Академический Документы

Профессиональный Документы

Культура Документы

Testing and Commissioning Procedure For Motors

Загружено:

Praful SupekarОригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Testing and Commissioning Procedure For Motors

Загружено:

Praful SupekarАвторское право:

Доступные форматы

Energy & Power For All !

Home

Technical Articles

Subscribe to arti cles

Subscribe to downloads

Categories

Electrical Spreadsheets

Engineeri ng Gui des

EE General guides

Power Substations

Schneider Electric CTs

Siemens Basics of EE

Automation and Control

Alternati ve Energy

EE Resources

EE Video Course

PLC Programming Course

Testi ng and Commi ss.

Network Theorems

Contact

Testing and Commissioning Procedure For

Motors

Testing and Commissioning Procedure For Motors // Photo by TECO Middle East (TME)

Scope Of Motor Testing

It shoul d be noted that the scope of motor testing depends upon the motor type and size, this

being indicated on the inspection forms.

Motor vibration shall be measured in a tri-axial direction, i.e.:

Point x axis side of bearing housing at shaft height

Point y axis top of bearing housi ng

Point z axis axi al of beari ng housing at shaft hei ght

The measurements shal l be carried out with an instrument conformi ng to ISO 2954 (10-1000

Hz f requency range). Wi th the motor at normal operating temperature, the vibration vel ocity shal l not

exceed 2.8 mm/s RMS, or 4 mm/s PEAK, in any direction.

For bearings fitted with proximity probes, the unfiltered peak-to-peak value of vibration

(i ncluding shaft run-out) at any load between no l oad and full l oad, shal l not exceed the following

values:

50 m for two-pole motors

60 m for four-pole motors

75 m for si x-pole or hi gher motors

Motor bearing (photo by CCLW INTERNATIONAL)

Bearing temperature rise limits following a heat run of 3.5 4 hours are as follows:

Rolling bearings:

Outer ri ng measurement max. 90 C

Temperature rise from ambient max. 50 C

Sleeve bearings:

Oi l temperature max. 90 C

Bearing temperature rise by RTD max. 50

C

Lub. oil temperature ri se from ambi ent

max. 30 C (for forced l ub. oil systems ).

When commissioni ng or re-commissioning

motors, precauti ons shall be taken to

avoid excessive vibration caused by the

phenomenon known as soft foot; i. e.

feet whi ch do not have soli d flat contact

wi th the base prior to the ti ghtening of

the holding-down bolts.

This may be measured and rectified

during i nstallation or detected during running by the loosening of each holdi ng-down bolt in turn

while measuring motor vibration.

Motor Soft Foot Condition

Soft feet are those whi ch do not have solid flat contact with the base prior to the tightening

of the hol ding-down bol ts; one or more feet may be soft as shown in Figures 1 to 3.

The profile of the foot contact area may be as shown i n Figures 4 to 6.

The profile of the foot contact area (Figures 1, 2 and 3)

Figure 1 - Machi ne resting on 3 feet, foot 4 is rai sed or soft

Figure 2 - Machi ne resting on diagonal formed by feet 3 and 4, feet 1 and 4 are soft

Figure 3 - Bottoms of al l 4 feet are not parallel with base, feet 3 and 4 are soft

Profil e of 'soft foot' contact area

NOTE: Re-

machining of

rotor feet is

required in

Fi gures 4 and

5; temporary

use of wedge-shaped shi ms may be acceptable (maintenance).

Forms

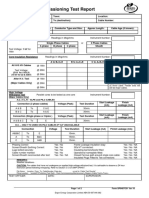

Form 14 Inspection of electric motor Cage-induction type (incl. control unit)

Inspection of electri c motor cage-induction type (including control uni t)

Form 4 Inspection of Switching Units HV Switchgear

Inspection of Switchi ng Uni ts - HV Switchgear

Form 11 Inspection Of Outgoing Unit LV Switchboard

Inspection Of Outgoing Unit - LV Switchboard

Reference: Field Commissi oning and Maintenance Of El ectrical Installations and Equipment Manual

Recommended EE articles

Edvard - Electrical engineer, programmer and founder of EEP. Highly special ized for design of

LV high power busbar trunking (<6300A) in power substati ons, buil dings and industry fascil ities.

Designing of LV/MV switchgears. Professi onal i n AutoCAD programmi ng and web-desi gn. Present

on Googl e+.

2014 EEP - Electrical Engineering Portal. Al l Rights Reserved | Pri vacy Policy | 44 queries in

0. 373 seconds.

Powered by CsanyiGroup

SHARE

TOP

Get

PDF

Вам также может понравиться

- Checklist For Protection Relays General Electrical Tests Rev00Документ2 страницыChecklist For Protection Relays General Electrical Tests Rev00Anonymous dH3DIEtz67% (3)

- Maint - Check List - Oil Filled TransforsДокумент2 страницыMaint - Check List - Oil Filled TransforsramОценок пока нет

- Earthpit Resistance Testing RecordsheetДокумент1 страницаEarthpit Resistance Testing RecordsheetawsomeОценок пока нет

- 7420p008 Uptimax Ni-CD BatteryДокумент16 страниц7420p008 Uptimax Ni-CD BatteryNazif HawariОценок пока нет

- Typical Authorisation Test QuestionsДокумент11 страницTypical Authorisation Test QuestionsArchiford NdhlovuОценок пока нет

- Overcurrent and Earth Fault Relay Calibration CertificateДокумент2 страницыOvercurrent and Earth Fault Relay Calibration Certificateroslan yusofОценок пока нет

- NGR Routine Test ProcedureДокумент6 страницNGR Routine Test Procedurezaheer ahamedОценок пока нет

- Motor Test FormДокумент1 страницаMotor Test FormArie Yantoe100% (1)

- MCC PanelДокумент86 страницMCC PanelRavindra TiwariОценок пока нет

- HT MotorДокумент25 страницHT MotorgaladrialОценок пока нет

- Grid Station General Checking Checklist YittiДокумент2 страницыGrid Station General Checking Checklist Yittianurag_jay12464100% (1)

- Method Statement For Cable Laying, Glanding and TerminationДокумент12 страницMethod Statement For Cable Laying, Glanding and TerminationSajid Raza100% (1)

- HT Motor PrecommissioningДокумент6 страницHT Motor PrecommissioningJarrett Mathews100% (1)

- Tan Delta Test For Power TransformersДокумент9 страницTan Delta Test For Power TransformersBashir AhmadОценок пока нет

- 11kv Rmu PDFДокумент27 страниц11kv Rmu PDFSanda KinithiОценок пока нет

- Check List For Installation of Earthing System: Contractor: Sub-ContractorДокумент4 страницыCheck List For Installation of Earthing System: Contractor: Sub-ContractorRyn RcioОценок пока нет

- Inspection Test Plan (ITP) Procedure-DigabungkanДокумент9 страницInspection Test Plan (ITP) Procedure-Digabungkanpankrasius herbudiОценок пока нет

- Testing and Commissioning of UPS System Method StatementДокумент3 страницыTesting and Commissioning of UPS System Method StatementHumaid Shaikh100% (1)

- Transformer Maintenance Checklist - 5 Must Do Routine ChecksДокумент3 страницыTransformer Maintenance Checklist - 5 Must Do Routine Checksmurthy237Оценок пока нет

- Caterpillar - Class of Insulation and Temprature Rise - Online CommunityДокумент3 страницыCaterpillar - Class of Insulation and Temprature Rise - Online Communitylbk50Оценок пока нет

- Maintenance Manual of TransformerДокумент19 страницMaintenance Manual of TransformerSidhartha MallickОценок пока нет

- Erection Procedure For 6.6 KV Bus DuctДокумент7 страницErection Procedure For 6.6 KV Bus DuctAnmohieyОценок пока нет

- SOP & Control PhilosophyДокумент2 страницыSOP & Control PhilosophyAshish M50% (2)

- Switchgear ChecklistДокумент2 страницыSwitchgear ChecklistAnonymous IeFbdsfCo100% (1)

- Precommissioning Procedures of Testing Commissioning PDFДокумент96 страницPrecommissioning Procedures of Testing Commissioning PDFRatheesh Kumar100% (1)

- Isolation & Maintenance of Power Transformers.Документ4 страницыIsolation & Maintenance of Power Transformers.अभिषेक कुमार उपाध्यायОценок пока нет

- Genset Load TestДокумент10 страницGenset Load Testjavad100% (1)

- Inspection and Testing Transformer InstallationsДокумент37 страницInspection and Testing Transformer InstallationsJellyn Base100% (1)

- Power Transformer MaintenanceДокумент5 страницPower Transformer MaintenanceSantoshkumar Gupta100% (1)

- FAT Capacitor BankДокумент5 страницFAT Capacitor BankDannis SanciptoОценок пока нет

- VCB PM PDFДокумент15 страницVCB PM PDFAccidental EngineerОценок пока нет

- Earthing MaintenanceДокумент1 страницаEarthing Maintenancepk_shahana100% (5)

- HV Switching ProcedureДокумент6 страницHV Switching Procedurekyawswarpm100% (3)

- DG Maintenance Manual PDFДокумент39 страницDG Maintenance Manual PDFvij200950% (2)

- Flow Chart EHV Transformer Installation PDFДокумент1 страницаFlow Chart EHV Transformer Installation PDFPandurang Yadav100% (1)

- SOP For Testing TransformerДокумент1 страницаSOP For Testing TransformerPARAMSIVAMОценок пока нет

- ACB Maintenance ProcedureДокумент1 страницаACB Maintenance ProcedureMartono Abu HanifОценок пока нет

- Method Statement For MV Switchgear (Inspire)Документ5 страницMethod Statement For MV Switchgear (Inspire)Gajendran Sriram50% (2)

- How To Use A Megger Insulation TesterДокумент2 страницыHow To Use A Megger Insulation TesterRakesh Babu0% (1)

- Method Statement For Testing & Commissioning of Diesel GeneratorДокумент6 страницMethod Statement For Testing & Commissioning of Diesel Generatorvin ss100% (1)

- Power Transformer Testing (25 MVA, 132/33 KV)Документ3 страницыPower Transformer Testing (25 MVA, 132/33 KV)Manish Pareek0% (1)

- Method Statement For Installation of Electrical DB, SMDB and MDB PanelboardsДокумент6 страницMethod Statement For Installation of Electrical DB, SMDB and MDB Panelboardsnidhinm92Оценок пока нет

- Elum ePowerControl HFS Datasheet 102019Документ4 страницыElum ePowerControl HFS Datasheet 102019CyrilColin100% (1)

- 7 - Bus Bar & Ducts - YearlyДокумент3 страницы7 - Bus Bar & Ducts - Yearlyrishimaran100% (1)

- MFM Consolidated Preventive Maintenance Ver 2 - 3132017Документ201 страницаMFM Consolidated Preventive Maintenance Ver 2 - 3132017Paul CansinoОценок пока нет

- Site Test Report: Under Ground Cables Precommissioning Test SheetДокумент1 страницаSite Test Report: Under Ground Cables Precommissioning Test SheetNaser Mahamid100% (1)

- S.NO. Equipment Details Test Details List of Pre-Commissioning Tests of Ac EquipmentsДокумент5 страницS.NO. Equipment Details Test Details List of Pre-Commissioning Tests of Ac EquipmentsnagarajanОценок пока нет

- Check List For UPSДокумент1 страницаCheck List For UPSsiruslara6491Оценок пока нет

- Manual MotorsДокумент10 страницManual Motorst_syamprasadОценок пока нет

- Solo Run For MotorsДокумент8 страницSolo Run For MotorsMohamed Haleem100% (1)

- Genset - Electrical ChecklistДокумент1 страницаGenset - Electrical ChecklistKarl Jared MasanqueОценок пока нет

- SP0407C01 HV Cable Commissioning Test ReportДокумент2 страницыSP0407C01 HV Cable Commissioning Test Reportkajale.shrikantОценок пока нет

- Megger Testing Method StatementДокумент7 страницMegger Testing Method StatementRay Agacia0% (1)

- Capacitor TestДокумент2 страницыCapacitor TestdineshОценок пока нет

- Testing and Commissioning Procedure For Electric MotorsДокумент7 страницTesting and Commissioning Procedure For Electric MotorsJoel AlcantaraОценок пока нет

- 3.1 Testing - and - Commissioning - Procedure - For - MotorsДокумент7 страниц3.1 Testing - and - Commissioning - Procedure - For - MotorsEdison EstrellaОценок пока нет

- Testing and Commissioning Procedure For MotorsДокумент7 страницTesting and Commissioning Procedure For MotorsDeepak Jha KashyapОценок пока нет

- Testing and Commissioning Procedure For MotorsДокумент6 страницTesting and Commissioning Procedure For MotorsArnold StevenОценок пока нет

- Maintenanceboth Q and AДокумент46 страницMaintenanceboth Q and AMMS SОценок пока нет

- Konsep Negara Hukum Dalam Perspektif Hukum IslamДокумент11 страницKonsep Negara Hukum Dalam Perspektif Hukum IslamSiti MasitohОценок пока нет

- EHVACДокумент16 страницEHVACsidharthchandak16Оценок пока нет

- Neural Computing and ApplicationsДокумент49 страницNeural Computing and ApplicationsLine PhamОценок пока нет

- Amberjet™ 1500 H: Industrial Grade Strong Acid Cation ExchangerДокумент2 страницыAmberjet™ 1500 H: Industrial Grade Strong Acid Cation ExchangerJaime SalazarОценок пока нет

- Iot Based Garbage and Street Light Monitoring SystemДокумент3 страницыIot Based Garbage and Street Light Monitoring SystemHarini VenkatОценок пока нет

- MIDTERM Exam - Programming 2 - 2SEM 2020Документ3 страницыMIDTERM Exam - Programming 2 - 2SEM 2020Bab bidiОценок пока нет

- Cet Admissions 2018 FinalДокумент225 страницCet Admissions 2018 FinalkiranОценок пока нет

- Blackstone The Dash Model #1610 Owner's ManualДокумент53 страницыBlackstone The Dash Model #1610 Owner's ManualSydney Adam SteeleОценок пока нет

- BIO122 - CHAPTER 7 Part 1Документ53 страницыBIO122 - CHAPTER 7 Part 1lili100% (1)

- Cot Observation ToolДокумент14 страницCot Observation ToolArnoldBaladjayОценок пока нет

- ASM1 ProgramingДокумент14 страницASM1 ProgramingTran Cong Hoang (BTEC HN)Оценок пока нет

- GT-3000 PrintДокумент3 страницыGT-3000 Printmanual imbОценок пока нет

- TakeawaysДокумент2 страницыTakeawaysapi-509552154Оценок пока нет

- Arte PoveraДокумент13 страницArte PoveraSohini MaitiОценок пока нет

- IJISRT23JUL645Документ11 страницIJISRT23JUL645International Journal of Innovative Science and Research TechnologyОценок пока нет

- Module 0-Course Orientation: Objectives OutlineДокумент2 страницыModule 0-Course Orientation: Objectives OutlineEmmanuel CausonОценок пока нет

- RRB 17 Sep Set 2 Ibps Guide - Ibps Po, Sbi Clerk, RRB, SSC - Online Mock TestДокумент46 страницRRB 17 Sep Set 2 Ibps Guide - Ibps Po, Sbi Clerk, RRB, SSC - Online Mock TestBharat KumarОценок пока нет

- 1.3.3 1.3.4 1.3.5 Input, Output & Storage Devices Workbook by Inqilab Patel PDFДокумент173 страницы1.3.3 1.3.4 1.3.5 Input, Output & Storage Devices Workbook by Inqilab Patel PDFRayyan MalikОценок пока нет

- BS EN 50483-6-2009 EnglishДокумент27 страницBS EN 50483-6-2009 EnglishДмитро Денис100% (2)

- Defenders of The Empire v1.4Документ13 страницDefenders of The Empire v1.4Iker Antolín MedinaОценок пока нет

- M4110 Leakage Reactance InterfaceДокумент2 страницыM4110 Leakage Reactance InterfaceGuru MishraОценок пока нет

- End Points SubrogadosДокумент3 страницыEnd Points SubrogadosAgustina AndradeОценок пока нет

- 96 Dec2018 NZGeoNews PDFДокумент139 страниц96 Dec2018 NZGeoNews PDFAditya PrasadОценок пока нет

- KV4BBSR Notice ContractuaL Interview 2023-24Документ9 страницKV4BBSR Notice ContractuaL Interview 2023-24SuchitaОценок пока нет

- Historical Roots of The "Whitening" of BrazilДокумент23 страницыHistorical Roots of The "Whitening" of BrazilFernandoMascarenhasОценок пока нет

- Medha Servo Drives Written Exam Pattern Given by KV Sai KIshore (BVRIT-2005-09-ECE)Документ2 страницыMedha Servo Drives Written Exam Pattern Given by KV Sai KIshore (BVRIT-2005-09-ECE)Varaprasad KanugulaОценок пока нет

- Integra Facade BrochureДокумент2 страницыIntegra Facade BrochureHarshit PatadiyaОценок пока нет

- Advocating For Appropriate Educational ServicesДокумент32 страницыAdvocating For Appropriate Educational ServicesTransverse Myelitis AssociationОценок пока нет

- Solutions Jet FuelДокумент4 страницыSolutions Jet FuelkevinОценок пока нет

- Chapter 3 PayrollДокумент5 страницChapter 3 PayrollPheng Tiosen100% (2)