Академический Документы

Профессиональный Документы

Культура Документы

Analyst Check List

Загружено:

jsmnjasminesАвторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Analyst Check List

Загружено:

jsmnjasminesАвторское право:

Доступные форматы

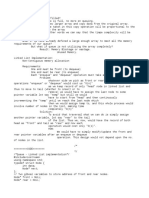

ANALYST CHECK LIST, GLOBAL ANALYSIS

Revision:

ANALYST CHECK LIST, GLOBAL ANALYSIS

STRESS CALC. NUMBER:

SYSTEM DESCRIPTION:

Revision

Used Chkd

ID REFERENCE DESCRIPTION

COMPUTER INPUT DATA

Piping Code Is correct piping code (B31.3, B31.4, B31.8, EN13480 etc) used?

Numbering Is the calculation number correct and according to project procedure?

Units Are correct units ?

Pipe Spec Is the correct pipe spec (diameter, thickness, material properties, corrosion allowance,

fabrication tolerances, weld joint factor etc)?

Fluid Is the density of internal fluid correct or conservative?

Pressure Correct pressures (design, operating, hydro test)?

Temperature Correct temp (installation, ambient, operating, high & low design)?

Insulation Insulation density and thickness?

Weights Correct weight of flanges, bolts, valves and valve actuators?

Equipment

Are the locations of fixed and sliding supports correctly modelled?

Are nozzle movements due to temperature, live-and dead loads applied?

Is nozzle to shell flexibility correctly applied, if ?

Acceleration Earthquake, Wave-induced, Lifting, Landing, directions?

Deflection Structural Deflections (Live load, Lifting, SAG/HOG etc) ?

Blast Is the drag pressure, structural deflections, Cd, and DLF correct? ?

Wind Is the wind speed, relevant directions and Cd coefficient correct? ?

Reaction Forces Typical: PSV relief, Bursting Disc, Flare Ignition, Fluid Hammer,

Surge,

Slugs, adequate use of dynamic load factors, DLF?

Dynamic Analysis Unrealistic results are ca by springs, gaps, friction, no guides, no

added mass from seawater, etc. ?

Load cases Relevant combination of load cases including code req. ?

3D Model Geometry Coordinates and pipe routing according to ISO drawing? ?

Restraints/supports?

Are functions according to stress isometrics or pipe support drawing? ?

Are the restraints modelled realistically (gaps, stiffness, friction, etc.)? ?

Fatigue Are fatigue cycles and stress range input realistic (ref. PD 5500)? ?

CALCULATIONS AND OUTPUT

FEA Calculation output

Have all relevant load-cases been analysed? Are combinations of loadcases ?

realistic?

Are deflections and loads at restraints and equipment nozzles OK? ?

Are strains and stresses calculated within code allowed and is the allowable?

stress correct according to the piping code ? Have SIFs and?

SCFs been included according to code requirements? ?

Are results from fatigue and dynamic analysis realistic and conservative? ?

Stress Iso Drawing Check tables with input data & output results. Data nodes, pipe-

supports,

weights, boundary conditions, references and notes. Signed the drawing.

Hand calculations to be

included in the Pipe Stress?

Report Appendices

Have thrust-load calculations as input for FEA been reviewed and

filed? ?

Have stress calculations of special components, flange leakage calculations and fatigue

calculations been performed? ?

Special vendor info such as reaction loads from PSV and flare tip filed?

Use of Checklist: Y=Yes, N=No, OK=OK NA= Not Applicable, NC= Not Checke

Analysis by: Date:

Checked by: Date

Вам также может понравиться

- Company Policy TemplateДокумент4 страницыCompany Policy TemplatejsmnjasminesОценок пока нет

- Fea 7 Fem ConceptsДокумент104 страницыFea 7 Fem Conceptsjsmnjasmines100% (1)

- Metric1807 1808Документ1 страницаMetric1807 1808jsmnjasminesОценок пока нет

- Case Study UberДокумент2 страницыCase Study UberjsmnjasminesОценок пока нет

- Reliance CaseДокумент3 страницыReliance CaseAshok ChoudharyОценок пока нет

- Health and Safety Manual SampleДокумент20 страницHealth and Safety Manual Samplefaluda1973Оценок пока нет

- 10 Quadratic Equations-1Документ8 страниц10 Quadratic Equations-1Jonie Quintal MatienzoОценок пока нет

- Applications of Computational Fluid DynamicsДокумент7 страницApplications of Computational Fluid DynamicsjsmnjasminesОценок пока нет

- Technology Training & Research Centre Recruitment Drive For Airframe Aerodesigns PVT LTD Objective Questionnaire. Set 1Документ1 страницаTechnology Training & Research Centre Recruitment Drive For Airframe Aerodesigns PVT LTD Objective Questionnaire. Set 1jsmnjasminesОценок пока нет

- C 2 Tutorial BДокумент4 страницыC 2 Tutorial BjsmnjasminesОценок пока нет

- 1Документ14 страниц1jsmnjasmines100% (1)

- Answers Key: SET 1: 1.B 2.B 3.B 4.A 5.BДокумент2 страницыAnswers Key: SET 1: 1.B 2.B 3.B 4.A 5.BjsmnjasminesОценок пока нет

- Balykina GalinaДокумент8 страницBalykina GalinajsmnjasminesОценок пока нет

- Automation With APDLДокумент40 страницAutomation With APDLjsmnjasminesОценок пока нет

- Raci Matrix Template Aaplmajestic JV For TTRCДокумент3 страницыRaci Matrix Template Aaplmajestic JV For TTRCjsmnjasminesОценок пока нет

- 100 Dia Pre ChecklistДокумент2 страницы100 Dia Pre ChecklistjsmnjasminesОценок пока нет

- CAEA v14 Update Part1 Struct Demos 0Документ135 страницCAEA v14 Update Part1 Struct Demos 0joejo_s_hotmailОценок пока нет

- Assembly Mdli Modeling Elearning: Peter Barrett November 2012Документ16 страницAssembly Mdli Modeling Elearning: Peter Barrett November 2012jsmnjasminesОценок пока нет

- Redbus Online Ticket ModelДокумент1 страницаRedbus Online Ticket Modelranju93100% (1)

- CAEA v145 Update CFDДокумент39 страницCAEA v145 Update CFDAnonymous ETBwIduGiОценок пока нет

- CAEA Fracture MechanicsДокумент13 страницCAEA Fracture MechanicsjsmnjasminesОценок пока нет

- AAPL Capability StatementДокумент41 страницаAAPL Capability StatementjsmnjasminesОценок пока нет

- SL - No Type Course Title Description Duration Next Batch - Last Date FeesДокумент1 страницаSL - No Type Course Title Description Duration Next Batch - Last Date FeesjsmnjasminesОценок пока нет

- Dr. I Ramesh Mithanthaya: 1. Prof. / Vice Principal / Dean (Academics) / Chief Project LeaderДокумент7 страницDr. I Ramesh Mithanthaya: 1. Prof. / Vice Principal / Dean (Academics) / Chief Project LeaderjsmnjasminesОценок пока нет

- Adventure Works Adventure Works: S B S ! S B S !Документ1 страницаAdventure Works Adventure Works: S B S ! S B S !jsmnjasminesОценок пока нет

- Design of Compression MemberДокумент29 страницDesign of Compression MemberFerry Triyana AnirunОценок пока нет

- Erecting Altering Dismantling Scaffolding Prefabricated Steel Modular Scaffolding Industry Safety Standard 2373Документ32 страницыErecting Altering Dismantling Scaffolding Prefabricated Steel Modular Scaffolding Industry Safety Standard 2373madhav0303Оценок пока нет

- Scaffolding WorkДокумент56 страницScaffolding Workjsmnjasmines100% (1)

- (Business Name) : We Have Your Landscape Needs CoveredДокумент1 страница(Business Name) : We Have Your Landscape Needs CoveredjsmnjasminesОценок пока нет

- GPLДокумент5 страницGPLAjay DevОценок пока нет

- The Yellow House: A Memoir (2019 National Book Award Winner)От EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Рейтинг: 4 из 5 звезд4/5 (98)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceОт EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceРейтинг: 4 из 5 звезд4/5 (895)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeОт EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeРейтинг: 4 из 5 звезд4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingОт EverandThe Little Book of Hygge: Danish Secrets to Happy LivingРейтинг: 3.5 из 5 звезд3.5/5 (400)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaОт EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaРейтинг: 4.5 из 5 звезд4.5/5 (266)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureОт EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureРейтинг: 4.5 из 5 звезд4.5/5 (474)

- Never Split the Difference: Negotiating As If Your Life Depended On ItОт EverandNever Split the Difference: Negotiating As If Your Life Depended On ItРейтинг: 4.5 из 5 звезд4.5/5 (838)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryОт EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryРейтинг: 3.5 из 5 звезд3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerОт EverandThe Emperor of All Maladies: A Biography of CancerРейтинг: 4.5 из 5 звезд4.5/5 (271)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyОт EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyРейтинг: 3.5 из 5 звезд3.5/5 (2259)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersОт EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersРейтинг: 4.5 из 5 звезд4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnОт EverandTeam of Rivals: The Political Genius of Abraham LincolnРейтинг: 4.5 из 5 звезд4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaОт EverandThe Unwinding: An Inner History of the New AmericaРейтинг: 4 из 5 звезд4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreОт EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreРейтинг: 4 из 5 звезд4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)От EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Рейтинг: 4.5 из 5 звезд4.5/5 (121)

- Lesson 2. WHAT IS AGROTECHNOPRENEURSHIPДокумент23 страницыLesson 2. WHAT IS AGROTECHNOPRENEURSHIPRhea Jane DugadugaОценок пока нет

- Quiz 1 - Domain Modeling With Answer KeyДокумент5 страницQuiz 1 - Domain Modeling With Answer Keyprincess100267% (3)

- BEVERAGE SERVICE INDUSTRY Lesson 1Документ18 страницBEVERAGE SERVICE INDUSTRY Lesson 1milyn maramagОценок пока нет

- Violence Against NursesДокумент22 страницыViolence Against NursesQuality Assurance Officer Total Quality ManagementОценок пока нет

- Accounting QuestionsДокумент16 страницAccounting QuestionsPrachi ChananaОценок пока нет

- 03 CTAL TM Sample ISTQB Questions - v2.04Документ35 страниц03 CTAL TM Sample ISTQB Questions - v2.04CorniciucOanaОценок пока нет

- ''Adhibeo'' in LatinДокумент5 страниц''Adhibeo'' in LatinThriw100% (1)

- TSD OSD Portal Quick Start Guide V1.0Документ5 страницTSD OSD Portal Quick Start Guide V1.0sijovow282Оценок пока нет

- Economics: PAPER 1 Multiple ChoiceДокумент12 страницEconomics: PAPER 1 Multiple ChoiceigcsepapersОценок пока нет

- STB9NK60Z, STP9NK60Z, STP9NK60ZFPДокумент19 страницSTB9NK60Z, STP9NK60Z, STP9NK60ZFPyokonakagimaОценок пока нет

- Thoughts On Iphone Demand - Update On Delivery Times, Carrier IncentivesДокумент10 страницThoughts On Iphone Demand - Update On Delivery Times, Carrier Incentivesalpha123@tutopiaОценок пока нет

- Job Schedule Sheet: 'Lead Time Monitoring GraphДокумент48 страницJob Schedule Sheet: 'Lead Time Monitoring GraphEndraОценок пока нет

- GSM Controlled RobotДокумент33 страницыGSM Controlled RobotAbhishek KunalОценок пока нет

- Ahi Evran Sunum enДокумент26 страницAhi Evran Sunum endenizakbayОценок пока нет

- City of London SWM Guidelines 2Документ22 страницыCity of London SWM Guidelines 2Dotan NutodОценок пока нет

- Queue Using Linked ListДокумент2 страницыQueue Using Linked ListHassan ZiaОценок пока нет

- Debugging With The PL/SQL Debugger: PhilippДокумент51 страницаDebugging With The PL/SQL Debugger: PhilippBenjytox BenjytoxОценок пока нет

- Assy Conveyor 4 MTR (2 Unit) : Part Number Description Qty. Item NOДокумент11 страницAssy Conveyor 4 MTR (2 Unit) : Part Number Description Qty. Item NOFaiz Qilafa ZimamОценок пока нет

- Fault Tree AnalysisДокумент23 страницыFault Tree Analysiskenoly123Оценок пока нет

- Kumara SwamiyamДокумент21 страницаKumara SwamiyamVijey KumarОценок пока нет

- COURT CLERK NoticeДокумент10 страницCOURT CLERK NoticeED Curtis100% (3)

- Evaporative Cooling Design Spreadsheet 2014 - MetricДокумент1 страницаEvaporative Cooling Design Spreadsheet 2014 - MetricCristian MoratayaОценок пока нет

- 20-21 Ipads Shopping GuideДокумент1 страница20-21 Ipads Shopping Guideapi-348013334Оценок пока нет

- Soal PAS-UAS Bahasa Inggris Kelas 11 SMAДокумент10 страницSoal PAS-UAS Bahasa Inggris Kelas 11 SMAAlexander TristanОценок пока нет

- Optimizing The Office.: Transforming Business ProcessesДокумент10 страницOptimizing The Office.: Transforming Business ProcessesNOSHEEN MEHFOOZОценок пока нет

- Civil Procedure Flash CardsДокумент48 страницCivil Procedure Flash CardsNick Ashjian100% (1)

- Acctg 14 - MidtermДокумент5 страницAcctg 14 - MidtermRannah Raymundo100% (1)

- Tan vs. CincoДокумент2 страницыTan vs. CincoKing Badong67% (3)

- BSM - Company ProfileДокумент15 страницBSM - Company ProfileLarasanto Cipta AgungОценок пока нет

- HboДокумент126 страницHboKunal ChaudhryОценок пока нет