Академический Документы

Профессиональный Документы

Культура Документы

A380-LEVEL III - ATA 26 Fire - Smoke Detection

Загружено:

Abolfazl Mazloomi100%(2)100% нашли этот документ полезным (2 голоса)

908 просмотров42 страницыAirbus A380 Technical Training Manual (TTM)

Full Document

New Version

The first A380 technical manual, the "Airplane Characteristics for Airport Planning," was released this month. It can be consulted and/or downloaded from the A380 Family page on Airbus' web site at www.airbus.com. This is the first time a technical manual of this nature has been made available so early, some three years before the first flight of the aircraft.

The Airplane Characteristics manual provides specific A380 data needed by airport authorities and planners to support the operation of the A380 within their airports. Data such as airplane dimensions, take off and landing distances, terminal operations data, taxiing, parking and pavement loading requirements are provided for the A380-800 and A380-800F, the passenger and freighter versions of the A380.

Airbus has been working with planning teams from 50 major airports in five continents to ensure smooth handling of the A380 when it enters service in 2006 and the Airplane Characteristics manual is a major support for this.

Following release of this first manual and up to entry into service of the A380, Airbus will deliver a full range of technical data for the maintenance, engineering, material support and flight operations departments of A380 airline customers. Technical data for the A380 will be available in electronic format according to the most recent aviation industry standards, which are more efficient and user friendly. They will be accessible through Airbus On Line Services, the Airbus portal for Customer Support.

Оригинальное название

A380-LEVEL III - ATA 26 Fire _ Smoke Detection

Авторское право

© © All Rights Reserved

Доступные форматы

PDF, TXT или читайте онлайн в Scribd

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документAirbus A380 Technical Training Manual (TTM)

Full Document

New Version

The first A380 technical manual, the "Airplane Characteristics for Airport Planning," was released this month. It can be consulted and/or downloaded from the A380 Family page on Airbus' web site at www.airbus.com. This is the first time a technical manual of this nature has been made available so early, some three years before the first flight of the aircraft.

The Airplane Characteristics manual provides specific A380 data needed by airport authorities and planners to support the operation of the A380 within their airports. Data such as airplane dimensions, take off and landing distances, terminal operations data, taxiing, parking and pavement loading requirements are provided for the A380-800 and A380-800F, the passenger and freighter versions of the A380.

Airbus has been working with planning teams from 50 major airports in five continents to ensure smooth handling of the A380 when it enters service in 2006 and the Airplane Characteristics manual is a major support for this.

Following release of this first manual and up to entry into service of the A380, Airbus will deliver a full range of technical data for the maintenance, engineering, material support and flight operations departments of A380 airline customers. Technical data for the A380 will be available in electronic format according to the most recent aviation industry standards, which are more efficient and user friendly. They will be accessible through Airbus On Line Services, the Airbus portal for Customer Support.

Авторское право:

© All Rights Reserved

Доступные форматы

Скачайте в формате PDF, TXT или читайте онлайн в Scribd

100%(2)100% нашли этот документ полезным (2 голоса)

908 просмотров42 страницыA380-LEVEL III - ATA 26 Fire - Smoke Detection

Загружено:

Abolfazl MazloomiAirbus A380 Technical Training Manual (TTM)

Full Document

New Version

The first A380 technical manual, the "Airplane Characteristics for Airport Planning," was released this month. It can be consulted and/or downloaded from the A380 Family page on Airbus' web site at www.airbus.com. This is the first time a technical manual of this nature has been made available so early, some three years before the first flight of the aircraft.

The Airplane Characteristics manual provides specific A380 data needed by airport authorities and planners to support the operation of the A380 within their airports. Data such as airplane dimensions, take off and landing distances, terminal operations data, taxiing, parking and pavement loading requirements are provided for the A380-800 and A380-800F, the passenger and freighter versions of the A380.

Airbus has been working with planning teams from 50 major airports in five continents to ensure smooth handling of the A380 when it enters service in 2006 and the Airplane Characteristics manual is a major support for this.

Following release of this first manual and up to entry into service of the A380, Airbus will deliver a full range of technical data for the maintenance, engineering, material support and flight operations departments of A380 airline customers. Technical data for the A380 will be available in electronic format according to the most recent aviation industry standards, which are more efficient and user friendly. They will be accessible through Airbus On Line Services, the Airbus portal for Customer Support.

Авторское право:

© All Rights Reserved

Доступные форматы

Скачайте в формате PDF, TXT или читайте онлайн в Scribd

Вы находитесь на странице: 1из 42

A380

TECHNICAL TRAINING MANUAL

MAINTENANCE COURSE - T1 & T2 (RR / Metric)

LEVEL III - ATA 26 Fire & Smoke Detection

This document must be used for training purposes only

Under no circumstances should this document be used as a reference

It will not be updated.

All rights reserved

No part of this manual may be reproduced in any form,

by photostat, microfilm, retrieval system, or any other means,

without the prior written permission of AIRBUS S.A.S.

LEVEL III - ATA 26 FIRE & SMOKE DETECTION

Engine, APU & Main Landing Gear Fire Protection

Engine, APU & Main Landing Gear Fire Protection Description (3) . .

2

Engine, APU & Main Landing Gear Fire Protection System Maintenance

(3) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Engine, APU & Main Landing Gear Fire Protection Component Location

(3) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Cabin & Cargo Compartment Fire Protection

Cabin & Cargo Compartment Fire Protection Description (3) . . . . . 20

Avionics, Cargo Compartment, Lavatory, Cabin & Sub-Cabin

Compartment, Fire Protection System Maintenance (3) . . . . . . 32

Smoke Protection Component Location (3) . . . . . . . . . . . . . . . . . . . 36

MAINTENANCE COURSE - T1 & T2 (RR / Metric)

LEVEL III - ATA 26 Fire & Smoke Detection

TABLE OF CONTENTS Mar 21, 2006

Page 1

A380 TECHNICAL TRAINING MANUAL

L

0

Y

0

6

0

8

2

-

L

0

D

T

0

T

0

ENGINE, APU & MAIN LANDING GEAR FIRE PROTECTION DESCRIPTION (3)

General

The Fire Protection System includes the Fire Detection and the Fire

Extinguishing systems.

Three fire zones are fire detected on each engine and one on each pylon.

The APU compartment and the Main Landing Gear Bay are also fire

detected.

A fire extinguishing system is installed for the engine and the APU. For

the Main Landing Gear Bay any extinguishing is installed.

A single Fire Detection Unit (FDU) is dedicated for the whole: engine,

APU and Main Landing Gear Bay fire extinguishing system.

MAINTENANCE COURSE - T1 & T2 (RR / Metric)

LEVEL III - ATA 26 Fire & Smoke Detection

ENGINE, APU & MAIN LANDING GEAR FIRE PROTECTION

DESCRIPTION (3)

Mar 17, 2006

Page 2

A380 TECHNICAL TRAINING MANUAL

L

0

Y

0

6

0

8

2

-

L

0

D

T

0

T

0

-

L

M

2

6

D

1

0

0

0

0

0

0

0

0

1

GENERAL

MAINTENANCE COURSE - T1 & T2 (RR / Metric)

LEVEL III - ATA 26 Fire & Smoke Detection

ENGINE, APU & MAIN LANDING GEAR FIRE PROTECTION

DESCRIPTION (3)

Mar 17, 2006

Page 3

A380 TECHNICAL TRAINING MANUAL

L

0

Y

0

6

0

8

2

-

L

0

D

T

0

T

0

-

L

M

2

6

D

1

0

0

0

0

0

0

0

0

1

ENGINE, APU & MAIN LANDING GEAR FIRE PROTECTION DESCRIPTION (3)

Fire Detection

For each engine, the protected zones are:

o the fan zone (zone 1) protected by two pairs of fire detectors,

o the intermediate compressor zone (zone 2) protected by one pair of fire

detectors,

o the core zone (zone 3) protected by one pair of fire detectors,

o and the pylon zone protected by one pair of fire detectors installed

above the combustion chamber

The APU compartment is protected by one pair of fire detectors installed

in parallel and connected to a dual loop.

For the Main Landing Gear Bay, the protected zones are:

o the right WLG bay protected by one pair of fire detectors,

o the left WLG bay protected by one pair of fire detectors,

o In the BLG bay, the right and left hand sides are each one protected by

a pair of fire detectors.

The detectors use electro-pneumatic technology.

The smoke detector has a sensing element and a responder assembly.

The responder assembly is made of stainless steel body. It contains a

chamber connected to two pressure switches: an alarm switch and an

integrity switch. The position of the two pressure switches generates three

states: normal, fault or fire states.

The sensing element is made of hydrogen charged core, surrounded by

helium gas and soldered by an end cap. This gas reacts according to the

ideal gas law.

MAINTENANCE COURSE - T1 & T2 (RR / Metric)

LEVEL III - ATA 26 Fire & Smoke Detection

ENGINE, APU & MAIN LANDING GEAR FIRE PROTECTION

DESCRIPTION (3)

Mar 17, 2006

Page 4

A380 TECHNICAL TRAINING MANUAL

L

0

Y

0

6

0

8

2

-

L

0

D

T

0

T

0

-

L

M

2

6

D

1

0

0

0

0

0

0

0

0

1

FIRE DETECTION

MAINTENANCE COURSE - T1 & T2 (RR / Metric)

LEVEL III - ATA 26 Fire & Smoke Detection

ENGINE, APU & MAIN LANDING GEAR FIRE PROTECTION

DESCRIPTION (3)

Mar 17, 2006

Page 5

A380 TECHNICAL TRAINING MANUAL

L

0

Y

0

6

0

8

2

-

L

0

D

T

0

T

0

-

L

M

2

6

D

1

0

0

0

0

0

0

0

0

1

ENGINE, APU & MAIN LANDING GEAR FIRE PROTECTION DESCRIPTION (3)

Fire Detection (continued)

Smoke Detectors

In NORMAL STATE, the INTEGRITY switch is closed and the

ALARM switch is open.

In ALARM STATE:

The effect of an average temperature expands the helium (inert) gas,

which in turn closes the ALARM switch,

or the effect of heat caused by a flame or hot gas, releases core (active)

gas from the hybrid core, which in turn closes the ALARM switch.

In both cases, the detector sends a fire signal.

In FAULT STATE:

In the event of gas pressure loss (pipe fracture or cut off due to a

torching flame), the INTEGRITY switch opens and generates a fault

signal.

MAINTENANCE COURSE - T1 & T2 (RR / Metric)

LEVEL III - ATA 26 Fire & Smoke Detection

ENGINE, APU & MAIN LANDING GEAR FIRE PROTECTION

DESCRIPTION (3)

Mar 17, 2006

Page 6

A380 TECHNICAL TRAINING MANUAL

L

0

Y

0

6

0

8

2

-

L

0

D

T

0

T

0

-

L

M

2

6

D

1

0

0

0

0

0

0

0

0

1

FIRE DETECTION - SMOKE DETECTORS

MAINTENANCE COURSE - T1 & T2 (RR / Metric)

LEVEL III - ATA 26 Fire & Smoke Detection

ENGINE, APU & MAIN LANDING GEAR FIRE PROTECTION

DESCRIPTION (3)

Mar 17, 2006

Page 7

A380 TECHNICAL TRAINING MANUAL

L

0

Y

0

6

0

8

2

-

L

0

D

T

0

T

0

-

L

M

2

6

D

1

0

0

0

0

0

0

0

0

1

ENGINE, APU & MAIN LANDING GEAR FIRE PROTECTION DESCRIPTION (3)

Fire Detection (continued)

Loops and Conversion Module

For engine, APU and MLG bay fire detection, two continuous loops

are installed in parallel and operate according to an AND logic.

Each fire detection loop continuously monitored:

o five fire detectors for one engine,

o one fire detector for the APU,

o four fire detectors for the MLG bay

Each loop is connected to a separate channel in the CM: Loop A on

Channel A and Loop B on Channel B.

In the vicinity of each area, a conversion module is installed to digitize

the information of each detector, and transmit it to the Fire detection

Unit.

A Conversion Module (CM) per Engine is installed in the fire

protection system.

One is installed for the APU and one for the Main Landing Gear bay.

Each Conversion Module receive signal from each fire detector.

The CM has two channels A and B.

Fire detector on loop A is related to channel A

Fire detector on loop B is related to channel B.

Each channel also receives signals from the Temperature Compensated

Pressure Switch (TCPS) of fire extinguisher bottle.

Each channel of the CM works independently.

Its internal function is to convert ANALOG to DIGITAL values:

- analog signal from the responder of the detector,

- discrete signal from the pressure switch of extinguisher bottle.

Each channel communicates only with its associated FDU Operational

cards through a CAN Bus link.

MAINTENANCE COURSE - T1 & T2 (RR / Metric)

LEVEL III - ATA 26 Fire & Smoke Detection

ENGINE, APU & MAIN LANDING GEAR FIRE PROTECTION

DESCRIPTION (3)

Mar 17, 2006

Page 8

A380 TECHNICAL TRAINING MANUAL

L

0

Y

0

6

0

8

2

-

L

0

D

T

0

T

0

-

L

M

2

6

D

1

0

0

0

0

0

0

0

0

1

FIRE DETECTION - LOOPS AND CONVERSION MODULE

MAINTENANCE COURSE - T1 & T2 (RR / Metric)

LEVEL III - ATA 26 Fire & Smoke Detection

ENGINE, APU & MAIN LANDING GEAR FIRE PROTECTION

DESCRIPTION (3)

Mar 17, 2006

Page 9

A380 TECHNICAL TRAINING MANUAL

L

0

Y

0

6

0

8

2

-

L

0

D

T

0

T

0

-

L

M

2

6

D

1

0

0

0

0

0

0

0

0

1

ENGINE, APU & MAIN LANDING GEAR FIRE PROTECTION DESCRIPTION (3)

Fire Detection (continued)

Fire Detection Unit

The Fire Detection Unit is located in the Main Avionics bay.

The FDU is composed by four independent Operational cards (OP

card) or channels

And BITE Card dedicated to BITE functions composed the FDU.

This BITE card is connected to each OP cards.

The FDU receives inputs from:

o the CM through CAN Bus,

o the Landing Gear Extension/Retraction System (LGERS),

o the Push-Button Test of the ENGine/FIRE Integrated Control Panel

o the Engine and APU fire extinguisher bottles.

The FDU processes data delivered by the Conversion Module through

CAN Bus.

It monitors the fire detection system.

The FDU monitors the bottle (bottle pressure and bottle filament state,

power supply, state of fire handle and of the agent)

The FDU activates the extinguishing system automatically if a fire

occurs for APU when the aircraft is on ground.

The output signals are generated and sent to :

- The FWS in ARINC 429,

- The ENGine/FIRE ICP with discrete signals,

- The ENGine/MASTER Control Panel with discrete signals.

The FDU Operational cards (OP card) monitor:

For OP card#1 detection for ENGine 1 and 4 and APU on Loop A,

For OP card#2 detection for ENGine 1 and 2 and APU on Loop B,

For OP card#3 detection for ENGine 2 and 3 and MLG bay on Loop

A,

For OP card#4 detection for ENGine 3 and 4 and MLG bay on Loop

B.

The FDU Bite is a standard B, type 1

Its function is to monitor each Operational Card of the FDU and

process the result of this monitoring.

Then the BITE card builds failure messages, memorized and sends

this failure message to the CMS through the SCI.

It also activates the Interactive Test and the Operational test on Engine,

APU and MLG bay when action is initiated by pressing the test

Pushbuttons on ICP.

MAINTENANCE COURSE - T1 & T2 (RR / Metric)

LEVEL III - ATA 26 Fire & Smoke Detection

ENGINE, APU & MAIN LANDING GEAR FIRE PROTECTION

DESCRIPTION (3)

Mar 17, 2006

Page 10

A380 TECHNICAL TRAINING MANUAL

L

0

Y

0

6

0

8

2

-

L

0

D

T

0

T

0

-

L

M

2

6

D

1

0

0

0

0

0

0

0

0

1

FIRE DETECTION - FIRE DETECTION UNIT

MAINTENANCE COURSE - T1 & T2 (RR / Metric)

LEVEL III - ATA 26 Fire & Smoke Detection

ENGINE, APU & MAIN LANDING GEAR FIRE PROTECTION

DESCRIPTION (3)

Mar 17, 2006

Page 11

A380 TECHNICAL TRAINING MANUAL

L

0

Y

0

6

0

8

2

-

L

0

D

T

0

T

0

-

L

M

2

6

D

1

0

0

0

0

0

0

0

0

1

ENGINE, APU & MAIN LANDING GEAR FIRE PROTECTION DESCRIPTION (3)

Fire Extinguishing

The fire extinguishing system is composed:

For the engine, of:

o Two bottles on the rear secondary structure of each engine pylon,

o An extinguishing distribution line system from the bottles to the Zone

1 (Fan compartment), the Zone 2 (Intermediate Compressor Compartment)

and the Zone 3 (Core Compartment) of the engine,

o The extinguishing agent is sprayed out on this zone by extinguisher

nozzles.

For the APU, of:

- A single bottle installed behind the firewall,

- A distribution pipe,

- And extinguisher nozzle to spray out the extinguishing agent.

The extinguisher bottle is composed of:

A spherical container witch contains the Halon, an extinguishing agent,

a fill fitting, mounting lugs and handles.

The discharge head position on bottle 1 is different from that on bottle

2.

The cartridge is an electro-pyrotechnic element, which is fired by two

filaments. The percussion breaks the rupture disk, then the extinguishing

agent can flow through the discharge head in the distribution system.

The Temperature Compensated Pressure Switch (TCPS) monitors the

pressure in the bottle, the DISCH legend is on when container is

discharged. The TCPS is connected to the CM via the FDU. The TCPS

bottle 1 is linked to channel A of the CM, and for bottle 2 to channel B.

The push-to-test pushbutton switch is used to do the test of the pressure

switch.

MAINTENANCE COURSE - T1 & T2 (RR / Metric)

LEVEL III - ATA 26 Fire & Smoke Detection

ENGINE, APU & MAIN LANDING GEAR FIRE PROTECTION

DESCRIPTION (3)

Mar 17, 2006

Page 12

A380 TECHNICAL TRAINING MANUAL

L

0

Y

0

6

0

8

2

-

L

0

D

T

0

T

0

-

L

M

2

6

D

1

0

0

0

0

0

0

0

0

1

FIRE EXTINGUISHING

MAINTENANCE COURSE - T1 & T2 (RR / Metric)

LEVEL III - ATA 26 Fire & Smoke Detection

ENGINE, APU & MAIN LANDING GEAR FIRE PROTECTION

DESCRIPTION (3)

Mar 17, 2006

Page 13

A380 TECHNICAL TRAINING MANUAL

L

0

Y

0

6

0

8

2

-

L

0

D

T

0

T

0

-

L

M

2

6

D

1

0

0

0

0

0

0

0

0

1

ENGINE, APU & MAIN LANDING GEAR FIRE PROTECTION SYSTEM MAINTENANCE (3)

Fire Protection System Tests

The Fire Protection System (FPS) fulfills the following test:

- FPS Tests

- Reports

- Specific functions

These tests are launched from the OMS HMI.

MAINTENANCE COURSE - T1 & T2 (RR / Metric)

LEVEL III - ATA 26 Fire & Smoke Detection

ENGINE, APU & MAIN LANDING GEAR FIRE PROTECTION

SYSTEM MAINTENANCE (3)

Mar 17, 2006

Page 14

A380 TECHNICAL TRAINING MANUAL

L

0

Y

0

6

0

8

2

-

L

0

D

T

0

T

0

-

L

M

2

6

Y

1

M

A

I

N

T

0

0

0

1

FIRE PROTECTION SYSTEM TESTS

MAINTENANCE COURSE - T1 & T2 (RR / Metric)

LEVEL III - ATA 26 Fire & Smoke Detection

ENGINE, APU & MAIN LANDING GEAR FIRE PROTECTION

SYSTEM MAINTENANCE (3)

Mar 17, 2006

Page 15

A380 TECHNICAL TRAINING MANUAL

L

0

Y

0

6

0

8

2

-

L

0

D

T

0

T

0

-

L

M

2

6

Y

1

M

A

I

N

T

0

0

0

1

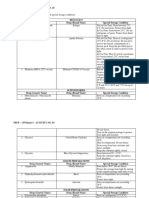

ENGINE, APU & MAIN LANDING GEAR FIRE PROTECTION SYSTEM MAINTENANCE (3)

FPS menu

The FPS MENU page of the Onboard Maintenance System (OMS) gives

the following functions:

Tests:

. APU Functions activation

. System test

Reports:

. Detectors value/state

. Fire event detector value

Specific functions:

. Bite memory dump

Obey these safety precautions:

WARNING: BE CAREFUL WHEN YOU REMOVE OR INSTALL

THIS EQUIPMENT. THIS EQUIPMENT IS HEAVY

(MORE THAN 12 KG (26.5 lb)) AND CAUSE INJURY

AND/OR DAMAGE.

BE VERY CAREFUL WHEN YOU DO THIS

PROCEDURE. THE BOTTLE CAN FIRE

ACCIDENTALLY AND CAUSE IMPORTANT INJURY

TO PERSONS WHO ARE IN THE AREA ADJACENT

TO THE FIRE EXTINGUISHER BOTTLE.

MAKE SURE THAT THERE IS A GOOD FLOW OF AIR

THROUGH THE WORK AREA.

FUMES FROM A DISCHARGED FIRE EXTINGUISHER

BOTTLE CAN CAUSE INJURY TO PERSONS.

BE VERY CAREFUL WHEN YOU MOVE A FILLED

FIRE EXTINGUISHER BOTTLE. A HEAVY SHOCK

CAN CAUSE UNWANTED DISCHARGE AND INJURY

TO PERSONS.

MAKE SURE THAT THE SAFETY DEVICES AND THE

WARNING NOTICES ARE IN POSITION BEFORE YOU

START A TASK ON OR NEAR :

- THE FLIGHT CONTROLS

- THE FLIGHT CONTROL SURFACES

- THE LANDING GEAR AND RELATED DOORS

- COMPONENTS THAT MOVE.

MOVEMENT OF COMPONENTS CAN KILL OR CAUSE

INJURY TO PERSONS AND CAN CAUSE DAMAGE.

MAKE SURE THAT THE TRAVEL RANGES OF THE

FLIGHT CONTROL SURFACES ARE CLEAR.

MOVEMENT OF THE FLIGHT CONTROL SURFACES

CAN CAUSE INJURY TO PERSONS AND DAMAGE

TO THE AIRCRAFT OR EQUIPMENT.

MAINTENANCE COURSE - T1 & T2 (RR / Metric)

LEVEL III - ATA 26 Fire & Smoke Detection

ENGINE, APU & MAIN LANDING GEAR FIRE PROTECTION

SYSTEM MAINTENANCE (3)

Mar 17, 2006

Page 16

A380 TECHNICAL TRAINING MANUAL

L

0

Y

0

6

0

8

2

-

L

0

D

T

0

T

0

-

L

M

2

6

Y

1

M

A

I

N

T

0

0

0

1

FPS MENU

MAINTENANCE COURSE - T1 & T2 (RR / Metric)

LEVEL III - ATA 26 Fire & Smoke Detection

ENGINE, APU & MAIN LANDING GEAR FIRE PROTECTION

SYSTEM MAINTENANCE (3)

Mar 17, 2006

Page 17

A380 TECHNICAL TRAINING MANUAL

L

0

Y

0

6

0

8

2

-

L

0

D

T

0

T

0

-

L

M

2

6

Y

1

M

A

I

N

T

0

0

0

1

ENGINE, APU & MAIN LANDING GEAR FIRE PROTECTION COMPONENT LOCATION (3)

MAINTENANCE COURSE - T1 & T2 (RR / Metric)

LEVEL III - ATA 26 Fire & Smoke Detection

ENGINE, APU & MAIN LANDING GEAR FIRE PROTECTION

COMPONENT LOCATION (3)

Mar 17, 2006

Page 18

A380 TECHNICAL TRAINING MANUAL

L

0

Y

0

6

0

8

2

-

L

0

D

T

0

T

0

-

L

M

2

6

C

1

L

E

V

E

L

0

3

0

1

Landing Gear Fire Detection

A/C Zone 124

A/C Zone 199

A/C Zone 143

A/C Zone 144

A/C Zone 145

A/C Zone 146

Engine Fire Detection

A/C ZONE 410

A/C Zone 412

A/C Zone 413

A/C Zone 451

A/C Zone 455

A/C Zone 420

A/C Zone 422

A/C Zone 423

A/C Zone 461

A/C Zone 465

A/C Zone 430

A/C Zone 432

A/C Zone 433

A/C Zone 471

A/C Zone 475

A/C Zone 440

A/C Zone 442

A/C Zone 443

A/C Zone 481

A/C Zone 485

A/C Zone 000

Engine Fire Extinguishing

A/C ZONE 450

A/C Zone 460

A/C Zone 470

A/C Zone 480

APU Fire Detection Components

A/C Zone 315

A/C Zone 152

APU Fire Extinguishing

A/C Zone 313

MAINTENANCE COURSE - T1 & T2 (RR / Metric)

LEVEL III - ATA 26 Fire & Smoke Detection

ENGINE, APU & MAIN LANDING GEAR FIRE PROTECTION

COMPONENT LOCATION (3)

Mar 17, 2006

Page 19

A380 TECHNICAL TRAINING MANUAL

L

0

Y

0

6

0

8

2

-

L

0

D

T

0

T

0

-

L

M

2

6

C

1

L

E

V

E

L

0

3

0

1

CABIN & CARGO COMPARTMENT FIRE PROTECTION DESCRIPTION (3)

General

In non-customized area, the smoke detection is done in the Cargo

compartment, Avionics compartment and Additional Electronic

Compartment.

The smoke detectors in this area, communicate over CAN buses with the

CIDS-SDF of the CIDS Directors.

In customized area, the smoke detection is done in the lavatory, in the

cabin Sub-compartment and in the crew rest compartment.

The smoke detectors in this area communicate over CAN buses with the

Decoder Encoder Units type B (DEU-B). The DEU-B are linked to the

CIDS Directors by Ethernet data buses.

A fire extinguishing system is installed in the cargo compartment, in the

crew rest compartment and in the lavatory.

The portable extinguisher bottle is installed in the cabin for fire

extinguishing in cabin, cabin sub-compartment and crew rest

compartment.

The FAP is the main user interface with the CIDS.

The CARGO SMOKE panel activates the cargo fire extinguishing.

MAINTENANCE COURSE - T1 & T2 (RR / Metric)

LEVEL III - ATA 26 Fire & Smoke Detection

CABIN & CARGO COMPARTMENT FIRE PROTECTION

DESCRIPTION (3)

Mar 17, 2006

Page 20

A380 TECHNICAL TRAINING MANUAL

L

0

Y

0

6

0

8

2

-

L

0

D

T

0

T

0

-

L

M

2

6

D

2

0

0

0

0

0

0

0

0

1

GENERAL

MAINTENANCE COURSE - T1 & T2 (RR / Metric)

LEVEL III - ATA 26 Fire & Smoke Detection

CABIN & CARGO COMPARTMENT FIRE PROTECTION

DESCRIPTION (3)

Mar 17, 2006

Page 21

A380 TECHNICAL TRAINING MANUAL

L

0

Y

0

6

0

8

2

-

L

0

D

T

0

T

0

-

L

M

2

6

D

2

0

0

0

0

0

0

0

0

1

CABIN & CARGO COMPARTMENT FIRE PROTECTION DESCRIPTION (3)

Smoke Detectors

In the pressurized area, there are two types of smoke detectors: the duct

type and the ambient type.

Duct type smoke detectors are installed in the Avionics compartment, in

the emergency compartment, in the IFE compartment and in the

Additional Electronic compartment.

Ambient type smoke detectors are installed in the cargo compartment,

in the lavatory, in the cabin sub-compartment and in the crew rest

compartment.

Duct Type Smoke Detector

The duct type smoke detector is installed on the air duct.

The photoelectric cell senses airborne combustion particles, transported

by the air ducted. This detector is installed housing with an air inlet

and air outlet.

Ambient Type Smoke Detector

This type of smoke detector is primarily used in monitored and closed

areas.

An optical cell senses obscuration resulting in presence of airborne

particles.

These airborne particles enter through the open housing.

Smoke Detector Description

These two types of smoke detector cells are based on the principle of

reverse scattered light.

Each detector includes a light source, a labyrinth and a photocell

arranged in a horizontal plane so that the photocell cannot receive

light.

But when there is smoke, the smoke particles reflect and diffuse part

of the light beam.

The smoke detector has two chambers:

-the reference chamber

-the measurement chamber.

The reference chamber manages the differential pressure and the

temperature differences and makes sure that the detectors operate on

ground and in flight with the same level of sensitivity.

The measurement chamber compares the analog voltage of the sensor

with the different levels of the threshold (fault, normal and smoke).

MAINTENANCE COURSE - T1 & T2 (RR / Metric)

LEVEL III - ATA 26 Fire & Smoke Detection

CABIN & CARGO COMPARTMENT FIRE PROTECTION

DESCRIPTION (3)

Mar 17, 2006

Page 22

A380 TECHNICAL TRAINING MANUAL

L

0

Y

0

6

0

8

2

-

L

0

D

T

0

T

0

-

L

M

2

6

D

2

0

0

0

0

0

0

0

0

1

SMOKE DETECTORS - DUCT TYPE SMOKE DETECTOR ... SMOKE DETECTOR DESCRIPTION

MAINTENANCE COURSE - T1 & T2 (RR / Metric)

LEVEL III - ATA 26 Fire & Smoke Detection

CABIN & CARGO COMPARTMENT FIRE PROTECTION

DESCRIPTION (3)

Mar 17, 2006

Page 23

A380 TECHNICAL TRAINING MANUAL

L

0

Y

0

6

0

8

2

-

L

0

D

T

0

T

0

-

L

M

2

6

D

2

0

0

0

0

0

0

0

0

1

CABIN & CARGO COMPARTMENT FIRE PROTECTION DESCRIPTION (3)

Smoke Detection Function (CIDS DIRECTOR)

The directors of the CIDS integrate a Smoke Detection Function (SDF),

which is an independent hardware part.

The CIDS-SDF is a segregated hard and software platform within the

ARINC 600 CIDS Director.

An AFDX interface gives the primary communication to other aircraft

systems.

The DEU-Bs are linked with the Directors by Ethernet data busses called

"Middle lines"

The DEU-B is a LRU, which operates like a remote data concentrator,

It manages and power supplies up to 8 smoke detectors.

A dedicated fault and alarm outputs as well as a reset input enable local

indication and control of smoke detection functions.

The FAP is the main user interface with the CIDS.

The sub-panel of the FAP has the SMOKE RESET functional areas to

reset the audio smoke alert.

The MINI-FAP has in basic pages the smoke detection item to visualize

the location of the detection and a SMOKE RESET hard key.

The Fire Extinguishing System (FES) panel is used to control and indicate

the fire extinguishing procedure.

It is installed in the stair house.

The FES panel is a human interface to command ignition of the fire

extinguishing bottle and give indications on the status of the fire

extinguishing.

The Fire Extinguishing Data Converter (FEDC) controls and monitors

the condition of each installed fire-extinguishing bottle and detects the

extinguishing agent pressure inside.

It operates on the principle of an interface translator between discrete

signals and CAN bus.

The FEDC is a remote data concentrator, monitoring the pressure switches

and the squib circuit of the Fire Extinguishing System.

It ignites all squibs of the agent bottle.

MAINTENANCE COURSE - T1 & T2 (RR / Metric)

LEVEL III - ATA 26 Fire & Smoke Detection

CABIN & CARGO COMPARTMENT FIRE PROTECTION

DESCRIPTION (3)

Mar 17, 2006

Page 24

A380 TECHNICAL TRAINING MANUAL

L

0

Y

0

6

0

8

2

-

L

0

D

T

0

T

0

-

L

M

2

6

D

2

0

0

0

0

0

0

0

0

1

SMOKE DETECTION FUNCTION (CIDS DIRECTOR)

MAINTENANCE COURSE - T1 & T2 (RR / Metric)

LEVEL III - ATA 26 Fire & Smoke Detection

CABIN & CARGO COMPARTMENT FIRE PROTECTION

DESCRIPTION (3)

Mar 17, 2006

Page 25

A380 TECHNICAL TRAINING MANUAL

L

0

Y

0

6

0

8

2

-

L

0

D

T

0

T

0

-

L

M

2

6

D

2

0

0

0

0

0

0

0

0

1

CABIN & CARGO COMPARTMENT FIRE PROTECTION DESCRIPTION (3)

Fire Extinguishing System

Cargo Fire Extinguishing

The cargo fire extinguishing system has three fire extinguishing bottles

located in the FWD cargo compartment connected to a flow metering

equipment and to a diverter valve.

Within the three fire extinguisher bottles, one is high rated, and the

two other are flow-metered.

The bottles, made of stainless steel, contain the fire-extinguishing

agent, halon 1301 and are hermetically sealed and refillable.

Each bottle has:

- a Temperature-Compensated Pressure Switch (TCPS),

- a fill and a safety relief valve.

Each discharge head has:

- an electrically operated cartridge,

Each cartridge has two squibs (squib A and squib B) receiving a

separate power supply (HOT BUS and DC BUS power).

When the electrical power supplies both squibs, the cartridge explodes

and ruptures the metal diaphragm in the discharge outlet.

Extinguishing agent flows through the discharge head into distribution

pipes.

The diverter valve has two outlets to direct the Halon via piping one

for the FWD and the other one for the AFT/BULK Cargo

Compartment.

Each outlet is sealed with a plug. A pyrotechnical cartridge opens it.

The Flow metering equipment regulates the outflow of the second

and the third bottle, maintaining the extinguishing agent concentration

to a minimal time of 240 minutes.

It includes a water absorbing filter element, a solid particle filter

element, a pressure switch, a pressure reducer, a restrictor and a check

valve.

Four nozzles are located in the FWD cargo compartment and five are

in the AFT/BULK cargo compartment.

There are installed on the ceiling in the same cavity and between the

two smoke detectors, and are protected by a metallic grid.

MAINTENANCE COURSE - T1 & T2 (RR / Metric)

LEVEL III - ATA 26 Fire & Smoke Detection

CABIN & CARGO COMPARTMENT FIRE PROTECTION

DESCRIPTION (3)

Mar 17, 2006

Page 26

A380 TECHNICAL TRAINING MANUAL

L

0

Y

0

6

0

8

2

-

L

0

D

T

0

T

0

-

L

M

2

6

D

2

0

0

0

0

0

0

0

0

1

FIRE EXTINGUISHING SYSTEM - CARGO FIRE EXTINGUISHING

MAINTENANCE COURSE - T1 & T2 (RR / Metric)

LEVEL III - ATA 26 Fire & Smoke Detection

CABIN & CARGO COMPARTMENT FIRE PROTECTION

DESCRIPTION (3)

Mar 17, 2006

Page 27

A380 TECHNICAL TRAINING MANUAL

L

0

Y

0

6

0

8

2

-

L

0

D

T

0

T

0

-

L

M

2

6

D

2

0

0

0

0

0

0

0

0

1

CABIN & CARGO COMPARTMENT FIRE PROTECTION DESCRIPTION (3)

Fire Extinguishing System (continued)

Lavatory Fire Extinguishing

A fire extinguisher bottle is installed above the waste bin in each

lavatory.

If a fire occurs in the waste bin, the fire extinguishing operates

automatically.

The lavatory fire extinguishers operate independently of other systems.

Each fire extinguisher has:

- a spherical container made of brass,

- an identification label bonded to the container with the following

information: part number, serial number, date of manufacture, type

of extinguisher agent, and total weight of the bottle.

- a fill port with a fill valve, to re-charge the container of extinguisher

agent,

- mounting bracket,

- a discharge tube with a fusible plug, which melts to let the agent

flowing into the waste bin when the temperature increases to

approximately 77C (170.60 Deg. F)

- a pressure gage, installed on the fill port indicates if the container is

charged or empty.

MAINTENANCE COURSE - T1 & T2 (RR / Metric)

LEVEL III - ATA 26 Fire & Smoke Detection

CABIN & CARGO COMPARTMENT FIRE PROTECTION

DESCRIPTION (3)

Mar 17, 2006

Page 28

A380 TECHNICAL TRAINING MANUAL

L

0

Y

0

6

0

8

2

-

L

0

D

T

0

T

0

-

L

M

2

6

D

2

0

0

0

0

0

0

0

0

1

FIRE EXTINGUISHING SYSTEM - LAVATORY FIRE EXTINGUISHING

MAINTENANCE COURSE - T1 & T2 (RR / Metric)

LEVEL III - ATA 26 Fire & Smoke Detection

CABIN & CARGO COMPARTMENT FIRE PROTECTION

DESCRIPTION (3)

Mar 17, 2006

Page 29

A380 TECHNICAL TRAINING MANUAL

L

0

Y

0

6

0

8

2

-

L

0

D

T

0

T

0

-

L

M

2

6

D

2

0

0

0

0

0

0

0

0

1

CABIN & CARGO COMPARTMENT FIRE PROTECTION DESCRIPTION (3)

Fire Extinguishing System (continued)

Cabin, Cabin Crew Rest Compartment Fire Extinguishing

In the Cabin, portable fire extinguisher bottles are installed.

This bottle contains the pressurized extinguisher agent, a bonded

information label gives the necessary information to operate and check

the extinguisher,

The operating head is an operating lever, with a carrying handle, a

valve assembly, a safety device, a nozzle and an indicator disc to

indicate the bottle pressure.

In the Cabin Crew Rest Compartment, if a fire is not controllable by

portable fire extinguisher and in case of any risk, the crew has to fight

the fire through the Fire Extinguishing System (FES).

The FES panel installed in the stair house activates and controls the

extinguishing system.

Two fire extinguishing bottles are located in the AFT lower deck

cargo compartment

Spray nozzles are located in the ceiling of the Cabin Crew Rest

compartment to spray the fire extinguishing agent in the compartment.

Flow metering equipment regulates the flow of the second bottle.

MAINTENANCE COURSE - T1 & T2 (RR / Metric)

LEVEL III - ATA 26 Fire & Smoke Detection

CABIN & CARGO COMPARTMENT FIRE PROTECTION

DESCRIPTION (3)

Mar 17, 2006

Page 30

A380 TECHNICAL TRAINING MANUAL

L

0

Y

0

6

0

8

2

-

L

0

D

T

0

T

0

-

L

M

2

6

D

2

0

0

0

0

0

0

0

0

1

FIRE EXTINGUISHING SYSTEM - CABIN, CABIN CREW REST COMPARTMENT FIRE EXTINGUISHING

MAINTENANCE COURSE - T1 & T2 (RR / Metric)

LEVEL III - ATA 26 Fire & Smoke Detection

CABIN & CARGO COMPARTMENT FIRE PROTECTION

DESCRIPTION (3)

Mar 17, 2006

Page 31

A380 TECHNICAL TRAINING MANUAL

L

0

Y

0

6

0

8

2

-

L

0

D

T

0

T

0

-

L

M

2

6

D

2

0

0

0

0

0

0

0

0

1

AVIONICS, CARGO COMPARTMENT, LAVATORY, CABIN & SUB-CABIN COMPARTMENT, FIRE

PROTECTION SYSTEM MAINTENANCE (3)

Smoke Detection Function Tests

The Smoke Detection Function (SDF) provides the following test:

- SDF Tests

- Reports

- Specific functions.

These tests are launched from the OMS HMI.

MAINTENANCE COURSE - T1 & T2 (RR / Metric)

LEVEL III - ATA 26 Fire & Smoke Detection

AVIONICS, CARGO COMPARTMENT, LAVATORY, CABIN &

SUB-CABIN COMPARTMENT, FIRE PROTECTION SYSTEM

MAINTENANCE (3)

Mar 17, 2006

Page 32

A380 TECHNICAL TRAINING MANUAL

L

0

Y

0

6

0

8

2

-

L

0

D

T

0

T

0

-

L

M

2

6

Y

2

M

A

I

N

T

0

0

0

1

SMOKE DETECTION FUNCTION TESTS

MAINTENANCE COURSE - T1 & T2 (RR / Metric)

LEVEL III - ATA 26 Fire & Smoke Detection

AVIONICS, CARGO COMPARTMENT, LAVATORY, CABIN &

SUB-CABIN COMPARTMENT, FIRE PROTECTION SYSTEM

MAINTENANCE (3)

Mar 17, 2006

Page 33

A380 TECHNICAL TRAINING MANUAL

L

0

Y

0

6

0

8

2

-

L

0

D

T

0

T

0

-

L

M

2

6

Y

2

M

A

I

N

T

0

0

0

1

AVIONICS, CARGO COMPARTMENT, LAVATORY, CABIN & SUB-CABIN COMPARTMENT, FIRE

PROTECTION SYSTEM MAINTENANCE (3)

SDF Menu

The SDF MENU page of the Onboard Maintenance System (OMS) gives

the following functions:

Tests:

. Smoke warn test

. Fire extinguishing tests

. Safety test

. System test

. Automatic safety test only for display purpose

Reports

. Status page for pin programming

. Smoke warnings report

. Automatic recoveries report

. HMI Report

Specific functions

. Time since last safety test

WARNING: BE CAREFUL WHEN YOU REMOVE OR INSTALL

THIS EQUIPMENT. THIS EQUIPMENT IS HEAVY

(MORE THAN 12 KG (26.5 lb)) AND CAUSE INJURY

AND/OR DAMAGE.

BE VERY CAREFUL WHEN YOU DO THIS

PROCEDURE. THE BOTTLE CAN FIRE

ACCIDENTALLY AND CAUSE IMPORTANT INJURY

TO PERSONS WHO ARE IN THE AREA ADJACENT

TO THE FIRE EXTINGUISHER BOTTLE.

MAKE SURE THAT THERE IS A GOOD FLOW OF AIR

THROUGH THE WORK AREA.

FUMES FROM A DISCHARGED FIRE EXTINGUISHER

BOTTLE CAN CAUSE INJURY TO PERSONS.

BE VERY CAREFUL WHEN YOU MOVE A FILLED

FIRE EXTINGUISHER BOTTLE. A HEAVY SHOCK

CAN CAUSE UNWANTED DISCHARGE AND INJURY

TO PERSONS.

MAKE SURE THAT THE SAFETY DEVICES AND THE

WARNING NOTICES ARE IN POSITION BEFORE YOU

START A TASK ON OR NEAR:

- THE FLIGHT CONTROLS

- THE FLIGHT CONTROL SURFACES

- THE LANDING GEAR AND RELATED DOORS

- COMPONENTS THAT MOVE.

MOVEMENT OF COMPONENTS CAN KILL OR CAUSE

INJURY TO PERSONS AND CAN CAUSE DAMAGE.

MAKE SURE THAT THE TRAVEL RANGES OF THE

FLIGHT CONTROL SURFACES ARE CLEAR.

MOVEMENT OF THE FLIGHT CONTROL SURFACES

CAN CAUSE INJURY TO PERSONS AND DAMAGE

TO THE AIRCRAFT OR EQUIPMENT.

MAINTENANCE COURSE - T1 & T2 (RR / Metric)

LEVEL III - ATA 26 Fire & Smoke Detection

AVIONICS, CARGO COMPARTMENT, LAVATORY, CABIN &

SUB-CABIN COMPARTMENT, FIRE PROTECTION SYSTEM

MAINTENANCE (3)

Mar 17, 2006

Page 34

A380 TECHNICAL TRAINING MANUAL

L

0

Y

0

6

0

8

2

-

L

0

D

T

0

T

0

-

L

M

2

6

Y

2

M

A

I

N

T

0

0

0

1

SDF MENU

MAINTENANCE COURSE - T1 & T2 (RR / Metric)

LEVEL III - ATA 26 Fire & Smoke Detection

AVIONICS, CARGO COMPARTMENT, LAVATORY, CABIN &

SUB-CABIN COMPARTMENT, FIRE PROTECTION SYSTEM

MAINTENANCE (3)

Mar 17, 2006

Page 35

A380 TECHNICAL TRAINING MANUAL

L

0

Y

0

6

0

8

2

-

L

0

D

T

0

T

0

-

L

M

2

6

Y

2

M

A

I

N

T

0

0

0

1

SMOKE PROTECTION COMPONENT LOCATION (3)

Avionics Bay Smoke Detection

A/C Zone 292

A/C Zone 120

A/C Zone 260

Cargo Bay Smoke Detection

A/C Zone 131

A/C Zone 132

A/C Zone 151

A/C Zone 152

A/C Zone 161

A/C Zone 162

Cargo Bay Fire Extinguishing

A/C Zone 131

Crew Rest Smoke Detection

A/C Zone 150

A/C Zone 222

Crew Rest Compartment Fire Extinguishing

A/C Zone 151

Portable Fire Extinguishing

A/C Zone 210

MAINTENANCE COURSE - T1 & T2 (RR / Metric)

LEVEL III - ATA 26 Fire & Smoke Detection

SMOKE PROTECTION COMPONENT LOCATION (3) Mar 17, 2006

Page 36

A380 TECHNICAL TRAINING MANUAL

L

0

Y

0

6

0

8

2

-

L

0

D

T

0

T

0

-

L

M

2

6

C

2

L

E

V

E

L

0

3

0

1

This Page Intentionally Left Blank

MAINTENANCE COURSE - T1 & T2 (RR / Metric)

LEVEL III - ATA 26 Fire & Smoke Detection

SMOKE PROTECTION COMPONENT LOCATION (3) Mar 17, 2006

Page 37

A380 TECHNICAL TRAINING MANUAL

L

0

Y

0

6

0

8

2

-

L

0

D

T

0

T

0

-

L

M

2

6

C

2

L

E

V

E

L

0

3

0

1

AIRBUS S.A.S.

31707 BLAGNAC cedex, FRANCE

STM

REFERENCE L0Y06082

MARCH 2006

PRINTED IN FRANCE

AIRBUS S.A.S. 2006

ALL RIGHTS RESERVED

AN EADS JOINT COMPANY

WITH BAE SYSTEMS

Вам также может понравиться

- A380-LEVEL II - ATA 26 Fire Protection SystemsДокумент52 страницыA380-LEVEL II - ATA 26 Fire Protection SystemsAbolfazl Mazloomi100% (6)

- A380-Level II - Ata 49 Apu SystemsДокумент36 страницA380-Level II - Ata 49 Apu SystemsAbolfazl Mazloomi100% (1)

- A380-Level I - Ata 33 LightsДокумент90 страницA380-Level I - Ata 33 LightsAbolfazl Mazloomi67% (3)

- A380-Level I - Ata 32 Landing GearДокумент50 страницA380-Level I - Ata 32 Landing GearAbolfazl Mazloomi100% (3)

- 33 LightsДокумент142 страницы33 Lightsfourj747100% (1)

- Level I - Ata 33 LightsДокумент90 страницLevel I - Ata 33 Lightswagdi100% (1)

- 36 PneumaticДокумент74 страницы36 Pneumaticfourj747100% (2)

- A380-LEVEL III - ATA 42 Integrated Modular Avionics - Avionics DaДокумент66 страницA380-LEVEL III - ATA 42 Integrated Modular Avionics - Avionics DaAbolfazl Mazloomi100% (11)

- LEVEL II - ATA 26 Fire Protection SystemsДокумент58 страницLEVEL II - ATA 26 Fire Protection SystemswagdiОценок пока нет

- A380-LEVEL III - ATA 50 Cargo - Accessory CompartmentsДокумент22 страницыA380-LEVEL III - ATA 50 Cargo - Accessory CompartmentsAbolfazl MazloomiОценок пока нет

- A380-LEVEL I - ATA 31 Indicating - Recording SystemsДокумент70 страницA380-LEVEL I - ATA 31 Indicating - Recording SystemsAbolfazl Mazloomi100% (1)

- A380-LEVEL I - ATA 50 Cargo - Accessory CompartmentsДокумент20 страницA380-LEVEL I - ATA 50 Cargo - Accessory CompartmentsAbolfazl MazloomiОценок пока нет

- A380-LEVEL I - ATA 30 Ice - Rain ProtectionДокумент44 страницыA380-LEVEL I - ATA 30 Ice - Rain ProtectionAbolfazl Mazloomi100% (5)

- A380-Level I - Ata 36 PneumaticДокумент26 страницA380-Level I - Ata 36 PneumaticAbolfazl Mazloomi100% (3)

- Level I - Ata 46 Nss & OisДокумент20 страницLevel I - Ata 46 Nss & OiswagdiОценок пока нет

- LEVEL I - ATA 28 FuelДокумент66 страницLEVEL I - ATA 28 Fuelwagdi100% (1)

- A380-Level I - Ata 44 Cabin SystemsДокумент42 страницыA380-Level I - Ata 44 Cabin SystemsAbolfazl Mazloomi100% (10)

- A380-LEVEL I - ATA 46 Network Server System - Onboard InformationДокумент20 страницA380-LEVEL I - ATA 46 Network Server System - Onboard InformationAbolfazl Mazloomi100% (6)

- A380-LEVEL III - ATA 46 Network Server System - Onboard InformatiДокумент52 страницыA380-LEVEL III - ATA 46 Network Server System - Onboard InformatiAbolfazl Mazloomi100% (11)

- 52 DoorsДокумент188 страниц52 DoorsJoe HoОценок пока нет

- A380-LEVEL I - ATA 25 Equipment - FurnishingsДокумент54 страницыA380-LEVEL I - ATA 25 Equipment - FurnishingsAbolfazl Mazloomi100% (1)

- A380-Level I - Ata 51 StructureДокумент10 страницA380-Level I - Ata 51 StructureAbolfazl MazloomiОценок пока нет

- LEVEL II - Aircraft VisitДокумент54 страницыLEVEL II - Aircraft Visitwagdi0% (1)

- A380-LEVEL I - ATA 23 CommunicationsДокумент50 страницA380-LEVEL I - ATA 23 CommunicationsAbolfazl Mazloomi100% (4)

- 49 Apu PDFДокумент68 страниц49 Apu PDFAaron Harvey50% (2)

- A380-Level III - Ata 38 Water - WasteДокумент40 страницA380-Level III - Ata 38 Water - WasteAbolfazl Mazloomi100% (2)

- A380-LEVEL I - ATA 27 Flight ControlsДокумент66 страницA380-LEVEL I - ATA 27 Flight ControlsAbolfazl Mazloomi86% (7)

- LEVEL III - ATA 45 Onboard Maintenance SystemДокумент186 страницLEVEL III - ATA 45 Onboard Maintenance Systemwagdi100% (3)

- Level II - Airbus DocumentationДокумент24 страницыLevel II - Airbus DocumentationwagdiОценок пока нет

- LEVEL III - ATA 23 CommunicationsДокумент50 страницLEVEL III - ATA 23 CommunicationswagdiОценок пока нет

- LEVEL I - ATA 27 Flight ControlsДокумент66 страницLEVEL I - ATA 27 Flight ControlswagdiОценок пока нет

- Level III - Ata 35 OxygenДокумент58 страницLevel III - Ata 35 Oxygenwagdi0% (1)

- Level II - Ata 36-21-30 Air SystemsДокумент88 страницLevel II - Ata 36-21-30 Air SystemswagdiОценок пока нет

- A380-Level II&III - Ata 29 Hydraulic PowerДокумент56 страницA380-Level II&III - Ata 29 Hydraulic Powerfiretooth10Оценок пока нет

- ATA 44 Cabin Systems PDFДокумент26 страницATA 44 Cabin Systems PDFGoitom Teclai100% (3)

- LEVEL I - ATA 50 Cargo & Accessory CompartmentsДокумент20 страницLEVEL I - ATA 50 Cargo & Accessory Compartmentswagdi100% (1)

- LEVEL II - ATA 27 Flight ControlsДокумент36 страницLEVEL II - ATA 27 Flight ControlswagdiОценок пока нет

- Level III - Ata 49 ApuДокумент60 страницLevel III - Ata 49 Apuwagdi100% (2)

- A330 Ice and Rain ProtectionДокумент54 страницыA330 Ice and Rain ProtectionPratap Reddy75% (4)

- A330/340E Indicating/Recording Systems: Lufthansa Technical TrainingДокумент54 страницыA330/340E Indicating/Recording Systems: Lufthansa Technical TrainingMark McKinsnkeyОценок пока нет

- Level III - Ata 38 Water - WasteДокумент40 страницLevel III - Ata 38 Water - WastewagdiОценок пока нет

- Level III - Ata 44 Cabin SystemsДокумент100 страницLevel III - Ata 44 Cabin Systemswagdi100% (1)

- A318-21 32 B12 1sep2014Документ262 страницыA318-21 32 B12 1sep2014Quynh Nguyen100% (1)

- A380-LEVEL I - ATA 21 Air ConditioningДокумент62 страницыA380-LEVEL I - ATA 21 Air ConditioningAbolfazl Mazloomi100% (10)

- 49 Apu PDFДокумент110 страниц49 Apu PDFyogaga100% (2)

- Level III - Ata 52 DoorsДокумент72 страницыLevel III - Ata 52 Doorswagdi100% (1)

- A330 Aircraft General l2 eДокумент75 страницA330 Aircraft General l2 eaerologik100% (8)

- A380 - Level I - Ata 28 FuelДокумент84 страницыA380 - Level I - Ata 28 FuelSantty JamiОценок пока нет

- Undercowl Pocket Guide RRДокумент32 страницыUndercowl Pocket Guide RRbnmmauricio100% (3)

- Level I - Ata 44 Cabin SystemsДокумент42 страницыLevel I - Ata 44 Cabin Systemswagdi67% (3)

- LEVEL III - ATA 25 Equipment - FurnishingДокумент72 страницыLEVEL III - ATA 25 Equipment - Furnishingwagdi0% (1)

- 01 General Level 2 & 3Документ60 страниц01 General Level 2 & 3MugilanОценок пока нет

- LEVEL I - ATA 29 Hydraulic PowerДокумент24 страницыLEVEL I - ATA 29 Hydraulic PowerwagdiОценок пока нет

- Ata 49 ApuДокумент77 страницAta 49 ApuSohaib Aslam Chaudhary100% (1)

- LEVEL I - ATA 31 Indicating - Recording SystemsДокумент70 страницLEVEL I - ATA 31 Indicating - Recording SystemswagdiОценок пока нет

- A330-200 Flight ControlsДокумент20 страницA330-200 Flight ControlsTarik BenzinebОценок пока нет

- LEVEL III - ATA 26 Fire & Smoke DetectionДокумент42 страницыLEVEL III - ATA 26 Fire & Smoke Detectionwagdi100% (1)

- 26 Fire ProtectionДокумент82 страницы26 Fire Protectionfourj747Оценок пока нет

- 26 Fire Protection-A330FДокумент26 страниц26 Fire Protection-A330Fpratt777Оценок пока нет

- Airbus 26 A300 A310 Fire ProtectionДокумент110 страницAirbus 26 A300 A310 Fire ProtectionElijah Paul Merto100% (1)

- A380-LEVEL III - ATA 50 Cargo - Accessory CompartmentsДокумент22 страницыA380-LEVEL III - ATA 50 Cargo - Accessory CompartmentsAbolfazl MazloomiОценок пока нет

- A380-Level III - Ata 38 Water - WasteДокумент40 страницA380-Level III - Ata 38 Water - WasteAbolfazl Mazloomi100% (2)

- A380-LEVEL III - ATA 42 Integrated Modular Avionics - Avionics DaДокумент66 страницA380-LEVEL III - ATA 42 Integrated Modular Avionics - Avionics DaAbolfazl Mazloomi100% (11)

- A380-Level II&III - Ata 29 Hydraulic PowerДокумент56 страницA380-Level II&III - Ata 29 Hydraulic Powerfiretooth10Оценок пока нет

- A380-LEVEL III - ATA 46 Network Server System - Onboard InformatiДокумент52 страницыA380-LEVEL III - ATA 46 Network Server System - Onboard InformatiAbolfazl Mazloomi100% (11)

- A380-Level I - Ata 44 Cabin SystemsДокумент42 страницыA380-Level I - Ata 44 Cabin SystemsAbolfazl Mazloomi100% (10)

- A380-Level II - Ata 29 Hydraulic PowerДокумент54 страницыA380-Level II - Ata 29 Hydraulic PowerAbolfazl Mazloomi100% (2)

- A380-LEVEL I - ATA 50 Cargo - Accessory CompartmentsДокумент20 страницA380-LEVEL I - ATA 50 Cargo - Accessory CompartmentsAbolfazl MazloomiОценок пока нет

- A380-Level I - Ata 51 StructureДокумент10 страницA380-Level I - Ata 51 StructureAbolfazl MazloomiОценок пока нет

- A380-LEVEL I - ATA 23 CommunicationsДокумент50 страницA380-LEVEL I - ATA 23 CommunicationsAbolfazl Mazloomi100% (4)

- A380-Level II - Ata 27 Flight ControlsДокумент36 страницA380-Level II - Ata 27 Flight ControlsAbolfazl Mazloomi100% (1)

- A380-LEVEL I - ATA 46 Network Server System - Onboard InformationДокумент20 страницA380-LEVEL I - ATA 46 Network Server System - Onboard InformationAbolfazl Mazloomi100% (6)

- A380-LEVEL I - ATA 27 Flight ControlsДокумент66 страницA380-LEVEL I - ATA 27 Flight ControlsAbolfazl Mazloomi86% (7)

- A380-Level I - Ata 36 PneumaticДокумент26 страницA380-Level I - Ata 36 PneumaticAbolfazl Mazloomi100% (3)

- A380-LEVEL I - ATA 42 Integrated Modular Avionics - Avionics DataДокумент20 страницA380-LEVEL I - ATA 42 Integrated Modular Avionics - Avionics DataAbolfazl Mazloomi78% (9)

- A380-LEVEL I - ATA 30 Ice - Rain ProtectionДокумент44 страницыA380-LEVEL I - ATA 30 Ice - Rain ProtectionAbolfazl Mazloomi100% (5)

- A380-LEVEL I - ATA 31 Indicating - Recording SystemsДокумент70 страницA380-LEVEL I - ATA 31 Indicating - Recording SystemsAbolfazl Mazloomi100% (1)

- A380-LEVEL I - ATA 25 Equipment - FurnishingsДокумент54 страницыA380-LEVEL I - ATA 25 Equipment - FurnishingsAbolfazl Mazloomi100% (1)

- A380-LEVEL I - ATA 24 Electrical PowerДокумент62 страницыA380-LEVEL I - ATA 24 Electrical PowerAbolfazl Mazloomi82% (11)

- A380 - Level I - Ata 28 FuelДокумент84 страницыA380 - Level I - Ata 28 FuelSantty JamiОценок пока нет

- A380-LEVEL I - ATA 21 Air ConditioningДокумент62 страницыA380-LEVEL I - ATA 21 Air ConditioningAbolfazl Mazloomi100% (10)

- Ieee 05486259Документ6 страницIeee 05486259Abolfazl MazloomiОценок пока нет

- Civil Aircraft Advacned Avionics Architectures - Shri. C.M. AnandaДокумент23 страницыCivil Aircraft Advacned Avionics Architectures - Shri. C.M. AnandaKeerthiPratheek ReddyОценок пока нет

- Aircraft Radio Systems - James Powell - 1981Документ260 страницAircraft Radio Systems - James Powell - 1981Abolfazl Mazloomi100% (18)

- 6th Central Pay Commission Salary CalculatorДокумент15 страниц6th Central Pay Commission Salary Calculatorrakhonde100% (436)

- Advances in Agronomy v.84Документ333 страницыAdvances in Agronomy v.84luisiunesОценок пока нет

- "Hiv and Aids Awareness of Junior and Senior High School Students" Part I: Profile of RespondentsДокумент1 страница"Hiv and Aids Awareness of Junior and Senior High School Students" Part I: Profile of RespondentsDahl xxОценок пока нет

- CGMP Training ToolДокумент21 страницаCGMP Training Toolbabusure99Оценок пока нет

- Iso 2281 1990Документ8 страницIso 2281 1990jesus torresОценок пока нет

- Biology Lab ReportДокумент5 страницBiology Lab Reportapi-2576094460% (1)

- Reading TOEFL - Short Reading Per Question TypeДокумент25 страницReading TOEFL - Short Reading Per Question Typejax7202Оценок пока нет

- Labor EstimateДокумент26 страницLabor EstimateAngelica CabreraОценок пока нет

- Mrunal Handout 12 CSP20Документ84 страницыMrunal Handout 12 CSP20SREEKANTHОценок пока нет

- Infographic Humanistic PsychologyДокумент2 страницыInfographic Humanistic Psychologyvivain.honnalli.officialОценок пока нет

- De Thi Chon HSGДокумент10 страницDe Thi Chon HSGKiều TrangОценок пока нет

- Building Technology (CE1303) : Window: Lecturer: Madam FatinДокумент19 страницBuilding Technology (CE1303) : Window: Lecturer: Madam FatinRazif AjibОценок пока нет

- Open Courses Myanmar Strategic English Week 4: U Yan Naing Se NyuntДокумент24 страницыOpen Courses Myanmar Strategic English Week 4: U Yan Naing Se NyuntYan Naing Soe NyuntОценок пока нет

- 13 Methods To Increase Your Conditioning - Strength by SkylerДокумент5 страниц13 Methods To Increase Your Conditioning - Strength by SkylerMarko Štambuk100% (1)

- Powador 7700 - 7900 8600 - 9600: OriginalДокумент52 страницыPowador 7700 - 7900 8600 - 9600: Originalashraf-84Оценок пока нет

- Section-A: Terrace Ramp To Basement BalconiesДокумент4 страницыSection-A: Terrace Ramp To Basement BalconiesRitikaОценок пока нет

- Keandalan Bangunan Rumah SusunДокумент9 страницKeandalan Bangunan Rumah SusunDewi ARimbiОценок пока нет

- Damasco - Cpi - Activity No. 10Документ18 страницDamasco - Cpi - Activity No. 10LDCU - Damasco, Erge Iris M.Оценок пока нет

- Cough: A Rapid Expulsion of Air FromДокумент2 страницыCough: A Rapid Expulsion of Air FromaubyangОценок пока нет

- MLT IMLT Content Guideline 6-14Документ4 страницыMLT IMLT Content Guideline 6-14Arif ShaikhОценок пока нет

- Strict and Absolute LiabilityДокумент29 страницStrict and Absolute LiabilityShejal SharmaОценок пока нет

- Design and Fabrication of Floor Cleaning Machine - A ReviewДокумент4 страницыDesign and Fabrication of Floor Cleaning Machine - A ReviewIJIERT-International Journal of Innovations in Engineering Research and Technology100% (1)

- Choke Manifold Procedures 3932324 01Документ4 страницыChoke Manifold Procedures 3932324 01Saïd Ben Abdallah100% (1)

- MN - 2019 01 29Документ28 страницMN - 2019 01 29mooraboolОценок пока нет

- Fitness Program: Save On Health Club Memberships, Exercise Equipment and More!Документ1 страницаFitness Program: Save On Health Club Memberships, Exercise Equipment and More!KALAI TIFYОценок пока нет

- Electronic Fetal MonitoringДокумент4 страницыElectronic Fetal MonitoringMauZungОценок пока нет

- Full Download Small Animal Care and Management 4th Edition Warren Test BankДокумент35 страницFull Download Small Animal Care and Management 4th Edition Warren Test Bankkrzyszhugvik6100% (20)

- Saa6d107e 1CC S N 26540705 Up - Parts Book Do Motor GD655-5Документ164 страницыSaa6d107e 1CC S N 26540705 Up - Parts Book Do Motor GD655-5kit101Оценок пока нет

- Mock Test MCQ 2017Документ18 страницMock Test MCQ 2017Alisha ChopraОценок пока нет

- How To Defend The Faith Without Raising Your VoiceДокумент139 страницHow To Defend The Faith Without Raising Your VoiceCleber De Souza Cunha100% (2)

- Unit 5.4 - Incapacity As A Ground For DismissalДокумент15 страницUnit 5.4 - Incapacity As A Ground For DismissalDylan BanksОценок пока нет