Академический Документы

Профессиональный Документы

Культура Документы

Granzow As Article

Загружено:

FA Ay0 оценок0% нашли этот документ полезным (0 голосов)

19 просмотров2 страницыInstrument Air Compressors and Dryer Package

Оригинальное название

Granzow as Article

Авторское право

© © All Rights Reserved

Доступные форматы

PDF, TXT или читайте онлайн в Scribd

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документInstrument Air Compressors and Dryer Package

Авторское право:

© All Rights Reserved

Доступные форматы

Скачайте в формате PDF, TXT или читайте онлайн в Scribd

0 оценок0% нашли этот документ полезным (0 голосов)

19 просмотров2 страницыGranzow As Article

Загружено:

FA AyInstrument Air Compressors and Dryer Package

Авторское право:

© All Rights Reserved

Доступные форматы

Скачайте в формате PDF, TXT или читайте онлайн в Scribd

Вы находитесь на странице: 1из 2

Granzow is a leading supplier for the industry of screw compressors,

compressed air treatment, energy friendly compressor controls.

Tey also produce a complete range of automation products, such as

bursting discs, bursting panels, fttings, thermostats, valves, pneumatic

cylinders. An extensive program of efcient pumps as high pressure pumps,

diaphragm pumps, hose pumps, mobile pumps. Complete line of vacuum

pumps, measurement equipment, leak detection systems and sputter

systems.

Product Spotlight: Instrument Air

Compressors and Dryer Package

For the Ofshore industry, the Instrument Air Compressor & Dryer Package is an essential technology in terms of

the reliability for the continuous operation of machinery working on the platforms.

Tese packages have been built in the past to fulfll f.ex. EEx e IIT1 or T3 standards. Today the certifcation

will be in accordance with both the ATEX regulations, Zone II or Zone I. Many packages have been evaluated to a

be delivered as a complete build in package, with an air fresh water cooled compressor and a heatless adsorption

dryer, controlled by a dew point control and the necessary inlet and outlet flters. Tis results in a compressed air

quality in accordance with ISO8573-1 :

Particles CLASS 1 less than 0,1 micron

Water content CLASS 2 dew point 40 degr.C ( 0,12 g H2O/m3)

Rest content of oil CLASS 1 0,01 mg/m3

Surface treatment

Te compressed air will then be able to

be used as air suitable for breathing, if each

person has a small flter unit before his actual

use of the air before his reduction valve. Te

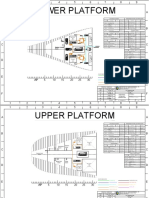

illustrated container plant, has a 132 kW, 10 bar

air compressor mounted inside the container,

followed by a heatless low temperature

adsorption dryer, which guarantee the user

the quality described previously. Te electrical

control panel is mounted in the container, this

means that electrical ofshore cables do not

have to used inside the compressor or dryer.

Te compressor power cable can be standard

cables, as the nature of the ofshore cables in

terms of dimension and fexibility, do not

match the mounting inside the units.

Te container version as shown, has features

which complicate the stainless steel container.

Te container does have to be designed and

calculated for ofshore lifing. Tis can be a

challenge for the factory which fabricates the

container. Certifcation on all material used,

WEP and WPS, NDT procedures, structural

design calculations, structural detail drawings

and lifing equipment calculations follow

the correct weighing procedure. Single line

electrical diagrams for control panels, air

compressor and dryer and instrument data

sheets can all to be accepted by, or under a FAT

in our test bed. Additionally, the package had

to be used in a hazardous area, thus making

the door construction a challenge as well. Te

lubricated air compressor will work with a

capacity (in accordance with ISO1217) of 1260

m3/h at designed outlet pressure of 10

Today the

certifcation

will be in

accordance with

both the ATEX

regulations, Zone

II or Zone I.

bar.g. Te total capacity through the outlet

compressed air pipe will then be 1075 m3/h

at 85 % load and 9.5 bar working pressure,

calculated with a pressure drop over dryer and

flters, to approximately 0.5 bar.

Te heatless dryer uses compressed air for

regeneration, the outlet compressor capacity

has to be deducted the regeneration capacity

a diference between 1260 and 1075 m3/h.

Tis design, for heatless dryers, gives the user a

simple reliable low temperature dryer function.

Te alternative adsorption dryer, with heat

regeneration work with temperatures up to

180 degr.C - from the heating elements in the

dryer vessels, for this capacity total 15 kW.

For reasons regarding temperature the heatless

dryer is the preferred choice in this situation.

Te dryers will always be mounted with a dew

point control, with the purpose of securing

the user the right dew point. Te signal 4/20

mAmp to SCADA further this control will

reduce the power, kW or compressed air, in

proportion with the fow through the actual

dryer. In total this container version only has

one inlet electrical gland connection, one

compressed air outlet and two cooling water

connection. Terefore the package when

accepted under the FAT, which will be ready

to be started up when placed on the platform.

Tis article was written by: T.S.Mortensen,

Mechanical Engineer B.Sc, Granzow, Denmark

www.granzow.dk Package leaving our factory afer FAT

Container with a heatless dryer

Вам также может понравиться

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryОт EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryРейтинг: 3.5 из 5 звезд3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)От EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Рейтинг: 4.5 из 5 звезд4.5/5 (121)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaОт EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaРейтинг: 4.5 из 5 звезд4.5/5 (266)

- The Little Book of Hygge: Danish Secrets to Happy LivingОт EverandThe Little Book of Hygge: Danish Secrets to Happy LivingРейтинг: 3.5 из 5 звезд3.5/5 (399)

- Never Split the Difference: Negotiating As If Your Life Depended On ItОт EverandNever Split the Difference: Negotiating As If Your Life Depended On ItРейтинг: 4.5 из 5 звезд4.5/5 (838)

- The Emperor of All Maladies: A Biography of CancerОт EverandThe Emperor of All Maladies: A Biography of CancerРейтинг: 4.5 из 5 звезд4.5/5 (271)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeОт EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeРейтинг: 4 из 5 звезд4/5 (5794)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyОт EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyРейтинг: 3.5 из 5 звезд3.5/5 (2259)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersОт EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersРейтинг: 4.5 из 5 звезд4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnОт EverandTeam of Rivals: The Political Genius of Abraham LincolnРейтинг: 4.5 из 5 звезд4.5/5 (234)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreОт EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreРейтинг: 4 из 5 звезд4/5 (1090)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceОт EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceРейтинг: 4 из 5 звезд4/5 (895)

- CHE10709 Air CompressorsДокумент29 страницCHE10709 Air CompressorsFA Ay100% (1)

- Internal Combustion EnginesДокумент14 страницInternal Combustion EnginesAnonymous 1zFjCuBxОценок пока нет

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureОт EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureРейтинг: 4.5 из 5 звезд4.5/5 (474)

- The Unwinding: An Inner History of the New AmericaОт EverandThe Unwinding: An Inner History of the New AmericaРейтинг: 4 из 5 звезд4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)От EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Рейтинг: 4 из 5 звезд4/5 (98)

- Astral Attack and DefenseДокумент21 страницаAstral Attack and DefenseFA AyОценок пока нет

- GE Cycles Lecture Info 2009Документ18 страницGE Cycles Lecture Info 2009Sayantan Datta Gupta100% (1)

- Solar MPPT PresentationДокумент21 страницаSolar MPPT PresentationPravat SatpathyОценок пока нет

- Renewable EnergyДокумент13 страницRenewable EnergyMATHANKUMAR.SОценок пока нет

- Heat Exchanger PerformanceДокумент31 страницаHeat Exchanger PerformanceFA AyОценок пока нет

- DSLP CalculationДокумент7 страницDSLP Calculationravi shankar100% (1)

- CHE10710 NitrogenДокумент32 страницыCHE10710 NitrogenFA Ay100% (1)

- A Study of Manufacturing of Steam TurbinesДокумент40 страницA Study of Manufacturing of Steam TurbinesSaketh Varma MudunuriОценок пока нет

- Engineering Encyclopedia: Saudi Aramco Desktop StandardsДокумент12 страницEngineering Encyclopedia: Saudi Aramco Desktop StandardsFA Ay100% (1)

- CHE10209 Couplings Seals BearingsДокумент36 страницCHE10209 Couplings Seals BearingsFA AyОценок пока нет

- Engineering Design Guideline - HX Rev 3Документ24 страницыEngineering Design Guideline - HX Rev 3axle_ramОценок пока нет

- Liquid Process Piping: Part 5: ValvesДокумент23 страницыLiquid Process Piping: Part 5: ValvesFA AyОценок пока нет

- Generator Protection FundamentalsДокумент102 страницыGenerator Protection Fundamentalsghass100% (1)

- Standard Overhauling Procedure of Single Stage Horizontal Centrifugal PumpДокумент3 страницыStandard Overhauling Procedure of Single Stage Horizontal Centrifugal PumpNilesh GohelОценок пока нет

- Boiler Feedwater DeaerationДокумент5 страницBoiler Feedwater DeaerationFA AyОценок пока нет

- Solar PV Installer (Suryamitra) : Educate Your Mind in The Right DirectionДокумент2 страницыSolar PV Installer (Suryamitra) : Educate Your Mind in The Right DirectiondaynongОценок пока нет

- M Alkalinity and P AlkalinityДокумент3 страницыM Alkalinity and P AlkalinityFA AyОценок пока нет

- Instrument QuestionsДокумент71 страницаInstrument QuestionsFA AyОценок пока нет

- FluxДокумент10 страницFluxRJG0409Оценок пока нет

- NOx Booklet MarkedДокумент19 страницNOx Booklet MarkedFA AyОценок пока нет

- Weyer Group Engineering ConsultingДокумент2 страницыWeyer Group Engineering ConsultingFA AyОценок пока нет

- Burner SystemДокумент1 страницаBurner SystemFA AyОценок пока нет

- TDLS200 CombustionДокумент4 страницыTDLS200 CombustionFA AyОценок пока нет

- Classification of PolymersДокумент14 страницClassification of PolymersFA Ay67% (6)

- SIM4ME ThermodynamicsДокумент137 страницSIM4ME ThermodynamicsFA AyОценок пока нет

- Mech Seals Selection Guide 2Документ6 страницMech Seals Selection Guide 2taghdirimОценок пока нет

- Polymerization Techniques Advantages and DisadvantagesДокумент1 страницаPolymerization Techniques Advantages and DisadvantagesFA Ay100% (6)

- Centrifugal Pump AnalysisДокумент69 страницCentrifugal Pump AnalysisFA AyОценок пока нет

- FormulaДокумент6 страницFormulaanon-963224100% (5)

- Intro To Steam Boilers and Turbines For Power PlantsДокумент57 страницIntro To Steam Boilers and Turbines For Power PlantsFA AyОценок пока нет

- Heat Exchangers Design DOEДокумент25 страницHeat Exchangers Design DOEPedro DiazОценок пока нет

- Flow Measurement in Pipes and DuctsДокумент24 страницыFlow Measurement in Pipes and DuctshozipekОценок пока нет

- KLM Process Furnace Rev 3Документ5 страницKLM Process Furnace Rev 3FA AyОценок пока нет

- KLM Intro Process Control Rev 3Документ6 страницKLM Intro Process Control Rev 3FA AyОценок пока нет

- ENGINEERING DESIGN GUIDELINE - Flare Rev1.1Документ19 страницENGINEERING DESIGN GUIDELINE - Flare Rev1.1ashutosh_mishra_9Оценок пока нет

- KLM Intro Process Control Rev 3Документ6 страницKLM Intro Process Control Rev 3FA AyОценок пока нет

- Vapor Power Cycles Lecture 1Документ23 страницыVapor Power Cycles Lecture 1Albert Shesman100% (1)

- Pipe 100 Up (Dated - Docx Version 1Документ13 страницPipe 100 Up (Dated - Docx Version 1AjayBravoОценок пока нет

- Materials For Low-Carbon Power - A White PaperДокумент49 страницMaterials For Low-Carbon Power - A White PaperWalter Guzman MezaОценок пока нет

- Germany-P2G Case-Story LAY2Документ4 страницыGermany-P2G Case-Story LAY2Eduardo TamargoОценок пока нет

- Goodman ss-gsz16Документ36 страницGoodman ss-gsz16nam nguyenОценок пока нет

- Commercial Unit Coolers Cubic Series Type: S3HC 59 E 65 N. Units: 1Документ2 страницыCommercial Unit Coolers Cubic Series Type: S3HC 59 E 65 N. Units: 1hamzehОценок пока нет

- Boiler Control Process OverviewДокумент27 страницBoiler Control Process OverviewSandeep Kumar Krishnaraj100% (1)

- Question Bank - AEDДокумент3 страницыQuestion Bank - AEDbhuvan raju t kОценок пока нет

- GIS in PREPA-PonceДокумент44 страницыGIS in PREPA-PonceRafael Pagán CáceresОценок пока нет

- 2153 SSTДокумент2 страницы2153 SSTkhurram_razОценок пока нет

- P&I Diagram Steam Boiler Plant With Standard EquipmentДокумент1 страницаP&I Diagram Steam Boiler Plant With Standard Equipmentrachman hardianОценок пока нет

- Adetunji Timilehin Eee191334Документ4 страницыAdetunji Timilehin Eee191334somoyetobi8Оценок пока нет

- SB2-P-T-PS-0009-R0 - Bolt, Nut and Gasket ListДокумент92 страницыSB2-P-T-PS-0009-R0 - Bolt, Nut and Gasket ListATN NОценок пока нет

- AEO2023 Release PresentationДокумент25 страницAEO2023 Release Presentationdhananjaya.geoОценок пока нет

- 4.1 Properties of LPG As Engine Fuel: Prepared By:-Prajwal WaghmareДокумент3 страницы4.1 Properties of LPG As Engine Fuel: Prepared By:-Prajwal WaghmareAniket DhoneОценок пока нет

- BurnerДокумент3 страницыBurnerRavi sharmaОценок пока нет

- Tabel Pompe NocchiДокумент19 страницTabel Pompe NocchiAdrian DragusinОценок пока нет

- C17D5Документ3 страницыC17D5nuqОценок пока нет

- Annotated Bibliography-Solar EnergyДокумент6 страницAnnotated Bibliography-Solar Energyapi-355597172Оценок пока нет

- Dwg. No.10 - 42 20 DN002 - ERДокумент4 страницыDwg. No.10 - 42 20 DN002 - ERSean Chen GyarinoОценок пока нет