Академический Документы

Профессиональный Документы

Культура Документы

4 Strokeengine

Загружено:

ifzaeОригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

4 Strokeengine

Загружено:

ifzaeАвторское право:

Доступные форматы

Today Internal combustion engines in cars, trucks, motorcycles, construction machinery

and many others, most commonly use a four-stroke cycle. The four strokes refer to

intake, compression, combustion and exhaust strokes that occur during two crankshaft

rotations per working cycle of Otto Cycle and Diesel engines.

Contents

[hide]

1 The Otto cycle

2 Valve train

3 Valve clearance adjustment

3.1 Valve clearance measurement

3.1.1 Valve clearance too wide

3.1.2 Valve clearance too narrow

3.2 Adjusting valve clearance

4 Port flow

5 Output limit

6 Bibliography

7 See also

8 External links

[edit] The Otto cycle

The Otto cycle engine was first patented by Eugenio Barsanti and Felice Matteucci in

1854 followed by a first prototype in 1860. It was also conceptualized by French

engineer, Alphonse Beau de Rochas in 1862 and independently, by the German engineer

Nicolaus Otto in 1876

[citation needed]

. Its power cycle consists of adiabatic compression, heat

addition at constant volume, adiabatic expansion and rejection of heat at constant volume

and characterized by four strokes, or reciprocating movements of a piston in a cylinder:

1. intake/induction stroke

2. compression stroke

3. power stroke

4. exhaust stroke

Four-stroke cycle (or Otto cycle)

The cycle begins at top dead center (TDC), when the piston is furthest away from the

crankshaft. On the first stroke (intake/induction) of the piston, as the piston descends it

reduces the pressure in the cylinder, a mixture of fuel and air is forced, by at least

atmospheric pressure, into the cylinder through the intake (inlet) port. The intake (inlet)

valve (or valves) then close(s) and the following stroke (compression) compresses the

fuel-air mixture.

The air-fuel mixture is then ignited, usually by a spark plug for a gasoline or Otto cycle

engine or by the heat and pressure of compression for a Diesel cycle or compression

ignition engine, at approximately the top of the compression stroke. The resulting

expansion of burning gases pushes the piston downward for the third stroke (power) and

in the fourth stroke (exhaust) the piston pushes the products of combustion from the

cylinder through an exhaust valve or valves.

[edit] Valve train

The valves are typically operated by a camshaft, with a series of cams along its length,

each designed to open a valve appropriately for the execution of intake or exhaust strokes

while rotating at half crankshaft speed. A tappet between valve and cam furnishes a

contact surface on which the cam slides to open the valve. The location of the camshaft

varies, as does the quantity. Most engines use overhead cams, or even dual overhead

cams, as in the illustration, in which cams directly actuate valves through a flat tappet.

This design is typically capable of higher engine speeds because it gives the most direct

and shortest inelastic path between cam and valve. In other engine designs, the cam shaft

is placed in the crankcase and its motion transmitted by a push rod, rocker arms, and

valve stems.

Starting position, intake stroke, and compression stroke.

Ignition of fuel, power stroke, and exhaust stroke.

[edit] Valve clearance adjustment

Valve clearance refers to the small gap between valve lifter and valve stem (or rocker

arm and valve stem) that ensures that the valve completely closes, an expansion joint in

the valve train. Most engines have the valve clearance set by grinding the end of the

valve stem during engine assembly, overhead cams not needing subsequent adjustment.

In earlier engines, mostly with push rods and rocker arms used adjustable tappets or

hydraulic tappets to adjust for valve and cam wear. Lack of valve clearance will prevent

valve closure causing leakage and valve damage.

[edit] Valve clearance measurement

Valve clearance is measured with the valve closed, typically at Top dead centre of the

compression stroke. The tappet will be resting on the heel of the cam lobe. A feeler gauge

must pass through the clearance space. The feeler gauge should fit in and out with a slight

drag. If the feeler gauge will not fit in, then the clearance is too small. If the blade of the

feeler gauge fits in too loose then the clearance is too big.

[edit] Valve clearance too wide

A too wide valve clearance will cause excessive wear to the camshaft and valve lifter

contact areas, the pushrods can also bend and the engine will be noisy. Should the

clearance become wide enough, valve timings will change resulting in poor performance.

[edit] Valve clearance too narrow

A narrow valve clearance will not allow for heat expansion and will result in the failure

of the valve to close on its seat. The combustion chamber will not seal properly,

producing poor compression and power. It is also possible that the valve can become hot

enough to melt.

[edit] Adjusting valve clearance

Valve clearance adjustment must be performed to manufacturer's specifications. It is

normal that the exhaust valve will have a larger clearance. Adjustment is performed by

either adjusting the rocker arm or by placing shims between cam follower and valve

stem. Most modern engines have Hydraulic lifters and require no adjustment.

[edit] Port flow

The power input of the motor is dependent on the ability of the engine to allow a volume

flow of both air-fuel mixture and exhaust gas through the respective valve ports, typically

located in the cylinder head. Therefore time is spent designing this part of an engine.

Factory flow specifications are generally lower than what the engine is capable of, but

due to the time and expensive nature of smoothing the entire intake and exhaust track,

compromises in flow for reductions in costs is often made. In order to gain power,

irregularities such as casting flaws are removed and with the aid of a flow bench, the radii

of valve port turns and valve seat configuration can be modified to promote high flow.

This process is called porting, and can be done by hand, or via CNC machine.

There are many common design and porting strategies to increase flow. Increasing the

diameter of the valves to take up as much the cylinder diameter as possible to increase the

flow through the intake and exhaust ports is one method. However, increased valve size

can decrease valve shrouding (the impedance of flow created by the cylinder floor.) To

counter this, valves are commonly designed to open into the middle of the cylinder (such

as the Chrysler Hemi or the Ford Cleveland engines with canted valves). Also, increasing

valve lift, or the distance valves are opened into the cylinder or using multiple smaller

valves can increase flow. With the advent of computer technology, in modern engines

valves events can be controlled directly by the engine's computer, minimizing engine

operation at any speed or load.

[edit] Output limit

The amount of power generated by a four-stroke engine is proportional to its speed. The

speed is ultimately limited due to material strength. Since valves, pistons and connecting

rods are accelerated and decelerated very quickly, the materials used must be strong

enough to withstand these forces. Both physical breakage and piston ring flutter can

occur, resulting in power loss or even engine destruction. Piston ring flutter occurs when

the piston rings change direction so quickly that they are forced from their seat on the

ring land and the cylinder walls, resulting in a loss of cylinder sealing and power as well

as possible breakage of the ring. Worst is overreving (overspeed) when valves lose their

forced contact with the valve train. This would occur if the valve (spring normally)

closing force would be exceeded by the inertia force resulting in valve contact with the

piston causing major damage. Various countermeasures are reducing the valve train

mass, for instance: OHC instead of OHV, four instead of two valves (even more air/gas

flow)

One important factor in engine design is the rod/stroke ratio. Rod/stroke ratio is the ratio

of the length of the connecting rod to the length of the crankshaft's stroke. An increase in

the rod/stroke ratio (a longer rod, shorter stroke, or both,) results in a decrease in piston

speed. However, again due to strength and size concerns, there is a limit to how long a

rod can be in relation to the stroke. A longer rod (and consequently, higher rod/stroke

ratio,) can potentially create more power, due to the fact that with a longer connecting

rod, more force from the piston is delivered tangentially to the crankshafts rotation,

delivering more torque. A shorter rod/stroke ratio creates higher piston speeds, but this

can be beneficial depending on other engine characteristics. Increased piston speeds can

create tumble or swirl within the cylinder and reduce detonation. Increased piston speeds

can also draw fuel/air mix into the cylinder more quickly through a larger intake runner,

promoting good cylinder filling.

An engine where the bore dimension is larger than the stroke is commonly known as an

oversquare engine, and such engines have the ability to attain higher RPM. Conversely,

an engine with a bore that is smaller than its stroke is an undersquare engine.

Respectively, it cannot attain as many RPM, but is liable to make more torque at lower

RPM. In addition, an engine with a bore and stroke that are the same is referred to as a

square engine.

Вам также может понравиться

- Buku Pengurusan Peribadi 2015 Terbaik Oleh Cikgu Suriati Ku IshakДокумент24 страницыBuku Pengurusan Peribadi 2015 Terbaik Oleh Cikgu Suriati Ku Ishaks0feaОценок пока нет

- Breast Cancer Screening and DiagnosisДокумент2 страницыBreast Cancer Screening and DiagnosisifzaeОценок пока нет

- Flyer - MBSB Personal Financing-I 2016 - OL PDFДокумент2 страницыFlyer - MBSB Personal Financing-I 2016 - OL PDFifzaeОценок пока нет

- Maxis Home FibreДокумент2 страницыMaxis Home FibreifzaeОценок пока нет

- What Is Breast CancerДокумент1 страницаWhat Is Breast CancerifzaeОценок пока нет

- Uninstall Trend Micro OfficeScan Without The PasswordДокумент2 страницыUninstall Trend Micro OfficeScan Without The PasswordifzaeОценок пока нет

- MAXIS Fibre Broadband FTTH Residential Wifi Modem GuideДокумент25 страницMAXIS Fibre Broadband FTTH Residential Wifi Modem GuideSimon CondorОценок пока нет

- Pseudocode Starts HereДокумент1 страницаPseudocode Starts HereifzaeОценок пока нет

- Calculating Averages - Flowcharts and PseudocodeДокумент4 страницыCalculating Averages - Flowcharts and PseudocodeLee Kah Hou67% (3)

- IslamicAmMoneyLine iProfitRateДокумент1 страницаIslamicAmMoneyLine iProfitRateifzaeОценок пока нет

- Pseudocode Starts HereДокумент1 страницаPseudocode Starts HereifzaeОценок пока нет

- Uninstall Trend Micro OfficeScan Without The PasswordДокумент2 страницыUninstall Trend Micro OfficeScan Without The PasswordifzaeОценок пока нет

- Uninstall Trend Micro OfficeScan Without The PasswordДокумент3 страницыUninstall Trend Micro OfficeScan Without The PasswordifzaeОценок пока нет

- Print Cell Without ColourДокумент4 страницыPrint Cell Without ColourifzaeОценок пока нет

- Sri Computer Laptop Price - 24Документ2 страницыSri Computer Laptop Price - 24ifzaeОценок пока нет

- Jayacom Laptop Price - 16Документ4 страницыJayacom Laptop Price - 16ifzaeОценок пока нет

- Sri Computer Laptop Price - 24Документ2 страницыSri Computer Laptop Price - 24ifzaeОценок пока нет

- Model Solar Boat Guide 2007Документ38 страницModel Solar Boat Guide 2007Elyyana97Оценок пока нет

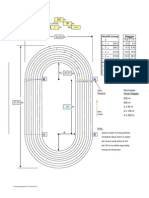

- 200m Track: Pitch Marking GuidlinesДокумент1 страница200m Track: Pitch Marking GuidlinesShafiullaShaikОценок пока нет

- How To Install Windows 8Документ5 страницHow To Install Windows 8ifzaeОценок пока нет

- FORMULA GEAR METRIC CALCULATIONSДокумент2 страницыFORMULA GEAR METRIC CALCULATIONSifzaeОценок пока нет

- List Barang Myvi 1.3Документ1 страницаList Barang Myvi 1.3ifzaeОценок пока нет

- Track design layout 400mДокумент19 страницTrack design layout 400mNoriza E-ja100% (1)

- Takaful MyHealth Protector BrochureДокумент12 страницTakaful MyHealth Protector BrochureAmnah Mohamad100% (1)

- Laptops ViewnetДокумент2 страницыLaptops ViewnetifzaeОценок пока нет

- Hormat Pengakap Dan Lencana KeahlianДокумент13 страницHormat Pengakap Dan Lencana KeahlianifzaeОценок пока нет

- DNS ServerДокумент1 страницаDNS ServerifzaeОценок пока нет

- How a 2-Stroke Engine WorksДокумент6 страницHow a 2-Stroke Engine WorksifzaeОценок пока нет

- Acknowledgement: Mohd Nawawi Abd Halim DCS 041 125Документ17 страницAcknowledgement: Mohd Nawawi Abd Halim DCS 041 125ifzaeОценок пока нет

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeОт EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeРейтинг: 4 из 5 звезд4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingОт EverandThe Little Book of Hygge: Danish Secrets to Happy LivingРейтинг: 3.5 из 5 звезд3.5/5 (399)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryОт EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryРейтинг: 3.5 из 5 звезд3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceОт EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceРейтинг: 4 из 5 звезд4/5 (894)

- The Yellow House: A Memoir (2019 National Book Award Winner)От EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Рейтинг: 4 из 5 звезд4/5 (98)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureОт EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureРейтинг: 4.5 из 5 звезд4.5/5 (474)

- Never Split the Difference: Negotiating As If Your Life Depended On ItОт EverandNever Split the Difference: Negotiating As If Your Life Depended On ItРейтинг: 4.5 из 5 звезд4.5/5 (838)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaОт EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaРейтинг: 4.5 из 5 звезд4.5/5 (265)

- The Emperor of All Maladies: A Biography of CancerОт EverandThe Emperor of All Maladies: A Biography of CancerРейтинг: 4.5 из 5 звезд4.5/5 (271)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersОт EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersРейтинг: 4.5 из 5 звезд4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnОт EverandTeam of Rivals: The Political Genius of Abraham LincolnРейтинг: 4.5 из 5 звезд4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaОт EverandThe Unwinding: An Inner History of the New AmericaРейтинг: 4 из 5 звезд4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyОт EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyРейтинг: 3.5 из 5 звезд3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreОт EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreРейтинг: 4 из 5 звезд4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)От EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Рейтинг: 4.5 из 5 звезд4.5/5 (119)

- Juego de Válvulas - AjustaДокумент4 страницыJuego de Válvulas - AjustaQuirozRojasCesarОценок пока нет

- Grizzly Service ManualДокумент480 страницGrizzly Service Manualb18crman50% (2)

- BMW n54 Can Dme Code ListДокумент8 страницBMW n54 Can Dme Code ListSimple GameplayОценок пока нет

- New Lanos Engine4 (Diagnosis)Документ11 страницNew Lanos Engine4 (Diagnosis)Nhật ĐặngОценок пока нет

- Connector: C175E: Powertrain Control Module (PCM) BK 12B637/14290 12A659 Not AvailableДокумент3 страницыConnector: C175E: Powertrain Control Module (PCM) BK 12B637/14290 12A659 Not AvailableencontreelrepuestoОценок пока нет

- Internal Combustion Engines - Saleel and Sivakumar PDFДокумент86 страницInternal Combustion Engines - Saleel and Sivakumar PDFRam NareshОценок пока нет

- Valve AnalysisДокумент5 страницValve AnalysisghostrpgОценок пока нет

- Engine Valve Lash - Inspect AdjustДокумент6 страницEngine Valve Lash - Inspect AdjustMejia M NestОценок пока нет

- VVT-i (Variable Valve Timing-Intelligent) System: GeneralДокумент4 страницыVVT-i (Variable Valve Timing-Intelligent) System: GeneralLuqman AzamОценок пока нет

- SSP 23 1.8 L 110kw Turbo Petrol Engine 1.8 L 92kw Petrol EngineДокумент34 страницыSSP 23 1.8 L 110kw Turbo Petrol Engine 1.8 L 92kw Petrol EngineRiahi RezegОценок пока нет

- Docking List 2021Документ12 страницDocking List 2021boe cahyaОценок пока нет

- Service Manual Nissan Engine Model PДокумент127 страницService Manual Nissan Engine Model PChristie Munday100% (6)

- Engine Service Manual 8.1L SpecsДокумент177 страницEngine Service Manual 8.1L SpecsleejoОценок пока нет

- 194 294 VSG411Документ124 страницы194 294 VSG411john_cegelkaОценок пока нет

- VTDДокумент5 страницVTDSumit JainОценок пока нет

- QSX 15 T3Документ100 страницQSX 15 T3T4NI M4JU50% (2)

- Fir Engine TP-542 FMX - 440Документ21 страницаFir Engine TP-542 FMX - 440CwsОценок пока нет

- PMS InstructionsДокумент44 страницыPMS InstructionsDamien DrakeОценок пока нет

- JD 7515 Parts-PC9366Документ576 страницJD 7515 Parts-PC9366Luylly alejandroОценок пока нет

- 8YS1-Up, 9NS1-Up Disassembly-AssemblyДокумент124 страницы8YS1-Up, 9NS1-Up Disassembly-AssemblyJonathan Luiz PolezaОценок пока нет

- Catalogo Motoniveladora GD655-5 PDFДокумент444 страницыCatalogo Motoniveladora GD655-5 PDFNilton Junior Kern100% (3)

- Hyosung Gt650 Part CatalogueДокумент112 страницHyosung Gt650 Part CatalogueClinton MoodleyОценок пока нет

- Harlan Gasoline Towing Tractor Parts ManualДокумент174 страницыHarlan Gasoline Towing Tractor Parts ManualCLO CRM100% (2)

- Pps 922903 2l Tfsi Caeb Enigine W Acs Eng PDFДокумент55 страницPps 922903 2l Tfsi Caeb Enigine W Acs Eng PDFKandy KnОценок пока нет

- Wolf 3D V3.0 W3dv3 0 ManualДокумент82 страницыWolf 3D V3.0 W3dv3 0 ManuallyndondrОценок пока нет

- Speeduino Manual-4Документ16 страницSpeeduino Manual-4Makson VieiraОценок пока нет

- 1402 ContentsДокумент5 страниц1402 ContentsLinusОценок пока нет

- Ecus 4E-FTEДокумент0 страницEcus 4E-FTELuis Lezama67% (3)

- Automotive Interview and ReviewerДокумент20 страницAutomotive Interview and ReviewerMichael Radan90% (10)

- Arstra 1.8 2002.ecu ConectorДокумент3 страницыArstra 1.8 2002.ecu Conectorcarlos eli olveraОценок пока нет