Академический Документы

Профессиональный Документы

Культура Документы

Anatomy of A 96 Mustang CCRM-R1

Загружено:

Troy Larimer100%(1)100% нашли этот документ полезным (1 голос)

260 просмотров3 страницыmustang relay module

Оригинальное название

Anatomy of a 96 Mustang CCRM-R1

Авторское право

© © All Rights Reserved

Доступные форматы

PDF, TXT или читайте онлайн в Scribd

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документmustang relay module

Авторское право:

© All Rights Reserved

Доступные форматы

Скачайте в формате PDF, TXT или читайте онлайн в Scribd

100%(1)100% нашли этот документ полезным (1 голос)

260 просмотров3 страницыAnatomy of A 96 Mustang CCRM-R1

Загружено:

Troy Larimermustang relay module

Авторское право:

© All Rights Reserved

Доступные форматы

Скачайте в формате PDF, TXT или читайте онлайн в Scribd

Вы находитесь на странице: 1из 3

Anatomy of a 96 Mustang CCRM

Mark Olson, 2013

Rev. 1.4

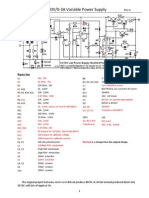

This document describes what I learned from reverse engineering the Constant Control Relay Module (CCRM) from my

1996 Ford Mustang Cobra. You use this document at your own risk. At times Ford made significant changes to parts

such as this, so your CCRM might be different. But if your CCRM is similar to mine, this document could help you to

test, debug and repair your CCRM. One interesting thing I noticed was that the 96 Mustang EVTM describes the AC

clutch relay in the CCRM as a solid state relay while mine is a traditional relay. Photos of 94/95 CCRMs shows solid

state relay circuitry for the AC clutch, while newer CCRMs have traditional relays. According to my local Ford parts

department, the CCRMs are the same part number from 1994-2000.

This annotated photo shows the top of the 96 CCRM PCB and has all of the key components labeled. EDF is Low

Speed, HEDF is high Speed. (Note that you have to drill out the rivets to remove the case and drill out two more rivets

to release the PCB.

Q2

Q5

Q6

(Male Pin Side of Connector on Harness)

Anatomy of a 96 Mustang CCRM

Schematics

P

o

w

e

r

Pin 8

Pin 10

Pin 13

Hot at all Times

Hot in Start & Run

P

o

w

e

r

D1

K1

Pin 16

Pin 15 G

N

D

To IMRC & AC Clutch

From

Chassis

Ground

PCM

Relay

Pin 12

Pin 24 P

C

M

P

o

w

e

rPCM Power

K2

Fuel

Pump

Relay

Pin 11

Pin 18

Hot at all times

P

o

w

e

r

F

u

e

l

P

u

m

p

R

e

l

a

y

I

n

p

u

t

R25*

K?

AC

Clutch

Relay

Pin 21

A

C

H

i

P

r

e

s

s

/

F

a

n

S

w

i

t

c

h

Pin 5

F

u

e

l

P

u

m

p

O

u

t

p

u

t

Pin 22

A

C

W

O

T

C

u

t

o

u

t

R

e

l

a

y

I

n

p

u

t

Note:

- All diodes are 4201A

- All transistors are N530 (Fairchild FPN 530 Low Saturation NPN transistor equiv?)

- 1998 CCRM uses Fairchild B744 transistors

- All resistors are 1/4W, 5% (W6 is 1% in 98)

- K? is a relay that is not marked on the silk screen

- K1, K3, K4 are 40A Bosch PCB-mount relays (Tyco V23234-B0001-X011 in 98)

- K2 is an Omron G8H-UA-007108 (G8HL-1A4P in 98)

- K? is an Omron G8SN-UA-007116

- Items with an asterisk (*) are not installed, D8 is not installed in 1998 CCRMs.

- I have no idea what the resistor between Pin 19 and ground is for

Pin 23

A

C

C

l

u

t

c

h

O

u

t

p

u

t

D8

K3

High

Speed

Fan

Relay

Pin 3

Pin 4 P

o

w

e

rHot at all Times

Pin 17

H

i

g

h

S

p

e

e

d

F

a

n

I

n

p

u

t

Pin 6

Pin 7

H

i

g

h

S

p

e

e

d

F

a

n

O

u

t

Pin 14

L

o

w

S

p

e

e

d

F

a

n

I

n

p

u

t

Pin 1

Pin 2

L

o

w

S

p

e

e

d

F

a

n

O

u

t

D10*

R4

1

5

0

0

R9

100K

C4 C9

47uF

10V

0.01uF R19

100

R11

1

0

0

K

Q2

C

B

E

Q5

C

B

E

1

0

0

K

R

1

2

2

2

K

R

1

4

Q6

C

B

E

K4

Low

Speed

Fan

Relay

D5

C3 1uF

100V

Pin 19

N

o

t

U

s

e

d

W6 1K

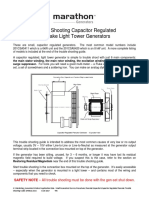

Low Speed Fan Circuit Analysis:

The low speed fan PCM output appears to be a logic-level

output. When Pin 14 is high, Q2 is turned on, Q5 is turned

off and Q6 is turned on, which turns on the fan. When Pin

14 is low, Q2 is turned off, Q5 is turned on and Q6 is

turned off, which turns off the fan. D5 protects Q6 from the

relay field collapse EMF. R14 supplies base current to turn

Q6 on. R12 supplies base current to turn Q5 on. R11 and

R19 + R9 cuts the input voltage to 1/3 of the voltage on Pin

14. Assuming the PCM has an open-collector output, R4

pulls pin 14 to near battery voltage when the input is high.

At 12V, the input to Q2 will try to go to 3V, which pumps

plenty of current into the base, turning Q2 on. At near 0v,

the base of Q2 is very close to 0V, turning Q2 off. C4 and

C9 act in conjunction with the resistors as low and higher

frequency filters, respectively.

NO

NO

NC

NO

NO

Anatomy of a 96 Mustang CCRM

Bench Testing

Mark Olson, 2013

1

13

2 3 4 5 6 7 8 10 11 12

14 15 16 17 18 21 22 23 24

CCRM Connector

Female Pin Side

(CCRM Itself)

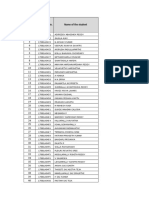

CCRM Testing Procedure:

1. Test PCM relay K1 and D1: Put the ohmmeter red lead on Pin13, and the black lead on Pin 15. You should read

about 2.5M ohms. Reverse the leads and you should read an open circuit. If you dont get that, open the CCRM and

check for the same resistances across D1. If you dont get it, replace D1. Check the K1 coil for about 85 ohms. If you

get an open circuit, replace K1. Check the resistance across Pins 8 & 12. You should read an open circuit. If the coil

and diode are good, put +12V on Pin 13 and ground on Pin 15. You should hear the relay click and read near 0 ohms

across Pins 8 & 12. If Pins 8 & 12 dont behave correctly replace relay K1.

2. Test Fuel Pump relay K2: Put an ohmmeter across Pins 12 & 18. You should read about 75 ohms. If it is an open

circuit or a hard short, replace relay K2. Check the resistance across Pins 5 & 11. It should read an open circuit. Put

12V across pins 12 & 18. You should hear the relay click and you should then see near 0 ohms across pins 5 & 11. If

Pins 5 & 11 dont behave correctly replace relay K2.

3. Test AC Clutch relay K?: Put an ohmmeter across Pins 12 & 22. You should read about 180 ohms. If it is an open

circuit or a hard short, replace relay K?. Put the ohmmeter red lead on Pin 15 and the black lead on Pin 23. You should

read about 2.5M ohms. Reverse the leads and you should read an open circuit. Check the resistance across Pins 21 &

23. It should read a short circuit. Put 12V across pins 12 & 22. You should hear the relay click and you should then

see an open circuit across pins 21 & 23. If Pins 21 & 23 dont behave correctly replace relay K?.

4. Test High Speed Fan relay K3: Put an ohmmeter across Pins 12 & 17. You should read about 85 ohms. If it is an

open circuit or a hard short, replace relay K3. Check the resistance across Pins 3 & 6. It should read an open circuit.

Put 12V across pins 12 & 17. You should hear the relay click and you should then see near 0 ohms across pins 3 & 6.

If Pins 3 & 6 dont behave correctly replace relay K3.

5. Test Low Speed Fan relay K4: Check the resistance across Pins 1 & 3. You should read an open circuit. If you dont,

replace relay K4. Put +12V on Pin 12 and Ground on Pin 15. You should hear the relay click and see a closed circuit

across Pins 1 & 3. Ground Pin14, and you should hear the relay click and see an open circuit across Pins 1 & 3. If Pins

1 & 3 dont behave correctly, follow the debug strategy in 6 below.

6. Debug Low Speed Fan solid state circuit: (rough guidelines) With +12V on Pin 12 and Ground on Pin 14, you should

see about 1.145V on the base of Q2. If you see near 0V, replace Q2. You should see about 0.5V on the collector of

Q2. If you see 12V, replace Q2. If you see near 0.5V on Q2's collector, go to A below. Ground Pin14. You should see

very near 0V on the base of Q2. You should see near 12V on the collector of Q2. If you see 1V or less, replace Q2. If

you see near 12V on Q2's collector, go to A below.

A. Debug Transistor Q5: With Pin 14 not grounded, you should see about 12V on the collector of Q5. When you ground

Pin 14, the collector of Q5 should go to 1.4V or less. If the Q5 collector doesnt behave that way, replace Q5. If it does

behave that way, go to B below.

B. Debug Transistor Q6: With Pin 24 not grounded, the collector of Q6 should be less than 1V. When you ground Pin

14, the collector of Q6 should go to about 12V. If the Q6 collector doesnt behave that way, replace Q6. If it does

behave that way, go to C below.

C. Debug Relay K4: Unhook power and grounds. Measure the resistance across the windings of Relay K4. It should

read near 85 ohms. If not, replace relay K4.

Вам также может понравиться

- Servicing The KL400Документ20 страницServicing The KL400Pisu Miau Pisu MiauОценок пока нет

- Car Battery 6V or 12V ChargerДокумент14 страницCar Battery 6V or 12V ChargerryandisinfixtifОценок пока нет

- PNEUMATICS AND AIR CIRCUITS UNDERSTANDING THE CASCADE VALVE AND PLC UNDERSTANDINGОт EverandPNEUMATICS AND AIR CIRCUITS UNDERSTANDING THE CASCADE VALVE AND PLC UNDERSTANDINGОценок пока нет

- Astron TroubleshootingДокумент7 страницAstron TroubleshootingLuis CarlosОценок пока нет

- Power Supply Projects: A Collection of Innovative and Practical Design ProjectsОт EverandPower Supply Projects: A Collection of Innovative and Practical Design ProjectsРейтинг: 3 из 5 звезд3/5 (2)

- SGDO-FSU Troubleshooting ProcedureДокумент2 страницыSGDO-FSU Troubleshooting ProcedurePeter SnellОценок пока нет

- Typical Mercury Ignition SystemsДокумент11 страницTypical Mercury Ignition SystemswguenonОценок пока нет

- Troubleshooting and Service Information For Voltmaster GeneratorsДокумент15 страницTroubleshooting and Service Information For Voltmaster GeneratorsMd Rodi Bidin100% (1)

- Dentron MLA-2500 GI7B Modification Procedure 3Документ27 страницDentron MLA-2500 GI7B Modification Procedure 3david bonilla pinoОценок пока нет

- N2CX Accuprobe Plus Assembly InstructionsДокумент12 страницN2CX Accuprobe Plus Assembly InstructionsRafael SuarezОценок пока нет

- Automatic Battery Charger CircuitsДокумент25 страницAutomatic Battery Charger Circuitsrowell ramosОценок пока нет

- Checking Print HeadДокумент15 страницChecking Print HeadMukesh Joshi50% (2)

- ReguladorRectificador Troubleshoting PDFДокумент1 страницаReguladorRectificador Troubleshoting PDFNicoОценок пока нет

- A Look at The Yaqin MC10LДокумент51 страницаA Look at The Yaqin MC10Lozzy123Оценок пока нет

- FYI 4L60E Common Problems FailuresДокумент3 страницыFYI 4L60E Common Problems Failurescyber_nauticaОценок пока нет

- Lucas Generator and Control Box TestsДокумент28 страницLucas Generator and Control Box Testsruben_balea100% (1)

- AV1000 + Assembly + ManualДокумент22 страницыAV1000 + Assembly + ManualAnonymous V1NW1Cm3w4100% (3)

- Repair Autocom CDP VCIДокумент5 страницRepair Autocom CDP VCIMed Ali cОценок пока нет

- Gel Cell Charger, I: Parts ListДокумент11 страницGel Cell Charger, I: Parts ListsundeepgjОценок пока нет

- RJSINGLEДокумент88 страницRJSINGLEAbhishek TiwariОценок пока нет

- ONAN Charging SystemДокумент2 страницыONAN Charging Systemcaptals100% (1)

- Cobra: Tips and TricksДокумент8 страницCobra: Tips and TricksGeraldrum Zyzcom HdzОценок пока нет

- SSM2166 - Compressor, Limiter and GateДокумент4 страницыSSM2166 - Compressor, Limiter and Gatedetroit_me2553Оценок пока нет

- ART Tube MP ModificationДокумент14 страницART Tube MP Modificationtitov33Оценок пока нет

- 2-FM Electrical TroubleshootingДокумент38 страниц2-FM Electrical TroubleshootingAlexandre SilvaОценок пока нет

- Winco 60711-018 Rotating Field Ts GuideДокумент4 страницыWinco 60711-018 Rotating Field Ts GuideZeck100% (1)

- Repair Autocom CDP VCIДокумент5 страницRepair Autocom CDP VCIvalentyn kulkovОценок пока нет

- Anti-Lock Brake SystemДокумент21 страницаAnti-Lock Brake SystemWoong-Sub LeeОценок пока нет

- Snoa 474Документ14 страницSnoa 474whynot05Оценок пока нет

- Automatic 12V Lead Acid Battery ChargerДокумент10 страницAutomatic 12V Lead Acid Battery ChargerRajib ChatterjeeОценок пока нет

- Repair Autocom CDP VCIДокумент5 страницRepair Autocom CDP VCIAdi Catanescu100% (2)

- PWMcircuit 08Документ10 страницPWMcircuit 08kcarringОценок пока нет

- 2 Disconnect The Yellow WiresДокумент1 страница2 Disconnect The Yellow Wiresanderson valerioОценок пока нет

- Jeep CJ Gauge Sender Diagnostics 72 86 by John Foutz 1300221252Документ6 страницJeep CJ Gauge Sender Diagnostics 72 86 by John Foutz 1300221252Steve HirstОценок пока нет

- 3 Axis 4AUPC Rev0 Driver Board Kit InstructionsДокумент3 страницы3 Axis 4AUPC Rev0 Driver Board Kit InstructionsmarceloОценок пока нет

- SSA120Документ13 страницSSA120carlos alvaresОценок пока нет

- How To Wind Your Own Audio TransformersДокумент3 страницыHow To Wind Your Own Audio TransformerspomodoroОценок пока нет

- Bitx Version 3 Linear Amplifier AssemblyДокумент14 страницBitx Version 3 Linear Amplifier Assemblyapi-26282181100% (1)

- 4L60E Common ProblemsДокумент4 страницы4L60E Common ProblemsTransmisiones Automáticas Chepe100% (2)

- 1525 BR ManualДокумент15 страниц1525 BR Manualatgordon1Оценок пока нет

- D&R CompressorДокумент5 страницD&R CompressorJoseph Brooks100% (1)

- 400W Rms Hexfet Mosfet Symmetrical AmplifierДокумент10 страниц400W Rms Hexfet Mosfet Symmetrical Amplifieralbedo367Оценок пока нет

- 4L60E Transmission Info. RepairДокумент3 страницы4L60E Transmission Info. RepairMike L.Оценок пока нет

- Lead Acid Battery ChargerДокумент2 страницыLead Acid Battery ChargermuaazgujjarОценок пока нет

- Merc Force 1994 2006Документ4 страницыMerc Force 1994 2006Monika Edyta ChojnackaОценок пока нет

- Mecc Alte Portable Ts GuideДокумент9 страницMecc Alte Portable Ts GuidesfeОценок пока нет

- Modified 0-30V - 0-3A Variable Power Supply - Rev.2Документ2 страницыModified 0-30V - 0-3A Variable Power Supply - Rev.2Manuel Cereijo NeiraОценок пока нет

- TCL Series Solid State Tesla CoilДокумент20 страницTCL Series Solid State Tesla CoilNayanka SpringerОценок пока нет

- Kawa Ninja 650-Charging SystemДокумент20 страницKawa Ninja 650-Charging SystemFrancisco Alberto Comas Garcia100% (2)

- IC 555 ProjectsДокумент6 страницIC 555 ProjectsManan SanghviОценок пока нет

- F A N U C 5t 5mДокумент5 страницF A N U C 5t 5mmradivojeОценок пока нет

- Another Interesting Circuit From Burt Design PadДокумент13 страницAnother Interesting Circuit From Burt Design PadmoisesHolaОценок пока нет

- Trouble Shooting Capacitor Regulated Pancake Light Tower GeneratorsДокумент7 страницTrouble Shooting Capacitor Regulated Pancake Light Tower GeneratorsBilly MecanizadoОценок пока нет

- Inverter Troubleshooting ChecksДокумент4 страницыInverter Troubleshooting ChecksTarak BenslimaneОценок пока нет

- RF 382 InterfaceДокумент7 страницRF 382 InterfaceΒΕΗΣ ΣΤΕΛΙΟΣ Veis SteliosОценок пока нет

- Getting The Most From Your AR-88Документ10 страницGetting The Most From Your AR-88Eugenio Martin CuencaОценок пока нет

- Hitachi Plasma TipsДокумент10 страницHitachi Plasma TipsricardoОценок пока нет

- Peavey Cs-1000 AmplifierДокумент1 страницаPeavey Cs-1000 AmplifierTroy Larimer100% (2)

- Si 3865 SatasheetДокумент6 страницSi 3865 SatasheetTroy LarimerОценок пока нет

- Vertex Standard Vx-351pmr446Документ30 страницVertex Standard Vx-351pmr446Troy LarimerОценок пока нет

- Philips Master RemoteДокумент3 страницыPhilips Master RemoteTroy LarimerОценок пока нет

- Yorkville Mp8Документ24 страницыYorkville Mp8Troy LarimerОценок пока нет

- 50a60 SMДокумент50 страниц50a60 SMmazdog69Оценок пока нет

- High-Frequency Modeling of Power Transformers For Use in Frequency Response Analysis (FRA)Документ8 страницHigh-Frequency Modeling of Power Transformers For Use in Frequency Response Analysis (FRA)alireza shaОценок пока нет

- IcaДокумент6 страницIcasruthiОценок пока нет

- High-Performance Magnetic Gears: Kais Atallah, Stuart D. Calverley, David HoweДокумент3 страницыHigh-Performance Magnetic Gears: Kais Atallah, Stuart D. Calverley, David HoweTrung PhanОценок пока нет

- IEC62271-200 Metal-Clad Type High Voltage Marine Switchboard Training Course Examination Written TestДокумент4 страницыIEC62271-200 Metal-Clad Type High Voltage Marine Switchboard Training Course Examination Written Testdedik83Оценок пока нет

- Physics Sarawak Zon A Trial SPM 2008Документ85 страницPhysics Sarawak Zon A Trial SPM 2008Carolyn Chang Boon ChuiОценок пока нет

- Module 3Документ73 страницыModule 3Mahesh Shalinda MendisОценок пока нет

- Magnetically Coupled Circuits: Chapter ObjectivesДокумент25 страницMagnetically Coupled Circuits: Chapter ObjectivesNitin MarwahОценок пока нет

- Physics 2Документ3 страницыPhysics 2Jo PanОценок пока нет

- MIT2 003SCF11 Pset2 SolДокумент16 страницMIT2 003SCF11 Pset2 SolproflaruscoОценок пока нет

- Biomechanical Analysis of The Single-Leg Decline Squat: Original ArticleДокумент5 страницBiomechanical Analysis of The Single-Leg Decline Squat: Original ArticleGonzalo GonzalesОценок пока нет

- Experiment No. 4 Study of Various Types of EarthingДокумент14 страницExperiment No. 4 Study of Various Types of EarthingJude JohnОценок пока нет

- Backer Material For Use With Cold-And Hot-Applied Joint Sealants in Portland-Cement Concrete and Asphalt JointsДокумент4 страницыBacker Material For Use With Cold-And Hot-Applied Joint Sealants in Portland-Cement Concrete and Asphalt JointsSafiullah KhanОценок пока нет

- P1 Chapter 1Документ1 страницаP1 Chapter 1Rehan ShahОценок пока нет

- Contactors and Contactor Assemblies: Contactors For Switching MotorsДокумент10 страницContactors and Contactor Assemblies: Contactors For Switching MotorschochoroyОценок пока нет

- Module13 TestДокумент4 страницыModule13 TestAaron BundaОценок пока нет

- A Novel Adaptive Commutation Angle Method ForДокумент4 страницыA Novel Adaptive Commutation Angle Method ForatulhinduОценок пока нет

- Under The Guidance Of: Prof. Ajoya Ku Pradhan HOD Dept. of Electrical EngineeringДокумент27 страницUnder The Guidance Of: Prof. Ajoya Ku Pradhan HOD Dept. of Electrical Engineeringishfaq222100% (1)

- Magnetic AcousticДокумент8 страницMagnetic AcousticPavan SandeepОценок пока нет

- TD2: Control Rectifier and Full Wave RectifierДокумент8 страницTD2: Control Rectifier and Full Wave RectifierSokNov NaiОценок пока нет

- Dynamic Response of Ship Hull Due To SlammingДокумент116 страницDynamic Response of Ship Hull Due To SlammingJorge CiprianoОценок пока нет

- Digital Multimeter: Instruction ManualДокумент16 страницDigital Multimeter: Instruction ManualHenryAndersonAroapazaCasillaОценок пока нет

- Protection Against Overload CurrentДокумент21 страницаProtection Against Overload CurrentAzzhariff AHОценок пока нет

- Fluid Ch-1-1 Introduction and DimensionsДокумент34 страницыFluid Ch-1-1 Introduction and Dimensionsأزهار برديОценок пока нет

- Piezoelectric or Strain Gauge Based Force TransducersДокумент5 страницPiezoelectric or Strain Gauge Based Force TransducersAydinОценок пока нет

- Machine Protection PDFДокумент14 страницMachine Protection PDFAbdelsalam ElhaffarОценок пока нет

- 2 MultiBody DynamicsДокумент22 страницы2 MultiBody Dynamicsbiruk1Оценок пока нет

- Gas Insulated Substation: Electrical Engineering DepartmentДокумент24 страницыGas Insulated Substation: Electrical Engineering DepartmentChandrika Reddy2727Оценок пока нет

- Grade 10 Magnetic Effects of Current: Magnetic Field Lines (Properties) 1. 2. 3. 4Документ3 страницыGrade 10 Magnetic Effects of Current: Magnetic Field Lines (Properties) 1. 2. 3. 422550Оценок пока нет

- RPT Physics STPM Term 2 2020Документ8 страницRPT Physics STPM Term 2 2020marcella silunОценок пока нет

- 5.troubleshooting of TransformerДокумент3 страницы5.troubleshooting of Transformerprotection50% (2)

- Strong Is the New Beautiful: Embrace Your Natural Beauty, Eat Clean, and Harness Your PowerОт EverandStrong Is the New Beautiful: Embrace Your Natural Beauty, Eat Clean, and Harness Your PowerРейтинг: 4 из 5 звезд4/5 (5)

- Training for the Uphill Athlete: A Manual for Mountain Runners and Ski MountaineersОт EverandTraining for the Uphill Athlete: A Manual for Mountain Runners and Ski MountaineersРейтинг: 5 из 5 звезд5/5 (13)

- The Darkest White: A Mountain Legend and the Avalanche That Took HimОт EverandThe Darkest White: A Mountain Legend and the Avalanche That Took HimРейтинг: 4 из 5 звезд4/5 (1)

- Climb to Conquer: The Untold Story of WWII's 10th Mountain Division Ski TroopsОт EverandClimb to Conquer: The Untold Story of WWII's 10th Mountain Division Ski TroopsРейтинг: 5 из 5 звезд5/5 (1)

- Hockey: Hockey Made Easy: Beginner and Expert Strategies For Becoming A Better Hockey PlayerОт EverandHockey: Hockey Made Easy: Beginner and Expert Strategies For Becoming A Better Hockey PlayerОценок пока нет

- The Art of Fear: Why Conquering Fear Won't Work and What to Do InsteadОт EverandThe Art of Fear: Why Conquering Fear Won't Work and What to Do InsteadРейтинг: 4 из 5 звезд4/5 (10)

- Winterdance: The Fine Madness of Running the IditarodОт EverandWinterdance: The Fine Madness of Running the IditarodРейтинг: 4.5 из 5 звезд4.5/5 (279)

- Higher Love: Climbing and Skiing the Seven SummitsОт EverandHigher Love: Climbing and Skiing the Seven SummitsРейтинг: 5 из 5 звезд5/5 (5)

- Training for the Uphill Athlete: A Manual for Mountain Runners and Ski MountaineersОт EverandTraining for the Uphill Athlete: A Manual for Mountain Runners and Ski MountaineersРейтинг: 4.5 из 5 звезд4.5/5 (8)

- Strong is the New Beautiful: Embrace Your Natural Beauty, Eat Clean, and Harness Your PowerОт EverandStrong is the New Beautiful: Embrace Your Natural Beauty, Eat Clean, and Harness Your PowerРейтинг: 4 из 5 звезд4/5 (22)

- Backcountry Avalanche Safety: A Guide to Managing Avalanche Risk - 4th EditionОт EverandBackcountry Avalanche Safety: A Guide to Managing Avalanche Risk - 4th EditionОценок пока нет

- Mistake-Free Golf: First Aid for Your Golfing BrainОт EverandMistake-Free Golf: First Aid for Your Golfing BrainРейтинг: 4 из 5 звезд4/5 (1)

- The Art of Fear: Why Conquering Fear Won't Work and What to Do InsteadОт EverandThe Art of Fear: Why Conquering Fear Won't Work and What to Do InsteadРейтинг: 3 из 5 звезд3/5 (5)