Академический Документы

Профессиональный Документы

Культура Документы

Turn G

Загружено:

Enrique Elias Peñaloza GutierrezОригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Turn G

Загружено:

Enrique Elias Peñaloza GutierrezАвторское право:

Доступные форматы

G 1

T a b l e o f c o n t e n t s

HIGH SPEED STEEL TOOLS

Sandvik Corona tool bits and toolholders

Tool bits

Parting blades

Toolholders

Spare parts

Cutting data

Technical information

G 2

G 4

G 5

G 6

G 6

G 7

G

G1-G8 2-05-16 17.05 Sida G 1

G

Example (metric size):

G 2

HIGH SPEED STEEL TOOLS Sandvik Corona

TB S4 63

Ordering example: 100 pieces TB S4 63 C45

TB S

ISO 5421-1977

Metric sizes

Inch sizes

Ordering

code

Ordering

code

Ordering

code

Ordering

code

Ordering

code

No./

package

No./

package

No./

package

No./

package

No./

package

Grades

Grades

Grades Grades

Grades

s; iW l

2

s; iW l

2

C

4

5

C

6

0

C

4

5

C

6

0

C

4

5

C

6

0

C

4

5

C

6

0

C

4

5

C

6

0

Sandvik Corona high speed steel tool bits complement cemented carbide in operations where cutting

speeds or edge profiles are not suitable for hard tool materials. HSS tool bits are a suitable alternative

because they are:

extremely tough tool material; work well at low

cutting speeds and in intermittent cuts.

regrindable; a large number of cutting edges can be

produced on same tool.

easy to grind into sharp, positive edges; useful for small

component manufactures

possible to ground cutting edge profiles as required and

easily adaptable to a very wide range of customer

needs.

Grades

Grade C45 should always be first choice with C60 as an

alternative when high wear resistance is required.

Standard:

(h13)

(h13)

Square tool bits

TB S4 63 10

TB S5 63 10

TB S6 63 10

6 100 10

6 160 10

6 200 10

TB S7 200 10

TB S8 63 10

8 80 10

8 100 10

8 160 10

8 200 10

TB S10 63 10

10 100 10

10 125 10

10 160 10

10 200 10

TB S12 63 10

12 100 10

12 160 10

12 200 10

TB S14 100 5

14 160 5

14 200 5

TB S16 100 5

16 125 5

16 160 5

16 200 5

TB S18 200 3

TB S20 160 3

20 200 3

TB S25 160 2

25 200 2

TB S

3

/16 2

1

/2 10 4,76 63,5

3

/16 4 10 4,76 101,6

TB S

1

/4 2

1

/2 10 6,35 63,5

1

/4 4 10 6,35 101,6

1

/4 8 10 6,35 203,2

TB S

5

/16 2

1

/2 10 7,94 63,5

5

/16 3 10 7,94 76,2

5

/16 4 10 7,94 101,6

5

/16 8 10 7,94 203,2

TB S

3

/8 3 10 9,53 76,2

3

/8 4 10 9,53 101,6

3

/8 6 10 9,53 152,4

3

/8 8 10 9,53 203,2

TB S

7

/16 3

1

/2 10 11,11 76,2

TB S

1

/2 4 10 12,70 101,6

1

/2 6 10 12,70 152,4

1

/2 8 10 12,70 203,2

TB S

5

/8 4

1

/2 5 15,88 114,3

5

/8 6 5 15,88 152,4

TB S

3

/4 5 3 19,05 127,0

3

/4 6 3 19,05 152,4

TB S 1 8 2 25,40 203,2

P M K

Material

First choice

Grade recommendations

Complementary

C45 C45 C45

C60 C60 C60

l

2

= length

s = thickness

iW = width

S = square

G 6 G 7

Cutting data Technical information

G1-G8 2002-03-13 16.12 Sida G 2

G

TB F12 3 90

l

2

= length

s = thickness

iW = width

F = flat

l

2

= length

iC= diameter

R = round

TB F

Ordering example: 100 pieces TB R3 100 C45

Ordering example: 100 pieces TB F12 3 90 C45

ISO 5421-1977

Ordering

code

Ordering

code

No./

package

No./

package

No./

package

No./

package

Grades Grades Grades

Grades

Grades

No./

package

No./

package

No./

package

No./

package

Ordering

code

Ordering

code

Ordering

code

Ordering

code

Ordering

code

Grades

Grades

iC l

2 iC l

2

C

4

5

C

6

0

C

4

5

C

6

0

C

4

5

C

6

0

C

4

5

C

6

0

C

4

5

C

6

0

Inch sizes

Metric sizes

TB R3 100

Example (metric size):

Example (metric size):

C

4

5

C

6

0

C

4

5

C

6

0

Standard:

ISO 5421-1977

Standard:

Rectangular tool bits, metric sizes

TB R

Round tool bits, metric and inch sizes

Ordering

code

Metric sizes

(h13)

TB R3 x 100 10

TB R4 x 40 10

4 x 80 10

4 x 100 10

TB R5 x 100 10

5 x 160 10

TB R6 x 63 10

6 x 80 10

6 x 100 10

6 x 160 10

TB R8 x 100 10

8 x 160 10

8 x 200 10

TB R10 x 100 10

10 x 160 10

10 x 200 10

TB R12 x 100 10

12 x 160 10

12 x 200 10

TB R14 x 100 5

14 x 160 5

14 x 200 5

TB R15 x 100 5

TB R16 x 100 5

16 x 160 5

16 x 200 5

TB R18 x 100 3

18 x 160 3

18 x 200 3

TB R20 x 100 3

20 x 200 3

TB R

1

/8 4 10 3,18 101,6

TB R

3

/16 4 10 4,76 101,6

TB R

1

/4 4 10 6,35 101,6

TB R

5

/16 4 10 7,94 101,6

TB R

3

/8 4 10 9,53 101,6

TB R

3

/8 6 10 9,53 152,4

TB R

1

/2 4 10 12,70 101,6

P M K

Material

First choice

Grade recommendations

Complementary

C45 C45 C45

C60 C60 C60

P M K

Material

First choice

Grade recommendations

Complementary

C45 C45 C45

C60 C60 C60

(h9)

G 3

Sandvik Corona HIGH SPEED STEEL TOOLS

Grades

C

4

5

C

6

0

G 6 G 7

Cutting data Technical information

TB F 12 3 90 10

12 3 200 10

TB F10 4 100 10

10 4 120 10

10 4 200 10

16 4 160 10

16 4 200 10

20 4 200 10

TB F12 5 90 10

18 5 200 10

20 5 200 10

TB F8 6 70 10

10 6 200 10

12 6 200 10

14 6 140 10

14 6 200 10

TB F16 6 200 10

18 6 140 10

20 6 200 10

25 6 200 10

TB F12 8 160 10

12 8 200 10

16 8 200 10

20 8 200 10

32 8 200 10

TB F12 10 200 10

14 10 80 10

14 10 200 10

16 10 80 10

16 10 160 5

16 10 200 5

TB F20 10 160 5

20 10 200 5

25 10 200 5

40 10 200 5

TB F16 12 200 5

20 12 160 5

20 12 200 5

25 12 200 5

TB F30 12 200 5

TB F20 14 200 5

20 14 200 5

TB F20 16 200 3

25 16 200 3

32 16 160 2

TB F25 20 200 3

G1-G8 2-05-17 08.10 Sida G 3

G

G 4

HIGH SPEED STEEL TOOLS Sandvik Corona

TB A12 3 90

l

2

= length

l

a

= thickness

s = width

TB A TB C

Ordering example: 100 pieces TB A12 3 90 C45

SANDVIK

Ordering

code

No./

package

Grades

Example (metric size):

C

4

5

C

6

0

Standard:

Parting blades, metric sizes

Metric sizes

P M K

Material

First choice

Grade recommendations

Complementary

C45 C45 C45

C60 C60 C60

p

V

1

p

f

a

1

b

n

TB A12 3 90 10 15 15

12 3 120 10 15 15

20 3 125 10 10,57 13,43

16 4 140 10 15 15 2 15

18 4 140 10 15 15

25 4 150 10 10,57 13,17

12 5 120 10 15 15

16 6 140 10 15 15

TB C16 3 140 10

15 15 4 15

0,6 1,5

20 4 140 10 0,6 2,0

TB L12 3 90

l

2

= length

l

a

= thickness

s = width

TB L

Ordering example: 100 pieces TB L12 3 90 C45

SANDVIK

Ordering

code

No./

package

Grades

Example (metric size):

C

4

5

C

6

0

Standard:

Parting blades, metric sizes

Metric sizes

P M K

Material

First chioce

Grade recommendations

Complementary

C45 C45 C45

C60 C60 C60

p

V

1

p

f

rf

TB L12 3 90 10 15 15 2 15 0,5

20 3,5 125 10 10,57 13,43 1,43 15 0,5

25 4,5 150 10 10,83 13,17 1,17 15 0,44

TB S

Ordering example: 100 pieces TB S-0 C45

SANDVIK

Ordering

code

No./

package

Grades

C

4

5

C

6

0

Standard:

Parting blades, inch sizes

P M K

Material

First choice

Grade recommendations

Complementary

C45 C45 C45

C60 C60 C60

l

2

s l

a

p

p

f

TB S-0 10 110 12,70 2,50 15 2 15

-1 10 125 15,87 3,17 15 2 15

-2 10 150 19,05 3,17 15 2 15

-3 10 175 22,22 3,97 15 2 15

-4 10 200 25,40 4,76 15 2 15

Inch sizes

G 6 G 7

Cutting data Technical information

G1-G8 2002-03-13 16.12 Sida G 4

G

G 5

Sandvik Corona HIGH SPEED STEEL TOOLS

G 6 G 7

Spare parts Technical information

for square tool bits

External US 101

Ordering example: 100 pieces US 101-0606

SANDVIK

Ordering

code

Tool bits

Metric

size

Inch size

Standard:

Toolholders

Toolholders

h h

1

h

2

b l

1x

l

c

US 101-0606 20 10 31 14 130 100 6

1

/4

-0808 25 14 36 16 150 120 8

5

/16

-1010 25 15 36 20 150 120 10

3

/8

-1212 32 18 43 22 160 130 12

1

/2

For parting blades with side

clearance

SS 101

Ordering example: 100 pieces SS 101-120

SANDVIK

Ordering

code

Parting blades

Metric size Inch size

Standard:

h h

1

i

2

b l

1x

l

c

SS 101-120 23 15,5 33 19 135 105 A12x3x90, A12x3x120, A12x5x120

-127 23 16,3 33 19 135 105 S-0

-158 27 20,0 37 19 150 120 S-1

-160 27 20,0 37 19 150 120 A16x4x140, A16x6x140 S-1

-180 31 22,6 41 19 150 120 A18x4x140

-190 31 23,8 41 19 150 120 S-2

-200 32 24,5 42 21 165 135 A20x3x125

-222 34 26,9 44 21 165 135 S-3

-250 40 31,7 50 25 185 155 A25x4x150

-254 40 31,7 50 25 185 155 S-4

G1-G8 2002-03-13 16.12 Sida G 5

G

G 6

HIGH SPEED STEEL TOOLS Sandvik Corona

Parting blades with side clearance

Ordering exampIe: 10 pieces US 101-640

US 101-0606 US 101-1010 US 101-640 US 101-650 174.1-864 (3,0)

US 101-1212 US 101-642 US 101-652 3021 010-050 (5,0)

2

3

1

3

2

Square tooI bits

Wedge Screw

Standard parts

Delivered with the tool

1 2 3

Key

(mm)

TooIhoIder

1

Ordering example: 10 pieces SS 1-640

SS 101-120 SS 101-222 SS 1-640 SS 1-650 3021 010-040 (4,0)

SS 101-250 SS 101-254 SS 1-642 SS 1-652 3021 010-050 (5,0)

Wedge Screw

Standard parts

Delivered with the tool

1 2 3

Key

(mm)

TooIhoIder

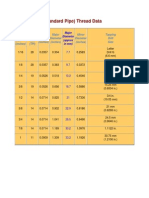

Nominal cutting speed and feed values

The recommendations are valid for rough turning with Sandvik Corona grades and use of cutting fluid.

Approximate tool life with C45/60: 2 hours (or 1 hour with approx . 20% higher speed)

For a cutting depth 1,5 mm the nose radius should be 1,0 mm.

For a cutting depth <1,5 mm the nose radius should be <1,0 mm.

P

CMC

No.

Material Hardness

Brinell

HB

ISO

Specific

cutting

force k

c

0,4

Feed mm/rev

Cutting

speed m/min

0.1 0.2 0.3 0.4

01.1 1900 125 85 65 55 45

01.2 2100 150 70 55 45 40

01.3 2250 200 50 40 35 30

02.1 2100 180 60 45 40 30

02.2 2600 275 40 30 25 20

02.2 2700 300 35 25 20 15

02.2 2850 350 25 20 15 10

03.1 2600 200 40 30 25 20

03.2 3900 325 25 20 15 10

05.10 2300 200 40 30 25 20

06.1 2000 180 50 40 35 15

06.2 2500 200 40 30 25 20

06.3 2700 225 35 25 20 15

05.21 2450 175 35 25 20 15

20.11 3000 200 15 10

20.12 3050 280 10 10

20.21, 20.31 3500 250 10 5

20.22, 20.32 4150 350 10 5

20.24, 20.33 4150 320 5 5

04 4500 55 HRC 20 15 15 10

06.33 3600 250 25 20 15 10

08.1 1100 180 60 45 40 30

08.2 1500 260 40 30 25 20

30 900 90 290 240 210 180

33.1 700 110 210 170 150 130

33.2 750 90 140 115 100 85

33.3 1750 100 85 70 60 55

Non-alloy

carbon steel

C=0,15%

C=0,35%

C=0,60%

Alloy steel Annealed

Hardened and tempered

Hardened and tempered

Hardened and tempered

High-alloy steel Annealed

Hardened

Martensitic/ferritic

Steel castings Non-alloy

Low-alloy

High-alloy

Stainless steel

Annealed

Austenitic

Heat resistant alloys

Nickel or cobalt base

Hard steel

Cast-iron, low tensile

Cast-iron, high tensile

Bronze-Brass alloys Lead alloys, Pb>1%

Brass, red brass

Hardened steel

Manganese steel 12%

Annealed

Aged

Iron base

Annealed

Aged

Cast

M

K

Stainless steel

Annealed

Aluminium alloys

Bronze and lead-free copper

incl. electrolytic copper

Spare parts

N/mm

2

G1-G8 2002-03-13 16.12 Sida G 6

G

G 7

Sandvik Corona HIGH SPEED STEEL TOOLS

Sandvik Corona grades

The Sandvik Corona grades C45 and C60 give the

essential properties of wear resistance, toughness

and ease of grinding. Grade properties are obtai-

ned by combining the steel compositions and

structure with the most advanced manufacturing

methods.

Grade C45. Should always be first choice.

A high alloyed High Speed Steel capable of withs-

tanding high temperatures at the cutting edge.

Grade C60. Alternative to be used when high wear

resistance or good grinding properties are decisive

criteria. A high alloy powder metallurgical grade

with a more even distribution of carbide particles.

C45 C60

C 1,40 2,30

Cr 4,2 4,0

Mo 3,5 7,0

W 8,5 6,5

V 3,5 6,5

Co 11,0 10,5

Cutting geometry

Machine type and workpiece material determine

the cutting tool geometry with a general rule that

the cutting edge should be provided with positive

angles. The recommendations are nominal values

which may have to be changed according to

machining conditions. When using heavy feed the

clearance angle (

n

) and rake angle (

n

) should be

reduced to achieve a stronger cutting edge (

n

).

Chipbreaking

When machining long chipping materials a chip-

breaker (h

B

) can be ground for better chipbrea-

king. However, too large an h

B

-value may cause

chip-jamming.

Grinding

The characteristics of the tool bit depends to a

large extent on how the grinding and sharpening

of the cutting edge is carried out. To obtain the

best result, the grinding data should be selected in

consultation with the grinding wheel supplier. The

data given are general recommendations.

n

n

n

<175 8 15 67

175250 8 8 74

>250 6 0 84

8 15 67

<250 8 8 74

>250 6 0 84

10 10 70

8 10 72

10 30 50

10 35 45

IK 3646

HJ 2446

HJ 4680

GI 4680 75 151

GL 160220 175100 151107

Grinding

operation

Aluminium oxide Boron nitride

Hardness Grain size Concentration Grain size

n

Sandvik Corona grade

Steel

analysis %

Rough grinding

Manual

Automatic

Finishing

Manual

Automatic

Profile grinding

Steel

Steel

Steel

Stainless steel

Cast iron

Cast iron

Brass

Bronze

Copper

Aluminium

Material

Hardness

HB

G1-G8 2002-03-13 16.12 Sida G 7

G

G 8

G1-G8 2002-03-13 16.12 Sida G 8

Вам также может понравиться

- VMC1000IIPARTSLISTPL97Документ105 страницVMC1000IIPARTSLISTPL97Nica BogdanОценок пока нет

- English - Lathe NGC - Operator's Manual - 2018Документ456 страницEnglish - Lathe NGC - Operator's Manual - 2018Francisco Salas GalvánОценок пока нет

- Programming TT Series CNCДокумент6 страницProgramming TT Series CNCRevolusiSoekarnoОценок пока нет

- VMC 4020Документ11 страницVMC 4020Arul SakthiОценок пока нет

- CNC LecturaДокумент157 страницCNC LecturaPablo PillajoОценок пока нет

- Topsolid: Topsolid'Cam From Missler SoftwareДокумент2 страницыTopsolid: Topsolid'Cam From Missler SoftwareBG2012Оценок пока нет

- 118 - Puma 240Документ24 страницы118 - Puma 240TombongОценок пока нет

- Turning Tools 2015 ENGДокумент1 253 страницыTurning Tools 2015 ENGMaria MarinОценок пока нет

- Doosan G76Документ17 страницDoosan G76Pham LongОценок пока нет

- Turning Tools - General InformationДокумент22 страницыTurning Tools - General Informationenamicul50Оценок пока нет

- FeatureCAM Fundamentals - Turning PDFДокумент11 страницFeatureCAM Fundamentals - Turning PDFBita MohajerniaОценок пока нет

- Live Tool Drill TapДокумент25 страницLive Tool Drill TapRA Javier100% (1)

- G Code FanukДокумент5 страницG Code FanukCucoș Marius MarianОценок пока нет

- English - Mill NGC - Operator's Manual - 2020Документ536 страницEnglish - Mill NGC - Operator's Manual - 2020Sermchart PakumОценок пока нет

- HaasLiveToolOpProgram - W - DS Manual PDFДокумент70 страницHaasLiveToolOpProgram - W - DS Manual PDFGuillermo RamirezОценок пока нет

- Puma TT 1500 1800Документ20 страницPuma TT 1500 1800Selvedin GudicОценок пока нет

- Anilam 4200t CNC Programming and Operations ManualДокумент355 страницAnilam 4200t CNC Programming and Operations ManualAlexandru PrecupОценок пока нет

- Getting Started With Mill-TurnДокумент158 страницGetting Started With Mill-TurnDiogenes CardosoОценок пока нет

- C500 en PDFДокумент18 страницC500 en PDFKiril AngelovОценок пока нет

- 2050 Panther LatheДокумент2 страницы2050 Panther Lathepramod_tryОценок пока нет

- Doosan Puma 2600yДокумент24 страницыDoosan Puma 2600ybaumgconradoОценок пока нет

- Hass AnswersДокумент7 страницHass AnswersRelu ChiruОценок пока нет

- NTP Thread Program Rev. AДокумент1 страницаNTP Thread Program Rev. Arajkumar931Оценок пока нет

- Doosan Puma MX Series PDFДокумент68 страницDoosan Puma MX Series PDFGuillermo RamirezОценок пока нет

- Syntec InfoДокумент14 страницSyntec InfoGeorgi HelyanОценок пока нет

- PowerSHAPE 2015 - Delcam Electrode enДокумент120 страницPowerSHAPE 2015 - Delcam Electrode enairshow19100% (1)

- Milling MachinesДокумент48 страницMilling MachinesAliah IzzahОценок пока нет

- Touch Probes enДокумент44 страницыTouch Probes enMonteagudoОценок пока нет

- Fanuc 15i AlarmsДокумент17 страницFanuc 15i AlarmsRevolusiSoekarnoОценок пока нет

- Pickoff Pull Cutoff Application Guide in MasterCamДокумент20 страницPickoff Pull Cutoff Application Guide in MasterCameltklasОценок пока нет

- VT1150Документ14 страницVT1150camb2270Оценок пока нет

- Shortcuts For MastercamДокумент1 страницаShortcuts For MastercamSalah benhsОценок пока нет

- CNC Stands For Computer Numerical Control, And: G-Code. CNC Was Developed inДокумент4 страницыCNC Stands For Computer Numerical Control, And: G-Code. CNC Was Developed inKhateeb Ul Islam QadriОценок пока нет

- DNM ENG Series PDFДокумент24 страницыDNM ENG Series PDFLevi BriceñoОценок пока нет

- Doosan BMT65 ToolingДокумент28 страницDoosan BMT65 Toolingmarcos lemosОценок пока нет

- Siemens Operator ManuelДокумент64 страницыSiemens Operator ManuelFikret SönmezОценок пока нет

- Charmille SДокумент12 страницCharmille SmecschioОценок пока нет

- MC v9 Moldplus Application GuideДокумент126 страницMC v9 Moldplus Application Guidechicho6404100% (2)

- Centroid v3.16 Mill Operator ManualДокумент307 страницCentroid v3.16 Mill Operator ManualEmmanuel GaytanОценок пока нет

- Biax ManualДокумент16 страницBiax Manualtm100% (1)

- Mastercam 2017 Lathe CY Axis Toolpaths Tutorial SAMPLEДокумент32 страницыMastercam 2017 Lathe CY Axis Toolpaths Tutorial SAMPLEsekhon8751150% (1)

- Files and Mastercam PDFДокумент38 страницFiles and Mastercam PDFGuillermo RamirezОценок пока нет

- CNC enДокумент24 страницыCNC enActem PmeОценок пока нет

- DMG MillPlusV521 ProgManualДокумент649 страницDMG MillPlusV521 ProgManuallastowlОценок пока нет

- Post Processing For Milling Trning and Wire EDMДокумент91 страницаPost Processing For Milling Trning and Wire EDMatilapaixaoОценок пока нет

- Winstart-CKE6150-1500MM CNC Lathe OfferДокумент12 страницWinstart-CKE6150-1500MM CNC Lathe OfferSergio Salazar MarulandaОценок пока нет

- Constant Cutter Load: You Will LearnДокумент7 страницConstant Cutter Load: You Will LearntsaladygaОценок пока нет

- Fanuc 0 CNC Identification SheetДокумент1 страницаFanuc 0 CNC Identification Sheetanthony solizОценок пока нет

- Bending (Metalworking) : "Metal Bending" Redirects Here. For The Form of Stage Magic, SeeДокумент10 страницBending (Metalworking) : "Metal Bending" Redirects Here. For The Form of Stage Magic, SeeJordan MosesОценок пока нет

- BSP Pipe ThreadДокумент1 страницаBSP Pipe ThreadgvmindiaОценок пока нет

- Heidenhain TNC 640Документ24 страницыHeidenhain TNC 640WalkerMachineryОценок пока нет

- Puma Work Ejector Tip ReplacementДокумент3 страницыPuma Work Ejector Tip ReplacementpaulОценок пока нет

- Doosan Puma MX Series BrochureДокумент28 страницDoosan Puma MX Series BrochuremarkoskitpОценок пока нет

- SAMPLE Mastercam X9 Handbook Volume 2Документ36 страницSAMPLE Mastercam X9 Handbook Volume 2Eduardo Aleman ReynaОценок пока нет

- PDFДокумент514 страницPDFRizki PrasetyoОценок пока нет

- Cutting Speed Feed andДокумент22 страницыCutting Speed Feed andashokrangasamyОценок пока нет

- Fanuc Lathe ProgramДокумент93 страницыFanuc Lathe Programnguyenanhso100% (1)

- Machine Tools, Metal Cutting Types World Summary: Market Values & Financials by CountryОт EverandMachine Tools, Metal Cutting Types World Summary: Market Values & Financials by CountryОценок пока нет

- Smooth Flow: Tubing & Fittings SpecificationsДокумент28 страницSmooth Flow: Tubing & Fittings SpecificationsedgardomichligОценок пока нет

- Assessment of CorrosionДокумент30 страницAssessment of CorrosionCarlos ReОценок пока нет

- Adobe Industrial Systems Company Profile - PVDДокумент10 страницAdobe Industrial Systems Company Profile - PVDadobeindustrialsystemsОценок пока нет

- What Are The Types of Ties Used in Building ConstructionДокумент4 страницыWhat Are The Types of Ties Used in Building ConstructioncarmeloОценок пока нет

- Elegance Range Tech Catalogue PDFДокумент37 страницElegance Range Tech Catalogue PDFSreehari SM TeslaОценок пока нет

- Material ConsumptionДокумент3 страницыMaterial ConsumptionDarshit VejaniОценок пока нет

- U Value CalculatorДокумент19 страницU Value CalculatorjothamОценок пока нет

- Pocket PenetrometerДокумент4 страницыPocket Penetrometertag_jОценок пока нет

- Settlement 1Документ16 страницSettlement 1James Anthony TorresОценок пока нет

- 111 Hume Rotherys RuleДокумент14 страниц111 Hume Rotherys RulemohansaiОценок пока нет

- Laminations Led To IncidentДокумент3 страницыLaminations Led To IncidentAhmad KadafiОценок пока нет

- Painting Procedure - PolyurethaneДокумент2 страницыPainting Procedure - PolyurethanesanjeetkarОценок пока нет

- PHB2 PVДокумент5 страницPHB2 PVMarusan Petpookaew0% (1)

- Lecture Plate Girder Intro DSS 2Документ37 страницLecture Plate Girder Intro DSS 2Amarendra KojjaОценок пока нет

- Noida Metro Rail Project Cec-Sam-Jv.: Presentation On U-Girder Casting by L.K.PrasadДокумент116 страницNoida Metro Rail Project Cec-Sam-Jv.: Presentation On U-Girder Casting by L.K.PrasadLOHITH N100% (1)

- Brochure - Specialty Effects For Polymer ProcessingДокумент6 страницBrochure - Specialty Effects For Polymer ProcessingXuân Giang NguyễnОценок пока нет

- LTI Boiler Application 3pagesДокумент3 страницыLTI Boiler Application 3pagesVijay - Spantech EngineersОценок пока нет

- Mechanics of Materials 7th Edition Beer Johnson Chapter 6Документ134 страницыMechanics of Materials 7th Edition Beer Johnson Chapter 6Riston Smith95% (96)

- RETA Steel PipeДокумент5 страницRETA Steel PipeBehnam AshouriОценок пока нет

- Gate Valve Cast A494 CW12MW Body UNS N10276 TrimДокумент1 страницаGate Valve Cast A494 CW12MW Body UNS N10276 TrimGiovanni PetrizzoОценок пока нет

- Electrolux Esf 2410Документ16 страницElectrolux Esf 2410michalis5255Оценок пока нет

- Jute Fiber-Reinforced Polymer Composites: A Comprehensive ReviewДокумент21 страницаJute Fiber-Reinforced Polymer Composites: A Comprehensive ReviewbiniyamОценок пока нет

- Introduction Kirsch y LameДокумент2 страницыIntroduction Kirsch y LameAlvaro FabianОценок пока нет

- Quaker Passive House' School Is First of Its Kind in Maine: Heating BillДокумент10 страницQuaker Passive House' School Is First of Its Kind in Maine: Heating BillEss AarОценок пока нет

- Kondo ScatteringДокумент8 страницKondo ScatteringPRIYA MANDALОценок пока нет

- Cost Comparison Between Foundry ProcessesДокумент14 страницCost Comparison Between Foundry ProcessesSUNDARRAJAN BОценок пока нет

- Helicoil Catalogue PDFДокумент34 страницыHelicoil Catalogue PDFnitin9860Оценок пока нет

- Integral Concrete Bridge EC2 - 2010Документ98 страницIntegral Concrete Bridge EC2 - 2010paramsandhu100% (1)

- NSRP LLM WPQTДокумент3 страницыNSRP LLM WPQTtranvando1986Оценок пока нет

- BS 648Документ50 страницBS 648Michael Newton0% (1)

- Controls and Flowmeters PDFДокумент40 страницControls and Flowmeters PDFibharОценок пока нет