Академический Документы

Профессиональный Документы

Культура Документы

Tms320F2812 Assembly Language Tutorial 2: Controlling The XF LED

Загружено:

abpatki@yahoo.comИсходное описание:

Оригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Tms320F2812 Assembly Language Tutorial 2: Controlling The XF LED

Загружено:

abpatki@yahoo.comАвторское право:

Доступные форматы

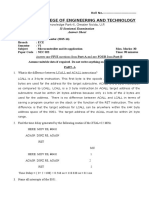

TMS320F2812 Assembly Language: Tutorial 2 Date: 25 May 2014

1

TMS320F2812 ASSEMBLY LANGUAGE

Tutorial 2: Controlling the XF LED

New Instructions Introduced

SETC

NOP

B

New Test Condition Introduced

NBIO

Introduction

In the previous tutorial we saw how the TMS320F2812 DSP Starter Kit (DSK)

powers up with the XF (external flag) LED on. We also saw how we can turn this

LED off under the control of software. In this tutorial we shall use software to control

the brightness of the XF LED.

Turning the XF LED Off and On

To turn the XF LED off we use the instruction CLRC XF. How do we turn the XF

LED back on again?

To do so we need to use the instruction SETC (set control bit). The instruction SETC

takes a single operand, which is the name of the flag, in this case XF.

Example 2-1.

SETC XF ; Turn on the XF LED.

The instruction SETC sets a control bit. By the term set we mean make the value logic

level 1 which approximates to 3.3V on the physical XF pin. This is opposite to the

term clear which means make the logic level 0, which approximates to 0V on the

physical XF pin.

We shall now write a program to repeatedly turn the XF LED on and off. This is

shown in Example 2-2.

Example 2-2.

start: SETC XF ; Turn on XF LED.

CLRC XF ; Turn off XF LED.

TMS320F2812 Assembly Language: Tutorial 2 Date: 25 May 2014

2

B start, UNC ; Go round again.

When the code in Example 2-2 is assembled and then run on the DSK, what happens?

The XF LED comes on, but dimmed in comparison with the power LED that is full

on. Why should this be the case?

Output Wave-form at XF

If we were to look at the output on the XF pin of the TMS320F2812 DSK using an

oscilloscope, we would see the waveform shown in Figure 2-1.

Figure 2-1. Wave-form at XF Pin

3.3V

0V

333 ns 400 ns

66.7 ns

It can be seen from Figure 2-1 that there is a repeating pattern at the XF pin. The

output is high (at approximately 3.3V) for 66.7 ns, then low (at approximately 0V) for

333 ns. The pattern repeats every 400 ns. This corresponds to a frequency of 2.495

MHz.

The XF LED is in fact being switched on and off 2495000 times every second.

Because this is faster than the human eye can see and the LED is off more than it is

on, the LED appears to be dimmed.

Timings of XF Wave-form

Why are the timings of the waveform at the XF pin as they are?

Each TMS320F2812 instruction takes a certain amount of time to execute. This time

is derived from the number of processor machine cycles. The execution time for every

instruction can be expressed in terms of processor machine cycles, more commonly

referred to simply as cycles. On the TMS320F2812 DSK, each cycle takes 66.7 ns.

We can measure this time by measuring the output at the XCLKOUT pin on the

TMS320F2812 DSK using an oscilloscope or a frequency meter.

Let us re-write Example 2-2, but this time putting in the number of cycles.

TMS320F2812 Assembly Language: Tutorial 2 Date: 25 May 2014

3

Example 2-3.

start: SETC XF ; Turn on XF LED. 1 cycle.

CLRC XF ; Turn off XF LED. 1 cycle.

B start, UNC ; Go round again. 4 cycles.

Example 2-3 shows how the instructions SETC and CLRC both execute in a single

cycle, whereas the instruction B requires 4 cycles. The total time to complete the loop

is therefore 1 + 1 + 4 = 6 cycles.

When calculating the time to execute a block of code, it is normal practice to express

the execution time in cycles rather than in divisions of a second. This is because the

number of clock cycles is always the same, regardless of the speed on XCLKOUT.

The actual timings can then be calculated by multiplying the number of cycles by the

time per cycle.

Note that XF pin stays in the same state until the instruction has finished executing.

When XF is at logic 1, it takes 1 cycle (66.7ns) for the instruction CLRC XF to take

effect.

A Brighter XF LED

Let us now re-write Example 2-3, but this time reversing the order in which the SETC

XF and CLRC XF instructions occur.

Example 2-4.

start: CLRC XF ; Turn off XF LED. 1 cycle.

SETC XF ; Turn on XF LED. 1 cycle.

B start, UNC ; Go round again. 4 cycles.

In this case the XF LED will be off for 66.7 ns and on for 333 ns. As in Example 2-3,

the frequency will be 2.459 MHz.

If the code is run on the DSK, then the XF LED will be on at almost full brightness, as

compared with the power LED. Figure 2-2 shows the waveform at the XF pin.

Figure 2-2. Wave-form at XF Pin

TMS320F2812 Assembly Language: Tutorial 2 Date: 25 May 2014

4

3.3V

0V

333 ns 400 ns

66.7 ns

Equal On and Off Times

In Examples 2-3 and Example 2-4, the XF LED is off for a different time to which it

is on. How do we make the on and off times identical?

One way is to add some padding. We require an instruction that does nothing other

than take up execution time. For this we use the instruction NOP (no operation), which

takes a single cycle to execute.

Example 2-5.

start: CLRC XF ; Turn off XF LED. 1 cycle.

NOP ; No operation. 1 cycle.

NOP ; No operation. 1 cycle.

NOP ; No operation. 1 cycle.

NOP ; No operation. 1 cycle.

SETC XF ; Turn on XF LED. 1 cycle.

B start, UNC ; Go round again. 4 cycles.

In Example 2-5, the XF LED will be off for 1 + 1 + 1 + 1 + 1 = 5 cycles and on for 4

+ 1 = 5 cycles. This corresponds to an on time of 5 x 66.7 ns = 333 ns and an off time

of 5 x 66.7 ns = 333 ns.

If we were to assemble and run Example 2-5, then using an oscilloscope we would see

the waveform as shown at Figure 2-3.

Figure 2-3. Equal on and off times

3.3V

0V

333 ns 333 ns

TMS320F2812 Assembly Language: Tutorial 2 Date: 25 May 2014

5

The total cycle time = 10 x 66.7 ns = 667 ns = 0.67 s. This corresponds to a

frequency measured at the XF pin of 1.5 MHz.

External Control of the XF LED

The TMS320F2812 has a dedicated physical input pin (XBIO) that can be used to

control the execution of the program. When the input pin XBIO is pulled down to

logic 0 (0V), then a branch can be made to occur. When the input pin XBIO is left

unconnected or connected to 3.3V (logic 1), then no branch occurs.

The C code to carry out this operation would be of the form:

Example 2-6.

for ( ; ; )

{

if (XBIO == 0) /* Test if XBIO pin is zero */

XF = 0; /* Turn XF LED off */

else

XF = 1; /* Turn XF LED on */

}

To implement Example 2-6 in assembly language we could write:

Example 2-7.

start: BCND off, NBIO ; Test if XBIO pin is low

; (logic 0). If so, branch to

; label off.

SETC XF ; Turn on XF LED.

B done, UNC ; Do not execute next

; instruction.

off: CLRC XF ; Turn off XF LED.

done: B start, UNC ; Go round again.

The instruction B (branch conditionally) takes two operands. The first (left-hand)

operand is where the branch is to go and is specified by a label. The second (right-

hand) operand is the test condition.

If the test condition evaluates to TRUE, then a branch occurs. Here the test condition

to be evaluated is the XBIO pin is at logic 0 (low)? If this is true, then the branch

occurs. Note that the physical pin is called XBIO, but the operand is called NBIO.

If the condition under test does not evaluate to true, which will be the case when the

XBIO pin is at logic 1, then a branch does not occur. The next instruction to be

executed is the one immediately following the instruction B.

Example 2-8 shows some right and wrong ways to use the instruction B:

TMS320F2812 Assembly Language: Tutorial 2 Date: 25 May 2014

6

Example 2-8.

start: B done, NBIO ; Correct syntax.

B NBIO ; Incorrect. Missing operand.

done: B NBIO, start ; Incorrect. Operands reversed.

B start, XBIO ; Wrong condition name.

We can only branch on the condition that the XBIO pin is low (logic 0). There is no

conditional branch available on XBIO pin high (logic 1).

Timing of the Loop

We can re-write the code in Example 2-7 showing the instruction cycles.

Example 2-9.

start: BCND off, NBIO ; 7 cycles when branch occurs,

; otherwise 4 cycles.

SETC XF ; 1 cycle.

B done, UNC ; 4 cycles.

off: CLRC XF ; 1 cycle.

done: B start, UNC ; 4 cycles.

Note that the number of cycles taken by the instruction B depends on whether the

branch occurs. If the branch occurs, then the instruction takes 7 cycles. If the branch

does not occur, then the instruction takes only 4 cycles.

When the XBIO pin is high (logic 1) then the condition NBIO low evaluates to

FALSE. Therefore, the instruction B does not branch but falls through to the next

instruction. The loop executes in 4 + 1 + 4 + 4 = 13 cycles.

On the other hand, when the pin XBIO is low (logic 0) then the condition NBIO

evaluates to TRUE. The conditional branch B causes program execution to continue at

the label off. The loop executes in 4 + 1 + 4 = 9 cycles.

In this case, the loop executes in different numbers of cycles depending upon the

physical status of the XBIO pin.

The Importance of Instruction Cycles

In this tutorial, the execution times of the instructions have been stated in cycles.

When performing real-time programming, the speed of operation can often

be crucial and effort goes into optimizing the code. Instruction cycles give us the

speed of throughput through the code. When using a C compiler, we do not have total

control of which instructions are actually being used and how well the code is

optimized.

TMS320F2812 Assembly Language: Tutorial 2 Date: 25 May 2014

7

DC Outputs

In Example 2-3, Example 2-4 and Example 2-5 we have produced an output

waveform on the XF pin, which affects the brightness of the XF LED. So far we have

looked at this output as an alternating (A.C.) signal. However, if we were to measure

the output at the XF pin with an analog meter set to a 5V DC or 10V DC range, then

we would measure a voltage at the XF pin as follows:

Table 2-1.

Program XF on time XF off time D.C. Voltage

Power up XF full on None 3.3 V

Example 2-3 on 66.7 ns off 333 ns 0.55 V

Example 2-4 on 333 ns off 66.7 ns 2.75 V

Example 2-5 on 333 ns off 333 ns 1.65 V

To calculate the DC output we need to find the average value that the output produces.

In the case of Example 2-3, the output is 0V for 66.7 ns and 3.3V for 333 ns. The

average is:

66.7/(333+66.7) * 3.3V + 333/(333+66.7) * 0.0V = 0.55V.

Similarly:

0.55V = 3.3V x 1/6

2.75V = 3.3V x 5/6

1.65V = 3.3V x 3/6

Digital to Analogue Conversion

By altering the time the XF pin is high / low we have been able to vary the D.C.

output. This is a commonly used method used to generate analog outputs from a

digital source. The TMS320F2812 has a series of timers that can be configured to

produce output pulses of different widths for use as D-to-A converters.

Upgrading from the TMS320C/F24x to the TMS320F2812

The differences between the two processors are given in Table 2-2.

Table 2-2. Comparison of TMS320C/F24x and TMS320F2812 Instructions

TMS320C24x TMS320C28x Comments

CLRC XF CLRC XF Same syntax

SETC XF SETC XF Same syntax

BCND label, BIO B label, NBIO Different command,

and different

second operand.

TMS320F2812 Assembly Language: Tutorial 2 Date: 25 May 2014

8

TMS320F2812 DSK EXPERIMENTS

Equipment required: TMS320F2812 DSK.

Digital frequency meter (0 - 4 MHz) or oscilloscope.

Analog D.C. meter 0 - 5V or 0 10V (or analog multi-meter).

Switch and resistors to short out XBIO pin to ground.

Note: Some frequency meters are designed for 1:1 mark to space ratio, and may give

erroneous readings with some of the waveforms.

Experiment 2-1.

Objective: To Measure the Clock Frequency of the TMS320F2812 DSK

Measure the frequency on the XCLKOUT pin of the TMS320F2812 DSK using a

frequency meter or an oscilloscope. Connect one probe to XCLKOUT (Connector P8,

Pin 29) and the other probe to GND (Connector P8, Pin 39 or Pin 40).

For the TMS320F2812 DSK, the frequency on XCLKOUT is 3.75 MHz, which

corresponds to an instruction time of 66.7 ns.

Experiment 2-2.

Objective: To Generate 0.55V D.C. on the XF Pin

Enter the code in Example 2-2 or 2-3, assemble it and run it on the TMS320F2812

DSK.

The frequency on the XF LED measured between XF (Connector P4, Pin 17 or one

end of the XF LED itself) and GND (Connector P8, Pin 39 or 40) should be 2.495

MHz.

If an oscilloscope is available, then using a Y deflection of 1V/cm and a time-base of

500 ns per division, the output should be as per Figure 2-1.

If an analog D.C. meter is used to measure the output on the XF pin, then the

measured voltage should be 0.55V.

Experiment 2-3.

Objective: To Generate 2.75V D.C. on the XF Pin

TMS320F2812 Assembly Language: Tutorial 2 Date: 25 May 2014

9

Enter the code in Example 2-4, save it, assemble it and run the program on the

TMS320F2812 DSK.

The frequency on the XF LED should be 2.495 MHz and output should be as per

Figure 2-2. The D.C value should be 2.75V.

Experiment 2-4.

Objective: To Generate 1.65V D.C. on the XF Pin

Enter the code in Example 2-5, save it, assemble it then run it on the TMS320F2812

DSK.

The frequency on the XF LED should be 2.495 MHz and output should be as per

Figure 2-3. The D.C value should be 1.65V.

Experiment 2-5.

Objective: To Control the XF LED using the XBIO Pin

Connect a switch to the XBIO pin shown in Figure 2-4. For the TMS320F2812 DSK,

the supply can be a maximum of 3.3V. Care should be taken not to exceed this voltage

because damage is likely to be done to the device. In Figure 2-4, even though the

circuit runs from 5.0V, the maximum voltage at the input pin of the TMS320F2812

will be 3V.

Figure 2-4. Suggested Connection of Switch to XBIO Pin

2k2

10 k

Push

Button

To Port

Pin

0 V

5.0V

Supply

3k3

3V

Enter the code in Example 2-7, save it, assemble it and run it on the TMS320F2812

DSK.

The XF LED should be off. Short the XBIO pin to ground to turn on the XF LED. On

the TMS320F2812 DSK, the XBIO pin is Connector P8, Pin 22 and the ground is

Connector P8, Pin 39 or 40.

TMS320F2812 Assembly Language: Tutorial 2 Date: 25 May 2014

10

Design Problem 2-1.

Rewrite the code in Example 2-7 so that when the XBIO pin is unconnected the XF

LED is off, and when the XBIO pin is shorted to ground, the XF LED comes on.

Design Problem 2-2.

In Example 2-9, when the XBIO pin is high (3.3V which corresponds to logic 1), the

loop executes in 11 cycles. Re-write Example 2-9 so that when XBIO pin is high, the

loop executes in 7 cycles.

Design Problem 2-3.

Rewrite the code in Example 2-9 so that the loop always executes in the same time,

regardless whether or not the button is pressed. Hint: Insert NOPs in the fastest loop

to slow it down to the same time as the slowest loop.

TMS320F2812 Assembly Language: Tutorial 2 Date: 25 May 2014

11

Self-Test Questions

1. What is meant by the term set when applied to a control bit?

2. What is meant by the term clear when applied to a control bit?

3. Which two of the following instructions are correct?

a) SET XF

b) SETC XF

c) CLR XF

d) CLRC XF

4. In order turn on the XF LED on the DSK, which instruction do we use?

5. In order to turn off the XF LED on the DSK, which instruction do we use?

6. If we repeatedly flash the XF LED on and off rapidly, why does the XF

LED appear dimmed?

7. Why is the frequency on the XCLKOUT pin important?

8. Why do we express execution time in cycles rather than in divisions of

seconds?

9. What effect does the instruction NOP have?

10. Which one of the following commands is correct?

a) B label, NBIO

b) B label, XBIO

c) B label,

d) B XBIO, label

e) B NBIO, label

f) B label1, label2

11. How would we use the XBIO pin to control software?

12. The instruction B always takes 7 cycles to execute. Is this true or false?

13. Why are timing cycles important for real-time programming?

14. How do we use the output on the XF pin as a simple digital-to-analog

converter (D-to-A)?

References

TMS320C28x DSP CPU and Instruction Set Reference Guide. Literature Reference

Number: SPRU430.

TMS320C2812 DSK User Manual.

Вам также может понравиться

- Chapter 3Документ46 страницChapter 3r4royalcОценок пока нет

- ECET105 Lab 7 Enhanced Adder-SubtractorДокумент14 страницECET105 Lab 7 Enhanced Adder-SubtractorMicro EmissionОценок пока нет

- Instruction Cycle Time PDFДокумент6 страницInstruction Cycle Time PDFOcbit LowbyteОценок пока нет

- MPHS EXAM 13/06/16 - Prof. Luca Benini Name: Nmat:: Load 4'b1000Документ7 страницMPHS EXAM 13/06/16 - Prof. Luca Benini Name: Nmat:: Load 4'b1000Sudhir Borra100% (1)

- Chapter 3 - ASSEMBLYДокумент56 страницChapter 3 - ASSEMBLYHiếu TrungОценок пока нет

- EE 5311 Digital IC Design Tutorial 3 - Sep 25, 2015: N Ox 2 P Ox 2 Min Min T T Dsat Dsat DDДокумент2 страницыEE 5311 Digital IC Design Tutorial 3 - Sep 25, 2015: N Ox 2 P Ox 2 Min Min T T Dsat Dsat DDHarshithОценок пока нет

- Osmeoisis 2022-09-06 15-33-19PIC - Enh - A - 3Документ15 страницOsmeoisis 2022-09-06 15-33-19PIC - Enh - A - 3Tomás BurónОценок пока нет

- Assighnment:-2: Omputer Peripherals & InterfacesДокумент10 страницAssighnment:-2: Omputer Peripherals & InterfacesAnkur SinghОценок пока нет

- Counters & Time DelaysДокумент16 страницCounters & Time Delaysapi-3724082100% (16)

- Flancter App NoteДокумент11 страницFlancter App NotebigdogguruОценок пока нет

- ECE 206 Lab ManualДокумент17 страницECE 206 Lab ManualArian BidgoliОценок пока нет

- Microcontroller and Its Appl Ans (NEC 022-IiS)Документ5 страницMicrocontroller and Its Appl Ans (NEC 022-IiS)Sachin PalОценок пока нет

- Chapter 6 Challenges: Phototransistor Voltage Output CircuitДокумент3 страницыChapter 6 Challenges: Phototransistor Voltage Output Circuitapi-357589598Оценок пока нет

- Exp - 08 Flight86Документ6 страницExp - 08 Flight86Muhammad SaqibОценок пока нет

- The 8051 Microcontroller and Embedded Systems: Jump, Loop, and Call InstructionsДокумент26 страницThe 8051 Microcontroller and Embedded Systems: Jump, Loop, and Call InstructionsFajar PrasetyaОценок пока нет

- Lab 4 - Finite State Machines: GoalsДокумент7 страницLab 4 - Finite State Machines: GoalsJoey WangОценок пока нет

- Step Replace Module Flexi BSC NokiaДокумент19 страницStep Replace Module Flexi BSC Nokiarudibenget0% (1)

- Demonstration of Call, Loops, Jumps and Delay CalculationsДокумент6 страницDemonstration of Call, Loops, Jumps and Delay CalculationsUmar KhanОценок пока нет

- Grupo 23 - Tarea 4Документ23 страницыGrupo 23 - Tarea 4alexis pedrozaОценок пока нет

- Chapter 6 ChallengesДокумент3 страницыChapter 6 Challengesapi-358351745Оценок пока нет

- Cc1110 Cc2510 Basic Software Examples OverviewДокумент9 страницCc1110 Cc2510 Basic Software Examples Overviewalongdayx3Оценок пока нет

- Pic Microcontroller: Technological University of The PhilippinesДокумент15 страницPic Microcontroller: Technological University of The PhilippinesRonnel Joseph Cooper Renedo100% (1)

- Unit 6 ChallengesДокумент8 страницUnit 6 Challengesapi-358099446Оценок пока нет

- EDT IMP QuestionsДокумент1 страницаEDT IMP QuestionsMayur MestryОценок пока нет

- Ceragon Exercise Handbook v2.4Документ90 страницCeragon Exercise Handbook v2.4mehdi_mehdiОценок пока нет

- Osmeoisis 2022-09-06 15-33-19PIC - Mid - C - 11Документ34 страницыOsmeoisis 2022-09-06 15-33-19PIC - Mid - C - 11Tomás BurónОценок пока нет

- EE 230 - Analog Circuits Lab - 2021-22/I (Autumn) Experiment 1: Familiarization With NGSPICE Circuit Simulator and Lab EquipmentДокумент7 страницEE 230 - Analog Circuits Lab - 2021-22/I (Autumn) Experiment 1: Familiarization With NGSPICE Circuit Simulator and Lab EquipmentTanmay JainОценок пока нет

- Osmeoisis 2022-09-06 15-33-19PIC - Mid - A - 5Документ15 страницOsmeoisis 2022-09-06 15-33-19PIC - Mid - A - 5Tomás BurónОценок пока нет

- Counters & Time DelaysДокумент16 страницCounters & Time DelaysmotoshanОценок пока нет

- Looping Instructions: 1.1 Unconditional LoopsДокумент5 страницLooping Instructions: 1.1 Unconditional LoopsakhiyarwaladiОценок пока нет

- Lab 5Документ11 страницLab 5Waleed Bashir KotlaОценок пока нет

- Laboratory Manual: Microcontroller & Embedded System Lab (EEE-433-F) (Vii Semester)Документ26 страницLaboratory Manual: Microcontroller & Embedded System Lab (EEE-433-F) (Vii Semester)Aanandha SaravananОценок пока нет

- Part 1 - FSM DesignДокумент3 страницыPart 1 - FSM DesignMENANI ZineddineОценок пока нет

- Lsli 02Документ32 страницыLsli 02APARNA MISHRAОценок пока нет

- MBS Lab 11Документ4 страницыMBS Lab 11MuhammadHadiОценок пока нет

- FemtoRV32 Piplined Processor ReportДокумент25 страницFemtoRV32 Piplined Processor ReportRatnakarVarunОценок пока нет

- LPU Assignmen Tno2 Computer Peripheral: Submitted To - Submitted BY-Mr - Sandeeep Ankur Singh E3801A29Документ9 страницLPU Assignmen Tno2 Computer Peripheral: Submitted To - Submitted BY-Mr - Sandeeep Ankur Singh E3801A29Ankur SinghОценок пока нет

- Exp7 ReportДокумент8 страницExp7 ReportMEGHANA R 20BEC1042Оценок пока нет

- Assignment #03: Course Instructor / Lab EngineerДокумент8 страницAssignment #03: Course Instructor / Lab EngineerNitasha HumaОценок пока нет

- SCP 1000Документ10 страницSCP 1000buzzo182Оценок пока нет

- Assignment #03: Course Instructor / Lab EngineerДокумент8 страницAssignment #03: Course Instructor / Lab EngineerNitasha HumaОценок пока нет

- QE Hands-OnДокумент9 страницQE Hands-Onw inxОценок пока нет

- Introduction To PIC Programming: Baseline Architecture and Assembly LanguageДокумент15 страницIntroduction To PIC Programming: Baseline Architecture and Assembly Languagemorcov19Оценок пока нет

- File11 Real Delays To Be Applied On CircuitДокумент3 страницыFile11 Real Delays To Be Applied On Circuitkaram abou sahyounОценок пока нет

- Osmeoisis 2022-09-06 15-33-19PIC - Mid - C - 10Документ6 страницOsmeoisis 2022-09-06 15-33-19PIC - Mid - C - 10Tomás BurónОценок пока нет

- Computer Architecture - tutorial 2 TUTOR COPYДокумент5 страницComputer Architecture - tutorial 2 TUTOR COPYHalim KorogluОценок пока нет

- Lab 5 - SIGEx Lab Manual SamplingДокумент18 страницLab 5 - SIGEx Lab Manual SamplingSoughah AlkendiОценок пока нет

- NodeB and RNC MML commands for troubleshooting 3G network issuesДокумент23 страницыNodeB and RNC MML commands for troubleshooting 3G network issuesmr_hemel2386Оценок пока нет

- Delay Programusing8051Документ20 страницDelay Programusing8051NonameОценок пока нет

- Tutorial Notes 2014 - Part 1Документ18 страницTutorial Notes 2014 - Part 1Syed Shahriar Zaman ShibleeyОценок пока нет

- Jump, Loop and Call Instructions AssemblyДокумент29 страницJump, Loop and Call Instructions AssemblyavmapОценок пока нет

- Interview Questions 1Документ40 страницInterview Questions 1Shru GopalОценок пока нет

- Appendix CДокумент7 страницAppendix Cqaesz63% (8)

- Simulation Results FiguresДокумент21 страницаSimulation Results Figuresapi-26331790Оценок пока нет

- Operational Amplifier Using Discrete Components: June 2017Документ7 страницOperational Amplifier Using Discrete Components: June 2017Alvaro Javier Baños RiveraОценок пока нет

- Projects With Microcontrollers And PICCОт EverandProjects With Microcontrollers And PICCРейтинг: 5 из 5 звезд5/5 (1)

- LEARN MPLS FROM SCRATCH PART-B: A Beginners guide to next level of networkingОт EverandLEARN MPLS FROM SCRATCH PART-B: A Beginners guide to next level of networkingОценок пока нет

- Blockchain ConceptДокумент3 страницыBlockchain Conceptabpatki@yahoo.comОценок пока нет

- Pancha Pak Shish AstraДокумент4 страницыPancha Pak Shish Astraರಾಜೇಂದ್ರ ಕುಮಾರ್ ಜೆОценок пока нет

- Pancha Pakshi ShastraДокумент20 страницPancha Pakshi ShastraKarthikeyan Jambulingam100% (1)

- Maths For Class VДокумент12 страницMaths For Class Vabpatki@yahoo.comОценок пока нет

- Sangeet Archana - Sangeet Karyalaya HathrasДокумент343 страницыSangeet Archana - Sangeet Karyalaya Hathrasabpatki@yahoo.comОценок пока нет

- Fake News Simulation 1Документ1 страницаFake News Simulation 1abpatki@yahoo.comОценок пока нет

- Abstract NetLogoДокумент1 страницаAbstract NetLogoabpatki@yahoo.comОценок пока нет

- Di F F Er Ent I at e Your Sel F F R Om The Rest: Suppor T Ed byДокумент12 страницDi F F Er Ent I at e Your Sel F F R Om The Rest: Suppor T Ed byabpatki@yahoo.comОценок пока нет

- MTech Thesis Topics - Approximate Computing, Chaotic Cryptography & MoreДокумент1 страницаMTech Thesis Topics - Approximate Computing, Chaotic Cryptography & Moreabpatki@yahoo.comОценок пока нет

- Maharashtra Public Holidays 2017 List: 26 HolidaysДокумент1 страницаMaharashtra Public Holidays 2017 List: 26 Holidaysabpatki@yahoo.comОценок пока нет

- CBS SimulationДокумент2 страницыCBS Simulationabpatki@yahoo.comОценок пока нет

- Maharashtra Public Holidays 2017 List: 26 HolidaysДокумент1 страницаMaharashtra Public Holidays 2017 List: 26 Holidaysabpatki@yahoo.comОценок пока нет

- MTech Thesis Topics - Approximate Computing, Chaotic Cryptography & MoreДокумент1 страницаMTech Thesis Topics - Approximate Computing, Chaotic Cryptography & Moreabpatki@yahoo.comОценок пока нет

- Maths For Fifth STDДокумент16 страницMaths For Fifth STDabpatki@yahoo.comОценок пока нет

- CBS PythonДокумент2 страницыCBS Pythonabpatki@yahoo.com100% (1)

- FPGA Implementation of A Reduct Generation Algorithm Based On Rough Set TheoryДокумент7 страницFPGA Implementation of A Reduct Generation Algorithm Based On Rough Set Theoryabpatki@yahoo.comОценок пока нет

- DSP Architecture First yr. M.Tech (SP) Assignment No 3Документ3 страницыDSP Architecture First yr. M.Tech (SP) Assignment No 3abpatki@yahoo.comОценок пока нет

- DSP Architecture First yr. M.Tech (SP) Assignment No 3Документ3 страницыDSP Architecture First yr. M.Tech (SP) Assignment No 3abpatki@yahoo.comОценок пока нет

- Chaos GPUДокумент5 страницChaos GPUabpatki@yahoo.comОценок пока нет

- AI SyllabusДокумент1 страницаAI Syllabusabpatki@yahoo.comОценок пока нет

- Presentation To Craig Mundie CTO MicrosoftДокумент14 страницPresentation To Craig Mundie CTO Microsoftabpatki@yahoo.com100% (2)

- AI SyllabusДокумент1 страницаAI Syllabusabpatki@yahoo.comОценок пока нет

- 28-136fuel Saving of An Automobile Using Fuzzy LogicДокумент5 страниц28-136fuel Saving of An Automobile Using Fuzzy Logicabpatki@yahoo.comОценок пока нет

- AI SyllabusДокумент1 страницаAI Syllabusabpatki@yahoo.comОценок пока нет

- OEC-II Artificial Intelligence: ReferencesДокумент1 страницаOEC-II Artificial Intelligence: Referencesabpatki@yahoo.comОценок пока нет

- Computational Modeling of Emotion: Toward Improving The Inter-And Intradisciplinary ExchangeДокумент21 страницаComputational Modeling of Emotion: Toward Improving The Inter-And Intradisciplinary Exchangeabpatki@yahoo.comОценок пока нет

- Jamia Milia Islamia Invited Talk - A.B. PatkiДокумент29 страницJamia Milia Islamia Invited Talk - A.B. Patkiabpatki@yahoo.comОценок пока нет

- Tms320F2812 Assembly Language Tutorial 2: Controlling The XF LEDДокумент11 страницTms320F2812 Assembly Language Tutorial 2: Controlling The XF LEDabpatki@yahoo.comОценок пока нет

- DSP Architecture First yr. M.Tech (SP) Assignment No 3Документ3 страницыDSP Architecture First yr. M.Tech (SP) Assignment No 3abpatki@yahoo.comОценок пока нет

- How to ping NodeB and RNC using RTN transmission IPДокумент14 страницHow to ping NodeB and RNC using RTN transmission IPPaulo DembiОценок пока нет

- Understanding Calculation ScriptsДокумент17 страницUnderstanding Calculation ScriptsKrishna TilakОценок пока нет

- True/False: List of Attempted Questions and AnswersДокумент15 страницTrue/False: List of Attempted Questions and AnswersDeepak Kumar VermaОценок пока нет

- Linear Loaded Vert 80-40Документ14 страницLinear Loaded Vert 80-40Claudio ChiconОценок пока нет

- Chap4 Student VersionДокумент39 страницChap4 Student VersionAzrif MoskamОценок пока нет

- Steel PTFE Pipes and Fittings DIN 2018Документ27 страницSteel PTFE Pipes and Fittings DIN 2018PeroJurevicОценок пока нет

- Datasheet TachogeneratorДокумент4 страницыDatasheet TachogeneratorNurulHidayatОценок пока нет

- West Bengal's Leather Industry OpportunitiesДокумент5 страницWest Bengal's Leather Industry OpportunitiesDeepak AgarwalОценок пока нет

- SWOT) Analysis, Marketing Process, Marketing PlanДокумент24 страницыSWOT) Analysis, Marketing Process, Marketing PlanSagar Patil100% (2)

- Example of BVP ProblemsДокумент3 страницыExample of BVP ProblemsAbhishek KumarОценок пока нет

- Bugcrowd Vulnerability Rating Taxonomy 1.7Документ13 страницBugcrowd Vulnerability Rating Taxonomy 1.7junior108Оценок пока нет

- Performance Appraisal Form From IndustryДокумент2 страницыPerformance Appraisal Form From IndustryJaspal SinghОценок пока нет

- Atmos GIGA N 32-160Документ1 страницаAtmos GIGA N 32-160Efril dilen franciscoОценок пока нет

- NT Photocurre Ed Unmultipli Primary NT Photocurre MultipliedДокумент50 страницNT Photocurre Ed Unmultipli Primary NT Photocurre Multipliedmayuri sritharanОценок пока нет

- 1st Term Exam Part 2 - QSДокумент10 страниц1st Term Exam Part 2 - QSMark Anthony TajonОценок пока нет

- Tahap Amalan Penggunaan Lestari Dalam Kalangan Guru Di Puchong, SelangorДокумент8 страницTahap Amalan Penggunaan Lestari Dalam Kalangan Guru Di Puchong, SelangorMasliana SahadОценок пока нет

- F Pv28T: PR EN 2714-013A/B/C/DДокумент2 страницыF Pv28T: PR EN 2714-013A/B/C/DFredОценок пока нет

- 3AH4 Breaker Cn (油品 P26)Документ29 страниц3AH4 Breaker Cn (油品 P26)kokonut1128Оценок пока нет

- 17012EДокумент7 страниц17012EAVINASHRAJОценок пока нет

- ACAS II Operations in The European RVSM EnvironmentДокумент45 страницACAS II Operations in The European RVSM Environmentali4957270Оценок пока нет

- Fast, Fast VP : FAST: Features, Drawbacks, Applications and Some QuestionsДокумент13 страницFast, Fast VP : FAST: Features, Drawbacks, Applications and Some QuestionsSraVanKuMarThadakamallaОценок пока нет

- Catalog Filters PDFДокумент53 страницыCatalog Filters PDFAlexandre Hugen100% (1)

- Techsheet ZerowasteДокумент2 страницыTechsheet ZerowastesunillimayeОценок пока нет

- EY Tax Administration Is Going DigitalДокумент12 страницEY Tax Administration Is Going DigitalVahidin QerimiОценок пока нет

- Step by Step Process To Run BEX Report in BackgroundДокумент23 страницыStep by Step Process To Run BEX Report in Backgroundalcast007Оценок пока нет

- Chain-On-Edge Spindle Conveyor Coating Systems: Processes & EquipmentДокумент1 страницаChain-On-Edge Spindle Conveyor Coating Systems: Processes & EquipmentRavindra MahadeokarОценок пока нет

- Utility Classes - Installation Guide: Dalestech LTDДокумент6 страницUtility Classes - Installation Guide: Dalestech LTDbvitalОценок пока нет

- ROSON Dental Accessories Price List-2019Документ83 страницыROSON Dental Accessories Price List-2019Anonymous XCJkPuVОценок пока нет

- 6.2.1.11 Dyan Indrayanto - Anatomy of MalwareДокумент3 страницы6.2.1.11 Dyan Indrayanto - Anatomy of MalwareDyan IndrayantoОценок пока нет

- CSD Counter Drone Systems ReportДокумент23 страницыCSD Counter Drone Systems ReportmrkuroiОценок пока нет