Академический Документы

Профессиональный Документы

Культура Документы

Flash Process

Загружено:

Kevin J. MillsАвторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Flash Process

Загружено:

Kevin J. MillsАвторское право:

Доступные форматы

Improvement of the Flash-Pyrolysis Process and Pilot Plant for Bio-Oils

Upgrading

Summary

The project has the overall objective of studying different methods of upgrading fast pyrolysis liquids

in order to overcome anticipated problems of utilising crude fast pyrolysis liquid derived from

biomass !t the time that the project "as proposed and agreed# there "as considerable interest in

the production of liquid fuels and a belief that the crude biomass derived fast pyrolysis liquid $bio-oil%

"as too unstable to be used directly in po"er and thermal applications There had already been

some success in upgrading bio-oil to hydrocarbons by hydrotreating on a laboratory scale to produce

a naphtha type product "hich could be upgraded by conventional refinery operations to diesel and

light fuel oil& and also 'eolite crac(ing to produce crude aromatics that could li(e"ise be upgraded to

gasoline by conventional refinery operations

The project therefore aimed to develop and evaluate t"o chemical upgrading processes

hydrotreating and 'eolite crac(ing !n assessment of upgrading through chemicals recovery "as

included )uring the contract negotiation stage an opportunity arose to participate in a bio-oil fired

gas turbine test programme in *anada and this "as included to gain first hand e+perience of the

problems arising from not upgrading

!ll of the initial objectives e+cept the construction of a dedicated bio-oil hydrotreating pilot plant

have been satisfactorily completed )ue to ban(ruptcy of the major project contractor# this element

could not be completed and this "as replaced by tests on an e+isting unit and detailed design

studies These have enabled the aims of providing a robust technical and economic evaluation to be

completed

)uring the course of the project# it became clear that the crude fast pyrolysis liquid - or bio-oil - could

be satisfactorily used in gas turbines $also in engines in parallel projects%# and the need for upgrading

"as thus obviated It is also clear that the costs of producing transport fuels are far too high# even

"ith major fiscal incentives Of the t"o main routes studied# the 'eolite crac(ing route "hich is

integral "ith the fast pyrolysis process seems to offer substantial economic benefits# although it is

less developed than hydrotreating It is recommended that attention be focused on stabilising the

crude liquid to ma(e it more amenable to "ider usage and to study the upgrading processes as a

means of deriving higher value chemicals

Introduction

,hen this contract "as a"arded in -../# there "as considerable interest in the production of liquid

fuels and a belief that the crude biomass derived fast pyrolysis liquid "as too unstable to be used

directly in po"er and thermal applications There had already been some success in upgrading bio-oil

to hydrocarbons by hydrotreating on a laboratory scale and the trials on 'eolite crac(ing for

aromatics production appeared promising This project therefore aimed to e+plore these upgrading

technologies by utilising both the e+isting industrial and academic e+pertise in 0urope and also by

commissioning "or( "ith leading organisations in 1orth !merica in order to provide the most

efficient and effective "ay of progressing the technologies

Objectives

The primary objective of the project is the design# construction# testing and evaluation of a pilot plant

to hydrotreat fast pyrolysis bio-oils for the production of hydrocarbon fuels *omplementary

objectives include an assessment of the performance and production cost of Robinia and s"eet

sorghum# evaluation of 'eolites as an alternative upgrading route# gas turbine testing on crude bio-

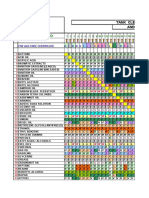

oils and an evaluation of the recovery of high value chemicals The structure of the project sho"ing

the activities and contributions as "ell as the interactions and relationships is summarised in the

Figure belo" This has been modified from the original plan to account for the consequences of the

retirement of Fochi# but is other"ise largely unchanged from the original plan

Progress

The problems met by the project are "ell documented in interim reports# but the most serious "as

the "ithdra"al of the lead contractor# Fochi# due to their liquidation The resultant time delay and

inability of finding another company to provide the necessary e+pertise and financial resources

"ithin the time constraints of the project meant that one of the primary objectives of the project to

build a hydrotreating plant became increasingly difficult to realise It "as also appreciated that there

"ere e+isting hydrotreating facilities at several centres in 0urope# "hich# coupled to the success of

other projects in using the crude bio-oil "ithout upgrading# and the severe shortage of funds in the

project# mitigated against pursuing construction of the pilot plant

In -..2 it "as agreed by all the partners and the *ommission to modify the "or( programme and

substitute construction of the hydrotreating pilot plant by tests and detailed design studies of

hydrotreating pilot plants "ith cost estimates

Activities

!ll objectives of the contract have been successfully completed apart from not building a

hydrotreating pilot plant ,ith the present (no"ledge of pyrolysis liquids# this is no" seen to be not

necessary# -so does not detract from the from the project The rest of the "or( can be summarised

on a tas( by tas( basis# as follo"s3

Test on growing, harvesting, chipping and storing Robinia and sweet sorghum, economic analysis of the

biomass production systems, market analysis of biomass availability and analysis of integrated supply

systems. Tests have been completed on s"eet sorghum and Robinia gro"ing# harvesting# drying and

transport ! linear programming model of biomass supply systems has been constructed !n analysis

of biomass supply sources and systems has been carried out The conclusions of this part of the "or(

"ere that results for production of sorghum "ere valuable the cultivars "ere not as satisfactory as

others tested else"here 4arvesting of 5obinia "as successful "ith the machine tested but the

equipment needs strengthening The model suggests that Cynara is the most promising biomass

crop# follo"ed by Arundo Donax. *ombined crops provide year round supply "hich has implications

for conversion plant specifications and design Biomass supplies have been identified in the Umbria

region "hich "ill provide a methodology and results for other areas

Characterisation of pyrolysis liuid and the upgraded products, evaluation of the hydrotreating plant and

supply of bio!oil. !s the hydrotreating plant "as not built some objectives could not be met *hemical

and physical properties "ere measured on bio-oil supplied by 0nsyn and Fenosa# and on partially

upgraded bio-oil from 6assari# and on fully upgraded oil from the )7T tests Upgrading processes

"ere revie"ed and it "as concluded that fast pyrolysis of biomass is not yet a "ell proven

technology# bio-oils from different sources e+hibit significantly different characteristics# the )7T

upgraded product consisted mostly of paraffinic hydrocarbons "hile there is a "ide variation in

upgraded product costs

Delivery of bio!oil from the "enosa pilot plant and techno!economic assessments of the #"$$ system

with a fluid bed pyrolyser operating at %&&'C and atmospheric pressure. This part of the project resulted

in samples of oil being delivered to . organisations *apital costs have been estimated for pyrolysis

processes from 89 7"e to :8 7"e "hich range from :298 0*U;(,e output for the pyrolysis plant

alone $no engine% at 89 7,e to /-:8 0*U;(,e at :8 7,e 7ass balances and electricity outputs

have been reported for pyrolysis processes from 89 7,e to :8 7,e It "as concluded that the

brea(-even for a -2< I55 is achieved at around = 7,e based on bio-oil as the product The "ater

content of the biomass has a significant effect on the production costs 6mall projects can only be

justified if there is a social credit >arge projects may be financially viable for lo" cost biomass feed

such as forestry residues

(ydrotreating on a laboratory scale unit and design of pilot plant. The laboratory scale process "as

successfully operated on bio-oil for the first stage of processing ! detailed pilot plant design "as

produced It "as concluded that full de-o+ygenation of bio-oil is possible by several routes Feasible

designs have been produced for hydrotreating pilot plants *omparisons "ith bio-diesel are

favourable "ith respect to hydrocarbon yield per ha and similar "ith respect to production cost If

bio-diesel is considered economically acceptable# then bio-naphtha is equally acceptable

Techno!economic assessments of the upgrading systems and evaluation of opportunities for recovering

chemicals. *apital cost estimates of seven processes for fast pyrolysis and upgrading have been

provided on a consistent basis at -88 t;h dry "ood input Production costs of crude and upgraded

products have been estimated on a consistent basis ! thorough revie" of chemicals recovery

processes has been completed It "as found that none of the pyrolysis or upgrading processes gives

a product that is economic currently *rude bio-oil and 'eolite crac(ing offer the best short term

prospects for a competitively priced fuel 4ydrotreating is very costly in terms of investment and

hydrogen requirement# even for partial upgrading Future "or( should focus on improving the crude

bio-oil and adapting applications to the crude bio-oil# as "ell as developing integrated processing

such as the 'eolite crac(ing process *hemicals recovery is feasible but the economics "ill depend

very much on mar(et evaluation and development

)xploratory research into existing and new catalysts for hydrotreating bio!oil to produce hydrocarbons

and*or improved stability oil. ! /-: (g;h laboratory unit "as successfully modified to operate "ith a

separate fi+ed catalytic bed and "ith replacement of the sand by catalyst# "ith four catalysts tested

The product proportions changed "ith increased gas and char;co(e production and "ith reduced

liquid yields The liquid "as generally in t"o phases and sho"ed substantially different

characteristics in particular being more distillable and "ith higher hydrocarbon levels It "as

concluded that 'eolite type catalysts can be successfully introduced into an 0nsyn 5TP pyrolysis

system Use of catalysts generally gives a significantly different product range >o"er temperatures

gave higher liquid yields The liquid had much higher levels of hydrocarbons of around .< compared

to -< in bio-oil "ithout catalyst

Tests on a +.% ,#e gas turbine on bio!oil with subsidiary ob-ectives of characterising bio!oil and testing

it for combustibility and effect on turbine components. The tests "ere successfully completed for a total

duration of -8 hours 0missions "ere measured and found to be belo" corresponding values for

diesel apart from particulates Flame tunnel testing of components "as carried out "ith some

deposition found# particularly on the first stage blade and first stage no''le It "as concluded that

there is a potential for bio-oil fired gas turbines 6ome deposition "as found on turbine components

from flame tunnel tests but these are not necessarily representative The emissions "ere entirely

acceptable for *O# 1O+# methane# equivalent total hydrocarbons and 68/- particulates "ere higher

than diesel

Development of hydrotreating using conventional hydrotreating catalysts to achieve low severity upgrading.

! laboratory scale unit "as successfully operated in do"nflo" mode and good mass balances

achieved ! revised pilot plant specification and design "ith capital cost estimate "as provided It

"as concluded that lo" severity hydrotreating is an alternative to full de-o+ygenation for improving

the properties of crude bio-oil# but still requires many of the features of full hydrotreating# but at a

lo"er capital cost The use of nic(el catalysts at lo" temperatures leads to alcohol formation giving a

more stable but o+ygenated product

Conclusions

)uring the course of the project# it "as found that the crude fast pyrolysis liquid - or bio-oil - could be

satisfactorily used in gas turbines $also in engines in parallel projects%# and the need for upgrading to

hydrocarbons "as thus obviated The costs of producing transport fuels is too high# even "ith major

fiscal incentives# Of the t"o main routes studied# the 'eolite crac(ing route "hich is integral "ith the

fast pyrolysis process seems to offer substantial economic benefits# although it is less developed

than hydrotreating It is recommended that attention be focused on stabilising the crude liquid to

ma(e it more amenable to "ider usage in different applications and to study the upgrading

processes as a means of deriving higher value chemicals

Вам также может понравиться

- G (X Zéáñxä U - Ääuétüw: Strong'S Concordance LegendДокумент1 страницаG (X Zéáñxä U - Ääuétüw: Strong'S Concordance LegendKevin J. MillsОценок пока нет

- Kinetic DiameterДокумент4 страницыKinetic DiameterKevin J. MillsОценок пока нет

- Logical Reasoning: January 2003Документ25 страницLogical Reasoning: January 2003Kevin J. MillsОценок пока нет

- Drug Policy NeuteredДокумент9 страницDrug Policy NeuteredKevin J. MillsОценок пока нет

- DBA CalculationДокумент4 страницыDBA CalculationKevin J. MillsОценок пока нет

- Julie Ellison: Prevent Rockfall and Calmly Handle EmergenciesДокумент2 страницыJulie Ellison: Prevent Rockfall and Calmly Handle EmergenciesKevin J. MillsОценок пока нет

- Hill Route DescriptionДокумент7 страницHill Route DescriptionKevin J. MillsОценок пока нет

- Plant Y09Документ1 056 страницPlant Y09Kevin J. MillsОценок пока нет

- Root & ShootДокумент6 страницRoot & ShootKevin J. MillsОценок пока нет

- Biomass Rules of ConductДокумент2 страницыBiomass Rules of ConductKevin J. MillsОценок пока нет

- Potential Partner PP Annual Revenue PP ResourcesДокумент1 страницаPotential Partner PP Annual Revenue PP ResourcesKevin J. MillsОценок пока нет

- Florida Tornado DataДокумент2 страницыFlorida Tornado DataKevin J. MillsОценок пока нет

- Propagation ChartДокумент2 страницыPropagation ChartKevin J. MillsОценок пока нет

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeОт EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeРейтинг: 4 из 5 звезд4/5 (5794)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceОт EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceРейтинг: 4 из 5 звезд4/5 (895)

- The Yellow House: A Memoir (2019 National Book Award Winner)От EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Рейтинг: 4 из 5 звезд4/5 (98)

- The Little Book of Hygge: Danish Secrets to Happy LivingОт EverandThe Little Book of Hygge: Danish Secrets to Happy LivingРейтинг: 3.5 из 5 звезд3.5/5 (400)

- The Emperor of All Maladies: A Biography of CancerОт EverandThe Emperor of All Maladies: A Biography of CancerРейтинг: 4.5 из 5 звезд4.5/5 (271)

- Never Split the Difference: Negotiating As If Your Life Depended On ItОт EverandNever Split the Difference: Negotiating As If Your Life Depended On ItРейтинг: 4.5 из 5 звезд4.5/5 (838)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyОт EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyРейтинг: 3.5 из 5 звезд3.5/5 (2259)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureОт EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureРейтинг: 4.5 из 5 звезд4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryОт EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryРейтинг: 3.5 из 5 звезд3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnОт EverandTeam of Rivals: The Political Genius of Abraham LincolnРейтинг: 4.5 из 5 звезд4.5/5 (234)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaОт EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaРейтинг: 4.5 из 5 звезд4.5/5 (266)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersОт EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersРейтинг: 4.5 из 5 звезд4.5/5 (345)

- The Unwinding: An Inner History of the New AmericaОт EverandThe Unwinding: An Inner History of the New AmericaРейтинг: 4 из 5 звезд4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreОт EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreРейтинг: 4 из 5 звезд4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)От EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Рейтинг: 4.5 из 5 звезд4.5/5 (121)

- Iso 9606 4 1999Документ11 страницIso 9606 4 1999Lino Alves InácioОценок пока нет

- BS en 10222-2 - 2017 PDFДокумент32 страницыBS en 10222-2 - 2017 PDFАртем Титов75% (4)

- Chapter 4 - Carbon and The Molecular Diversity of Life 1Документ5 страницChapter 4 - Carbon and The Molecular Diversity of Life 1Hezron BarnabasОценок пока нет

- Pyro FormulasДокумент121 страницаPyro FormulasMichael Beasley100% (4)

- Finalreport PDFДокумент47 страницFinalreport PDFNelCamHerОценок пока нет

- StereochemistryДокумент52 страницыStereochemistryTimmyОценок пока нет

- Astm A53 A53mДокумент23 страницыAstm A53 A53mRaviprakash Chauhan100% (2)

- Exergoeconomic Analysis of A Combined Heat and Power (CHP) SystemДокумент17 страницExergoeconomic Analysis of A Combined Heat and Power (CHP) Systemjhugo_mirandaОценок пока нет

- Ionic and Covalent BondsДокумент5 страницIonic and Covalent Bondsapi-233981890Оценок пока нет

- DehydrationДокумент13 страницDehydrationSaa D ShamimОценок пока нет

- 02 Torque and Socket OptimizeДокумент26 страниц02 Torque and Socket OptimizeANDI SETIAWANОценок пока нет

- Physics of Electromagnetic Calorimeters Based On Crystal ScintillatorsДокумент49 страницPhysics of Electromagnetic Calorimeters Based On Crystal ScintillatorsVigneshRamakrishnanОценок пока нет

- EXPERIMENT 1 DETERMINATION OF REACTION HEAT (Physical Chem)Документ17 страницEXPERIMENT 1 DETERMINATION OF REACTION HEAT (Physical Chem)siti irdinaОценок пока нет

- CH 0 Cleaning Cross Refference Table DREW AMEROIDДокумент36 страницCH 0 Cleaning Cross Refference Table DREW AMEROIDPavel ViktorОценок пока нет

- Exp 10 - Exp 7 A Green Synthesis of Camphor UploadДокумент4 страницыExp 10 - Exp 7 A Green Synthesis of Camphor UploadUyen V. NguyenОценок пока нет

- Hasil Uji Emisi Incenerator.2Документ2 страницыHasil Uji Emisi Incenerator.2UrlialyОценок пока нет

- Heat Treat System Assessment CQI-9Документ48 страницHeat Treat System Assessment CQI-9shashi kant kumarОценок пока нет

- Factors Influencing ToxicityДокумент7 страницFactors Influencing ToxicityderrickОценок пока нет

- Metron Fuel Quality Final PDFДокумент67 страницMetron Fuel Quality Final PDFpersadanusantara100% (1)

- Desalination Technologies, 4th Level, ERE414, 2023, ChapterДокумент49 страницDesalination Technologies, 4th Level, ERE414, 2023, ChapterMohamed HatemОценок пока нет

- State Wise Distribution of Units Registered Under Factories Act, 1948Документ6 страницState Wise Distribution of Units Registered Under Factories Act, 1948api-19850688Оценок пока нет

- C100E Resin PUROLITEДокумент3 страницыC100E Resin PUROLITEmilaОценок пока нет

- Haloalkane Note NДокумент109 страницHaloalkane Note NBichitra GautamОценок пока нет

- Engi 9625 Assignment 1Документ6 страницEngi 9625 Assignment 1nuvanОценок пока нет

- ks3 Acids and Alkalis Whats Your Idea PowerpointДокумент11 страницks3 Acids and Alkalis Whats Your Idea PowerpointManha abdellahОценок пока нет

- Alloy 276 Spec SheetДокумент3 страницыAlloy 276 Spec SheetermusatОценок пока нет

- Sika Igasol - 17: High Build, Bituminous Emulsion CoatingДокумент3 страницыSika Igasol - 17: High Build, Bituminous Emulsion CoatingAhmed AbdallahОценок пока нет

- Basics of RadiobiologyДокумент61 страницаBasics of RadiobiologyLikhon Amin AponОценок пока нет

- Solef Hylar PVDFДокумент60 страницSolef Hylar PVDFribeiro30Оценок пока нет

- Mechanical Properties of MaterialsДокумент3 страницыMechanical Properties of MaterialsTiras Ngugi0% (1)