Академический Документы

Профессиональный Документы

Культура Документы

Lime

Загружено:

jackiee_262000Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Lime

Загружено:

jackiee_262000Авторское право:

Доступные форматы

Balu

Lime

Introduction

Traditional mortars and renders have incorporated lime. There is now some clarity on the role

it plays, and why owners of Victorian and Edwardian houses should insist on its use in

restoring walls and avoid the indiscriminate use of cement.

What is Lime?

Lime is produced from limestone through these steps:

Limestone (calcium carbonate) is heated in a iln or iln pit until burnt, giving off

carbon dio!ide and leaving calcium o!ide ("uiclime).

#uiclime is mi!ed with water$ this produces heat. %f only a little water is added, the

result is a dry powder called hydrated lime or lime hydrate. %f a lot of water is added,

this &slaing& process forms calcium hydro!ide, usually called &slaed lime& or &lime

putty&. This is then left to mature for several wees. This process is called &hydration&.

'on(hydraulic lime (slaed lime) hardens by a slow process of drying and carbonation,

reacting with atmospheric carbon dio!ide to form calcium carbonate. This taes a period of

some wees.

)ydraulic lime, on the other hand, sets rapidly by reacting with water in a matter of hours.

* non(hydraulic lime can be made to set much more rapidly by the addition of an hydraulic

or &po++olanic& additive. This practice is nown as &gauging&. Typical additives are finely

crushed bric powder or cement. These contain highly reactive silica and,or alumina, which

give a rapid chemical set by reaction with water. -f these, cement is by far the most widely

used in the ./, and the cheapest. Typical proportions, commonly used, are 0:0:1 (cement:

lime: sand) and 0:2:3. .se sharp sand with lime.

Cement

4ortland cement was developed in 0526$ it was used in the role of a hydraulic binder, which

was very consistent and made the mi! set rapidly. This rapid set was an advantage in cold or

very wet conditions. 7uilders slowly abandoned lime mortar in favour of cement and sand

mortars.

7y the 0589&s, the 0:0:1 mi!ture of cement, lime and sand ratio had been firmly established.

.se soft sand with cement.

)owever, cement and sand mortars proved too strong for some applications and laced some

of the worability of lime mortar. 7y the late 0599&s cement(lime mi!es were again widely

used where increased plasticity, worability and controlled strength was re"uired.

4ortland cement remained costly into the 29th century so a minimum was used. :or e!ample,

the main bric mortar was lime and sand, but pointing included a little cement. *gain, render

generally used some cement.

4age 1 of 6

Balu

Why Use Lime?

E!perts in the restoration of old buildings argue that mortar should be softer than the brics

they bind. 7ecause most Victorian and Edwardian brics are soft inside a thin, harder outer

shell, they are vulnerable to damage to the surface layer, such as that caused by hard cement

pointing resisting movement due to settlement or temperature changes.

%n the case of renders and plasters, lime has benefits because of its fle!ibility and its porosity$

it helps moisture that has penetrated a wall to evaporate.

Lime is also less prone to crac than cement. Lime is even self(healing$ fine cracs allow

carbon dio!ide to penetrate. This reacts with free lime to harden and close the crac.

There is an ongoing debate on the use of cement with lime, or lime in a secondary role to

cement.

Using Lime with Cement

;hen added to a normal cement and sand mi!, lime maes the mortar more cohesive and

adhesive, and it maes the mortar &fatty& and worable so that it spreads well.

;hen it has hardened, lime allows mortar to achieve optimum strength because it increases

the fle!ibility of the mortar. Lime will give improved bond strength with the bric.

Lime also reduces water penetration by &autogenous healing&. This is because there will be

some free lime in the set mortar. This will re(carbonate over time, sealing any hairline cracs.

This is particularly important with renders.

Using Cement with Lime

<ement can be used as a &po++olanic& additive$ you can gauge a non(hydraulic mortar with

cement to mae it hydraulic.

The advantages are:

%t imparts a chemical set which occurs before full shrinage occurs, thereby reducing

the ris of cracing.

Layers may be built up more rapidly, without the need to wait a long time for one to

set fully before applying the ne!t.

%t hardens rapidly, thereby providing protection from rain before carbonation has been

completed.

7eing an artificial substance manufactured under closely controlled conditions, it is

reliable and predictable in use.

%t is available in a choice of colours, useful when it is necessary to match the colour of

an e!isting mortar or render.

The disadvantages are:

4age 2 of 6

Balu

The rapid setting time limits the time available to the user in which to wor with the

gauged mortar.

=ome cements contain appreciable amounts of soluble salts, in particular potassium

sulphate, which may cause salt damage to stonewor.

The use of cement tends to lead to the user treating the gauged lime mortar as if it

were a fully hydraulic lime or cement. Too much reliance on the initial chemical set

leads to neglect of the importance of the longer term carbonation of the non hydraulic

component present.

&=egregation& may occur, whereby the cement separates from the lime as the mortar

dries and hardens, blocing the pores in the mortar, reducing the porosity and

weaening the mortar.

The =meaton 4ro>ect, a research programme commenced by English )eritage, concluded that

a 0:0:1 (cement:lime:sand) mi! is unliely to segregate, while a 0:2:3 mi! will almost

certainly fail. *s the cement proportion is reduced further, the mortar will certainly fail.

Lime in Brickwork

The conclusion is that the best option for mortar and pointing is an un(gauged non hydraulic

lime mortar using well(matured lime putty and sharp and well(graded aggregate. This does

not re"uire special sills. .se non(hydraulic lime and sand in a 0:? ratio.

Lime in Render

The choices here are either a hydraulic lime, or non(hydraulic lime with some cement.

%f you are patching render, you must use the same mi! to avoid cracing.

There is more detailed guidance here.

Lime Plaster

Lime 4laster is the ideal finish for walls built using lime mortar$ because it is fle!ible it will

tolerate movement in the wall. *gain, lime plaster is best painted with lime wash, rather than

wallpaper or modern paints. Lime wash or distemper can be applied over lime plaster after a

few days but any impermeable coating must not be used for several months as lime plaster

needs air before it can harden.

Lime Wash

*s with other lime products, lime wash is porous and therefore e!cellent for surfaces where

the evaporation of moisture is important.

Limewash is a paint made from lime putty which has been matured for several months and

then thinned with water to mae limewash. Limewash is naturally white, matt, and slightly

chaly but can be coloured with pigments.

4age of 6

Balu

Lime wash can be used internally or e!ternally. 7ecause it wors by absorbtion into the

surface so it is best used on porous surfaces such as sandstone, lime plaster, lime render and

soft brics.

;hen lime wash is used e!ternally, raw linseed oil or tallow mi!ed into the lime wash help

shed rainwater.

-n materials including cement or modern plaster, casein should be added to the lime wash to

help it bond.

.

Colouring !ortar

To colour lime mortar, made from a mi! of lime and sand, we can use traditional methods.

These mi!es were used for &stopping&, the outer layer of the mortar between the >oints.

These recipes are:

@ed .sed for red stocs. Aae a dry mi! of one part grey lime to three parts of fine

washed sand, ideally red in colour. Venetian red and a little vegetable blac can be

used to tint the mi!ture. *fter the stopping is applied, it can be washed with more red

colouring.

Bellow Bellow stopping is made with one part grey lime putty and to three parts fine washed

sand. These ingredients are mi!ed together dry and then sifted before being added to

water with yellow ochre as a colouring. Bellow stopping does not need subse"uent

colouring with a wash.

7lac Less common, blac stopping can be made from grey lime, slaed and mi!ed with

foundry sand, and sieved. This is added to water and coloured with a little lamp or

vegetable blac if needed.

;hite %n this case, use chal lime, and either silver sand or marble dust. <hal lime dries

much whiter than grey lime. Aarble dust gives a better colour than silver sand.

Render

@ender is an all(over coating on an e!ternal wall. )ere we discuss the options for patching or

the complete rendering of a wall.

%f a wall is being completely rendered, the best option is an un(gauged non(hydraulic lime

mortar using well(matured lime putty and sharp and well(graded aggregate. This does not

re"uire special sills. .se non(hydraulic lime and sand in a 0:? ratio.

-therwise, in ine!perienced hands, 0:0:1 is a good standard mi! for render, ie including some

cement. %ncreasing the cement content will mae the mortar too hard and remove the benefits

of using lime, but any less than 0:2:3 must be avoided.

4age " of 6

Balu

%f applying more than one coat, always apply the stronger coat on the wall ( otherwise you

prevent air accessing it and carbonating the lime.

%f a chemical set is re"uired, perhaps because of low temperatures or high moisture levels, it

is best to use an hydraulic lime.

Patching Lime Render

To patch e!ist lime render, you must use a similar lime render to do the repair. %f the mi! is

very different, cracs will occur at the >oin between the old and the new material.

:ind out if the render was done with hydraulic lime which sets with water, is non(hydraulic ie

sets in air. %f it is hydraulic lime, this is easier, as it is mi!ed with sand and water and applied

lie a cement render.

%f the render is non(hydraulic then you need to mae the correct choice. Lime mortar, render

and plaster is the same. %t comes in two grades$ coarse &stuff& is a 0:8 mi! of lime and well(

graded sharp sand. :ine stuff is a 0:2 mi! of lime and a fine sand. %f the e!isting render has a

fairly rough te!ture then you can >ust use coarse stuff on its own. %f the te!ture is very

smooth, then you will probably need to fill the larger holes with coarse stuff leaving a

depression of 2(8mm for a top coat of fine stuff.

*s with all patching, ensure that the area to patch is clean of dust and that the edges are neat.

Aae the area to be rendered very wet, especially in warm weather. *pply the lime as you

would any normal plaster. .se a wooden float for fine stuff, as metal trowels and floats tend

to bring the lime fat to the surface and mae it difficult to wor.

Bou must stop non(hydraulic lime mi!es from drying out too "uicly$ if it dries too "uicly

then it will crac. 4rotect the wor from direct sunlight. %deally cover it with some damp

hessian and spray it with water regularly. *im to prolong the drying time for one to two

wees to avoid cracs.

%f cracs do start to appear then you can deal with them while the lime render is still wet by

scouring over the surface with a wooden float to consolidate it and close up the cracs. Bou

can also rub in some additional mortar.

Plaster

:or guidance on plaster, please see the %nternal ;alls

Internal Walls

This section e!plains how to repair and care for different types of internal wall in the period

house of the Ceorgian, Victorian and Edwardian eras in particular.

)ouses since 0599 have normally had walls of three types:

solid bric (or stone)

4age # of 6

Balu

studwor with lathes or plasterboard

studwor with bric in(fill

The e!ternal and loadbearing walls are in solid bric or stone, and internal and non(

loadbearing walls are made from wooden studwor. =ometimes studwor walls with a bric

in(fill are semi(loadbearing in that such a wall on the ground floor can carry the weight of a

similar wall upstairs.

=tudwor is a wooden frame$ &plates& go on the floor and ceiling, &studs& are the vertical

supports between the two plates, and &noggins& are hori+ontal pieces of timber nailed between

the studs.

Laths or &lathes& are strips of wood nailed to studs and noggins. Caps are left between the

laths$ when plastering, the plaster oo+es between and behind the laths locing the plaster to

the wall.

7ric in(fill is simply courses of bric laid with mortar, on and between the plates, studs and

noggins.

Aost internal walls are then plastered.

4age 6 of 6

Вам также может понравиться

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)От EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Рейтинг: 4.5 из 5 звезд4.5/5 (119)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaОт EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaРейтинг: 4.5 из 5 звезд4.5/5 (265)

- The Little Book of Hygge: Danish Secrets to Happy LivingОт EverandThe Little Book of Hygge: Danish Secrets to Happy LivingРейтинг: 3.5 из 5 звезд3.5/5 (399)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryОт EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryРейтинг: 3.5 из 5 звезд3.5/5 (231)

- Never Split the Difference: Negotiating As If Your Life Depended On ItОт EverandNever Split the Difference: Negotiating As If Your Life Depended On ItРейтинг: 4.5 из 5 звезд4.5/5 (838)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeОт EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeРейтинг: 4 из 5 звезд4/5 (5794)

- Team of Rivals: The Political Genius of Abraham LincolnОт EverandTeam of Rivals: The Political Genius of Abraham LincolnРейтинг: 4.5 из 5 звезд4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyОт EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyРейтинг: 3.5 из 5 звезд3.5/5 (2219)

- The Emperor of All Maladies: A Biography of CancerОт EverandThe Emperor of All Maladies: A Biography of CancerРейтинг: 4.5 из 5 звезд4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreОт EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreРейтинг: 4 из 5 звезд4/5 (1090)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersОт EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersРейтинг: 4.5 из 5 звезд4.5/5 (344)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceОт EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceРейтинг: 4 из 5 звезд4/5 (894)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureОт EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureРейтинг: 4.5 из 5 звезд4.5/5 (474)

- The Unwinding: An Inner History of the New AmericaОт EverandThe Unwinding: An Inner History of the New AmericaРейтинг: 4 из 5 звезд4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)От EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Рейтинг: 4 из 5 звезд4/5 (98)

- Insect PestsДокумент164 страницыInsect PestsKenneth100% (11)

- Validation and Verification of Cleanning ProcessДокумент42 страницыValidation and Verification of Cleanning ProcessEva Pa'e OОценок пока нет

- Special Process Audit Check Sheet - PlatingДокумент8 страницSpecial Process Audit Check Sheet - PlatingHariprasanth ChandranОценок пока нет

- Test For Cations, Anions and Gases (QA) NotesДокумент10 страницTest For Cations, Anions and Gases (QA) Noteschong56100% (2)

- FlexEJ Brochure Elaflex 10 2011Документ41 страницаFlexEJ Brochure Elaflex 10 2011harlyganОценок пока нет

- ZeTo RulesДокумент30 страницZeTo RulesRamli Disa100% (5)

- Identify Hazards and Risks in the WorkplaceДокумент7 страницIdentify Hazards and Risks in the WorkplaceLeah Rizza CabaliwОценок пока нет

- Skanda Shasti KavachamДокумент6 страницSkanda Shasti KavachamsriramanaОценок пока нет

- PAACДокумент6 страницPAACjackiee_262000Оценок пока нет

- Brick Stack Grapples Handle MaterialsДокумент3 страницыBrick Stack Grapples Handle Materialsjackiee_262000Оценок пока нет

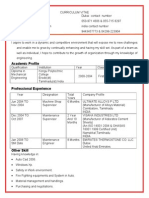

- CTC: 1.45 Lakhs Krunal Vasantrai Walekar (B.E. Mechanical) Personal InformationДокумент3 страницыCTC: 1.45 Lakhs Krunal Vasantrai Walekar (B.E. Mechanical) Personal Informationjackiee_262000Оценок пока нет

- Sathish BiodataДокумент2 страницыSathish Biodatajackiee_262000Оценок пока нет

- CTC 2 1akhs ApplicationДокумент4 страницыCTC 2 1akhs Applicationjackiee_262000Оценок пока нет

- Joint Venture Discussions for Autoklavtechnik Plant in DubaiДокумент2 страницыJoint Venture Discussions for Autoklavtechnik Plant in Dubaijackiee_262000Оценок пока нет

- Silica content determination using gravimetric methodДокумент1 страницаSilica content determination using gravimetric methodjackiee_262000Оценок пока нет

- Vimal Finalresume 2007Документ3 страницыVimal Finalresume 2007jackiee_262000Оценок пока нет

- Brick Grapple DetailsДокумент1 страницаBrick Grapple Detailsjackiee_262000Оценок пока нет

- Trouble Shutting During Vboard ProductionДокумент3 страницыTrouble Shutting During Vboard Productionjackiee_262000Оценок пока нет

- Presentation 1Документ1 страницаPresentation 1jackiee_262000Оценок пока нет

- Receipt 06 JUL 13Документ1 страницаReceipt 06 JUL 13jackiee_262000Оценок пока нет

- Upen Production ProfileДокумент3 страницыUpen Production Profilejackiee_262000Оценок пока нет

- MuraliДокумент2 страницыMuraliJackiee1983Оценок пока нет

- 30 4 Chicago 09-85 0184Документ3 страницы30 4 Chicago 09-85 0184Jackiee1983Оценок пока нет

- Employment and Salary Trends in The Gulf 2009 2010Документ28 страницEmployment and Salary Trends in The Gulf 2009 2010Ool4Оценок пока нет

- Receipt 15 APR 13Документ1 страницаReceipt 15 APR 13jackiee_262000Оценок пока нет

- Sachin C VДокумент5 страницSachin C Vjackiee_262000Оценок пока нет

- Nagendran PLC TechДокумент3 страницыNagendran PLC Techjackiee_262000Оценок пока нет

- Vimal Finalresume 2007Документ3 страницыVimal Finalresume 2007jackiee_262000Оценок пока нет

- Sudhakar: - ObjectiveДокумент3 страницыSudhakar: - Objectivejackiee_262000Оценок пока нет

- Prabhakaran New LogisticsДокумент2 страницыPrabhakaran New Logisticsjackiee_262000Оценок пока нет

- Kale Eswar AnДокумент4 страницыKale Eswar Anjackiee_262000Оценок пока нет

- Npmani StoresДокумент2 страницыNpmani Storesjackiee_262000Оценок пока нет

- CV Electrical Engineer Job ApplicationДокумент2 страницыCV Electrical Engineer Job Applicationjackiee_262000Оценок пока нет

- Contact Details in UaeДокумент2 страницыContact Details in Uaejackiee_262000Оценок пока нет

- Curriculum Vitae P.Chakaravarthy: ObjectiveДокумент4 страницыCurriculum Vitae P.Chakaravarthy: Objectivejackiee_262000Оценок пока нет

- Hari Brother Autoclave Opt ResumeДокумент4 страницыHari Brother Autoclave Opt Resumejackiee_262000Оценок пока нет

- Lightweight Foamed Concrete For Prefabricated House: Puput Risdanareni Mohammad Sulton Syahidah F. NastitiДокумент6 страницLightweight Foamed Concrete For Prefabricated House: Puput Risdanareni Mohammad Sulton Syahidah F. NastitiAfzalОценок пока нет

- Food Preservatives and Their Harmful EffДокумент2 страницыFood Preservatives and Their Harmful EffJo ShuОценок пока нет

- World Fertilizer Trends and Outlook To 2020Документ38 страницWorld Fertilizer Trends and Outlook To 2020SudhirОценок пока нет

- Wolter Jetfan Broschuere English 2017 PDFДокумент15 страницWolter Jetfan Broschuere English 2017 PDFViệt Đặng XuânОценок пока нет

- What Is A Fatigue Test?: High Cycle Fatigue (HCF)Документ4 страницыWhat Is A Fatigue Test?: High Cycle Fatigue (HCF)Taif AlhashimОценок пока нет

- Iron Staining Materials in Lightweight Concrete Aggregates: Standard Test Method ForДокумент4 страницыIron Staining Materials in Lightweight Concrete Aggregates: Standard Test Method ForJesús Luis Arce GuillermoОценок пока нет

- Unit 1 - Part A-Water Supply IДокумент24 страницыUnit 1 - Part A-Water Supply IIsha SinghОценок пока нет

- Mass Transfer 2Документ35 страницMass Transfer 2Zel SalvadorОценок пока нет

- 2 - Cleaning and Shaping in EndodonticsДокумент299 страниц2 - Cleaning and Shaping in EndodonticsElisabeth MarofОценок пока нет

- Slurry Pumps Parastaltic PumpsДокумент9 страницSlurry Pumps Parastaltic Pumpsmtl40Оценок пока нет

- Lesson 2 Dna Structure and Dna ExtractionДокумент8 страницLesson 2 Dna Structure and Dna ExtractionGreatel Elijah TorregosaОценок пока нет

- BenchTop Orbital Shakers GuideДокумент8 страницBenchTop Orbital Shakers Guidedéborah_rosales100% (1)

- MCQ IjsoДокумент20 страницMCQ IjsommhabgОценок пока нет

- Zuellig Pharma Corporation: Item Name of Medicine Brand Name Principal Name Quantity Unit PriceДокумент2 страницыZuellig Pharma Corporation: Item Name of Medicine Brand Name Principal Name Quantity Unit PriceJZik SibalОценок пока нет

- Stainless Steel 304 FlangesДокумент6 страницStainless Steel 304 FlangesiSteelindiaОценок пока нет

- Low Temp Refrigeration Oil DataДокумент1 страницаLow Temp Refrigeration Oil DataGeorgiana DumitruОценок пока нет

- Concrete Strength by Brick ChipsДокумент10 страницConcrete Strength by Brick ChipsHamayet RaselОценок пока нет

- Wilson Tool Coating Solutions - SMДокумент2 страницыWilson Tool Coating Solutions - SMSM TECH SRLОценок пока нет

- II - ITP - Defect Work FabricationДокумент5 страницII - ITP - Defect Work Fabricationmohd as shahiddin jafriОценок пока нет

- Principles of Drug Administration and OrderingДокумент26 страницPrinciples of Drug Administration and OrderingManasseh Mvula33% (3)

- Flax 7Документ7 страницFlax 7Rajyalakshmi MОценок пока нет

- Filter Elements, Parts for Compressors and EnginesДокумент2 страницыFilter Elements, Parts for Compressors and Enginespgm900Оценок пока нет