Академический Документы

Профессиональный Документы

Культура Документы

Hand Tool

Загружено:

Hamza Nouman0 оценок0% нашли этот документ полезным (0 голосов)

199 просмотров5 страницThis document provides a checklist for evaluating safety practices related to hand tools and power tools. It lists various safety items and requirements for tools, equipment, personal protective equipment, work areas, training, and other factors. Examples include ensuring tools are maintained and stored properly, wearing appropriate eye and ear protection, guarding of machine parts, using the right tool for the job, and inspecting equipment regularly. The goal is to help identify any safety issues and ensure proper safety protocols are followed when using hand tools and power tools.

Исходное описание:

Hand tools lllllllll

Авторское право

© © All Rights Reserved

Доступные форматы

PDF, TXT или читайте онлайн в Scribd

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документThis document provides a checklist for evaluating safety practices related to hand tools and power tools. It lists various safety items and requirements for tools, equipment, personal protective equipment, work areas, training, and other factors. Examples include ensuring tools are maintained and stored properly, wearing appropriate eye and ear protection, guarding of machine parts, using the right tool for the job, and inspecting equipment regularly. The goal is to help identify any safety issues and ensure proper safety protocols are followed when using hand tools and power tools.

Авторское право:

© All Rights Reserved

Доступные форматы

Скачайте в формате PDF, TXT или читайте онлайн в Scribd

0 оценок0% нашли этот документ полезным (0 голосов)

199 просмотров5 страницHand Tool

Загружено:

Hamza NoumanThis document provides a checklist for evaluating safety practices related to hand tools and power tools. It lists various safety items and requirements for tools, equipment, personal protective equipment, work areas, training, and other factors. Examples include ensuring tools are maintained and stored properly, wearing appropriate eye and ear protection, guarding of machine parts, using the right tool for the job, and inspecting equipment regularly. The goal is to help identify any safety issues and ensure proper safety protocols are followed when using hand tools and power tools.

Авторское право:

© All Rights Reserved

Доступные форматы

Скачайте в формате PDF, TXT или читайте онлайн в Scribd

Вы находитесь на странице: 1из 5

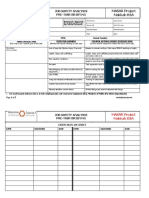

Hand tool and Power tool safety

Download additional self-inspection checklists at http://engineering.tamu.edu/safety/

Date __________________________________ Room No. __________________________________

Inspector __________________________________ Location __________________________________

Faculty/PI __________________________________ Dept. ____________________________

Items for evaluation Yes No Comments Action to be taken

General Safety Rules

Is the work area kept clear of clutter?

Is the work area well lighted?

Are the tools maintained and kept sharpened, oiled

and stored in a safe dry place?

Do workers wear ear and eye protection when

cutting, sawing, drilling or grinding?

Have the workers been instructed by the supervisor

on safe procedures before using the equipment?

Are the tools, cords and accessories inspected

regularly?

Are three-prong electric plugs, double insulated

tools and safety switches used?

Is the problem equipment repaired or replaced

immediately?

Are machine guards in place and not removed?

Is it ensured that no jewelry or loose clothing is

worn when operating equipment?

Are only qualified personnel allowed to install and

repair equipment?

Are the right tools used for the job?

Items for evaluation Yes No Comments Action to be taken

Is it ensured that sharps and edged tools are carried

pointed downward or placed in a tool belt or tool-

box?

Are sharps and edged blades protected with a shield

or guard?

Are sharps safeguarded and secure?

Are tools stored in drawers or chests with the

cutting edge down and/or guarded?

When using power tools, are safety glasses, face

shields, dust masks, hard hats, gloves, protective

clothing and other PPE used?

Are all hand-held power tools equipped with "dead-

man" control so power will be automatically cut of f

upon release of the control by the operator?

Are any activated or running tools left unattended?

Have any controls been disabled or bypassed?

Are all workers trained in the proper use of hand and

power tools?

Are tools of a non-sparking material used if fire or

explosion hazards exist?

Are all fuel-operated tools stopped and allowed t o

cool prior to being refueled, serviced, maintained or

stored?

Are tools fueled only in well ventilated areas?

Do power-grinding machines have proper grounding

and safe-guarding?

Are work rests kept at a distance not exceeding 1 / 8

inch from the wheel surface?

Do all persons using abrasive wheels wear approved

eye-protective devices and other PPE?

Is repetitive motion avoided and are tools held in

neutral position?

Items for evaluation Yes No Comments Action to be taken

Screwdrivers

Are insulated screwdrivers used when working with

electrical equipment?

Is it ensured that objects are not held in the palm of

one hand when pressing a screwdriver into them and

instead objects placed on a bench or table?

Is it ensured that screwdrivers are never used t o

hammer or pry?

Are all tools inspected for broken handles and bent

blades? Are tool inspections conducted

daily/weekly/before each use?

Pliers

Is it ascertained that pliers are not used as a

substitute for hammers or wrenches?

Are insulated pliers used when doing electrical work?

Is the insulation inspected frequently to make

certain that it is free of breaks and cracks?

Hammers

Is the correct type of hammer used for the type of

work to be done?

While using a hammer, is the swing unobstructed

and is there a lookout kept for overhead

interference?

Is the hammer checked for defects before using?

Wrenches

Is the wrench selected for the job of correct size?

Is it ensured that pipes are not used as wrench

handle extensions?

Is it ensured that too much leverage is not used

while operating the tool?

Is it ensured that instead of pushing against the

fixed jaw, the wrench is given a pull while standing in

a balanced position?

Chisels

Are safety goggles or a face shield worn when using

a chisel?

Items for evaluation Yes No Comments Action to be taken

Is the wood chisel driven outward and away from

the body?

Is it ensured that chisels are not used to pry?

Are edges kept sharp and protected when not in

use?

Knives, sharps and edged tools

Is the cut always made away from the body?

Are the hands and body clear of the knife stroke?

Are the blades kept sharp?

Are sharps, including needles/syringes handled

safely and disposed properly?

Are sharps safeguarded and secured when not in

use?

Is it ensured that single-use, disposable sharps are

not re-used?

Is it ensured that needles are not re-capped?

Is it ensured that only approved sharps disposal

containers are used?

Are contents encapsulated and disposed properly?

Portable Electric Equipment

Is it ensured that equipment is never raised or

lowered using the power cord?

Is it ensured that staples, tape etc. are not used t o

fasten a cord?

Are controls in place to prevent temporary cords

from being improperly used instead of NEC approved

permanent wiring?

Is it ensured that the equipment's casing or the cord

insulation is not damaged?

Is the equipment inspected before use and checked

for external and internal defects?

Items for evaluation Yes No Comments Action to be taken

Is damaged equipment removed from service and a

"Do not use" sign attached to it and given to the

supervisor?

Are guards used on all hand and power tools t hat

are designed to accommodate such guards?

Are temporary flexible cords(extension cords) put

away after use or at the end of the work period?

Is more than one fuse protected power strip used

with one extension cord?

Is power provided to laboratory equipment with

extension cord(s)?

Ladders

Are ladders placed at an angle so that the horizontal

distance between the f oot of the ladder and the

support where it has been placed is not more than

one-quarter the length of the ladder from the t op

point of support to its base?

Is it ensured that the doors the ladders are placed in

front of blocked open or locked doors only?

Are barriers and warning signs conspicuously placed

to prevent people from walking into the ladder?

Do ladders extend 3 feet above the top of the root

contact area?

Is appropriate fall protection used when working at

heights > = 6 feet?(6 f eet is the uniform threshold

height where fall protection is required)

Вам также может понравиться

- Permit Working at HeightДокумент4 страницыPermit Working at HeightkinaОценок пока нет

- JHA Blowing PressДокумент5 страницJHA Blowing PressLuqman OsmanОценок пока нет

- Hand and Power Tools Safety ExaminationДокумент5 страницHand and Power Tools Safety Examinationjohnvenom1979Оценок пока нет

- Job Safety Analysis - Clinker StorageДокумент4 страницыJob Safety Analysis - Clinker StorageMohammed MinhajОценок пока нет

- Project: Field Erection of 15000 Bbls Tank (Ik-2545) : Job Safety Analysis / Safe Work Method Statement-SWMSДокумент2 страницыProject: Field Erection of 15000 Bbls Tank (Ik-2545) : Job Safety Analysis / Safe Work Method Statement-SWMSJohn100% (1)

- 1 WAH ChecklistДокумент2 страницы1 WAH Checklistvirendra kumar singhОценок пока нет

- SOP SOP0022 Concrete Core DrillДокумент3 страницыSOP SOP0022 Concrete Core Drillkristian08Оценок пока нет

- JSA Format Erection of Column 903-C-02,03Документ5 страницJSA Format Erection of Column 903-C-02,03sakthi venkat100% (1)

- Crane Hoist Sling Safety ProgramДокумент14 страницCrane Hoist Sling Safety Programomar sadiqОценок пока нет

- Portable Grinder SafetyДокумент20 страницPortable Grinder SafetysabaОценок пока нет

- JSA Formet New Structural Steel FabricationДокумент7 страницJSA Formet New Structural Steel Fabricationsakthi venkatОценок пока нет

- Ra FormДокумент5 страницRa FormEngrHazrat MaazОценок пока нет

- LCC DOCS-11568884-V1-HS-PRO-013 Working in On Over or Adjacent To WaterДокумент13 страницLCC DOCS-11568884-V1-HS-PRO-013 Working in On Over or Adjacent To WaterabogadieОценок пока нет

- Hand and Portable Power Tools Pre Use Inspection ChecklistДокумент1 страницаHand and Portable Power Tools Pre Use Inspection ChecklistRoselyn SharronОценок пока нет

- 04, Use of Hand ToolsДокумент2 страницы04, Use of Hand ToolsFrancis K BonfulОценок пока нет

- Scaffolder Erector Medical ExaminationДокумент6 страницScaffolder Erector Medical ExaminationZulqarnain RamliОценок пока нет

- Scaffolding Risk AssesmentДокумент12 страницScaffolding Risk Assesmentsubhaschandra100% (1)

- Standard Operating Procedures of Hand and Power Tool SafetyДокумент3 страницыStandard Operating Procedures of Hand and Power Tool Safetysingenaadam100% (1)

- Lifting ChecklistДокумент13 страницLifting ChecklistEric T100% (1)

- Lockout - Tagout or LOTO ProcedureДокумент7 страницLockout - Tagout or LOTO ProcedureJose Mata100% (1)

- Akk Jha Installation of Diesel TankДокумент3 страницыAkk Jha Installation of Diesel TankDouglas Delly0% (1)

- Lifting Operations 2.034Документ10 страницLifting Operations 2.034svdnolen0% (1)

- Safe Work Method Statement - PlumbingДокумент4 страницыSafe Work Method Statement - PlumbingJohn KurongОценок пока нет

- Work at Height Regulations PDFДокумент25 страницWork at Height Regulations PDFBenedictus MurdonoОценок пока нет

- Work at Heights Self Assessment SheetДокумент4 страницыWork at Heights Self Assessment SheetBalogun IsaacОценок пока нет

- JGS SHES JHRA 002 13 Scaffolding Erection and DismantlingДокумент2 страницыJGS SHES JHRA 002 13 Scaffolding Erection and Dismantlingarnel sungkip100% (1)

- Activity Hazard AnalysisДокумент7 страницActivity Hazard AnalysisAnthony MacatangayОценок пока нет

- Forklift RAДокумент5 страницForklift RAFachri HidayatОценок пока нет

- Risk Assessment-Lifting of 10 Inch Pipeline With 6 CranesДокумент3 страницыRisk Assessment-Lifting of 10 Inch Pipeline With 6 CranesPerwez21Оценок пока нет

- EHS Occupational RegulationДокумент126 страницEHS Occupational RegulationKarthikeyan Sankarrajan100% (3)

- Pressure Testing Safety Awareness PDFДокумент15 страницPressure Testing Safety Awareness PDFShailendraОценок пока нет

- Power Tools - Montly HSE Inspection ChecklistДокумент3 страницыPower Tools - Montly HSE Inspection ChecklistphitoОценок пока нет

- JSA For Fab Erec of STRL Steel StackДокумент5 страницJSA For Fab Erec of STRL Steel StackkrishnakumarОценок пока нет

- Fse Risk Assessment ExampleДокумент11 страницFse Risk Assessment ExampleRami Fa'our100% (1)

- Job Safety Analysis Pre-Task Briefing: MASAR Project Makkah KSAДокумент2 страницыJob Safety Analysis Pre-Task Briefing: MASAR Project Makkah KSAmahammed saleem100% (2)

- DLF RCC HiraДокумент8 страницDLF RCC HiraskfahimuddinОценок пока нет

- Project Name of Inspector Location: Power Grinder InspectionДокумент1 страницаProject Name of Inspector Location: Power Grinder InspectionbalasubramaniamОценок пока нет

- Safe Work Procedure BulletinДокумент2 страницыSafe Work Procedure BulletinAndreas 'gondez' Siallagan100% (1)

- Safety: Life-Critical ProcedureДокумент12 страницSafety: Life-Critical ProcedureDharani SriramОценок пока нет

- Subject: Work at Height: Unit: Maihar Cement WorksДокумент3 страницыSubject: Work at Height: Unit: Maihar Cement Workskaka100% (1)

- Safe Work ProcedureДокумент2 страницыSafe Work Proceduresterlin gosineОценок пока нет

- HSA MEWPs GuidanceДокумент20 страницHSA MEWPs GuidancemadmossyОценок пока нет

- Monthly Store Inspection ReportДокумент1 страницаMonthly Store Inspection ReportgkОценок пока нет

- Appendix A-Job Safety Analysis FormДокумент3 страницыAppendix A-Job Safety Analysis Formjiks_i4uОценок пока нет

- Level Iii - Ims Operational Control Procedures Manual TITLE: Safe Handling of Tools Effective Date: January 21, 2018Документ9 страницLevel Iii - Ims Operational Control Procedures Manual TITLE: Safe Handling of Tools Effective Date: January 21, 2018arunkumar panigrahi100% (1)

- Hand and Power Tools Safety ExaminationДокумент21 страницаHand and Power Tools Safety ExaminationSharon GonzalezОценок пока нет

- PTA-JSA-003-Material Handling by Farhana F-15 CraneДокумент6 страницPTA-JSA-003-Material Handling by Farhana F-15 CraneSaiyad RiyazaliОценок пока нет

- Work at HightДокумент32 страницыWork at HightMY TEC SUPPORTОценок пока нет

- SFPSG-Rescue Persons From MEWPsДокумент10 страницSFPSG-Rescue Persons From MEWPsLyle KorytarОценок пока нет

- Chisels Risk AssessmentДокумент1 страницаChisels Risk AssessmentTawfik Mohamed Abu Zaid100% (1)

- JSA Template 2017-05-30 Powder Actuated ToolsДокумент19 страницJSA Template 2017-05-30 Powder Actuated ToolsJayvee Baradas Valdez100% (2)

- Grating Control ProcedureДокумент25 страницGrating Control ProcedureMuneeb Rehman100% (1)

- Manual Tig Welding (RRC) - Job ProcedureДокумент3 страницыManual Tig Welding (RRC) - Job Proceduretitto84886100% (1)

- Scffold & Lifitng Supervisor & Safety InspectorДокумент9 страницScffold & Lifitng Supervisor & Safety InspectorMuhamedragabОценок пока нет

- OCP 12 - Working at HeightДокумент2 страницыOCP 12 - Working at HeightVipin Kumar Parashar100% (1)

- Procedures For Gas Cutting EquipmentДокумент11 страницProcedures For Gas Cutting EquipmentJebaraj VОценок пока нет

- Window Cleaning Safety GuidelineДокумент4 страницыWindow Cleaning Safety Guidelinejhunvalencia1203Оценок пока нет

- Genie E Series Slab Scissor Lift OperationДокумент11 страницGenie E Series Slab Scissor Lift OperationSanket Arun MoreОценок пока нет

- Hand and Power Tools Safety PDFДокумент18 страницHand and Power Tools Safety PDFTim YapОценок пока нет

- Safety Checklist For Power Tools EquipmentДокумент5 страницSafety Checklist For Power Tools EquipmentLouieGonzales100% (1)

- CV Hamza wORKSHOP eNGINEERДокумент3 страницыCV Hamza wORKSHOP eNGINEERHamza NoumanОценок пока нет

- Direction On How To Replace A Fuel Filter.Документ5 страницDirection On How To Replace A Fuel Filter.Hamza NoumanОценок пока нет

- Replacing An Engine Drive BeltДокумент5 страницReplacing An Engine Drive BeltHamza NoumanОценок пока нет

- Quality Plan For WorkshopДокумент1 страницаQuality Plan For WorkshopHamza NoumanОценок пока нет

- List of Workshop Machines, 2011 RevisedДокумент3 страницыList of Workshop Machines, 2011 RevisedHamza Nouman100% (1)

- List of Documetns, Rev-2, 29-09-2012Документ4 страницыList of Documetns, Rev-2, 29-09-2012Hamza NoumanОценок пока нет

- Scaffolding: "It's Big, It's Ugly, It's There,"Документ2 страницыScaffolding: "It's Big, It's Ugly, It's There,"Hamza NoumanОценок пока нет

- Muhammad Rehan Khan Maintenance EngineerДокумент13 страницMuhammad Rehan Khan Maintenance EngineerHamza NoumanОценок пока нет

- Guidelines For Access ScaffoldingДокумент28 страницGuidelines For Access ScaffoldingHamza Nouman100% (1)

- Scaffold 2Документ2 страницыScaffold 2Hamza NoumanОценок пока нет

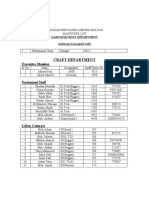

- Craft Department: Executive MemberДокумент2 страницыCraft Department: Executive MemberHamza NoumanОценок пока нет

- ER-Format (Version 1)Документ1 страницаER-Format (Version 1)Hamza NoumanОценок пока нет

- GRG-WP-IMS-005 Derating of Cranes Dump Truck (Updated)Документ5 страницGRG-WP-IMS-005 Derating of Cranes Dump Truck (Updated)Hamza NoumanОценок пока нет

- Introduction: Science and Environment: Brgy - Pampang, Angeles City, PhilippinesДокумент65 страницIntroduction: Science and Environment: Brgy - Pampang, Angeles City, PhilippinesLance AustriaОценок пока нет

- PANCREATITISДокумент38 страницPANCREATITISVEDHIKAVIJAYANОценок пока нет

- Original Sandeha NivariniДокумент117 страницOriginal Sandeha NivariniHmis BlrОценок пока нет

- PT4115EДокумент18 страницPT4115Edragom2Оценок пока нет

- Pelton2014 Para-Equilibrium Phase DiagramsДокумент7 страницPelton2014 Para-Equilibrium Phase DiagramsAbraham Becerra AranedaОценок пока нет

- Plaquette - PRECASEM - CIMEC 2019 English VersionДокумент18 страницPlaquette - PRECASEM - CIMEC 2019 English VersionFranck BertrandОценок пока нет

- Notice - Appeal Process List of Appeal Panel (Final 12.1.24)Документ13 страницNotice - Appeal Process List of Appeal Panel (Final 12.1.24)FyBerri InkОценок пока нет

- Part 3-Chap 2 - Classification of Buildings Based On OccupanciesДокумент60 страницPart 3-Chap 2 - Classification of Buildings Based On Occupanciesfaruque65Оценок пока нет

- Inverse Curve Trip Time Calculation: Enter Values in White CellДокумент3 страницыInverse Curve Trip Time Calculation: Enter Values in White CellVijay FxОценок пока нет

- Company Profile Pt. KPT PDFДокумент23 страницыCompany Profile Pt. KPT PDFfery buyaОценок пока нет

- Onitsuka Tiger PDFДокумент67 страницOnitsuka Tiger PDFAhmad Bilal MawardiОценок пока нет

- JMO 2023 (7, 8) Question PaperДокумент2 страницыJMO 2023 (7, 8) Question PaperSuryanshu BhardwajОценок пока нет

- Mono 108Документ438 страницMono 108pasaricaОценок пока нет

- BCSL 058 Previous Year Question Papers by IgnouassignmentguruДокумент45 страницBCSL 058 Previous Year Question Papers by IgnouassignmentguruSHIKHA JAINОценок пока нет

- American Pile Driving Equipment Equipment CatalogДокумент25 страницAmerican Pile Driving Equipment Equipment CatalogW Morales100% (1)

- Ah 1000Документ1 страницаAh 1000Zafir SihabuddinОценок пока нет

- Water Chemistry - An Introduction To The Chemistry of Natural and Engineered Aquatic Systems-Páginas-483-492Документ10 страницWater Chemistry - An Introduction To The Chemistry of Natural and Engineered Aquatic Systems-Páginas-483-492jhonier guevaraОценок пока нет

- Quality Traits in Cultivated Mushrooms and Consumer AcceptabilityДокумент40 страницQuality Traits in Cultivated Mushrooms and Consumer AcceptabilityShivendra SinghОценок пока нет

- The Hollow Boy Excerpt PDFДокумент52 страницыThe Hollow Boy Excerpt PDFCathy Mars100% (1)

- SVR Neuro Quote 2 PROvidoДокумент3 страницыSVR Neuro Quote 2 PROvidoChejarla Naveen KumarОценок пока нет

- Lecture 8Документ22 страницыLecture 8Ramil Jr. EntanaОценок пока нет

- UntitledДокумент413 страницUntitledjgj38j90Оценок пока нет

- Geology of Johannesburg ReadingДокумент2 страницыGeology of Johannesburg ReadingKavish DayaОценок пока нет

- Annie Ovenden Exibition 2017Документ19 страницAnnie Ovenden Exibition 2017Vitaliy ChuenkoОценок пока нет

- Psalm151 160Документ3 страницыPsalm151 160Gina KristenОценок пока нет

- Barium SulphateДокумент11 страницBarium SulphateGovindanayagi PattabiramanОценок пока нет

- Benefits of OTN in Transport SDNДокумент9 страницBenefits of OTN in Transport SDNGhallab AlsadehОценок пока нет

- What A Wonderful WorldДокумент3 страницыWhat A Wonderful Worldapi-333684519Оценок пока нет

- Diabetes in Pregnancy: Supervisor: DR Rathimalar By: DR Ashwini Arumugam & DR Laily MokhtarДокумент21 страницаDiabetes in Pregnancy: Supervisor: DR Rathimalar By: DR Ashwini Arumugam & DR Laily MokhtarHarleyquinn96 DrОценок пока нет

- Module 02 Connect Hardware Peripherals EndaleДокумент49 страницModule 02 Connect Hardware Peripherals EndaleSoli Mondo100% (1)