Академический Документы

Профессиональный Документы

Культура Документы

Enews 30 03 090601

Загружено:

sajuhere0 оценок0% нашли этот документ полезным (0 голосов)

38 просмотров4 страницыDedicated vent system

Оригинальное название

enews_30_03_090601

Авторское право

© © All Rights Reserved

Доступные форматы

PDF, TXT или читайте онлайн в Scribd

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документDedicated vent system

Авторское право:

© All Rights Reserved

Доступные форматы

Скачайте в формате PDF, TXT или читайте онлайн в Scribd

0 оценок0% нашли этот документ полезным (0 голосов)

38 просмотров4 страницыEnews 30 03 090601

Загружено:

sajuhereDedicated vent system

Авторское право:

© All Rights Reserved

Доступные форматы

Скачайте в формате PDF, TXT или читайте онлайн в Scribd

Вы находитесь на странице: 1из 4

providing insights for todays

hvac system designer

2001 American Standard Inc. All rights reserved Volume 30, No. 3 I

engineers newsletter

design tips for effective, efficient

Dedicated Ventilation Systems

from the editor

Often the Engineers Newsletter limits

its coverage of design concepts to

theoretical discussions. This issue

tackles the subject of ventilation

system design, but does so by adopting

a practical, workaday approach. If you

design HVAC systems for multiple-

space applications, we think youll

appreciate this ENs how-to

instructions for determining equipment

capacities. Youll also find ideas for

improving the efficiency of dedicated

ventilation systems.

For years, most HVAC installations

have been mixed-air systems in

which an air handler combined outdoor

air (OA) and return air, then conditioned

the resulting mixture and delivered it to

occupied spaces in the building. Such

systems made it easy to provide proper

ventilation: the designer could set the

outdoor-air damper or outdoor airflow to

accommodate the worst-case

ventilation requirements. Although this

simplistic solution satisfied the

immediate concern, indoor air quality, it

also required high outdoor airflow to

compensate for the low ventilation

efficiency of the system.

Ventilation efficiency describes the

percentage of first-pass outdoor air that

dilutes indoor contaminants before

being exhausted from the building. The

higher the percentage of used

ventilation air, the more efficient the

system.

Ventilation becomes less efficient

when the mixed-air system serves

multiple spaces with differing

ventilation needs. One space (the

critical space) receives precisely

enough outdoor air for adequate

ventilation; all other spaces are

overventilated. There are various ways

to improve ventilation efficiency, but

the dedicated ventilation system is

an increasingly popular solution.

What Is a Dedicated

Ventilation System?

A dedicated ventilation system uses

a separate air handler to condition the

outdoor air before delivering it to the

outdoor/mixed-air intakes of other

HVAC units or directly to the occupied

spaces. In either case, terminal units

handle the local space loads.

Whether it is called a dedicated OA unit

(as in this EN), a 100-percent OA unit,

or a fresh air unit, the air handler must

dehumidify, cool, heat, and sometimes

humidify the incoming outdoor air. For

now, lets focus our attention on

dehumidification and cooling

Most unit designs use chilled water or

DX coils to cool the air and either cold-

coil or active-desiccant technology to

dry it. For this discussion, well look

only at cold-coil dehumidification

because it is less expensive, less

complex, and more widely understood

and applied than active-desiccant

technology. Also, cold-coil designs

sufficiently dehumidify conditioned air

for most commercial and institutional

applications.

Implications for

SystemDesign

To demonstrate how a dedicated

ventilation system affects equipment

selection, lets consider the system in

Figure 1 (page 2). A dedicated OA unit

meets the minimum ventilation

requirement by treating the outdoor air

and then delivering the conditioned air

(CA) directly to the occupied spaces.

Fancoils, controlled by thermostats,

Cold or Neutral Conditioned Air?

When some spaces ventilated by a

dedicated OA unit need heating while

others need cooling, designers usually

choose to deliver neutral-temperature

conditioned air. Dry conditioned air must

be reheated to the desired dry-bulb

temperature (a subjective value that

typically ranges from 70F to 74F).

Neutral-temperature air minimizes the

additional heating load that the dedicated

OA unit imposes on the terminal units.

If most of the spaces ventilated by the

dedicated OA unit are thermally similar

(that is, all of them need either heating or

cooling), designers may choose to deliver

cold conditioned air. The conditioned-air

dry-bulb temperature depends on the

required supply-air dew point, typically

between 50F and 55F. Cold conditioned

air means smaller, therefore less costly,

terminal units. I

I 2 Trane Engineers Newsletter Vol. 30, No. 3

satisfy the local sensible load in each

space.

Selecting the dedicated OA unit.

Required airflow, dew point, and dry-

bulb temperature of the conditioned air

(CA) are key to the selection of the

dedicated OA unit. The inset at right

demonstrates the selection logic

described below.

1 Determine the enthalpy-based

design condition. The weather

(entering-coil) condition with the

highest enthalpythat is, peak wet

bulb and mean coincident dry bulb

generally sets the peak cooling capacity

required from the dedicated OA unit.

The ASHRAE HandbookFundamentals

provides climatic design data for

various geographical locations.

2 Choose the target condition for

the occupied space. Most designers

choose a dry-bulb temperature of 72F

to 76F as the setpoint. To discourage

microbial growth, ASHRAE Standard

621999 recommends a relative

humidity of 60 percent or less during

cooling. Therefore, select the dedicated

OA unit to limit the relative humidity in

all spaces to no more than 60 percent.

Designing a dedicated ventilation

system that limits the space relative

humidity to a lower value (50 percent,

for example) adds unnecessary cost

Figure 1. Dedicated Ventilation System

because it requires larger equipment

and increases energy consumption.

3 Determine the latent load for each

space. Latent loads in spaces, which

are usually unaffected by weather

conditions, can be calculated with the

help of load-design software.

4 Calculate the system-level

outdoor airflow by finding and

summing the minimum ventilation-

airflow values of the occupied spaces.

Minimum ventilation requirements are

set by local codes or by ASHRAE

Standard 621999.

5 Determine the largest rise among

the space humidity ratios. As noted in

a previous EN (volume 29, number 4),

constant-volume terminal units without

dehumidification enhancements usually

dont remove enough moisture at a

partial sensible load. By providing

conditioned air that is drier than the air

in each space, the dedicated OA unit

can offset the local latent loads and

maintain the relative humidity at or

below the 60-percent maximum limit.

Note: The space with the highest

latent load may not be the space with

the largest humidity-ratio rise.

6 Calculate the required humidity

ratio and corresponding dew point

for the conditioned air delivered by the

dedicated OA unit. To do so, subtract

the largest humidity-ratio rise from the

target humidity ratio for the spaces.

The dedicated ventilation system in

Figure 1 removes the entire outdoor

load and the latent load generated

within each space. When the latent-

critical space is at the relative-

humidity limit, all other spaces are drier.

Note: Designs that deliver conditioned

air at a humidity ratio or dew-point

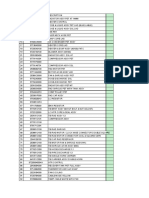

Practical Example: Selecting a Dedicated OA Unit

Lets see how the procedure outlined on

pages 23 can help us size a dedicated

outdoor-air (OA) unit that provides

ventilation directly to four classrooms in

a Jacksonville, Florida school:

1 Peak enthalpy condition (from

ASHRAE HandbookFundamentals):

T

oa

= 91F DB, 79F WB

2 Target space condition (designers

choice):

T

ra

= 74F DB (setpoint)

RH

ra

= 60% (maximum limit)

W

ra

= 75.2 gr/lb

3 Space latent and sensible loads (from

load calculations) in Btu/h:

Rm 1

Q

l

= 5,250;

Rm 1

Q

s

= 29,750

Rm 2

Q

l

= 5,465;

Rm 2

Q

s

= 26,775

Rm 3

Q

l

= 5,697;

Rm 3

Q

s

= 26,927

Rm 4

Q

l

= 5,250;

Rm 4

Q

s

= 28,262

4 Outdoor airflow (based on ASHRAE

Standard 621999) in cfm:

Rm 1

V

oa

= 15 cfm/p 29 people = 435

Rm 2

V

oa

= 15 cfm/p 30 people = 450

Rm 3

V

oa

= 15 cfm/p 32 people = 480

Rm 4

V

oa

= 15 cfm/p 29 people = 435

System

V

ot

= ! (V

oa

) = 1,800 cfm

5 Key humidity-ratio rise (calculated) in

gr/lb, that is, W = Q

l

/ (0.69 V

oa

):

Rm 1

W = 5,250 / (0.69 435) = 17.5

Rm 2

W = 5,465 / (0.69 450) = 17.6

Rm 3

W = 5,697 / (0.69 480) = 17.2

Rm 4

W = 5,250 / (0.69 435) = 17.5

6 Conditioned-air dew point (calculated):

W

ca

= W

ra

W

= 75.2 17.6 = 57.6 gr/lb

T

ca

= 52F DP

7 Conditioned-air dry bulb (designers

choice):

T

ca

= 71F DB (neutral), with reheat

or

T

ca

= 52F DB (cold), no reheat

Select the dedicated OA unit to deliver

1,800 cfm of ventilation air at a dew point

of 52F when the outdoor temperatures

are 91F DB and 79F WB. To deliver

neutral-temperature air, include reheat to

temper the ventilation air to 71F DB.

providing insights for todays HVAC system designer 3 I

temperature that equals the space

target cannot handle local latent loads.

These designs may result in a smaller

dedicated OA unit, but they require

larger terminal units and usually result

in higher indoor relative humidities.

7 Choose the required dry-bulb

temperature of the conditioned air.

If the system design requires

neutral-temperature conditioned air

(that is, conditioned air that

approximates the target for the space),

pick a dry-bulb value of 70F to 75F.

If the design requires cold ventilation

air, use a dry-bulb temperature that is

approximately equal to the required

dew point.

Selecting the terminal units. How

you select the dedicated OA unit can

significantly affect the required cooling

capacity (supply airflow and dry-bulb

temperature) for each terminal unit. The

inset on this page demonstrates the

following selection logic.

1 Determine the entering air

temperature. Terminal units see

only recirculated return air, which has a

temperature equaling the space target.

2 Calculate the sensible cooling

provided by the ventilation system.

Cold conditioned air provides

more sensible cooling than neutral

conditioned air, which is slightly cooler

than the space target. (See Cold or

Neutral Conditioned Air? on page 1.)

3 Determine the sensible cooling

load for each terminal unit. Subtract

the sensible cooling of the ventilation

system from the peak sensible load (at

the peak dry-bulb temperature), which

was calculated for each occupied space

with the help of load-design software.

4 Find the required supply

airflow for each terminal unit, given

an arbitrary supply-air temperature and

the sensible cooling load that the

terminal unit must satisfy. Unit

placement and geometry influence

the selection of a target supply-air

temperature, as does the design of

the dedicated ventilation system.

Delivering cold conditioned air

reduces required terminal-unit airflow

(and permits smaller terminal-unit

cabinets) than a system that delivers

neutral-temperature conditioned air.

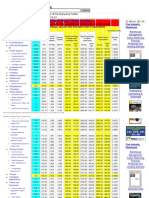

Figure 2 offers a psychrometric

summary of the equipment-selection

conditions.

Figure 2. Selection Summary

When designing a dedicated ventilation system

that delivers conditioned air directly to occupied

spaces:

I Size the dedicated OA unit so that it also

handles the latent loads in the spaces at the

peak enthalpy condition.

I Size each terminal unit to handle the sensible

load in the space at the peak sensible (dry-

bulb) condition.

Practical Example: Effect on Terminal-Unit Sizing

If the dedicated outdoor-air (OA) unit

handles the peak latent load for the four-

classroom system in our Jacksonville,

Florida example, then the terminal units

only need sufficient capacity to satisfy the

peak sensible load.

Select the terminal units to deliver the

required sensible capacity (depending on

whether the dedicated OA unit delivers

neutral or cold conditioned air, T

ca

) at

the assumed supply-air temperature and

calculated supply airflow.

Procedure

Neutral CA

(T

ca

= 71F DB)

Cold CA

(T

ca

= 52F DB)

1 Target space condition, T

ra

, (designer choice) 74F DB 74F DB

2 Sensible cooling provided by ventilation system

(calculated), that is, Q

ca

= 1.085 V

oa

(T

ra

T

ca

):

Rm 1

Q

ca

= 1.085 435 (74 T

ca

) =

Rm 2

Q

ca

= 1.085 450 (74 T

ca

) =

Rm 3

Q

ca

= 1.085 480 (74 T

ca

) =

Rm 4

Q

ca

= 1.085 435 (74 T

ca

) =

1,416 Btu/h

1,465 Btu/h

1,562 Btu/h

1,416 Btu/h

10,383 Btu/h

10,742 Btu/h

11,458 Btu/h

10,383 Btu/h

3 Sensible cooling load provided by terminal unit

(calculated), that is, Q

tu

= Q

s

Q

ca

:

Rm 1

Q

tu

= 29,750

Rm 1

Q

ca

=

Rm 2

Q

tu

= 26,775

Rm 2

Q

ca

=

Rm 3

Q

tu

= 26,927

Rm 3

Q

ca

=

Rm 4

Q

tu

= 28,262

Rm 4

Q

ca

=

28,334 Btu/h

25,310 Btu/h

25,365 Btu/h

26,846 Btu/h

19,367 Btu/h

16,033 Btu/h

15,469 Btu/h

17,879 Btu/h

4 Supply airflow from terminal unit (given supply-air

temperature), that is, V

tu

= Q

tu

/ [1.085 (T

ra

T

sa

)]:

Rm 1

V

sa

= Q

tu1

/ [1.085 (74 55)] =

Rm 2

V

sa

= Q

tu2

/ [1.085 (74 55)] =

Rm 3

V

sa

= Q

tu3

/ [1.085 (74 55)] =

Rm 4

V

sa

= Q

tu4

/ [1.085 (74 55)] =

1,374 cfm

1,228 cfm

1,230 cfm

1,302 cfm

939 cfm

778 cfm

750 cfm

867 cfm

I 4 ENEWS-30/3

Trane believes the facts and suggestions presented here to be accurate. However,

final design and application decisions are your responsibility. Trane disclaims

any responsibility for actions taken on the material presented.

The Trane Company

An American Standard Company

www.trane.com

For more information, contact your

local district office or e-mail us at

comfort@trane.com

Ways to Improve Efficiency

Various options such as energy

recovery can improve operating

efficiency. If the ventilation system

delivers neutral-temperature air,

recovered or transferred energy can

provide tempering. Such designs can

recover heat from the refrigeration

circuit in a direct-expansion (DX) unit or

from an air stream, usually by arranging

an air-to-air heat exchanger in series

with the cooling coil.

Using a total-energy wheel (or any

other air-to-air heat exchanger) to

precondition the entering outdoor air

reduces both cooling and heating loads.

Smaller loads not only enable you to

downsize the dedicated OA unit, but

can also reduce operating cost. To take

advantage of this benefit, however,

most of the building exhaust must be

routed back to the air handler. (For

details, see EN volume 29, number 5.)

Although most dedicated OA units are

designed to deliver a constant flow of

conditioned air, applications with

fluctuating occupancies may benefit

from variable airflow. Automatically

adjusting the flow of conditioned air to

match the systems current ventilation

requirements can reduce operating

costs without sacrificing indoor air

quality.

Adding an airside economizer also

reduces operating costs, but requires a

duct system that is entirely separate

from the dedicated OA unit. Thats

because the dedicated OA unit is

usually selected to accommodate only

minimum outdoor airflow and does not

handle recirculated return air.

(Alternatively, airside economizing can

occur at the terminal units, but effective

operation also requires a means for

modulated exhaust.)

Setpoint reset can improve system

efficiency, too. Raising the humidity

ratio (dew point) of the conditioned air

while limiting the humidity in the critical

space avoids overdrying and lowers

the operating cost of the dedicated OA

unit. Similarly, raising the conditioned-

air dry-bulb temperature while avoiding

heating in all spaces reduces the cost

of operating the terminal units. It also

delays cooling-to-heating changeover in

two-pipe systems.

To effectively control relative humidity,

unoccupied dehumidification may be

necessary. A dedicated OA unit with

DX cooling can provide this function

without operating chillers and cooling

towers. Implementation requires a

return-air path to the dedicated OA unit

and a humidity sensor in the critical

space.

Key Concepts

I Always provide conditioned air

that is drier than the space. This

practice minimizes the required

terminal-unit capacity and adequately

controls the indoor relative humidity

without additional dehumidification

enhancements in the terminal units.

I Deliver cold conditioned air

whenever possible. Neutral

conditioned air increases the

capacity needed from the terminal

units and requires reheat at the

dedicated OA unit.

I Select equipment to limit the

relative humidity to 60 percent.

Targeting a drier-than-necessary

condition in the space requires

oversized equipment and consumes

more energy. I

By Dennis Stanke, staff applications

engineer, and Brenda Bradley,

information designer, The Trane

Company.

You can find this and other issues

of the Engineers Newsletter in the

commercial section of www.trane.com.

To comment, send a note to The Trane

Company, Engineers Newsletter Editor,

3600 Pammel Creek Road, La Crosse,

WI 54601-7599, or e-mail us at

comfort@trane.com.

Вам также может понравиться

- Advanced Temperature Measurement and Control, Second EditionОт EverandAdvanced Temperature Measurement and Control, Second EditionОценок пока нет

- Sys Apg001 en PDFДокумент24 страницыSys Apg001 en PDFsenthilarasu5Оценок пока нет

- 2014 ASHRAE - Restroom Exhaust Design PDFДокумент4 страницы2014 ASHRAE - Restroom Exhaust Design PDFAntonio LebrunОценок пока нет

- ASHRAE Symposis Degrading Delta-T-TaylorДокумент13 страницASHRAE Symposis Degrading Delta-T-TaylormondsbaОценок пока нет

- ASHRAE Journal - Primary-Only Vs Primary-Secondary Variable Flow SystemsДокумент5 страницASHRAE Journal - Primary-Only Vs Primary-Secondary Variable Flow SystemsQaz Zaq100% (1)

- Humidity Control With Chilled BeamsДокумент7 страницHumidity Control With Chilled BeamsMelanie WilliamsОценок пока нет

- TRANE Airside EconomizerДокумент8 страницTRANE Airside EconomizerAhmed SherifОценок пока нет

- HVAC Handbook 11 All Water SystemДокумент35 страницHVAC Handbook 11 All Water SystemTanveer100% (2)

- Dual Duct Dual FanДокумент2 страницыDual Duct Dual FansajuhereОценок пока нет

- Acb40-50 Metric UsДокумент20 страницAcb40-50 Metric UsGeovanni Sanchez TrejoОценок пока нет

- Design Guide - Humidity ControlДокумент2 страницыDesign Guide - Humidity Controldzul92100% (1)

- Treatment of Outside AirДокумент4 страницыTreatment of Outside AirmohdnazirОценок пока нет

- SYS-APG001-EN - Application Guide - Designing Dedicated Outdoor-Air Systems - 2003Документ24 страницыSYS-APG001-EN - Application Guide - Designing Dedicated Outdoor-Air Systems - 2003samir rabia100% (1)

- Vav Box Reheat Selection: Krueger KruegerДокумент5 страницVav Box Reheat Selection: Krueger KruegerKia KhosraviОценок пока нет

- Trane OAUДокумент24 страницыTrane OAUEdОценок пока нет

- ECM4 Technical Information Warm-HumidДокумент11 страницECM4 Technical Information Warm-Humidmaaz ahmadОценок пока нет

- BR409 DisplacementDesignGuideДокумент52 страницыBR409 DisplacementDesignGuidecarlcrowОценок пока нет

- ECM4 Technical Information CompositeДокумент8 страницECM4 Technical Information CompositeninenergyОценок пока нет

- Displacement Design GuideДокумент52 страницыDisplacement Design GuideNoushad P HamsaОценок пока нет

- 7 3 PDFДокумент10 страниц7 3 PDFrkibОценок пока нет

- TRANE DOA App GuideДокумент20 страницTRANE DOA App GuideEduardoОценок пока нет

- HPT Optimizing Outside Air With HPTДокумент11 страницHPT Optimizing Outside Air With HPTNGUYEN QUANGОценок пока нет

- High Performance Data Centers: A Design Guidelines SourcebookДокумент63 страницыHigh Performance Data Centers: A Design Guidelines SourcebookRich Hintz100% (20)

- Part Load DehumidificationДокумент8 страницPart Load DehumidificationHai LeОценок пока нет

- Reasons Engineers Are Choosing Dedicated OA SystemsДокумент3 страницыReasons Engineers Are Choosing Dedicated OA SystemsADsupermanОценок пока нет

- BeatyДокумент5 страницBeatymayajogiОценок пока нет

- OAU Rev1Документ5 страницOAU Rev1Tassawac Koeiop100% (1)

- Doas DesignДокумент4 страницыDoas DesignBill ChambersОценок пока нет

- Hot Vs Cold Aisle Containment For DCДокумент13 страницHot Vs Cold Aisle Containment For DCtommylaw100% (1)

- Engineering: Energy RecoveryДокумент4 страницыEngineering: Energy RecoverySuchitKОценок пока нет

- Designing Dedicated Outdoor Air SystemsДокумент4 страницыDesigning Dedicated Outdoor Air Systemsrogel_ganaОценок пока нет

- ENP Energy Efficient Free Cooling For Data CentersДокумент16 страницENP Energy Efficient Free Cooling For Data CentersKarthi KeyanОценок пока нет

- Explanation of Cooling and Air Conditioning Terminology For IT ProfessionalsДокумент18 страницExplanation of Cooling and Air Conditioning Terminology For IT ProfessionalsPirozok PirozkovОценок пока нет

- Unit 7 Air Conditioning SystemsДокумент10 страницUnit 7 Air Conditioning SystemsJohnОценок пока нет

- Hap Ehelp 029Документ8 страницHap Ehelp 029Abed NaemОценок пока нет

- Offshore Hvac DesignДокумент6 страницOffshore Hvac DesignAndrew AlexОценок пока нет

- Dissertation HvacДокумент8 страницDissertation HvacCheapPaperWritingServiceAnchorage100% (1)

- Computational Fluid Dynamics Analysis of HVAC System in AuditoriumДокумент5 страницComputational Fluid Dynamics Analysis of HVAC System in AuditoriumMuhammad AshfaqОценок пока нет

- VVT System VentilationДокумент9 страницVVT System Ventilationenlightened1718Оценок пока нет

- Hot Aisle/Cold AisleДокумент1 страницаHot Aisle/Cold AisleKdc OuinbiloОценок пока нет

- 3 Simple WaysДокумент7 страниц3 Simple WaysAruna Prasanna DewasurendraОценок пока нет

- Dedicated OA Systems: Application IssuesДокумент3 страницыDedicated OA Systems: Application IssuesAshraf Adel Nashed ZakiОценок пока нет

- SYS-APG001-En 08-03-2012 Dedicated Outdoor Air Systems Trane DX Outdoor Air UnitДокумент24 страницыSYS-APG001-En 08-03-2012 Dedicated Outdoor Air Systems Trane DX Outdoor Air UnithsrairОценок пока нет

- 5 Livret Exo Selecting Induction Units and Active Chilled BeamsДокумент12 страниц5 Livret Exo Selecting Induction Units and Active Chilled BeamsmemoОценок пока нет

- HVACДокумент14 страницHVACbagi1900Оценок пока нет

- CARRIER Part-11 - All-Water-SystemДокумент35 страницCARRIER Part-11 - All-Water-SystemNahiyan AbdullahОценок пока нет

- Explanation of Cooling and Air Conditioning Terminology For IT ProfessionalsДокумент17 страницExplanation of Cooling and Air Conditioning Terminology For IT Professionalsamey8231Оценок пока нет

- Designing For ComfortДокумент6 страницDesigning For ComfortMohsin ShaikhОценок пока нет

- 7-TB - Indoor Pool DehumidificationДокумент6 страниц7-TB - Indoor Pool DehumidificationEugene PishchikerОценок пока нет

- Engineering GuideДокумент43 страницыEngineering GuideJohnMerrОценок пока нет

- Selecting Air Conditioners For EnclosureДокумент7 страницSelecting Air Conditioners For EnclosureErdinc KlimaОценок пока нет

- Temperature and Humidity Independent Control (THIC) of Air-conditioning SystemОт EverandTemperature and Humidity Independent Control (THIC) of Air-conditioning SystemОценок пока нет

- The Home Owner's Guide to HVAC: The Envelope and Green TechnologiesОт EverandThe Home Owner's Guide to HVAC: The Envelope and Green TechnologiesОценок пока нет

- A Guide to Natural Ventilation Design: A Component in Creating Leed ApplicationОт EverandA Guide to Natural Ventilation Design: A Component in Creating Leed ApplicationОценок пока нет

- Oral and Practical Review: Reflections on the Part 147 CourseОт EverandOral and Practical Review: Reflections on the Part 147 CourseОценок пока нет

- Ejectors for Efficient Refrigeration: Design, Applications and Computational Fluid DynamicsОт EverandEjectors for Efficient Refrigeration: Design, Applications and Computational Fluid DynamicsОценок пока нет

- Air-Cooled Condenser Fundamentals: Design, Operations, Troubleshooting, Maintenance, and Q&AОт EverandAir-Cooled Condenser Fundamentals: Design, Operations, Troubleshooting, Maintenance, and Q&AРейтинг: 5 из 5 звезд5/5 (1)

- Practical, Made Easy Guide To Building, Office And Home Automation Systems - Part OneОт EverandPractical, Made Easy Guide To Building, Office And Home Automation Systems - Part OneОценок пока нет

- The Complete HVAC BIBLE for Beginners: The Most Practical & Updated Guide to Heating, Ventilation, and Air Conditioning Systems | Installation, Troubleshooting and Repair | Residential & CommercialОт EverandThe Complete HVAC BIBLE for Beginners: The Most Practical & Updated Guide to Heating, Ventilation, and Air Conditioning Systems | Installation, Troubleshooting and Repair | Residential & CommercialОценок пока нет

- HPAC Operable Windows - Daly PDFДокумент8 страницHPAC Operable Windows - Daly PDFsajuhereОценок пока нет

- SandBookInterior r1Документ16 страницSandBookInterior r1sajuhereОценок пока нет

- Seidl NCBC08 Paper TR CorrectedДокумент10 страницSeidl NCBC08 Paper TR CorrectedsajuhereОценок пока нет

- Sizing Exhaust System For Refrigerating Machinery Rooms - Seidl, TaylorДокумент13 страницSizing Exhaust System For Refrigerating Machinery Rooms - Seidl, Taylorforevertay2000Оценок пока нет

- CoolTools ProjectggДокумент24 страницыCoolTools ProjectggdaveleyconsОценок пока нет

- Chapter 07Документ39 страницChapter 07kevinmathew27Оценок пока нет

- Fan SurgingДокумент10 страницFan SurgingPrashant SrivastavaОценок пока нет

- Contracting Business Magazine - Taking Controls in-House-FriedmanДокумент2 страницыContracting Business Magazine - Taking Controls in-House-FriedmanBasil OguakaОценок пока нет

- HPAC Article On Specifying VAV BoxesДокумент4 страницыHPAC Article On Specifying VAV Boxesjoejex123Оценок пока нет

- ASHRAE Symposium SE 99-16-3 Kammerud & Hydeman CB Analysis UncertaintyДокумент10 страницASHRAE Symposium SE 99-16-3 Kammerud & Hydeman CB Analysis UncertaintysajuhereОценок пока нет

- ASHRAE-Symposium WSE in Data Centers SteinДокумент9 страницASHRAE-Symposium WSE in Data Centers SteinDiego CMОценок пока нет

- HPAC A Fresh Look at Fans-FinalДокумент10 страницHPAC A Fresh Look at Fans-FinalsajuhereОценок пока нет

- ASHRAE Symposium HI-02!18!2 Symposium Hydeman & Webb New Chiller ModelДокумент10 страницASHRAE Symposium HI-02!18!2 Symposium Hydeman & Webb New Chiller ModelsajuhereОценок пока нет

- ASHRAE Journal - Select & Control Economizer Dampers in VAV Systems - TaylorДокумент7 страницASHRAE Journal - Select & Control Economizer Dampers in VAV Systems - Taylorsajuhere100% (1)

- ASHRAE Journal - VAV Box Duct Design - TaylorДокумент8 страницASHRAE Journal - VAV Box Duct Design - TaylorsajuhereОценок пока нет

- ASHRAE Journal - Stauffer Case StudyДокумент5 страницASHRAE Journal - Stauffer Case StudysajuhereОценок пока нет

- ASHRAE Journal - Staying OnlineДокумент6 страницASHRAE Journal - Staying OnlinesajuhereОценок пока нет

- ASHRAE Journal - Tips To Reduce Chilled Water Plant Costs - TaylorДокумент6 страницASHRAE Journal - Tips To Reduce Chilled Water Plant Costs - TaylorsajuhereОценок пока нет

- ASHRAE Journal - Return Fans in VAV Systems - TaylorДокумент6 страницASHRAE Journal - Return Fans in VAV Systems - TaylorAntonio LebrunОценок пока нет

- ASHRAE Journal - Return Air Systems - TaylorДокумент4 страницыASHRAE Journal - Return Air Systems - TaylorKadiri Olanrewaju100% (1)

- ASHRAE Journal - Retrofitting DDC Controls ASHRAE Journal June 2004Документ7 страницASHRAE Journal - Retrofitting DDC Controls ASHRAE Journal June 2004sajuhereОценок пока нет

- ASHRAE Journal - Underfloor Lessons Learned-DalyДокумент4 страницыASHRAE Journal - Underfloor Lessons Learned-DalysajuhereОценок пока нет

- ASHRAE Journal - Series Fan-Powered Boxes-Taylor PDFДокумент0 страницASHRAE Journal - Series Fan-Powered Boxes-Taylor PDFsajuhereОценок пока нет

- ASHRAE Journal - Optimizing Chilled Water Plant ControlsДокумент12 страницASHRAE Journal - Optimizing Chilled Water Plant ControlsAntonio LebrunОценок пока нет

- ASHRAE Journal - How To Design & Control Waterside Economizers-TaylorДокумент7 страницASHRAE Journal - How To Design & Control Waterside Economizers-TaylorsajuhereОценок пока нет

- ASHRAE Journal - LEED and Standard 62.1-TaylorДокумент4 страницыASHRAE Journal - LEED and Standard 62.1-TaylorNg Khanh100% (1)

- ASHRAE Journal - Humidity Controls in Data CentersДокумент8 страницASHRAE Journal - Humidity Controls in Data CentersAntonio LebrunОценок пока нет

- Lecture 1 Refrigerating Machine Reversed Carnot Cycle Simple Vapor Compression CycleДокумент14 страницLecture 1 Refrigerating Machine Reversed Carnot Cycle Simple Vapor Compression CycleDeniell Joyce MarquezОценок пока нет

- Cooling Tower Treatment TrainingДокумент114 страницCooling Tower Treatment TrainingMasood Ahmed100% (1)

- Lindab Price List 2015 PDFДокумент92 страницыLindab Price List 2015 PDFJeffry Gabilan100% (1)

- Legend: Mechanical Services, Sand Trap Louver & Exhaust Air Lover, Roof Floor 1Документ1 страницаLegend: Mechanical Services, Sand Trap Louver & Exhaust Air Lover, Roof Floor 1amith_kmОценок пока нет

- Exterran Drain: P&id No. P & Id TitleДокумент15 страницExterran Drain: P&id No. P & Id Titledilip matalОценок пока нет

- Straightforward Solutions of Heat Exchanger Networks (HEN) ProblemsДокумент8 страницStraightforward Solutions of Heat Exchanger Networks (HEN) ProblemsdingdongdiddlyОценок пока нет

- Eskabe BrochureДокумент2 страницыEskabe BrochureEmelia JugdavОценок пока нет

- Cooling Water System Optimization: Figure 1. Cross Section of Counter and Cross Flow TowersДокумент4 страницыCooling Water System Optimization: Figure 1. Cross Section of Counter and Cross Flow TowersLeo PunongbayanОценок пока нет

- Revision Summary - Science Form 1Документ8 страницRevision Summary - Science Form 1Beevy GB100% (1)

- Acrylic Acid ProcessДокумент21 страницаAcrylic Acid ProcessVinicius Gonçalves50% (2)

- Cooling Water Requirement For Molding MachinesДокумент5 страницCooling Water Requirement For Molding MachinesPinak ProjectsОценок пока нет

- Ultra Coolant LubricantДокумент3 страницыUltra Coolant Lubricantandri putrantoОценок пока нет

- Steam Tables Pressure Heat of VaporizatioДокумент5 страницSteam Tables Pressure Heat of VaporizatioMmmmohОценок пока нет

- Synthesis and Structural Modification of PolyanilineДокумент1 страницаSynthesis and Structural Modification of PolyanilineChax EdrallagОценок пока нет

- Room Air Conditioner Sizing and Choosing ChartДокумент6 страницRoom Air Conditioner Sizing and Choosing ChartNero NoiseОценок пока нет

- 2018 - Hallaaoui - One Dimensional Phosphate Flash Dryer Model For Design ApplicationДокумент11 страниц2018 - Hallaaoui - One Dimensional Phosphate Flash Dryer Model For Design ApplicationGuilherme Venturi RonchiОценок пока нет

- Book of Heat Transfer ReviewДокумент109 страницBook of Heat Transfer ReviewMd.Faysal Ahamed KhanОценок пока нет

- HVAC Turning Vanes ApplicationДокумент5 страницHVAC Turning Vanes ApplicationQfg Proiect SrlОценок пока нет

- Applsci 11 07341 v2Документ16 страницApplsci 11 07341 v2Julius VonОценок пока нет

- HYSYS Workshop - ONGC - CleanedДокумент144 страницыHYSYS Workshop - ONGC - Cleanedapoorv appuОценок пока нет

- MFS Fact Sheet Extinguishing A FireДокумент4 страницыMFS Fact Sheet Extinguishing A Firenarayananks1Оценок пока нет

- Point Maps Chillers AOSДокумент4 страницыPoint Maps Chillers AOScesarintiОценок пока нет

- Trane ENL ASHRAE 62.1 90.1 VAVДокумент54 страницыTrane ENL ASHRAE 62.1 90.1 VAVgary_robinsonОценок пока нет

- Process IntegrationДокумент37 страницProcess IntegrationMeareg100% (2)

- Hvac CVДокумент2 страницыHvac CVsarfaraz055Оценок пока нет

- TEDOM Tri Generation enДокумент2 страницыTEDOM Tri Generation enAnna DruzbovaОценок пока нет

- Hyundai - Parts - Aftermarket - Product List (HASI) PDFДокумент6 страницHyundai - Parts - Aftermarket - Product List (HASI) PDFSprinter Transit VanОценок пока нет

- Air System Sizing Summary For AHU-03Документ4 страницыAir System Sizing Summary For AHU-03Mohamed EidОценок пока нет

- The Advantages of QUANTUM Chillers: Superior Technology Becomes Customer ValueДокумент2 страницыThe Advantages of QUANTUM Chillers: Superior Technology Becomes Customer ValuesanpkaruОценок пока нет

- Mathematical Optimization of Solar Thermal Collectors Efficiency Function Using MATLABДокумент5 страницMathematical Optimization of Solar Thermal Collectors Efficiency Function Using MATLABSantiago Del Rio OliveiraОценок пока нет