Академический Документы

Профессиональный Документы

Культура Документы

WIS5 Imperfections 2006 PDF

Загружено:

Watcharapong Puangthaisong100%(1)100% нашли этот документ полезным (1 голос)

118 просмотров81 страницаОригинальное название

WIS5-Imperfections-2006.pdf

Авторское право

© © All Rights Reserved

Доступные форматы

PDF, TXT или читайте онлайн в Scribd

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

© All Rights Reserved

Доступные форматы

Скачайте в формате PDF, TXT или читайте онлайн в Scribd

100%(1)100% нашли этот документ полезным (1 голос)

118 просмотров81 страницаWIS5 Imperfections 2006 PDF

Загружено:

Watcharapong PuangthaisongАвторское право:

© All Rights Reserved

Доступные форматы

Скачайте в формате PDF, TXT или читайте онлайн в Scribd

Вы находитесь на странице: 1из 81

Copyright 2006, TWI Ltd

World Centre for Materials Joining Technology

CSWIP 3.1 Welding Inspection CSWIP 3.1 Welding Inspection

TWI Training & Examination TWI Training & Examination

Services Services

Welding & Welding & Materials Materials

Imperfections Imperfections

Course Reference WIS 5 Course Reference WIS 5

Course notes section reference 3, 6 & 16 Course notes section reference 3, 6 & 16

Copyright 2006, TWI Ltd

World Centre for Materials Joining Technology

Welding Imperfections Welding Imperfections

All welds have imperfections All welds have imperfections

Imperfections are classed as Imperfections are classed as defects defects when they are of a when they are of a

type, or size, not allowed by the Acceptance Standard type, or size, not allowed by the Acceptance Standard

A defect is an unacceptable imperfection A defect is an unacceptable imperfection

A weld imperfection may be allowed by one Acceptance A weld imperfection may be allowed by one Acceptance

Standard but be classed as a defect by another Standard Standard but be classed as a defect by another Standard

and require removal/rectification and require removal/rectification

Copyright 2006, TWI Ltd

World Centre for Materials Joining Technology

Welding Imperfections Welding Imperfections

Standards for Welding Imperfections Standards for Welding Imperfections

BS BS EN ISO 6520 EN ISO 6520- -1 1(1998) (1998) Welding and allied processes Welding and allied processes

Classification of geometric Classification of geometric

imperfections in metallic materials imperfections in metallic materials - -

Part 1: Fusion welding Part 1: Fusion welding

Imperfections are classified into 6 groups, namely: Imperfections are classified into 6 groups, namely:

1 Cracks 1 Cracks

2 Cavities 2 Cavities

3 Solid inclusions 3 Solid inclusions

4 Lack of fusion and penetration 4 Lack of fusion and penetration

5 Imperfect shape and dimensions 5 Imperfect shape and dimensions

6 Miscellaneous imperfections 6 Miscellaneous imperfections

Copyright 2006, TWI Ltd

World Centre for Materials Joining Technology

Welding Imperfections Welding Imperfections

Standards for Welding Imperfections Standards for Welding Imperfections

EN ISO 5817 EN ISO 5817 (2003) (2003) Welding Welding - - Fusion Fusion- -welded joints in steel, welded joints in steel,

nickel, titanium and their alloys (beam nickel, titanium and their alloys (beam

welding excluded) welding excluded) - - Quality levels for Quality levels for

imperfections imperfections

This main imperfections given in EN ISO 6520 This main imperfections given in EN ISO 6520- -1 are listed in 1 are listed in

EN ISO 5817 with acceptance criteria at 3 levels, namely EN ISO 5817 with acceptance criteria at 3 levels, namely

Level B (highest) Level B (highest)

Level C (intermediate) Level C (intermediate)

Level D (general) Level D (general)

This Standard is directly applicable to This Standard is directly applicable to visual visual testing of welds testing of welds

... ...(weld surfaces & macro examination) (weld surfaces & macro examination)

Copyright 2006, TWI Ltd

World Centre for Materials Joining Technology

Welding imperfections Welding imperfections

classification classification

Cracks Cracks

Copyright 2006, TWI Ltd

World Centre for Materials Joining Technology

Cracks Cracks

Cracks that may occur in welded materials are Cracks that may occur in welded materials are

caused generally by many factors and may be caused generally by many factors and may be

classified by shape and position. classified by shape and position.

Note: Note: Cracks are classed as Planar Defects. Cracks are classed as Planar Defects.

Classified by Shape Classified by Shape

Longitudinal Longitudinal

Transverse Transverse

Chevron Chevron

Lamellar Tear Lamellar Tear

Classified by Position Classified by Position

HAZ HAZ

Centerline Centerline

Crater Crater

Fusion zone Fusion zone

Parent metal Parent metal

Copyri t , I t

World Centre for Materials Joining Technology

Longitudinal parent metal Longitudinal parent metal

Longitudinal weld metal Longitudinal weld metal

Lamellar tearing Lamellar tearing

Transverse weld metal Transverse weld metal

Cracks Cracks

Copyright 2006, TWI Ltd

World Centre for Materials Joining Technology

Transverse crack Transverse crack Longitudinal crack Longitudinal crack

Cracks Cracks

Copyright 2006, TWI Ltd

World Centre for Materials Joining Technology

Main Crack Types Main Crack Types

Solidification Cracks Solidification Cracks

Hydrogen Induced Cracks Hydrogen Induced Cracks

Lamellar Tearing Lamellar Tearing

Reheat cracks Reheat cracks

Cracks Cracks

Copyright 2006, TWI Ltd

World Centre for Materials Joining Technology

Solidification Cracking Solidification Cracking

Occurs during weld solidification process Occurs during weld solidification process

Steels with high sulphur impurities content (low ductility at Steels with high sulphur impurities content (low ductility at

elevated temperature) elevated temperature)

Requires high tensile stress Requires high tensile stress

Occur longitudinally down centre of weld Occur longitudinally down centre of weld

Cracks Cracks

Copyright 2006, TWI Ltd

World Centre for Materials Joining Technology

Cracks Cracks

Hydrogen Induced Cold Cracking Hydrogen Induced Cold Cracking

Requires susceptible hard grain structure, stress, low Requires susceptible hard grain structure, stress, low

temperature and hydrogen temperature and hydrogen

Hydrogen enters weld via welding arc mainly as result of Hydrogen enters weld via welding arc mainly as result of

contaminated electrode or preparation contaminated electrode or preparation

Hydrogen diffuses out into parent metal on cooling Hydrogen diffuses out into parent metal on cooling

Cracking developing most likely in HAZ Cracking developing most likely in HAZ

Copyright 2006, TWI Ltd

World Centre for Materials Joining Technology

Cracks Cracks

Lamellar Tearing Lamellar Tearing

Step like appearance Step like appearance

Occurs in parent material or HAZ Occurs in parent material or HAZ

Only in rolled direction of the parent material Only in rolled direction of the parent material

Associated with restrained joints subjected to through Associated with restrained joints subjected to through

thickness stresses on corners, tees and fillets thickness stresses on corners, tees and fillets

Requires high sulphur or non Requires high sulphur or non- -metallic inclusions metallic inclusions

Copyright 2006, TWI Ltd

World Centre for Materials Joining Technology

Cracks Cracks

Re Re- -Heat Cracking Heat Cracking

Occurs mainly in HAZ of low alloy steels during post weld Occurs mainly in HAZ of low alloy steels during post weld

heat treatment or service at elevated temperatures heat treatment or service at elevated temperatures

Occurs in areas of high stress and existing defects Occurs in areas of high stress and existing defects

Prevented by toe grinding, elimination of poor profile Prevented by toe grinding, elimination of poor profile

material selection and controlled post weld heat treatment material selection and controlled post weld heat treatment

Copyright 2006, TWI Ltd

World Centre for Materials Joining Technology

Welding Imperfections Classification Welding Imperfections Classification

Cavities Cavities

Copyright 2006, TWI Ltd

World Centre for Materials Joining Technology

Gas Cavities Gas Cavities

Root piping Root piping

Cluster porosity Cluster porosity Gas pore Gas pore

Blow hole Blow hole

Herringbone porosity Herringbone porosity

Gas pore <1.5mm Gas pore <1.5mm

Blow hole.>1.6mm Blow hole.>1.6mm

Causes: Causes:

Loss of gas shield Loss of gas shield

Damp electrodes Damp electrodes

Contamination Contamination

Arc length too large Arc length too large

Damaged electrode flux Damaged electrode flux

Moisture on parent material Moisture on parent material

Welding current too low Welding current too low

Copyright 2006, TWI Ltd

World Centre for Materials Joining Technology

Root piping Root piping

Porosity Porosity

Gas Cavities Gas Cavities

Copyright 2006, TWI Ltd

World Centre for Materials Joining Technology

Cluster porosity Cluster porosity

Herringbone porosity Herringbone porosity

Gas Cavities Gas Cavities

Copyright 2006, TWI Ltd

World Centre for Materials Joining Technology

Crater pipe Crater pipe

Weld crater Weld crater

Crater Pipe Crater Pipe

Copyright 2006, TWI Ltd

World Centre for Materials Joining Technology

Crater pipe is a shrinkage defect and not a gas defect, it has Crater pipe is a shrinkage defect and not a gas defect, it has

the appearance of a gas pore in the weld crater the appearance of a gas pore in the weld crater

Causes: Causes:

Too fast a cooling Too fast a cooling

rate rate

Deoxidization Deoxidization

reactions and liquid reactions and liquid

to solid volume to solid volume

change change

Contamination Contamination

Crater cracks Crater cracks

(Star cracks) (Star cracks)

Crater pipe Crater pipe

Crater Pipe Crater Pipe

Copyright 2006, TWI Ltd

World Centre for Materials Joining Technology

Welding Imperfections Classification Welding Imperfections Classification

Solid Inclusions Solid Inclusions

Copyright 2006, TWI Ltd

World Centre for Materials Joining Technology

Solid Inclusions Solid Inclusions

Slag inclusions are defined as a non Slag inclusions are defined as a non- -metallic inclusion caused metallic inclusion caused

by some welding process by some welding process

Causes: Causes:

Slag originates from Slag originates from

welding flux welding flux

MAG and TIG welding MAG and TIG welding

process produce silica process produce silica

inclusions inclusions

Slag is caused by Slag is caused by

inadequate cleaning inadequate cleaning

Other inclusions include Other inclusions include

tungsten and copper tungsten and copper

inclusions from the TIG inclusions from the TIG

and MAG welding process and MAG welding process

Slag inclusions Slag inclusions

Parallel slag lines Parallel slag lines

Lack of sidewall Lack of sidewall

fusion with fusion with

associated slag associated slag

Lack of interun Lack of interun

fusion + slag fusion + slag

Copyright 2006, TWI Ltd

World Centre for Materials Joining Technology

Elongated slag lines Elongated slag lines Interpass slag inclusions Interpass slag inclusions

Solid Inclusions Solid Inclusions

Copyright 2006, TWI Ltd

World Centre for Materials Joining Technology

Welding Imperfections Classification Welding Imperfections Classification

Lack of Fusion Lack of Fusion

Copyright 2006, TWI Ltd

World Centre for Materials Joining Technology

Welding Imperfections Welding Imperfections

Typical Causes of Lack of Fusion: Typical Causes of Lack of Fusion:

welding current too low

bevel angle too steep

root face too large (single-sided weld)

root gap too small (single-sided weld)

incorrect electrode angle

linear misalignment

welding speed too high

welding process related particularly dip-transfer GMAW

flooding the joint with too much weld metal (blocking Out)

Copyright 2006, TWI Ltd

World Centre for Materials Joining Technology

Lack of Fusion Lack of Fusion

Incomplete filled groove + Incomplete filled groove +

Lack of sidewall fusion Lack of sidewall fusion

1 1

2 2

1. 1. Lack of sidewall fusion Lack of sidewall fusion

2. 2. Lack of inter Lack of inter- -run fusion run fusion

Causes: Causes:

Poor welder skill Poor welder skill

Incorrect electrode Incorrect electrode

manipulation manipulation

Arc blow Arc blow

Incorrect welding Incorrect welding

current/voltage current/voltage

Incorrect travel speed Incorrect travel speed

Incorrect inter Incorrect inter- -run cleaning run cleaning

Copyright 2006, TWI Ltd

World Centre for Materials Joining Technology

Lack of sidewall fusion + incomplete filled groove Lack of sidewall fusion + incomplete filled groove

Lack of Fusion Lack of Fusion

Copyright 2006, TWI Ltd

World Centre for Materials Joining Technology

Welding Imperfections Classification Welding Imperfections Classification

Overlap Overlap

Copyright 2006, TWI Ltd

World Centre for Materials Joining Technology

Overlap Overlap

An imperfection at the toe or root of a weld caused by metal An imperfection at the toe or root of a weld caused by metal

flowing on to the surface of the parent metal without fusing to it flowing on to the surface of the parent metal without fusing to it

Causes: Causes:

Contamination Contamination

Slow travel speed Slow travel speed

Incorrect welding Incorrect welding

technique technique

Current too low Current too low

Copyright 2006, TWI Ltd

World Centre for Materials Joining Technology

Overlap Overlap

Toe Overlap Toe Overlap

Toe Overlap Toe Overlap

Copyright 2006, TWI Ltd

World Centre for Materials Joining Technology

Welding Imperfections Classification Welding Imperfections Classification

Weld Root Imperfections Weld Root Imperfections

Copyright 2006, TWI Ltd

World Centre for Materials Joining Technology

Weld Root Imperfections Weld Root Imperfections

Incomplete root fusion Incomplete root fusion

Incomplete root penetration Incomplete root penetration

Causes: Causes:

Low Amps/volts Low Amps/volts

Large Root face Large Root face

Small Root Gap Small Root Gap

Fast Travel Speed Fast Travel Speed

Incorrect Electrode Incorrect Electrode

Angle Angle

Contamination Contamination

Arc blow Arc blow

Copyright 2006, TWI Ltd

World Centre for Materials Joining Technology

Lack of root penetration Lack of root penetration Lack of root fusion Lack of root fusion

Weld Root Imperfections Weld Root Imperfections

Copyright 2006, TWI Ltd

World Centre for Materials Joining Technology

Weld Root Imperfections Weld Root Imperfections

Lack of Root Fusion Lack of Root Fusion

Lack of Root Penetration Lack of Root Penetration

Copyright 2006, TWI Ltd

World Centre for Materials Joining Technology

Shrinkage groove Shrinkage groove

Causes: Causes:

Insufficient weld metal Insufficient weld metal

deposited in the root pass deposited in the root pass

Too fast a cooling rate Too fast a cooling rate

during the application of during the application of

the root bead pass the root bead pass

Poor welding technique Poor welding technique

A shallow groove caused by contraction in the weld metal A shallow groove caused by contraction in the weld metal

along each side of the penetration bead along each side of the penetration bead

Weld Root Imperfections Weld Root Imperfections

Copyright 2006, TWI Ltd

World Centre for Materials Joining Technology

Concave Root Concave Root

Causes: Causes:

Excessive back purge pressure Excessive back purge pressure

during TIG welding during TIG welding

Excessive root bead grinding Excessive root bead grinding

before the application of the before the application of the

second pass second pass

welding current too high for 2nd welding current too high for 2nd

pass pass overhead welding overhead welding

root gap too large root gap too large - - excessive excessive

weaving weaving

A shallow groove, which may occur in the root of a butt weld A shallow groove, which may occur in the root of a butt weld

Weld Root Imperfections Weld Root Imperfections

Copyright 2006, TWI Ltd

World Centre for Materials Joining Technology

Concave Root Concave Root

Weld Root Imperfections Weld Root Imperfections

Copyright 2006, TWI Ltd

World Centre for Materials Joining Technology

Excessive root penetration Excessive root penetration

Causes: Causes:

Root faces too small Root faces too small

Root gap too large Root gap too large

Excessive amps/volts Excessive amps/volts

Slow travel speed Slow travel speed

Root penetration bead in excess in accordance with the Root penetration bead in excess in accordance with the

relevant specification being used relevant specification being used

Weld Root Imperfections Weld Root Imperfections

Copyright 2006, TWI Ltd

World Centre for Materials Joining Technology

Excessive root Excessive root

penetration penetration

Weld Root Imperfections Weld Root Imperfections

Copyright 2006, TWI Ltd

World Centre for Materials Joining Technology

Concave root Concave root Excess root penetration Excess root penetration

Weld Root Imperfections Weld Root Imperfections

Copyright 2006, TWI Ltd

World Centre for Materials Joining Technology

Causes: Causes:

High Amps/volts High Amps/volts

Small Root face Small Root face

Large Root Gap Large Root Gap

Slow Travel Speed Slow Travel Speed

Burn through Burn through

A localized collapse of the weld pool due to excessive A localized collapse of the weld pool due to excessive

penetration resulting in a hole in the root run penetration resulting in a hole in the root run

Weld Root Imperfections Weld Root Imperfections

Copyright 2006, TWI Ltd

World Centre for Materials Joining Technology

Burn Through Burn Through

Weld Root Imperfections Weld Root Imperfections

Copyright 2006, TWI Ltd

World Centre for Materials Joining Technology

Causes: Causes:

Loss or insufficient back Loss or insufficient back

purging gas purging gas

Most commonly occurs Most commonly occurs

when welding stainless when welding stainless

steels steels

Purging gases include Purging gases include

argon, helium and argon, helium and

occasionally nitrogen occasionally nitrogen

Oxidized Root (Root Coking) Oxidized Root (Root Coking)

Copyright 2006, TWI Ltd

World Centre for Materials Joining Technology

Welding Imperfections Classification Welding Imperfections Classification

Imperfect Shape and Dimensions Imperfect Shape and Dimensions

Copyright 2006, TWI Ltd

World Centre for Materials Joining Technology

Weld Imperfections Weld Imperfections

Typical Causes of Imperfect Shape (including poor toe blend) Typical Causes of Imperfect Shape (including poor toe blend)

Poor welding technique is the usual cause these Poor welding technique is the usual cause these

imperfections, such as: imperfections, such as:

electrode size for the cap passes is too large electrode size for the cap passes is too large

welding speed too slow welding speed too slow

welding current too low welding current too low

arc voltage too low (SAW and GMAW) arc voltage too low (SAW and GMAW)

poor manipulation of the electrode poor manipulation of the electrode

incorrect weld bead positioning / placement incorrect weld bead positioning / placement

Copyright 2006, TWI Ltd

World Centre for Materials Joining Technology

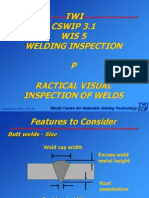

Surface and Profile Surface and Profile

Incomplete filled groove Incomplete filled groove Poor cap profile Poor cap profile

Excessive cap height Excessive cap height

Poor cap profiles and Poor cap profiles and

excessive cap reinforcements excessive cap reinforcements

may lead to stress may lead to stress

concentration points at the concentration points at the

weld toes and will also weld toes and will also

contribute to overall poor toe contribute to overall poor toe

blend blend

Copyright 2006, TWI Ltd

World Centre for Materials Joining Technology

Incomplete filled groove Incomplete filled groove Excess cap reinforcement Excess cap reinforcement

Surface and Profile Surface and Profile

Copyright 2006, TWI Ltd

World Centre for Materials Joining Technology

Surface and Profile Surface and Profile

Poor Cap Profile & Poor Toe Blend Poor Cap Profile & Poor Toe Blend

Copyright 2006, TWI Ltd

World Centre for Materials Joining Technology

Surface and Profile Surface and Profile

Poor Poor

Stop / Starts Stop / Starts

Copyright 2006, TWI Ltd

World Centre for Materials Joining Technology

Cap and Root Undercut Cap and Root Undercut

An irregular groove at the toe of a weld run in the parent metal An irregular groove at the toe of a weld run in the parent metal

Causes: Causes:

Excessive amps/volts Excessive amps/volts

Excessive travel speed Excessive travel speed

Incorrect electrode angle Incorrect electrode angle

Excessive weaving Excessive weaving

Incorrect welding Incorrect welding

technique technique

Electrode too large Electrode too large

Arc length too high Arc length too high

Copyright 2006, TWI Ltd

World Centre for Materials Joining Technology

Cap Undercut Cap Undercut

Intermittent Cap Undercut Intermittent Cap Undercut

Copyright 2006, TWI Ltd

World Centre for Materials Joining Technology

Cap undercut Cap undercut Root undercut Root undercut

Undercut Undercut

Copyright 2006, TWI Ltd

World Centre for Materials Joining Technology

Welding Imperfections Classification Welding Imperfections Classification

Miscellaneous Imperfections Miscellaneous Imperfections

Copyright 2006, TWI Ltd

World Centre for Materials Joining Technology

Welding Imperfections Welding Imperfections

Miscellaneous Imperfections Miscellaneous Imperfections

Arc strike or stray arc: Arc strike or stray arc:

accidental striking of an arc on to base material accidental striking of an arc on to base material

loss of welding cable insulation loss of welding cable insulation

poor connection of current return cable poor connection of current return cable

Spatter: Spatter:

excessive current or voltage excessive current or voltage

Grinding mark / mechanical damage: Grinding mark / mechanical damage:

Torn surface Torn surface

Copyright 2006, TWI Ltd

World Centre for Materials Joining Technology

Miscellaneous Imperfections Miscellaneous Imperfections

Causes: Causes:

Excessive current Excessive current

Damp electrodes Damp electrodes

Contamination Contamination

Incorrect wire feed speed Incorrect wire feed speed

when welding with the when welding with the

MAG welding process MAG welding process

Arc blow Arc blow

Spatter Spatter

Copyright 2006, TWI Ltd

World Centre for Materials Joining Technology

Miscellaneous Imperfections Miscellaneous Imperfections

Arc strike Arc strike

Causes: Causes:

Accidental striking of the Accidental striking of the

arc onto the parent arc onto the parent

material material

Faulty electrode holder Faulty electrode holder

Poor cable insulation Poor cable insulation

Poor return lead Poor return lead

clamping clamping

Copyright 2006, TWI Ltd

World Centre for Materials Joining Technology

Welding Imperfections Classification Welding Imperfections Classification

Mechanical Damage Mechanical Damage

Copyright 2006, TWI Ltd

World Centre for Materials Joining Technology

Mechanical Damage Mechanical Damage

Mechanical damage can be defined as any surface material Mechanical damage can be defined as any surface material

damage cause during the manufacturing process. damage cause during the manufacturing process.

Grinding Grinding

Hammering Hammering

Chiselling Chiselling

Chipping Chipping

Breaking off welded attachments Breaking off welded attachments

(torn surfaces) (torn surfaces)

Using needle guns to compress Using needle guns to compress

weld capping runs weld capping runs

Copyright 2006, TWI Ltd

World Centre for Materials Joining Technology

Mechanical Damage Mechanical Damage

Mechanical Damage/Grinding Mark Mechanical Damage/Grinding Mark

Chipping Marks Chipping Marks

Copyright 2006, TWI Ltd

World Centre for Materials Joining Technology

Welding Imperfections Classification Welding Imperfections Classification

Set Set- -Up Irregularities Up Irregularities

Copyri t , I t

World Centre for Materials Joining Technology

A variation of leg lengths on a fillet weld A variation of leg lengths on a fillet weld

Note: Note: Unequal leg lengths on a fillet weld may be specified as Unequal leg lengths on a fillet weld may be specified as

part of the design, in which case it will not be part of the design, in which case it will not be

considered as a defect. considered as a defect.

Unequal Leg Lengths Unequal Leg Lengths

Copyright 2006, TWI Ltd

World Centre for Materials Joining Technology

Set Set- -Up Irregularities Up Irregularities

Plate/pipe Linear Misalignment Plate/pipe Linear Misalignment

(Hi (Hi- -Lo) Lo)

Angular Misalignment Angular Misalignment

Linear misalignment Linear misalignment is is

measured from the lowest measured from the lowest

plate to the highest point. plate to the highest point.

Angular misalignment Angular misalignment is is

measured in degrees measured in degrees

Copyright 2006, TWI Ltd

World Centre for Materials Joining Technology

Set Set- -Up Irregularities Up Irregularities

Linear Misalignment Linear Misalignment

Copyright 2006, TWI Ltd

World Centre for Materials Joining Technology

Linear Misalignment Linear Misalignment

Set Set- -Up Irregularities Up Irregularities

Copyright 2006, TWI Ltd

World Centre for Materials Joining Technology

Any Questions Any Questions

Welding Imperfections Welding Imperfections

Copyright 2006, TWI Ltd

World Centre for Materials Joining Technology

Questions Questions

Weld Imperfections: Weld Imperfections:

QU 1. QU 1. Give two main causes for the occurrence of a burn Give two main causes for the occurrence of a burn- -through through

QU 2. QU 2. Give two main causes for the occurrence of excessive Give two main causes for the occurrence of excessive

root penetration on a single root penetration on a single- -V butt weld V butt weld

QU 3. QU 3. Give five defects, which may occur when welding carbon steel Give five defects, which may occur when welding carbon steel

using the MMA welding process with the current setting to low using the MMA welding process with the current setting to low

QU 4. QU 4. Give three possible causes for the occurrence of lack of side Give three possible causes for the occurrence of lack of side

wall fusion wall fusion

QU 5. QU 5. Sketch the following defects Sketch the following defects

a. a. Lack of root wall fusion Lack of root wall fusion b. b. Lack of root penetration Lack of root penetration

c. c. Incomplete filled groove Incomplete filled groove d. d. Concave root Concave root

Copyright 2006, TWI Ltd

World Centre for Materials Joining Technology

Material Inspection Material Inspection

Parent Material Imperfections Parent Material Imperfections

Copyright 2006, TWI Ltd

World Centre for Materials Joining Technology

Material Inspection Material Inspection

All materials arriving on site should be inspected for: All materials arriving on site should be inspected for:

Size / dimensions Size / dimensions

Condition Condition

Type / specification Type / specification

In addition other elements may need to be considered In addition other elements may need to be considered

depending on the materials form or shape depending on the materials form or shape

Copyri t , I t

World Centre for Materials Joining Technology

Condition

(Corrosion, Damage, Wall thickness Ovality, Laminations & Seam)

Specification

Welded

seam

Size

LP5

Pipe Inspection Pipe Inspection Pipe Inspection Pipe Inspection

Other checks may need to be made such as: distortion

tolerance, number of plates and storage*

Copyri t , I t

World Centre for Materials Joining Technology

Size

Condition

(Corrosion, Mechanical damage, Laps, Bands &

Laminations)

5L

Specification

Other checks may need to be made such as: distortion

tolerance, number of plates and storage*

Plate Inspection Plate Inspection Plate Inspection Plate Inspection

Copyri t , I t

World Centre for Materials Joining Technology

Laminations

Segregation

Cold Laps*

Direction of rolling

Rolling Imperfections Rolling Imperfections

Copyright 2006, TWI Ltd

World Centre for Materials Joining Technology

Parent Material Imperfections Parent Material Imperfections

Lamination Lamination

Mechanical damage Mechanical damage

Lap Lap

Segregation line Segregation line

Laminations Laminations are caused in the parent plate by the steel making are caused in the parent plate by the steel making

process, originating from ingot casting defects. process, originating from ingot casting defects.

Segregation bands Segregation bands occur in the centre of the plate and are low occur in the centre of the plate and are low

melting point impurities such as sulphur and phosphorous. melting point impurities such as sulphur and phosphorous.

Laps Laps are caused during rolling when overlapping metal does not are caused during rolling when overlapping metal does not

fuse to the base material. fuse to the base material.

Copyright 2006, TWI Ltd

World Centre for Materials Joining Technology

Lapping Lapping Lapping Lapping

Copyright 2006, TWI Ltd

World Centre for Materials Joining Technology

Lapping

Copyright 2006, TWI Ltd

World Centre for Materials Joining Technology

Lapping Lapping Lapping Lapping

Copyright 2006, TWI Ltd

World Centre for Materials Joining Technology

Lamination Lamination Lamination Lamination

Copyright 2006, TWI Ltd

World Centre for Materials Joining Technology

Laminations Laminations

Plate Lamination Plate Lamination

Copyright 2006, TWI Ltd

World Centre for Materials Joining Technology

Any Questions Any Questions

Material imperfections Material imperfections

Copyright 2006, TWI Ltd

World Centre for Materials Joining Technology

Questions Questions

Weld Repairs: Weld Repairs:

QU 1. QU 1. State six points of importance of repair welding. State six points of importance of repair welding.

QU 2. QU 2. State two NDT methods that may be applied in a weld State two NDT methods that may be applied in a weld

repair repair

QU 3. QU 3. State three documents, which the inspector should State three documents, which the inspector should

refer to when carrying out repairs. refer to when carrying out repairs.

QU 4. QU 4. In some cases why might a specification not allow a In some cases why might a specification not allow a

crack to be repaired, regardless of size or orientation? crack to be repaired, regardless of size or orientation?

Copyright 2006, TWI Ltd

World Centre for Materials Joining Technology

Elements Elements

Iron Iron Fe Fe

Carbon Carbon C C is for Strength is for Strength

Manganese Manganese Mn Mn is for Toughness is for Toughness

Silicon Silicon Si Si < 0.3% Deoxidiser < 0.3% Deoxidiser

Aluminium Aluminium Al Al Grain refiner, <0.008% Deoxidiser + Grain refiner, <0.008% Deoxidiser +

Toughness Toughness

Chromium Chromium Cr Cr Corrosion resistance Corrosion resistance

Molybdenum Molybdenum Mo Mo 1% is for Creep resistance 1% is for Creep resistance

Copyright 2006, TWI Ltd

World Centre for Materials Joining Technology

Elements Elements

Vanadium Vanadium VV Strength Strength

Nickel Nickel Ni Ni Low temperature applications Low temperature applications

Copper Copper Cu Cu Used for weathering steels (Corten) Used for weathering steels (Corten)

Sulphur Sulphur SS Residual element (can cause hot Residual element (can cause hot

shortness) shortness)

Phosphorous Phosphorous PP Residual element Residual element

Titanium Titanium Ti Ti Grain refiner, Used a a micro alloying Grain refiner, Used a a micro alloying

element (S&T) element (S&T)

Niobium Niobium Nb Nb Grain refiner, Used a a micro alloying Grain refiner, Used a a micro alloying

element element (S&T) (S&T)

(S&T) = Strength & Toughness (S&T) = Strength & Toughness

Copyright 2006, TWI Ltd

World Centre for Materials Joining Technology

Stainless Steel Stainless Steel

Вам также может понравиться

- Handbook of Mechanical Engineering TermsДокумент366 страницHandbook of Mechanical Engineering Termsjakejohns95% (44)

- RT Level L FINALДокумент80 страницRT Level L FINALSaad AfzalОценок пока нет

- 01 - WELDING DEFECTS (Surface) - May 2021Документ28 страниц01 - WELDING DEFECTS (Surface) - May 2021Gerry Dan ChanliongcoОценок пока нет

- Visual Weld Inspection and Defect Identification GuideДокумент46 страницVisual Weld Inspection and Defect Identification GuideDương PhúcОценок пока нет

- Day 1answersДокумент31 страницаDay 1answersMahmoud Elsayed MohamedОценок пока нет

- Various Welding ProcessДокумент50 страницVarious Welding Processsachin G.Оценок пока нет

- Cswip 2017Документ766 страницCswip 2017Arben MontellanoОценок пока нет

- Weld Defects and DiscontinuitiesДокумент78 страницWeld Defects and DiscontinuitiesGilbert MendozaОценок пока нет

- Cwi-Module1 - Welding Inspection & CertificationДокумент30 страницCwi-Module1 - Welding Inspection & CertificationPurvesh NanavatiОценок пока нет

- Weld RepairsДокумент24 страницыWeld RepairsLương Hồ VũОценок пока нет

- Richard M. Beldyk, PE, NSPE AWS Certified Welding Engineer AFE Certified Plant EngineerДокумент80 страницRichard M. Beldyk, PE, NSPE AWS Certified Welding Engineer AFE Certified Plant EngineerScott K.L LeeОценок пока нет

- The Ultimate Manifesting Money Blueprint by Sonia RicottiДокумент34 страницыThe Ultimate Manifesting Money Blueprint by Sonia RicottiViolet VioletОценок пока нет

- Penetrant Testing. Ultrasonic TestingДокумент74 страницыPenetrant Testing. Ultrasonic TestingHskumarReddy Karri100% (1)

- CSWIP 3.1 Welding Inspector Exam Day 1 AnswersДокумент31 страницаCSWIP 3.1 Welding Inspector Exam Day 1 Answershaoues23100% (2)

- TWI Radiographic Interpretation. (Weld Defects & Repair)Документ61 страницаTWI Radiographic Interpretation. (Weld Defects & Repair)jar_2100% (3)

- Cult of KUДокумент31 страницаCult of KUEli GiudiceОценок пока нет

- 03 06 16 WIS5 Imperfections 2006Документ81 страница03 06 16 WIS5 Imperfections 2006Daniel StuparekОценок пока нет

- 21 - Welding Terms and Definations - PPT Version 1Документ69 страниц21 - Welding Terms and Definations - PPT Version 1Shubham Shukla100% (1)

- Welding Inspection: Multiple-Choice Question Paper MSR-WI-1: Name: .. DateДокумент7 страницWelding Inspection: Multiple-Choice Question Paper MSR-WI-1: Name: .. DateBENNY BUSTOMI100% (1)

- Introduction to Gas Shielded Arc WeldingДокумент157 страницIntroduction to Gas Shielded Arc Weldingrohit mathankerОценок пока нет

- M13 - Solution of TrianglesДокумент5 страницM13 - Solution of Triangles9703693564Оценок пока нет

- 06 - Weld Ability and Defects in WeldmentsДокумент50 страниц06 - Weld Ability and Defects in Weldmentsamitjee138463Оценок пока нет

- Module 1Документ30 страницModule 1mahmoud aliОценок пока нет

- Welding - Inspection (TWI BOOK)Документ134 страницыWelding - Inspection (TWI BOOK)Iyappan BaluОценок пока нет

- TWI CSWIP 3.1 Wis 5 Welding Inspection Weldability: World Centre For Materials Joining TechnologyДокумент53 страницыTWI CSWIP 3.1 Wis 5 Welding Inspection Weldability: World Centre For Materials Joining TechnologyOnur Altuntaş100% (1)

- Gas Burners For Forges Furnaces and Kilns-Michael PorterДокумент208 страницGas Burners For Forges Furnaces and Kilns-Michael PorterEsmeralda Palatnic Ampuero95% (21)

- CSWIP 3.1 Welding Inspection Day 2 Questions and AnswersДокумент62 страницыCSWIP 3.1 Welding Inspection Day 2 Questions and Answershaoues23Оценок пока нет

- 3 Welding Imperfections and Materials InspectionДокумент31 страница3 Welding Imperfections and Materials InspectionSampath KumarОценок пока нет

- Module 8 Welding Metallurgy For The WIДокумент39 страницModule 8 Welding Metallurgy For The WIMiki Jaksic100% (1)

- Visual Welding Inspection: Course Reference WIS 1EДокумент136 страницVisual Welding Inspection: Course Reference WIS 1ENgoc Bang100% (3)

- TWI CSWIP 3.1 Wis 5 Welding Inspection Practical Visual Inspection of Pipe WeldsДокумент11 страницTWI CSWIP 3.1 Wis 5 Welding Inspection Practical Visual Inspection of Pipe WeldsJohn DareОценок пока нет

- Acceptance Criteria of Weld Defects As Per Different Codes - The Engineers Edge Institute of NDT CBEДокумент18 страницAcceptance Criteria of Weld Defects As Per Different Codes - The Engineers Edge Institute of NDT CBEEngineersEDGE CoimbatoreОценок пока нет

- TWI CSWIP 3 1 WIS 5 Welding InspectionДокумент11 страницTWI CSWIP 3 1 WIS 5 Welding Inspectionsenthilkumar100% (1)

- WELDABILITY of SteelДокумент41 страницаWELDABILITY of Steel0502ravi100% (1)

- Competitive Solutions For Joining TechnologyДокумент19 страницCompetitive Solutions For Joining Technologyjy12bhuОценок пока нет

- Cswip Exams 1 PDFДокумент65 страницCswip Exams 1 PDFFethi BELOUISОценок пока нет

- Acceptance CriteriaДокумент19 страницAcceptance CriteriaAnonymous 5iv0i3cZОценок пока нет

- 04 Briony Holmes - TWI PDFДокумент32 страницы04 Briony Holmes - TWI PDFSupratim Biswas100% (2)

- Welding Metallurgy and Weldability of Nickel-Base AlloysОт EverandWelding Metallurgy and Weldability of Nickel-Base AlloysРейтинг: 5 из 5 звезд5/5 (1)

- CSWIP WIS 5 General Quiz: TWI Training & Examination ServicesДокумент63 страницыCSWIP WIS 5 General Quiz: TWI Training & Examination Serviceshaoues23Оценок пока нет

- Practical Plate InspectionДокумент8 страницPractical Plate InspectionMohd Effiezool Yaser100% (1)

- Morning Day 4 QuestionsДокумент62 страницыMorning Day 4 Questionshaoues23Оценок пока нет

- Welding Inspection CSWIP PDFДокумент683 страницыWelding Inspection CSWIP PDFmohdrafeek83Оценок пока нет

- TWI CSWIP 3.1 Wis 5 Welding Inspection P Ractical Visual Inspection of WeldsДокумент40 страницTWI CSWIP 3.1 Wis 5 Welding Inspection P Ractical Visual Inspection of Weldsmuthuswamy77Оценок пока нет

- 'TWI CSWIP Macro Practical Inspection (Compatibility Mode)Документ36 страниц'TWI CSWIP Macro Practical Inspection (Compatibility Mode)Vinoth KannanОценок пока нет

- TWI CSWIP Visual Inspection of WeldДокумент102 страницыTWI CSWIP Visual Inspection of WeldHamdi Hamdi100% (1)

- VISUAL WELD INSPECTIONДокумент57 страницVISUAL WELD INSPECTIONQuang Duan Nguyen100% (4)

- TWI CSWIP Visual Inspection of WeldДокумент102 страницыTWI CSWIP Visual Inspection of WeldOnur Altuntaş100% (24)

- 'TWI CSWIP Macro Practical Inspection (Compatibility Mode)Документ36 страниц'TWI CSWIP Macro Practical Inspection (Compatibility Mode)Veeralekshmanan KumarОценок пока нет

- WI IntroductionДокумент13 страницWI IntroductionThanhdong DoОценок пока нет

- Twi - Welding Inspection - SteelsДокумент209 страницTwi - Welding Inspection - Steelsenels77Оценок пока нет

- Welding Inspection: Defects/Repairs Course Reference WIS 5Документ54 страницыWelding Inspection: Defects/Repairs Course Reference WIS 5verall_averusОценок пока нет

- CSWIP Practical Plate AnswersДокумент31 страницаCSWIP Practical Plate AnswersSha Zha100% (1)

- Macro Inspection Part IIДокумент16 страницMacro Inspection Part IImohammed dallyОценок пока нет

- CHECK LIST FOR HIGH RISE BUILDING NOCДокумент15 страницCHECK LIST FOR HIGH RISE BUILDING NOCNedunuri.Madhav Murthy100% (2)

- Course Note CSWIP 3.0Документ168 страницCourse Note CSWIP 3.0JohanSitorusОценок пока нет

- Cbydp Draft SK BaracbacДокумент13 страницCbydp Draft SK BaracbacLikey PromiseОценок пока нет

- Corrosion and Materials in Hydrocarbon Production: A Compendium of Operational and Engineering AspectsОт EverandCorrosion and Materials in Hydrocarbon Production: A Compendium of Operational and Engineering AspectsОценок пока нет

- Welding Imperfection and Material InspectionДокумент62 страницыWelding Imperfection and Material Inspectionintfarha10Оценок пока нет

- U.K.Singh Manufacturing ProcessesДокумент290 страницU.K.Singh Manufacturing ProcessesGirish Dey100% (7)

- Telecomm SwitchingДокумент49 страницTelecomm SwitchingTalha KhalidОценок пока нет

- Pyrolysis ProjectДокумент122 страницыPyrolysis ProjectSohel Bangi100% (1)

- HDL Coder™ ReferenceДокумент487 страницHDL Coder™ ReferenceVictor Colpo NavarreteОценок пока нет

- WPQR6Документ3 страницыWPQR6Dimitris NikouОценок пока нет

- Section 25.: World Centre For Materials Joining TechnologyДокумент36 страницSection 25.: World Centre For Materials Joining Technologyjar_2100% (1)

- Cement Kilns-Chlorine Impact On ProcessДокумент27 страницCement Kilns-Chlorine Impact On Processmuhaisen2009100% (4)

- Clinker Coolers: By: Oliver Christian D. DeyparineДокумент26 страницClinker Coolers: By: Oliver Christian D. Deyparinemoonbright27Оценок пока нет

- Sample Report Kiln Alignment PDFДокумент24 страницыSample Report Kiln Alignment PDFWatcharapong PuangthaisongОценок пока нет

- TWI CSWIP 3.1 Wis 5 Welding Inspection: World Centre For Materials Joining TechnologyДокумент26 страницTWI CSWIP 3.1 Wis 5 Welding Inspection: World Centre For Materials Joining TechnologyDanem HalasОценок пока нет

- Weldability and Joinability of Common MaterialsДокумент1 страницаWeldability and Joinability of Common MaterialsStefanArtemonMocanuОценок пока нет

- WI 01 - Introduction To WI ModuleДокумент14 страницWI 01 - Introduction To WI ModuledayalramОценок пока нет

- Module 4 Weld Geometry and Welding Symbols-1Документ87 страницModule 4 Weld Geometry and Welding Symbols-1Miki JaksicОценок пока нет

- Soldering & Brazing: Unit-IvДокумент15 страницSoldering & Brazing: Unit-IvRamu AmaraОценок пока нет

- PDFДокумент6 страницPDFWatcharapong PuangthaisongОценок пока нет

- PDFДокумент6 страницPDFWatcharapong PuangthaisongОценок пока нет

- Cement Concrete 1 PDFДокумент117 страницCement Concrete 1 PDFWatcharapong PuangthaisongОценок пока нет

- Electrostatic Precipitator PDFДокумент4 страницыElectrostatic Precipitator PDFWatcharapong PuangthaisongОценок пока нет

- Cement Concrete 1 PDFДокумент117 страницCement Concrete 1 PDFWatcharapong PuangthaisongОценок пока нет

- Limestone quarry cement process diagramДокумент1 страницаLimestone quarry cement process diagramUpul Samantha LiyanaarachchiОценок пока нет

- สุขภาพคนไทย 2006Документ123 страницыสุขภาพคนไทย 2006Watcharapong PuangthaisongОценок пока нет

- สุขภาพคนไทย 2551Документ131 страницаสุขภาพคนไทย 2551Watcharapong PuangthaisongОценок пока нет

- สุขภาพคนไทย 2551Документ120 страницสุขภาพคนไทย 2551Watcharapong PuangthaisongОценок пока нет

- Many Things To Many PeopleДокумент213 страницMany Things To Many PeoplethanyawanОценок пока нет

- Thai Health 2009Документ132 страницыThai Health 2009thanyawanОценок пока нет

- Hall Design For SpeechДокумент1 страницаHall Design For SpeechSarovar SaroОценок пока нет

- The Four Principles of SustainabilityДокумент4 страницыThe Four Principles of SustainabilityNeals QuennevilleОценок пока нет

- Disk Electrostatic Automatic Coating System - OTSON - DM - OTS - 5000!3!0Документ16 страницDisk Electrostatic Automatic Coating System - OTSON - DM - OTS - 5000!3!0otsontek9227Оценок пока нет

- Upper Six 2013 STPM Physics 2 Trial ExamДокумент11 страницUpper Six 2013 STPM Physics 2 Trial ExamOw Yu Zen100% (2)

- Thesis PromptsДокумент7 страницThesis Promptsauroratuckernewyork100% (2)

- ALT Company Introduction 20170524.1Документ51 страницаALT Company Introduction 20170524.1Terence WoonОценок пока нет

- AESCSF Framework Overview 2020-21Документ30 страницAESCSF Framework Overview 2020-21Sandeep SinghОценок пока нет

- Camp ApplianceДокумент1 страницаCamp ApplianceflyzalОценок пока нет

- Mobile-Friendly Cooperative WebДокумент7 страницMobile-Friendly Cooperative WebWahyu PОценок пока нет

- Vikash Kumar: 1. Aunico India May 2018Документ4 страницыVikash Kumar: 1. Aunico India May 2018Rama Krishna PandaОценок пока нет

- PremiumpaymentReceipt 10663358Документ1 страницаPremiumpaymentReceipt 10663358Kartheek ChandraОценок пока нет

- Estimating PSCC for Electrical InstallationsДокумент2 страницыEstimating PSCC for Electrical InstallationsgmuitaОценок пока нет

- Volume 4-6Документ757 страницVolume 4-6AKОценок пока нет

- Plant Processes: Lesson 3Документ3 страницыPlant Processes: Lesson 3Kayla Ta’jaeОценок пока нет

- PublicReviewDraft2742 (1) (002)Документ75 страницPublicReviewDraft2742 (1) (002)dhruv.encontrolsОценок пока нет

- Fixed Prosthodontics Provisional Materials: Making The Right Selection.Документ7 страницFixed Prosthodontics Provisional Materials: Making The Right Selection.veloso.rossana0% (1)

- Test 1 Grammar, Revised Ecpe HonorsДокумент3 страницыTest 1 Grammar, Revised Ecpe HonorsAnna Chronopoulou100% (1)

- IT Technician CVДокумент3 страницыIT Technician CVRavi KumarОценок пока нет

- X32 Digital Mixer: Quick Start GuideДокумент28 страницX32 Digital Mixer: Quick Start GuideJordán AstudilloОценок пока нет

- Booklet English 2016Документ17 страницBooklet English 2016Noranita ZakariaОценок пока нет

- Split Plot Design GuideДокумент25 страницSplit Plot Design GuidefrawatОценок пока нет

- CFC KIDS FOR CHRIST 2020 FINAL EXAMДокумент13 страницCFC KIDS FOR CHRIST 2020 FINAL EXAMKaisser John Pura AcuñaОценок пока нет