Академический Документы

Профессиональный Документы

Культура Документы

Pipe Support Calculation

Загружено:

jsmnjasminesАвторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Pipe Support Calculation

Загружено:

jsmnjasminesАвторское право:

Доступные форматы

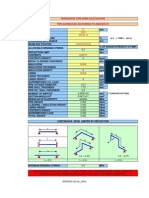

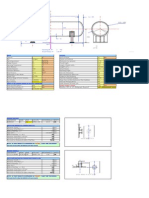

Client: Description: Prepared By: Approval: Date: Rev.

:

0

Customer No.: Item No.:

1

2

Owner No.: Dwg. No.:

3

Service: SG = 1.00 Measurement Units:

Design Temperature: 100 Deg. F Corrosion, erosion, mech. allow: C = 0.0000 inch

Factor of Safety: FS = 4.0 Ice Thickness (external): T

ice

= 0 inch

Pipe or Tubing Material: Pipe or Tube Dimensions:

ASTM A 53-B Type S Carbon Steel Pipe Nom. Size: NPS 8 (DN 200)

Hot modulus of elasticity 2.93E+07 psi E = 2.934E+07 psi Nom. Thk.: Sch 40 per ASME B36.10M

Hot allowable stress 20,000 psi S

h

= 20,000 psi Actual OD: 8.625 inch D

o

= 8.625 inch

Design stress, Sh / FS 5,000 psi S

a

= 5,000 psi Nominal thickness: 0.322 inch T

nom

= 0.322 inch

Material density P

den

= 2.833E-01 lb/in^3 Thickness tolerance: Mill = 12.5% and, h = 0.000 inch

Relative weight factor (vs. carbon steel) Mat = 1.000

Insulation: Semi-rigid Fiberglass Liner on ID: none

Density, I

ns

= 7.0 lb/ft^3 I

den

= 4.051E-03 lb/in^3 Density: 0.000 lb/in^3 L

den

= 0.000E+00 lb/in^3

Thk, T

i

= 2 inch Thickness: 0.000 inch T

r

= 0.000 inch

Comments:

Weight of concentrated load assumed at center of

span (valves + flanges + animal, etc.):

0.0 lbs W

c

= 0 lbs

Minimum pipe thickness, t = T

nom

- (T

nom

* Mill % / 100 ) - c - h t = 0.3216 inch

Outside radius of pipe, R = D

o

/ 2 R = 4.313 inch

Pipe moment of inertia (based on t ), I = / 64 [ D

o

4

- (D

o

- 2 t )

4

]

7.241E+01 in^4

I = 7.241E+01 in^4

Pipe inside diameter, d = D

o

- 2 T

nom

d = 7.981 inch

Pipe section modulus, Z = / 32 (D

o

4

- d

4

) / D

o 1.681E+01 in^3

Z = 1.681E+01 in^3

Metal area of pipe cross-section, A

m

= ( D

o

2

- d

2

) * / 4 A

m

= 8.40 in^2

Conversion factor, water density, dw = 62.4 lb / cu ft

d

w

= 62.40 lb/ft^3

Conversion factor: n = 1 ft / 12 in

n = 8.3333E-02 ft / in

Pipe weight per unit length, W

p

= P

den

* A

m

/ n W

p

= 28.55 lb / ft

Pipe or liner or refractory inside diameter, d

L

= d - 2 T

r

d

L

= 7.981 inch

Liner area cross-section, A

r

= ( d

2

- d

L

2

) * / 4 A

r

= 0.00 in^2

Liner weight per unit length, W

r

= L

den

* A

r

/ n W

r

= 0.00 lb / ft

Flow area, A

f

= d * L

2

* / 4 A

f

= 5.003E+01 in^2

Fluid weight per unit length, W

f

= SG * A

f

* n

2

* d

w

W

f

= 21.68 lb / ft

Insulation outside diameter, D

io

= D

o

+ 2 T

i

D

io

= 12.63 inch

Insulation area cross-section, A

i

= ( D

io

2

- D

o

2

) * / 4

A

i

= 66.76 in^2

Insulation weight per unit length (w/ factor 1.12 for lagging), W

i

= 1.12 * A

i

* n

2

* I

ns

W

i

= 3.63 lb / ft

Ice area cross-section, A

ice

= [ (Dio + ( 2 * T

ice

))

2

- D

io

2

] * / 4 A

ice

= 0.00 in^2

Ice weight (external w/ S.G. = 0.9) per unit length, W

ice

= 0.9 * A

ice

* n

2

* d

w

W

ice

= 0.00 lb / ft

Total weight per unit length, W = W

p

+ W

r

+ W

f

+ W

i

+ W

ice

(excluding W

c

)

53.87 lb / ft

W = 53.87 lb / ft

x

x

x

F C

Imperial

AAPL Pipe Support/Span Calculation Sheet

8/4/2010, Sup.xls

Pipe or Tubing Support Span Calculations

2 of 2

Type of support span

Length of support span 32.00 feet L = 32.00 feet

Factor for modifying stress value obtained by the basic formula for S fs = 1.250

4922.3 psi S = 4,922.3 psi

The calculated bending stress is within limits.

Factor for modifying deflection value obtained by the basic formula for y fy = 1.316

Deflection, y = fy (17.1 ( W L

4

/ E * I ) ) 0.598 inch y = 0.598 inch

Natural frequency estimate, fn = 3.13 / y

0.5

fn = 4.046 Hz

OK. Natural frequency above 4 Hz is recommended for most spans. Consider 8 Hz or more for pulsating line.

Slope of pipe between supports for drainage, h = (12 * L)

2

* y / ( 0.25 (12 * L)

2

- y

2

) 2.393 inch h = 2.393 inch

Length of support span (Single Span w/ Free Ends) 32.00 feet L

1

= 32.00 feet

Maximum bending stress, Sw

1

= ( 0.75 W * (L

1

)

2

+ 1.5 W

c

* L

1

) * D

o

/ I Sw

1

= 4,927.8 psi

Deflection, y

1

= (22.5 W * (L

1

)

4

+ 36 W

c

* (L

1

)

3

) / ( E * I ) 0.60 inch y

1

= 0.598 inch

The calculated bending stress is within limits. Deflection is within recommended limits.

Natural frequency estimate, fn

1

= 3.13 / ( y

1

)

0.5

fn

1

= 4.047 Hz

OK. Natural frequency above 4 Hz is recommended for most spans. Consider 8 Hz or more for pulsating line.

Slope between supports for drainage, h

1

= (12 * L

1

)

2

* y

1

/ ( 0.25 (12 * L

1

)

2

- (y

1

)

2

) 2.393 inch h

1

= 2.393 inch

Length of support span (Continuous Straight Run) 39.00 feet L

2

= 39.00 feet

Maximum bending stress, Sw

2

= ( 0.5 W * L

2

2

+ 0.75 W

c

* L

2

) * D

o

/ I Sw

2

= 4,879.7 psi

Deflection, y

2

= ( 4.5 W * (L

2

)

4

+ 9 W

c

* (L

2

)

3

) / ( E * I ) 0.26 inch y

2

= 0.264 inch

The calculated bending stress is within limits. Deflection is within recommended limits.

Natural frequency estimate, fn

2

= 3.13 / (y

2

)

0.5

fn

2

= 6.092 Hz

OK. Natural frequency above 4 Hz is recommended for most spans. Consider 8 Hz or more for pulsating line.

Slope between supports for drainage, h

2

= (12 * L

2

)

2

* y

2

/ ( 0.25 (12 * L

2

)

2

- (y

2

)

2

) 1.056 inch h

2

= 1.056 inch

Method ( B ) -- Reference Book: Piping Handbook, pg 22-47, by Crocker and King, Fifth Edition, 1967, McGraw-Hill

Method ( A ) -- Reference book Design Of Piping Systems, pp. 239 - 240 & 356 - 358, by M. W. Kellogg, Second Edition, 1956

Maximum calculated bending stress due to loads, S = fs ( 1.2 W L

2

/ Z ) ( 2 W

c

/ W L )

Wc

L

1

Single span, f ree ends

Wc

L

2

Вам также может понравиться

- Pipe or Tubing Support Span CalculationsДокумент9 страницPipe or Tubing Support Span CalculationskhaireddinОценок пока нет

- Underground Pipe THK CalДокумент12 страницUnderground Pipe THK Calmkchy12100% (3)

- Pipe or Tubing Support Span Calculations 5434Документ2 страницыPipe or Tubing Support Span Calculations 5434engg_mech7750% (2)

- Support Pipe Load CalculationДокумент6 страницSupport Pipe Load CalculationKumar R100% (1)

- Pipe Support CalcДокумент73 страницыPipe Support Calcmsvikhas032100% (3)

- Pipe SupportДокумент11 страницPipe SupportAditya Bagus M100% (3)

- Calculation of Pipe SupportДокумент8 страницCalculation of Pipe SupportPhyu Mar Thein Kyaw67% (6)

- DummyДокумент1 страницаDummythopa_nath100% (2)

- Trunnion load calcsДокумент4 страницыTrunnion load calcsChirag Shah50% (2)

- Saddle Support Calculation PD 5500,2000 Annex.G)Документ26 страницSaddle Support Calculation PD 5500,2000 Annex.G)Neeraj Kumar33% (3)

- Calculation of Pipe SupportДокумент6 страницCalculation of Pipe Supportnaveen_86Оценок пока нет

- Max pipe span table for carbon steel, stainless steel & individual supportsДокумент5 страницMax pipe span table for carbon steel, stainless steel & individual supportsSeungmin PaekОценок пока нет

- Operating Case Trunnion Calculation Sheet: Input DataДокумент1 страницаOperating Case Trunnion Calculation Sheet: Input DataJagadish JasОценок пока нет

- Pipe Load CalculationДокумент6 страницPipe Load CalculationSuthan SelvarajОценок пока нет

- Pipe Span Without Point LoadsДокумент36 страницPipe Span Without Point Loadsbakelly100% (4)

- Allowable Pipe Spans LoadsДокумент84 страницыAllowable Pipe Spans LoadsMalcolm Hutton100% (5)

- Buried PipeДокумент11 страницBuried PipePrashant Agrawal100% (4)

- Standard Shoe Verification Rev - AДокумент19 страницStandard Shoe Verification Rev - AballisnothingОценок пока нет

- Calculation of Pipe SupportДокумент2 страницыCalculation of Pipe Supportmuthuvelaa77% (26)

- Pipe support span calculationsДокумент2 страницыPipe support span calculationsalvinchuanОценок пока нет

- Appx-A Formula and CalculationДокумент20 страницAppx-A Formula and CalculationapiscobainОценок пока нет

- CALCULATION SHEETSДокумент27 страницCALCULATION SHEETSBharat Bellad100% (1)

- Reinforcement CalculationДокумент2 страницыReinforcement CalculationVekaymech100% (9)

- Expansion loop designДокумент1 страницаExpansion loop designalvinchuan100% (1)

- Flange From Plate - Asme 16.5Документ1 страницаFlange From Plate - Asme 16.5Rey Fiedacan100% (1)

- Hydrant Pipe CalculationДокумент3 страницыHydrant Pipe CalculationRevathi .G100% (1)

- Sif B31.3Документ10 страницSif B31.3Rob Gillespie100% (1)

- Trunnion CalculationДокумент8 страницTrunnion CalculationPrashant ChauhanОценок пока нет

- ASME B31.3 - 2008 PipeCalculationДокумент6 страницASME B31.3 - 2008 PipeCalculationArt G. Enzi100% (8)

- Load Check For Shoe Welded SupportДокумент313 страницLoad Check For Shoe Welded Supportscrbdgharavi100% (2)

- Nozzle Movement Calculation GuideДокумент23 страницыNozzle Movement Calculation GuidePriyanathan Thayalan100% (4)

- Pipe Saddle Support CalculationsДокумент1 страницаPipe Saddle Support CalculationsAbir Baran HandaОценок пока нет

- Buried Pipe Design (Flexible) 1Документ9 страницBuried Pipe Design (Flexible) 1Ah Leng Lau100% (2)

- Pipe Support-AA Design CalculationsДокумент24 страницыPipe Support-AA Design CalculationsRobina Kiran75% (4)

- Branch Reinforcement Pad Requirement CalculationДокумент2 страницыBranch Reinforcement Pad Requirement CalculationAntoshal100% (4)

- Standard piping support drawing for Iranian oil refineryДокумент320 страницStandard piping support drawing for Iranian oil refineryfloayzav568475% (8)

- Expansion Loop CalculationДокумент2 страницыExpansion Loop Calculationsk130986100% (1)

- Basic Calculations Piping System Design PDFДокумент14 страницBasic Calculations Piping System Design PDFjeff_shawОценок пока нет

- Reinf S1Документ2 страницыReinf S1tasingenieriaОценок пока нет

- 26 Pressure Vessel.Документ21 страница26 Pressure Vessel.mishtinil93% (14)

- Ibr Calc GSRДокумент4 страницыIbr Calc GSRAniket GaikwadОценок пока нет

- 1 For ProjectДокумент60 страниц1 For ProjectGhazanfer AliОценок пока нет

- Design Calculation 4-PadeyesДокумент4 страницыDesign Calculation 4-PadeyesMuhammad Yahdiman100% (3)

- 26 Pressure VesselДокумент21 страница26 Pressure VesseljnmanivannanmechОценок пока нет

- Boiler CalcДокумент92 страницыBoiler CalcPrasanta Kumar BeheraОценок пока нет

- Branch (1) Calculations: Pipe Branch Reinforcement Per ASME B31.1b - 2009 Power Piping CodeДокумент2 страницыBranch (1) Calculations: Pipe Branch Reinforcement Per ASME B31.1b - 2009 Power Piping Codedeua2004Оценок пока нет

- Ibr CalcДокумент4 страницыIbr CalcUmesh Kondkar100% (7)

- Corbel DesignДокумент3 страницыCorbel DesignManoj JaiswalОценок пока нет

- Pipe Heat Loss CalculationДокумент10 страницPipe Heat Loss Calculationingemarquintero67% (3)

- 1.0 7a - Pipe ThicknessДокумент11 страниц1.0 7a - Pipe ThicknessRavindra S. Jivani100% (1)

- Design Calculation Sheet: H2So4 Neutralization TankДокумент43 страницыDesign Calculation Sheet: H2So4 Neutralization TankEkki Petrus BubunОценок пока нет

- Canal DesignДокумент34 страницыCanal Designniranjan100% (2)

- Mechanical Design of MixerДокумент10 страницMechanical Design of MixerGabriel AyauОценок пока нет

- Lifting - Lug (Modification)Документ11 страницLifting - Lug (Modification)Sam LowОценок пока нет

- Contoh Proteksi Katodik PerhitunganДокумент6 страницContoh Proteksi Katodik PerhitunganDeo Harita100% (1)

- Rean'S Building 5/24/2002 Angle Plate Design: Framed Beam ConnectionДокумент11 страницRean'S Building 5/24/2002 Angle Plate Design: Framed Beam ConnectionrbalmodalОценок пока нет

- BuitizonДокумент13 страницBuitizonRocky SioresОценок пока нет

- Earthing CalculationДокумент15 страницEarthing CalculationFrancisco Zanin FernandesОценок пока нет

- Section VIII CalДокумент19 страницSection VIII CalPradeep Kothapalli100% (1)

- Health and Safety Manual SampleДокумент20 страницHealth and Safety Manual Samplefaluda1973Оценок пока нет

- Company Policy TemplateДокумент4 страницыCompany Policy TemplatejsmnjasminesОценок пока нет

- 10 Quadratic Equations-1Документ8 страниц10 Quadratic Equations-1Jonie Quintal MatienzoОценок пока нет

- 1Документ14 страниц1jsmnjasmines100% (1)

- Reliance CaseДокумент3 страницыReliance CaseAshok ChoudharyОценок пока нет

- Case Study UberДокумент2 страницыCase Study UberjsmnjasminesОценок пока нет

- Fea 7 Fem ConceptsДокумент104 страницыFea 7 Fem Conceptsjsmnjasmines100% (1)

- Metric1807 1808Документ1 страницаMetric1807 1808jsmnjasminesОценок пока нет

- 100 Dia Pre ChecklistДокумент2 страницы100 Dia Pre ChecklistjsmnjasminesОценок пока нет

- Answers Key: SET 1: 1.B 2.B 3.B 4.A 5.BДокумент2 страницыAnswers Key: SET 1: 1.B 2.B 3.B 4.A 5.BjsmnjasminesОценок пока нет

- Balykina GalinaДокумент8 страницBalykina GalinajsmnjasminesОценок пока нет

- C 2 Tutorial BДокумент4 страницыC 2 Tutorial BjsmnjasminesОценок пока нет

- Technology Training & Research Centre Recruitment Drive Objective Questionnaire Set 1Документ1 страницаTechnology Training & Research Centre Recruitment Drive Objective Questionnaire Set 1jsmnjasminesОценок пока нет

- Applications of Computational Fluid DynamicsДокумент7 страницApplications of Computational Fluid DynamicsjsmnjasminesОценок пока нет

- Automation With APDLДокумент40 страницAutomation With APDLjsmnjasminesОценок пока нет

- CAEA v145 Update CFDДокумент39 страницCAEA v145 Update CFDAnonymous ETBwIduGiОценок пока нет

- Safe Scaffolding CodeДокумент56 страницSafe Scaffolding Codejsmnjasmines100% (1)

- Adventure Works Adventure Works: S B S ! S B S !Документ1 страницаAdventure Works Adventure Works: S B S ! S B S !jsmnjasminesОценок пока нет

- Assembly Mdli Modeling Elearning: Peter Barrett November 2012Документ16 страницAssembly Mdli Modeling Elearning: Peter Barrett November 2012jsmnjasminesОценок пока нет

- ANSYS LEFM Example Demonstrates Methods to Predict Crack BehaviorДокумент13 страницANSYS LEFM Example Demonstrates Methods to Predict Crack BehaviorjsmnjasminesОценок пока нет

- GPLДокумент5 страницGPLAjay DevОценок пока нет

- Raci Matrix Template Aaplmajestic JV For TTRCДокумент3 страницыRaci Matrix Template Aaplmajestic JV For TTRCjsmnjasminesОценок пока нет

- AAPL Capability Statement - Engineering ServicesДокумент41 страницаAAPL Capability Statement - Engineering ServicesjsmnjasminesОценок пока нет

- CAEA v14 Update Part1 Struct Demos 0Документ135 страницCAEA v14 Update Part1 Struct Demos 0joejo_s_hotmailОценок пока нет

- SL - No Type Course Title Description Duration Next Batch - Last Date FeesДокумент1 страницаSL - No Type Course Title Description Duration Next Batch - Last Date FeesjsmnjasminesОценок пока нет

- Help with your trip ticketДокумент1 страницаHelp with your trip ticketranju93100% (1)

- (Business Name) : We Have Your Landscape Needs CoveredДокумент1 страница(Business Name) : We Have Your Landscape Needs CoveredjsmnjasminesОценок пока нет

- Design of Compression MemberДокумент29 страницDesign of Compression MemberFerry Triyana AnirunОценок пока нет

- Dr. I Ramesh Mithanthaya: 1. Prof. / Vice Principal / Dean (Academics) / Chief Project LeaderДокумент7 страницDr. I Ramesh Mithanthaya: 1. Prof. / Vice Principal / Dean (Academics) / Chief Project LeaderjsmnjasminesОценок пока нет

- Erecting Altering Dismantling Scaffolding Prefabricated Steel Modular Scaffolding Industry Safety Standard 2373Документ32 страницыErecting Altering Dismantling Scaffolding Prefabricated Steel Modular Scaffolding Industry Safety Standard 2373madhav0303Оценок пока нет

- Banking DictionaryДокумент499 страницBanking DictionaryVanessa Jenkins100% (4)

- Jmeter Performance Testing Your Webapp 1203622239433273 3Документ12 страницJmeter Performance Testing Your Webapp 1203622239433273 3pallavi91Оценок пока нет

- Prova ScrumДокумент11 страницProva ScrumJoanna de Cassia ValadaresОценок пока нет

- FSK Demodulator With PLLДокумент5 страницFSK Demodulator With PLLHema100% (1)

- Display PDF PDFДокумент7 страницDisplay PDF PDFSandeepОценок пока нет

- DigitalForensics 05 NOV2010Документ84 страницыDigitalForensics 05 NOV2010hhhzineОценок пока нет

- PROFILITE 60 EC Suspended 09 130 3001-01-830 Product Datasheet enДокумент4 страницыPROFILITE 60 EC Suspended 09 130 3001-01-830 Product Datasheet enGabor ZeleyОценок пока нет

- Tucker Northlake SLUPsДокумент182 страницыTucker Northlake SLUPsZachary HansenОценок пока нет

- CIT-Vs-NCR-Corporation-Pvt.-Ltd.-Karnataka-High-Court - ATMs Are ComputerДокумент15 страницCIT-Vs-NCR-Corporation-Pvt.-Ltd.-Karnataka-High-Court - ATMs Are ComputerSoftdynamiteОценок пока нет

- Tough Turkish TBM Moves Through Fractured and Faulted Rock: Issue 1 + 2014Документ8 страницTough Turkish TBM Moves Through Fractured and Faulted Rock: Issue 1 + 2014sCoRPion_trОценок пока нет

- Office of The Integrity Commissioner - Investigation Report Regarding The Conduct of Councillor Mark Grimes (July 05, 2016)Документ44 страницыOffice of The Integrity Commissioner - Investigation Report Regarding The Conduct of Councillor Mark Grimes (July 05, 2016)T.O. Nature & DevelopmentОценок пока нет

- Mohamed Khaled CVДокумент2 страницыMohamed Khaled CVMohamed KhaledОценок пока нет

- Speech ExamplesДокумент6 страницSpeech Examplesjayz_mateo9762100% (1)

- Ds Gigavue FM Fabric ManagerДокумент9 страницDs Gigavue FM Fabric ManagerMARCELOTRIVELATTOОценок пока нет

- Liftoff: Guide To Duo Deployment Best Practices: Version 2.1 Published October 3, 2019Документ14 страницLiftoff: Guide To Duo Deployment Best Practices: Version 2.1 Published October 3, 2019Johana RОценок пока нет

- Dyna PDFДокумент12 страницDyna PDFVernadette VenturaОценок пока нет

- Micom P139: Feeder Management and Bay ControlДокумент376 страницMicom P139: Feeder Management and Bay ControljjcanoolivaresОценок пока нет

- Cement Lined Piping SpecificationДокумент167 страницCement Lined Piping SpecificationvenkateshwaranОценок пока нет

- Alignment Cooling Water Pump 4A: Halaman: 1 Dari 1 HalamanДокумент3 страницыAlignment Cooling Water Pump 4A: Halaman: 1 Dari 1 Halamanpemeliharaan.turbin03Оценок пока нет

- Industrial Tour Report (JEWEL - MANAGEMENT-CU)Документ37 страницIndustrial Tour Report (JEWEL - MANAGEMENT-CU)Mohammad Jewel100% (2)

- PT-E - Fundamentals of Process Plant Layout and Piping DesignДокумент14 страницPT-E - Fundamentals of Process Plant Layout and Piping DesignNofrizal HasanОценок пока нет

- Group analyzes Sunsilk brand auditДокумент49 страницGroup analyzes Sunsilk brand auditinkLLL0% (1)

- Market ResearchДокумент89 страницMarket ResearchSankeitha SinhaОценок пока нет

- The Eco-Core SnowboardДокумент51 страницаThe Eco-Core SnowboardmoisesmoronsolerОценок пока нет

- Postal-BSNL Meeting MinutesДокумент5 страницPostal-BSNL Meeting MinutesP Karan JainОценок пока нет

- Concepts in Enterprise Resource Planning: Chapter Six Human Resources Processes With ERPДокумент39 страницConcepts in Enterprise Resource Planning: Chapter Six Human Resources Processes With ERPasadnawazОценок пока нет

- Spouses Aggabao v. Parulan, Jr. and ParulanДокумент5 страницSpouses Aggabao v. Parulan, Jr. and ParulanGeenea VidalОценок пока нет

- 325W Bifacial Mono PERC Double Glass ModuleДокумент2 страницы325W Bifacial Mono PERC Double Glass ModuleJosue Enriquez EguigurenОценок пока нет

- April 10, 2015 Strathmore TimesДокумент28 страницApril 10, 2015 Strathmore TimesStrathmore TimesОценок пока нет

- 2011 Ringgold County Fair EditionДокумент16 страниц2011 Ringgold County Fair EditionMountAyrRecordNewsОценок пока нет