures B and D$, the

annual revenue stream 7n has been

determined #8quation :=$ for each year

and making use of the parameters

presented in %able @. %hen, the !";s

are calculated. %he capital e&penditures

have been calculated with the values in

%able A, and in particular the fracturing

&-linked gel required to perform the

treatment #<EE,EEE lbm proppant mass$

has been assumed to be =?,EEE gals.

%wo values of !" have been

determined. one in which the pro-ect

lifetime N is the one at which the

abandonment pressure is reached in each

of the four drainage configurations, and

one in which the pro-ect lifetime N is the

one equal the one corresponding to the

abandonment time of the four-fractured

wells case #B@@ days$.

*igure :E shows the results of the

!" calculations for the )(' scenario,

all produced until the abandonment

pressure is reached. *or the !";s

evaluated at N G BB@ days #the green

columns$, it is clear that the infield

drilling P fracturing configuration

appears to be the best choice, thanks to

the cumulative amount of gas produced

in less than three years, versus all the

other 5sluggish6 configurations that still

have significant amount of gas to be

produced at the end of their respective

lifetimes. %his is a very important

finding supporting enhanced and

accelerated production.

/hen all the configurations are produced till the respective abandonment #the red columns$, the only configuration that

looks underperforming considerably is the single unfractured well, while the other three configurations offer similar values of

!", around N<A million. %his is e&plainable by observing that the different times to ultimate recovery #shown in *igure D$

impacts the !" value in such a way that it is widely compensated by the different values of capital investment. In simple

words, the 5revenue performances6 of the four fractured wells, the four unfractured wells and the single fractured well are

quite equivalent if compared to the investment needed to implement them.

*igure :: shows the results of the !"

calculations performed for the Overseas

scenario. %he Overseas scenario reveals the

severity of its economic parameters in both

set of columns of *igure ::. In fact, for the

!";s evaluated at N G BB@ days #the green

columns$ as well as for the !";s evaluated

when all the configurations are produced till

abandonment #the red columns$, the single

fractured well is the only option that really

appeals with its economic performance.

oticeable is the negative value of !" that

the four unfractured wells configuration

would achieve if evaluated at N G BB@ days.

1#...#...

1.#...#...

11#...#...

+.#...#...

+1#...#...

-.#...#...

1 <(F"A::6! 1 F"A::6! / <(F"A::6! / F"A::6!

(

P

;

#

<

S

!

All :ases Abandoned > 17.. ,si 885 days &:ase / Fracs Aband.*

Figure 1.: (P;4s for the <SA scenario# gas reservoir# 1 md.

)+#...#...

.

+#...#...

/#...#...

5#...#...

8#...#...

1.#...#...

1 <(F"A::6! 1 F"A::6! / <(F"A::6! / F"A::6!

(

P

;

#

<

S

!

All :ases Abandoned > 17.. ,si 885 days &:ase / Fracs Aband.*

Figure 11: (P;4s for the $verseas scenario# gas reservoir# 1 md.

E

=

@

D

:<

:?

:B

E <E >E @E BE :EE :<E :>E :@E :BE <EE <<E <>E <@E <BE =EE =<E

time# years

2

,

#

?

s

c

f

: *ractured /ell > *ractured /ells : )nfractured /ell > )nfractured /ells

Figure 1+: :umulative recovery forecast for drainage in

the ..1 md gas reservoir.

.9 SPE ...78/

%hese results reflect the detrimental effect of high values of discount rate #in this case i G <?O$ and capital e&penditure on the

!" model.

%he ne&t set of results is for the gas

reservoir characterized in %able ?, with

the only difference that this time the

reservoir permeability is equal to E.: md.

'gain, the same abandonment pressure

of :,AEE psi is assumed #starting from an

initial reservoir pressure of >,EEE psi$,

and the fracture optimization with the

)*+ method has been performed for a

proppant mass of <EE,EEE lbm of <EF>E

ceramic proppant #:?E,EEE md of

proppant pack permeability$, obtaining

the production forecasts for the four

configurations presented in *igure :<.

%he effect of the low permeability on

the productivity, and then on the time to

achieve the abandonment pressure, is

dramatic. the single unfractured well

would take =E> years, and the single

fractured well would take ?< years.

%he procedure already described for

the : md reservoir case has been

repeated. %he annual revenue stream 7n

and then the relative !";s have been

determined, again for the two scenarios

)(' and Overseas. %he two pro-ect

lifetime N alternatives are, first, N G

time at which the abandonment pressure

is reached in each of the four drainage

configurations, and, second, N is equal

for the four configurations and is the one

that corresponds to the abandonment

time of the four-fractured wells case #for

this e&le it is :<.? years$. %he capital

e&penditures are as shown in %able A

#again, the fracturing &-linked gel

required to perform the treatment has been assumed to be =?,EEE gals$.

*igures := and :> show the results of the !" calculations performed respectively for the )(' and Overseas scenarios.

(everal important conclusions can be inferred from this new set of !";s, as a consequence of the lower reservoir

permeability.

*irst, now the difference in !" values between the fully depleted cases #red columns$ and the ones for N G :<.?< years

#green columns$ is quite small. %his shows that e&tended periods of evaluation #i.e., high value of N$ are virtually

meaningless in the contribution to the !". *or instance, the single fractured well would be abandoned after ?< years of

production, with an associated !" of N:=.A million, while the !" evaluated for :<.?< years would be almost N:< million.

%he second meaningful observation is that in a tight reservoir environment, with low productivity and very long depletion

time, the two fractured configurations show their economic benefits in an even more noticeable way.

*or the )(' scenario #*igure :=$, the four fractured wells configuration is clearly dominating the economic

performances, with an !" of N<:.? million. the combination of low capital e&penditures and low discount rate i in a tight

reservoir emphasizes the potential of infield drilling and the hydraulic fracturing of those wells.

On the other hand, the penalizing capital e&penditures and high discount rates considered for the Overseas scenario

#*igure :>$ doom almost all of the development schemes in tight reservoirs.

.

/#...#...

8#...#...

1+#...#...

15#...#...

+.#...#...

+/#...#...

1 <(F"A::6! 1 F"A::6! / <(F"A::6! / F"A::6!

(

P

;

#

<

S

!

All :ases Abandoned > 17.. ,si 1+.1+ years &:ase / Fracs Aband.*

Figure 1-: (P;4s for the <SA scenario# gas reservoir# ..1 md.

)9#...#...

)7#...#...

)1#...#...

)-#...#...

)1#...#...

1#...#...

1 <(F"A::6! 1 F"A::6! / <(F"A::6! / F"A::6!

(

P

;

#

<

S

!

All :ases Abandoned > 17.. ,si 1+.1+ years &:ase / Fracs Aband.*

Figure 1/: (P;4s for the $verseas scenario# gas reservoir# ..1 md.

SPE ...78/ .1

%his finding e&plains the general

problem associated with production from

tight gas reservoirs in those Overseas

regions with e&tended resources but with

under-developed upstream business. '

wide set of currently unprofitable

pro-ects, could become more attractive if

massification of drilling and fracturing

were implemented, reducing their capital

e&penditures. %his concept is illustrated

in *igure :?, where the results of !"

calculations are shown for the usual four

configurations draining the E.: md gas

reservoir, considering the Overseas value

of discount rate but controlled costs #the

ones assumed for the )(' scenario$.

*igure :? is self-e&planatory.

massifying the drilling and fracturing

operations can lead to sufficiently low

capital e&penditures such that the

fractured wells configurations can lead to profitable resources currently labeled as stranded or unprofitable.

(P; as Function of the Pro,,ant Mass

%his e&ercise aims to provide a logic for using the )*+ approach to design a fracturing treatment and to estimate future well

performances. It should be clear by now that the solution for JD"max and the resulting optimum fracture conductivity indicate

that there is one pair of fracture length xf and width ' to provide the optimum.

It has also been shown that, virtually, there are no limits to the advantages achievable by in-ecting larger and larger

amounts of proppant and the model would provide an ever increasing value of JD"max.

%he )*+ model can be 5bounded6 with physical constraints #such as a ma&imum allowable net pressure$, which may

preclude the in-ection of a larger treatment. !roduction economics provide an additional level of constraints. (o the question

arises. /ithin the range of proppant mass that can be physically in-ected and used by the )*+ model, is there any specific

value at which the !" of the fractured well is ma&imizedR %o illustrate the concept, an application is presented below for

the undersaturated oil reservoir whose main parameters appear in %able B.

%he Havlena and Odeh

<@-<A

general material balance for oil reservoirs can be simplified for undersaturated reservoirs, and

proper manipulations #see 8conomides et al.

<?

$ yield to the equation

'c

t oi

o p

:

pc N1

1 N

:

#:>$

)1#...#...

.

1#...#...

+#...#...

-#...#...

/#...#...

1#...#...

5#...#...

1 <(F"A::6! 1 F"A::6! / <(F"A::6! / F"A::6!

(

P

;

#

<

S

!

All :ases Abandoned > 17.. ,si 1+.1+ years &:ase / Fracs Aband.*

Figure 11: (P;4s for the $verseas scenario# controlled costs#

gas reservoir# ..1 md.

.: SPE ...78/

where 1oi and 1o are oil formation volume factors #initial and

current, respectively$ in res bblF(%3, Np is oil cumulative

production in (%3, N is initial oil in place in (%3, :' is water

saturation, p is pressure step considered in the discretization of the

depletion and ct is the total compressibility of the system, in psi

-:

.

7oupling the material balance with a suitable undersaturated

well I!2 e&pression, a forecast of well performance versus time can

be developed readily.

' set of production forecasts has been obtained for a single

vertical fractured well, for a wide range of proppant mass

considered #<?,EEE to >?E,EEE lbm$ and for the values of E.: and :

md of reservoir permeability.

*igures :@ and :A show the results of the !" calculations.

%hese results not only confirm the suitability of the procedure

presented for the identification of the most profitable proppant mass

#i.e., for the E.: md reservoir !" peaks at about =EE,EEE lbm,

while for the : md reservoir !" peaks at about <EE,EEE lbm$, but

also provide evidence that economics corroborate one of the well

known tenets of hydraulic fracturing. larger fractures of much larger

length are indicated for low permeability reservoirs and relatively

smaller fractures #but with much larger widths$ are indicated for

higher permeability reservoirs.

able 8: Main design variable values

!roppant mass for #two wings$, lbm "ariable

(p gravity of proppant material #H<OG:$ <.@?

!orosity of proppant pack E.=B

!roppant pack permeability, md :?E,EEE

!ermeable #leakoff$ thickness, ft ?E

2eservoir permeability, md "ariable

2eservoir porosity #) E.<

/ell radius, ft E.>

/ell drainage area, acres =<E

*racture height, ft :EE

2eservoir pressure, psi ?,EEE

Soung;s 1odulus #E$, psi <

&

:E

-@

!oisson;s ratio, #$ E.=B

3ottom-hole flowing pressure, psi :,?EE

'bandonment pressure, psi :,@EE

2eservoir temperature, K* :BE

Interstitial water saturation #:'c$ E.=

/ater compressibility #c'$, psi

-:

=

&

:E

-@

2ock compressibility #cf$, psi

-:

=.:

&

:E

-@

Oil specific gravity, '!I >@

(olution gas-oil factor #7s$, (7*F(%3 >EE

-#...#...

-#1..#...

/#...#...

/#1..#...

1#...#...

. 1.#... 1..#... 11.#... +..#... +1.#... -..#... -1.#... /..#... /1.#... 1..#...

Pro,,ant Mass# lbm

(

P

;

#

<

S

!

..1 md

Figure 15: (P; vs ,ro,,ant mass in the <SA scenario#

oil reservoir# ..1 md.

7#...#...

7#+..#...

7#/..#...

7#5..#...

7#8..#...

8#...#...

. 1.#... 1..#... 11.#... +..#... +1.#... -..#... -1.#... /..#... /1.#... 1..#...

Pro,,ant Mass# lbm

(

P

;

#

<

S

!

1 md

Figure 17: (P; vs ,ro,,ant mass in the <SA scenario#

oil reservoir# 1 md.

SPE ...78/ .7

+onclusions

In this work the physical optimization that comes from the )*+ approach has been coupled to an economic optimization, by

balancing of incremental future revenue against the cost of e&ecution. It has been shown how the combination of the )*+

approach with the !" economic criterion can be standardized in a routine procedure and can be used as an effective quick-

look tool for screening oil and gas investments in a modern global portfolio.

%he )*+-derived dimensionless productivity inde& has been used in proper I!2 relationships coupled with material

balance schemes to produce production forecasts. ' new calculation scheme has been introduced for the generation of )*+-

based production forecasts for reservoirs in which the initial transient flow regime is not negligible.

!arametric studies for a range of reservoirs #in terms of permeability, drainage area, drainage configuration and type of

hydrocarbon$ and e&ecution variables have been performed, and economic variables that differ in various parts of the world

have been utilized. 'ggressive and optimized production schemes have been systematically considered, with the presumption

that the e&ecution of the hydraulic fracturing treatments follows the physical optimization as described by the )*+

methodology. In fact, badly or ad-hoc designed fracturing treatments may lead to different conclusions.

It has been illustrated how massification of drilling and fracturing operations in tight gas reservoirs can lead to

sufficiently low capital e&penditures such that the systematic application of hydraulic fracturing can lead to profitable

resources currently labeled as stranded or unprofitable. *inally, it has been shown how the mass of proppant in-ected can be

effectively used as main design optimization variable for hydraulic fracturing treatments.

,EFE,E)+ES

:. 8conomides, 1.,., Oligney, 2.8. and "alk9 !.!.. 5<nified Fracture !esign.6 Orsa !ress, 'lvin %Q, 1ay <EE<.

<. +emarchos, '.(., 7homatas, '.(. and 8conomides, 1.,.. 5!ushing the Cimits in Hydraulic *racture +esign.6 !aper (!8 B@>B=,

<EE>.

=. 8conomides, 1.,., +emarchos, '.(., 1ach, ,.1., 2ueda, ,. and /olcott, +.(.. 5!ushing the Cimits of Hydraulic *racturing in

2ussia.6 !aper (!8 DE=?A, <EE>.

>. +iyashev, I.2., 8conomides, 1.,.. 5' 0eneral 'pproach to /ell 8valuation.6 !aper (!8 D>@>>, <EE?.

?. /ang, Q., Indriati, (., "alk9, !.!. and 8conomides, 1.,.. 5!roduction Impairment and !urpose-3uilt +esign of Hydraulic

*ractures in 0as 7ondensate 2eservoirs.6 !aper (!8 @>A>D, <EEE.

@. 2omero, +.,., "alk9, !.!. and 8conomides, 1.,.. 5%he optimization of the productivity inde& and the fracture geometry of a

stimulated well with fracture face and choke skins.6 !aper (!8 A=A?B, <EE<.

A. 1ukher-ee, H. and 8conomides 1.,.. 5' !arametric (tudy of Horizontal and "ertical /ell !erformance.6 !aper (!8 :B=E=,

:DD:.

B. /ang, Q., 8conomides, 1.,.. 5'ggressive fracturing slashes turbulence in high permeability gas wells.6 ;orld 6il #,uly <EE>$

pp A=-AD.

D. Copez-Hernandez, H.+., "alk9, !.!. and !ham, %.%.. 5Optimum fracture treatment design minimizes the impact of non-+arcy

flow effects6. !roceedings - (!8 'nnual %echnical 7onference and 8&hibition, pp. :A<?-:A>E, <EE>.

:E. /ei, S., 8conomides, 1.,.. 5%ransverse Hydraulic *ractures from a Horizontal /ell.6 !aper (!8 D>@A:, <EE?.

::. +aal, ,.'., 8conomides, 1.,.. 5Optimization of hydraulically fractured wells in irregularly shaped drainage areas.6 !aper (!8

DBE>A, <EE@.

:<. +emarchos, '.(., 1arongiu-!orcu, 1. and 8conomides, 1.,.. 5%ransversely 1ulti-*ractured Horizontal /ells. ' 2ecipe for

(uccess.6 !aper (!8 :E<<@<, <EE@.

:=. 3ritt, C.M.. 5Optimized Oil /ell *racturing of 1oderate-!ermeability 2eservoirs.6 !aper (!8 :>=A:, :DB?.

:>. "eatch, 2./. ,r.. 58conomics of *racturing. (ome 1ethods, 8&les, and 7ase (tudies.6 !aper (!8 :??ED, :DB@.

:?. /arembourg, !.'., Mlingensmith, 8.'., Hodges, ,.8. and 8rdle, ,.8.. 5*racture (timulation +esign and 8valuation.6 !aper (!8

:>=AD, :DB?.

:@. 'ndersons, 2./., !hillips, '.1.. 5!ractical 'pplications of 8conomics /ell-!erformance 7riteria to the Optimization of

*racturing %reatments +esign.6 JP4 #*ebruary :DBB$ pp <<=-<<B.

:A. 3alen, 2.1., 1eng, H-T. and 8conomides, 1.,.. 5'pplication of the et !resent "alue #!"$ in the Optimization of Hydraulic

*ractures.6 !aper (!8 :B?>:, :DBB.

:B. 8conomides, 1.,., Oligney, 2.8., "alk9, !.. 5'pplying )nified *racture +esign to atural 0as wells.6 ;orld 6il #October <EE<$

pp ?E-@<.

:D. 0idley, ,.C.. 5' 1ethod for 7orrecting +imensionless *racture 7onductivity for on-+arcy *low 8ffects.6 !aper (!8 <EA:E,

:DDE.

<E. 7ooke, 7.8., ,r.. 57onductivity of !roppants in 1ultiple Cayers.6 JP4 #October :DD=$ pp ::E:-::EA.

<:. +ietz, +... 5+etermination of 'verage 2eservoir !ressure *rom 3uild-)! (urveys.6 JP4 #'ugust, :D@?$ pp D??-D?D.

<<. 7inco-Cey, H., (amaniego, *.".. 5%ransient !ressure 'nalysis for *ractured /ells.6 !aper (!8 A>DE, :DAB.

<=. 7inco-Cey, H., (amaniego, *.". and +ominguez .. 5%ransient !ressure 3ehavior for a /ell with a *inite-7onductivity "ertical

*racture.6 :PEJ #'ugust, :DAB$, pp <?=-<@>.

<>. (wift, 0./. and Miel, O.0.. 5%he !rediction of 0as-/ell !erformance Including the 8ffects of on-+arcy *low.6 JP4, #,uly

:D@<$ pp AD:-ADB.

<?. 8conomides, 1.,., Hill, '.+. and 8hlig-8conomides, 7.'.. 5Petroleum Production Systems.6 !rentice Hall, S, :DD>.

<@. Havlena, +., Odeh, '.(.. 5%he 1aterial 3alance as an 8quation of a (traight Cine.6 JP4 #'ugust :D@=$ pp BD@-DEE.

<A. Havlena, +., Odeh, '.(.. 5%he 1aterial 3alance as an 8quation of a (traight Cine. !art II U *ield 7ases.6 JP4 #,uly :D@>$ pp

B:?-B<<.

Вам также может понравиться

- A Natural Polymer-Based Cross-Linker System For Conformance Gel SystemsДокумент8 страницA Natural Polymer-Based Cross-Linker System For Conformance Gel SystemsRaemora Zaith IthinОценок пока нет

- Oilfield Review October 1992Документ69 страницOilfield Review October 1992Andres PaladiniОценок пока нет

- Productivity-Maximized Horizontal-Well Design With Multiple Acute-Angle Transverse FracturesДокумент13 страницProductivity-Maximized Horizontal-Well Design With Multiple Acute-Angle Transverse FracturesDaniel NavaОценок пока нет

- Assessing Shale ReactivityДокумент7 страницAssessing Shale ReactivityHenryОценок пока нет

- Paper 54722 - Insol PdvsaДокумент32 страницыPaper 54722 - Insol PdvsaVinh PhamthanhОценок пока нет

- Spe 184869 MSДокумент16 страницSpe 184869 MSSS100% (1)

- Master's Thesis on Riserless Managed Pressure DrillingДокумент112 страницMaster's Thesis on Riserless Managed Pressure DrillingRaul Blanco0% (1)

- EOR Methods GuideДокумент109 страницEOR Methods GuideKarwan DilmanyОценок пока нет

- Method Predicts Well Bore ScaleДокумент8 страницMethod Predicts Well Bore ScaleAnonymous JJ29r2oCОценок пока нет

- Chapter 5 Rock MechanicsДокумент59 страницChapter 5 Rock MechanicsjcОценок пока нет

- 3.6.7. Biosealers PDFДокумент1 страница3.6.7. Biosealers PDFpedro taquichiriОценок пока нет

- Reservoir Engineering CPG 2020 3 - 2Документ120 страницReservoir Engineering CPG 2020 3 - 2Chris ChijiokeОценок пока нет

- Master Thesis - Jose Maria MoratallaДокумент80 страницMaster Thesis - Jose Maria MoratallaorlandoОценок пока нет

- New and Novel Fracture Stimulation Technologies For The Revitalization of Existing Gas Storage Wells: Interim Project ResultsДокумент87 страницNew and Novel Fracture Stimulation Technologies For The Revitalization of Existing Gas Storage Wells: Interim Project ResultsPinkesh ShahОценок пока нет

- Natural Drive MechanismsДокумент4 страницыNatural Drive MechanismsWaleed Ejaz0% (1)

- Spe 135704 MS PDFДокумент9 страницSpe 135704 MS PDFKd FaОценок пока нет

- SPE-57390-Underbalance or Extreme OverbalanceДокумент10 страницSPE-57390-Underbalance or Extreme Overbalancecv sabiraОценок пока нет

- Fracturing in Gas Reservoirs: A Review of the Process and Environmental ImpactsДокумент5 страницFracturing in Gas Reservoirs: A Review of the Process and Environmental ImpactsUsman NaseemОценок пока нет

- Acoustic Well StimulationДокумент2 страницыAcoustic Well StimulationCristian BarbuceanuОценок пока нет

- Key Issues in Multilateral Technolog 1668247705Документ55 страницKey Issues in Multilateral Technolog 1668247705Dhani de EngineurОценок пока нет

- Perforating When Failure Is The ObjectiveДокумент14 страницPerforating When Failure Is The ObjectiveAnonymous DDqgH1Y2MKОценок пока нет

- SPE-169245-MS Overcoming Ultradeepwater Cementing Challenges in The CaribbeanДокумент16 страницSPE-169245-MS Overcoming Ultradeepwater Cementing Challenges in The CaribbeanAhmed Ali AlsubaihОценок пока нет

- SPE-160127-MS Kuparuk River Unit Field - The First 30 YearsДокумент13 страницSPE-160127-MS Kuparuk River Unit Field - The First 30 YearsGilbert OmittaОценок пока нет

- Application of Water Alaternating Gas (Wag) Injection For Heavy Oil Recovery in Niger DeltaДокумент71 страницаApplication of Water Alaternating Gas (Wag) Injection For Heavy Oil Recovery in Niger DeltaNdifreke Nsima WilliamsОценок пока нет

- 1001 385v2-STIMPRO ISДокумент2 страницы1001 385v2-STIMPRO ISRodolfo PerezОценок пока нет

- Propellant-Assisted Perforating  - An Alternative ...Документ15 страницPropellant-Assisted Perforating  - An Alternative ...Konul AlizadehОценок пока нет

- Spe 184834 MSДокумент11 страницSpe 184834 MSSSОценок пока нет

- An Expert System For Casing String Design SPE 20328 1990Документ8 страницAn Expert System For Casing String Design SPE 20328 1990alizareiforoushОценок пока нет

- SPE-191240-MS Experimental Evaluation of Sand Porosity in Eagle Ford Shale FracturesДокумент12 страницSPE-191240-MS Experimental Evaluation of Sand Porosity in Eagle Ford Shale FracturesJose LozanoОценок пока нет

- Editing - Petrobowl Questions - FlashcardsДокумент45 страницEditing - Petrobowl Questions - FlashcardsManuel Marquez CequeaОценок пока нет

- 2008 IPTC Conference Preview FINALДокумент72 страницы2008 IPTC Conference Preview FINALHing Chai ShingОценок пока нет

- Hole Conditioning Before Running Casing or LinerДокумент1 страницаHole Conditioning Before Running Casing or LinerYougchu LuanОценок пока нет

- Full Thesis ANALYSIS OF WELLBORE INSTABILITY WHILE DRILLING EXPLORATORY WELLS IN BANGLADESHДокумент92 страницыFull Thesis ANALYSIS OF WELLBORE INSTABILITY WHILE DRILLING EXPLORATORY WELLS IN BANGLADESHAhmed GharbiОценок пока нет

- PetroSkills - Surface Production OperationsДокумент2 страницыPetroSkills - Surface Production OperationsMausam GauravОценок пока нет

- WT AssignmentДокумент27 страницWT Assignmentabdilrhman sulimanОценок пока нет

- Review of Gas Injection Projects in CaliforniaДокумент12 страницReview of Gas Injection Projects in CaliforniaVoodoo ChildОценок пока нет

- FRACTURE GRADIENT CALCULATIONSДокумент18 страницFRACTURE GRADIENT CALCULATIONSElisha TalipОценок пока нет

- SPE 126719 Matrix Acid Systems For Formations With High Clay ContentДокумент15 страницSPE 126719 Matrix Acid Systems For Formations With High Clay ContentJose Miguel GonzalezОценок пока нет

- SPE 128115 Combining Selective Stimulation With Tailored Perforating Improves Injection Profile in A Carbonate Reservoir: A Case StudyДокумент14 страницSPE 128115 Combining Selective Stimulation With Tailored Perforating Improves Injection Profile in A Carbonate Reservoir: A Case StudyErika Daniela ReyesОценок пока нет

- Spe 169942Документ17 страницSpe 169942agihsalamОценок пока нет

- Geology & Geophysics: Coiled Tubing TechnologyДокумент4 страницыGeology & Geophysics: Coiled Tubing TechnologyUji PanuntunОценок пока нет

- Warrlich Et Al., 2019 (AAPG)Документ31 страницаWarrlich Et Al., 2019 (AAPG)redwanasisОценок пока нет

- Hydraulic Fracture Optimization in Unconventional ReservoirsДокумент15 страницHydraulic Fracture Optimization in Unconventional ReservoirsGuadalupe RuizОценок пока нет

- Rta Poster PDFДокумент1 страницаRta Poster PDFUjang Yana MaulanaОценок пока нет

- Artificial Lift TechДокумент59 страницArtificial Lift TechdepehajeОценок пока нет

- SPE-124295-PP New Integrated Approach For Updating Pore-Pressure Predictions During DrillingДокумент11 страницSPE-124295-PP New Integrated Approach For Updating Pore-Pressure Predictions During DrillingMarcelo Ayllón RiberaОценок пока нет

- Spe 175892 PaДокумент17 страницSpe 175892 PaSSОценок пока нет

- DCE-PMRE Gas Reserve MethodsДокумент21 страницаDCE-PMRE Gas Reserve MethodsAtif AbassОценок пока нет

- PDFДокумент11 страницPDFizzyguyОценок пока нет

- 01 Density PDFДокумент12 страниц01 Density PDFshoaib akhtarОценок пока нет

- SPE 160703 Simultaneous Well Stimulation and Scale Squeeze Treatments in Sandstone and Carbonate ReservoirsДокумент21 страницаSPE 160703 Simultaneous Well Stimulation and Scale Squeeze Treatments in Sandstone and Carbonate ReservoirsJose Miguel GonzalezОценок пока нет

- Ace 2018 Tpra 011618Документ100 страницAce 2018 Tpra 011618BilboОценок пока нет

- Hydraulic Fracturing Report 4.18.11Документ32 страницыHydraulic Fracturing Report 4.18.11Houston ChronicleОценок пока нет

- GiantДокумент10 страницGiantYücel Kaosjunkie100% (1)

- Hydraulic Fracturing Hydraulic FracturingДокумент50 страницHydraulic Fracturing Hydraulic FracturingbigbuldogОценок пока нет

- Hydrocarbon Fluid Inclusions in Petroliferous BasinsОт EverandHydrocarbon Fluid Inclusions in Petroliferous BasinsОценок пока нет

- Depositional History of Franchthi Cave: Stratigraphy, Sedimentology, and Chronology, Fascicle 12От EverandDepositional History of Franchthi Cave: Stratigraphy, Sedimentology, and Chronology, Fascicle 12Оценок пока нет

- Development and Application of Classical Capillary Number Curve TheoryОт EverandDevelopment and Application of Classical Capillary Number Curve TheoryОценок пока нет

- Deepwater Sedimentary Systems: Science, Discovery, and ApplicationsОт EverandDeepwater Sedimentary Systems: Science, Discovery, and ApplicationsJon R. RotzienОценок пока нет

- Approvals: Weigh Module Available Paramounts HE Paramounts HSДокумент1 страницаApprovals: Weigh Module Available Paramounts HE Paramounts HSJosé TimanáОценок пока нет

- XK3118T4F Technical ManualДокумент4 страницыXK3118T4F Technical ManualJosé TimanáОценок пока нет

- BVD 2257 GBДокумент4 страницыBVD 2257 GBmichaelОценок пока нет

- sb14 Beam Datasheet en PDFДокумент3 страницыsb14 Beam Datasheet en PDFJosé TimanáОценок пока нет

- Setra Field Guide To Understanding Pressure TransducersДокумент9 страницSetra Field Guide To Understanding Pressure TransducersJosé TimanáОценок пока нет

- RuedaCocheMinero (AI2018)Документ1 страницаRuedaCocheMinero (AI2018)José TimanáОценок пока нет

- ABB Sales SpecialistДокумент2 страницыABB Sales SpecialistJosé TimanáОценок пока нет

- Celda Carga - KIS-2BA - 5KNДокумент4 страницыCelda Carga - KIS-2BA - 5KNJosé TimanáОценок пока нет

- 2019 Iqube2 Junction BoxДокумент3 страницы2019 Iqube2 Junction BoxJosé TimanáОценок пока нет

- Perno VДокумент1 страницаPerno VJosé TimanáОценок пока нет

- OIMLR60Документ97 страницOIMLR60Waleed MouhammedОценок пока нет

- ACSEWДокумент1 страницаACSEWJosé TimanáОценок пока нет

- Request Quote Conveyor Belt ScaleДокумент1 страницаRequest Quote Conveyor Belt ScaleJosé TimanáОценок пока нет

- Vocabulary HP Back UpДокумент18 страницVocabulary HP Back UpJosé TimanáОценок пока нет

- Resumen Ejecutivo As 0322018 20181009 123751 468Документ3 страницыResumen Ejecutivo As 0322018 20181009 123751 468José TimanáОценок пока нет

- Conduit Bushings For Rigid Metal Conduit and IMC: Applications Features Material/Finish Certifications and CompliancesДокумент1 страницаConduit Bushings For Rigid Metal Conduit and IMC: Applications Features Material/Finish Certifications and CompliancesJosé TimanáОценок пока нет

- Ardy PDFДокумент4 страницыArdy PDFJosé TimanáОценок пока нет

- Aluminum Liquidtight ST Series Connectors With Plain ThroatДокумент1 страницаAluminum Liquidtight ST Series Connectors With Plain ThroatJosé TimanáОценок пока нет

- Cable Glands Cross ReferenceДокумент8 страницCable Glands Cross ReferenceUrip S. Setyadji100% (1)

- Expr 2 BP 29 eДокумент12 страницExpr 2 BP 29 eJosé TimanáОценок пока нет

- Ukavala Nge Mod 01b Introd Phsbeh (Base) (v20140528) PDFДокумент58 страницUkavala Nge Mod 01b Introd Phsbeh (Base) (v20140528) PDFJosé TimanáОценок пока нет