Академический Документы

Профессиональный Документы

Культура Документы

SATR-J - 6802 - Rev 0 PDF

Загружено:

Adel KlkОригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

SATR-J - 6802 - Rev 0 PDF

Загружено:

Adel KlkАвторское право:

Доступные форматы

A10

The "AC Safety Ground" bus shall be directly bolted to the cabinet

without the use of insulators.

23-SAMSS-010

Sec, 7.5.2.2

A9

AC Safety ground and instrumentation circuit ground shall conform to

NEC, Article 250.

23-SAMSS-010

Sec, 7.5.2.1

A4

Ensure that Items manufactured to this Specification(34-SAMSS-830)

are subject to the minimum Inspection Requirements as specified in

Saudi Aramco Inspection Requirement Form 175-344000.

34-SAMSS-830

Sec 12.2

34-SAMSS-830

Sec. 11.2.2

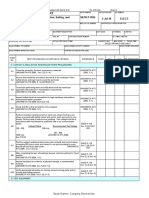

EC / PMCC / MCC NO. REV. NO. PURCHASE ORDER NUMBER

CONTRACTOR INSPECTION LEVEL

SAUDI ARAMCO TIP NUMBER SAUDI ARAMCO ACTIVITY NUMBER

RE-TEST DATE

ITEM

No.

TEST PROCEDURE ACCEPTANCE CRITERIA REFERENCE PASS FAIL N/A

TRAVEL TIME QUANTITY INSP.

WORK PERMIT REQUIRED?

ACTUAL INSPECTION DATE & TIME

SAUDI ARAMCO USE ONLY

MH's SPENT SCHEDULED INSPECTION DATE & TIME

SAUDI ARAMCO INSPECTION LEVEL

LAYOUT DRAWING NUMBER

PLANT NO. EQUIPMENT ID NUMBER(S) EQUIPMENT DESCRIPTION EQPT CODE SYSTEM ID.

PROJ ECT TITLE WBS / BI / J O NUMBER CONTRACTOR / SUBCONTRACTOR

Electronic Control Systems -PLC-Functional Testing

(Stand-alone as well as integrated with DCS)-

SATR-J-6802 1-Oct-05 INST

SAUDI ARAMCO ID/PID - 3/01/05 - REV 0 (Standards Cutoff - August 2004)

SAUDI ARAMCO TEST REPORT

SATR NUMBER DATE APPROVED QR NUMBER

A2

Review Factory Acceptance Test (FAT) documents detailing the set-up

and procedures for the Functional Test to be provided.

A3

Review documents that prove the following test has been conducted:

The radiated electromagnetic disturbance test shall be conducted in

accordance with IEC 60255-22-3, Test Method 'C', Severity Class -'II' or

IEC 61000-4-3, Level 3 (10 volts/meter).

A. General conformance of Tests

A1

34-SAMSS-830

Sec. 10 (h)

Vendor to provide Manufacturer's standard Programming, Installation,

Maintenance/Troubleshooting Manuals, and Processor, Power Supply,

Communications, I/O module specification sheets and tests conducted

for verification

34-SAMSS-830

Sec. 10 (g)

34-SAMSS-830,

Sec. 6

34-SAMSS-830,

Sec. 6.3.2

A5

Nonmaterial Requirements: The supplier shall provide nonmaterial items

as shown on Form NMR-7907.

34-SAMSS-830

Sec 12.2

A8

Tagging and Nameplates: All instruments, push buttons, switches,

lamps and other console mounted devices, as well as cabinets and

workstations shall be identified with tag numbers and service description.

The nameplates shall be permanently attached.

23-SAMSS-010

Sec, 7.5.1

A6

The PLC shall be self-checking, i.e., have automatic internal checking

capability (so-called 'self-diagnostics) to detect a failure. When a failure

occurs, an alarm shall be initiated.

A7

Communications driver software/firmware shall continuously monitor and

check the status of communication links and associated I/O.

Communication status indication shall be provided on the face plate of

each associated module.

A11

A No. 2 AWG screw-type compression connector shall be provided on

either end of each ground bar for interconnection with other ground

buses or to the Instrument System Ground Node (ISGN).

23-SAMSS-010

Sec, 7.5.2.3

A12

Ground buses inside termination cabinets shall be made of solid copper

measuring nominally in. x 1 in., suitably drilled and tapped for screw

terminals and wire lugs, or fitted with screw-type compression lugs.

23-SAMSS-010

Sec, 7.5.2.4

Page 1 of 3

B Functional Testing

SAUDI ARAMCO ID/PID - 3/01/05 - REV 0 (Standards Cutoff - August 2004)

SAUDI ARAMCO TEST REPORT

SATR NUMBER DATE APPROVED QR NUMBER

PASS FAIL

ITEM

No.

CONTRACTOR / SUBCONTRACTOR

Electronic Control Systems -PLC -Functional Testing

(Stand-alone as well as integrated with DCS)-

SATR-J-6802 1-Oct-05 INST

PROJ ECT TITLE WBS / BI / J O NUMBER

REFERENCE N/A RE-TEST DATE TEST PROCEDURE ACCEPTANCE CRITERIA

B3

A13

The ground bus bars shall be labeled as follows: a) "AC SAFETY

GROUND" for all exposed metal surface of cabinets, racks, chassis GND

connections, etc. Individual wiring interconnections shall be minimum 16

AWG copper wire, green or green with yellow tracer or green with yellow

tracer insulation.

23-SAMSS-010

Sec, 7.5.2.5 (a)

A15

The ground bus bars shall be labeled as follows: c) "DC REFERENCE

GROUND" (i.e., for all DC analog/digital commons). Interconnections

between DC common consolidation points and the bus bar shall be

minimum 18 AWG copper wire, insulation to be green or green with

yellow tracer.

23-SAMSS-010

Sec, 7.5.2.5(c)

34-SAMSS-830

Sec, 11.1.2

34-SAMSS-830

Sec, 11.1.1

B1

The Vendor is responsible for providing all test equipment required to

perform the tests described in this section. In addition, he shall perform

full functional tests and confirm that any problems have been resolved

prior to inviting Buyer's representative for the Buyer-witnessed functional

test.

B2

The complete system including all modules and interconnecting wiring

shall be subject to both hardware and software functional tests. These

tests shall demonstrate the functionality of each individual component

module within the integrated system, including individual I/O point tests.

Wire tagging and terminations shall be checked and "Tug" tested. (A tug

test involves physically stressing a wire termination to determine whether

it has been crimped and terminated properly. The intent is not to break

wiring or stress insulation but to test the integrity of the termination).

All software logic/application programs shall be checked against binary

logic diagrams and dynamically tested and verified for proper sequence

and functionality. The dynamic test will involve physically simulating all

inputs and outputs in their proper operational sequence, unexpected

operational sequence, and on power up to verify that the application

program logic is executed properly.

34-SAMSS-830

Sec, 11.1.3

B4

Any external communications link shall be functionally tested using reels

of cable to simulate the specified communication distance.

34-SAMSS-830

Sec, 11.1.4

B5

Radiated Electromagnetic Field Disturbance Test: The vendor shall

provide testing to confirm that the equipment will operate properly when

energized and subjected to an electromagnetic field from a radiating

source. In particular hand-held radio transceivers (walkie-talkies)

operating at 5 Watts within the frequency range of 68 MHz to 470 MHz.

34-SAMSS-830

Sec, 11.2.1

B6

The radiated electromagnetic disturbance test shall be conducted in

accordance with IEC 60255-22-3, Test Method 'C', Severity Class -'II' or

IEC 61000-4-3, Level 3 (10 volts/meter).

34-SAMSS-830

Sec, 11.2.2

A14

The ground bus bars shall be labeled as follows: b) "SHIELD

CONNECTION" for connecting cable and wire shields Interconnections

between shield consolidation points and the bus bar shall be minimum

16 AWG copper wire, green or green with yellow tracer insulation.

23-SAMSS-010

Sec, 7.5.2.5(b)

Page 2 of 3

SAUDI ARAMCO ID/PID - 3/01/05 - REV 0 (Standards Cutoff - August 2004)

SAUDI ARAMCO TEST REPORT

SATR NUMBER DATE APPROVED QR NUMBER

PASS FAIL

ITEM

No.

CONTRACTOR / SUBCONTRACTOR

Electronic Control Systems -PLC -Functional Testing

(Stand-alone as well as integrated with DCS)-

SATR-J-6802 1-Oct-05 INST

PROJ ECT TITLE WBS / BI / J O NUMBER

REFERENCE N/A RE-TEST DATE TEST PROCEDURE ACCEPTANCE CRITERIA

2. Attachment 2 --Segregation of parallel wiring internal to cabinets

3. 34-SAMSS-830. Programmable Logic Controller, 29 J anuary,2003

1. Schedule G -- Material, Tools and Equipment (Pro Forma MP-IK-LS Contract), J uly 1993

Name, Sign and Date:

Quality Record Approved:

Name, Organization,

Initials and Date:

Proponent and Others QC Supervisor

T&I Witnessed QC Record Reviewed

Name, Initials and Date:

Work Verified QC Record Reviewed T&I Witnessed

*Person Responsible for Completion of Quality Work / Test Y =YES N =NO F =FAILED

1. Approved - Acceptable to the authority having jurisdiction (i.e., Saudi Aramco ID).

QC Inspector

Work Verified

Name, Initials and Date:

Performed Inspection Work / Rework May Proceed

PID Representative

ATTACHMENTS:

2. Schedule Q -- Quality Requirements (Pro Forma Contract), November 2003

7. SAES-Z-001 Process Control Systems, 28 J anuary, 2004

Contractor / Third-Party Saudi Aramco

indicates compliance with appropriate standards or performance in a specified manner.

with product evaluation, that maintains periodic inspection of production of labeled equipment or materials, and by whose labeling the

that the equipment, material, or services either meets appropriate designated standards or has been tested and found suitable for a specified

NOTES:

2. Identified - Recognizable as suitable for the specific application by a qualified testing laboratory (i.e., listing and/or labeling).

REFERENCE DOCUMENTS:

REMARKS:

4. Labeled - Equipment or materials to which has been attached a label, symbol, or other identifying mark of an approved qualified organization

or services, that maintains periodic inspection of production of listed equipment or materials or periodic evaluation of services, and whose listing

1. Attachment-1 Air -borne dust concentration and contaminant levels 34-SAMSS-821 Sec 4.3

5. 23-SAMSS-010 Distributed Control Systems, 31 October, 1999.

6. 34-SAMSS-820- Instrument Control Cabinets - Indoor 29, May 2002

3. Listed - Equipment and materials included in a list published by an approved qualified organization concerned with evaluation of products

Work Verified

Construction Representative* PMT Representative

Name, Initials and Date:

Work is Complete and Ready for Inspection:

Name, Initials and Date:

T&I Witnessed QC Record Reviewed

4. 34-SAMSS-821- Instrument Control Cabinets - Outdoor 29, May 2002

Page 3 of 3

Вам также может понравиться

- Saudi Aramco Test Report: SATR-P-3210 3-Jul-18 Elect-Medium Voltage Power Cable, High-Potential Withstand TestingДокумент10 страницSaudi Aramco Test Report: SATR-P-3210 3-Jul-18 Elect-Medium Voltage Power Cable, High-Potential Withstand Testingkarthi51289Оценок пока нет

- Google Ads Certification - Study GuideДокумент6 страницGoogle Ads Certification - Study GuideHadassa KalungaОценок пока нет

- Inverter-Based Resource Performance Guideline NERCДокумент97 страницInverter-Based Resource Performance Guideline NERCSubhadeep PaladhiОценок пока нет

- Modeling and Control of Wind Power System PDFДокумент212 страницModeling and Control of Wind Power System PDFAdel Klk50% (2)

- Data Analyst Job DescriptionДокумент16 страницData Analyst Job DescriptionjannatbluebirdОценок пока нет

- Thomson Electrac HD Linear Actuator Motion Control per CAN BusОт EverandThomson Electrac HD Linear Actuator Motion Control per CAN BusОценок пока нет

- Intro Stats 5th Edition by Richard D de Veaux Ebook PDFДокумент42 страницыIntro Stats 5th Edition by Richard D de Veaux Ebook PDFdelmar.jackson88497% (36)

- Saudi Aramco Test ReportДокумент6 страницSaudi Aramco Test Reportkarthi51289Оценок пока нет

- SATR-J-6505-Rev 0 PDFДокумент5 страницSATR-J-6505-Rev 0 PDFAdel KlkОценок пока нет

- 400-200 KV Substation DesignДокумент62 страницы400-200 KV Substation DesignMousum91% (22)

- Satr-P-3210 Rev 7 FinalДокумент11 страницSatr-P-3210 Rev 7 FinalzhangОценок пока нет

- SATR-J-6601 Rev 0 PDFДокумент4 страницыSATR-J-6601 Rev 0 PDFAdel Klk100% (1)

- 123939-60A3 R1 Instrumentation Symbols and IdentificationДокумент31 страница123939-60A3 R1 Instrumentation Symbols and IdentificationSaid SalemОценок пока нет

- 34 Samss 820Документ33 страницы34 Samss 820Ramir AkbashevОценок пока нет

- Part - B: (Control and Instrumentation System)Документ267 страницPart - B: (Control and Instrumentation System)joydrathdey100% (1)

- Saudi Aramco Test ReportДокумент7 страницSaudi Aramco Test Reportkarthi51289Оценок пока нет

- SATR-J-6501 - Rev 0 PDFДокумент5 страницSATR-J-6501 - Rev 0 PDFAdel KlkОценок пока нет

- 43 - SAS EquipmentsДокумент65 страниц43 - SAS EquipmentsVelu SamyОценок пока нет

- Saic A 2011Документ5 страницSaic A 2011Anonymous 4e7GNjzGWОценок пока нет

- AWS Academy Cloud Architecting Module 12 Student Guide: 200-ACACAD-20-EN-SGДокумент53 страницыAWS Academy Cloud Architecting Module 12 Student Guide: 200-ACACAD-20-EN-SGM Rizki AsriyandaОценок пока нет

- Saudi Aramco Inspection Checklist: Verify Test Equipment (Safety Assessment) SAIC-A-2009 15-Dec-09 MechДокумент6 страницSaudi Aramco Inspection Checklist: Verify Test Equipment (Safety Assessment) SAIC-A-2009 15-Dec-09 MechEagle SpiritОценок пока нет

- 3 Day1 - Plant Operation Modes RAF - HandoutДокумент23 страницы3 Day1 - Plant Operation Modes RAF - HandoutAdel KlkОценок пока нет

- Network Design Manual v7.7Документ194 страницыNetwork Design Manual v7.7somchak2000100% (3)

- SATR-J-6602 Rev 0 PDFДокумент9 страницSATR-J-6602 Rev 0 PDFAdel KlkОценок пока нет

- Design of EHV SubstationДокумент66 страницDesign of EHV SubstationMadanasekhar Tadimarri100% (1)

- Saudi Aramco Pre-Commissioning Form: Outdoor SubstationsДокумент2 страницыSaudi Aramco Pre-Commissioning Form: Outdoor SubstationsHaleem Ur Rashid BangashОценок пока нет

- CFB PresentationДокумент48 страницCFB PresentationSam100% (3)

- Third-Party Tools As Destinations For OHDДокумент27 страницThird-Party Tools As Destinations For OHDNeha JhaОценок пока нет

- Cooling Tower Thermal DesignДокумент106 страницCooling Tower Thermal Designxuense100% (4)

- INFOSTEEL - Guide To Protection of Steel Against CorrosionДокумент8 страницINFOSTEEL - Guide To Protection of Steel Against CorrosionA87_navjОценок пока нет

- VIDS Message Center Keypad Operator Instruction: D10R D11R D11R CDДокумент24 страницыVIDS Message Center Keypad Operator Instruction: D10R D11R D11R CDADJIMGARОценок пока нет

- SAIC & SATR - InstrumentationДокумент7 страницSAIC & SATR - InstrumentationAdel KlkОценок пока нет

- Saudi Aramco Inspection ChecklistДокумент12 страницSaudi Aramco Inspection Checklistnisha_khanОценок пока нет

- Saudi Aramco Inspection ChecklistДокумент10 страницSaudi Aramco Inspection Checklistnisha_khanОценок пока нет

- Saudi Aramco Inspection ChecklistДокумент9 страницSaudi Aramco Inspection Checklistnisha_khanОценок пока нет

- Saudi Aramco Test Report: UPS Distribution System, Energized Bolted - Fault Test SATR-P-3112 3-Jul-18 ElectДокумент3 страницыSaudi Aramco Test Report: UPS Distribution System, Energized Bolted - Fault Test SATR-P-3112 3-Jul-18 Electkarthi51289Оценок пока нет

- Engineering Instruction Acceptance Testing of C-DOT ATM SystemДокумент8 страницEngineering Instruction Acceptance Testing of C-DOT ATM SystemApoorv VermaОценок пока нет

- SATR-P-3417 Rev 7 FinalДокумент6 страницSATR-P-3417 Rev 7 FinalzhangОценок пока нет

- Saudi Aramco Test Report: SATR-P-3105 Elect-UPS DC/AC Inverter, Pre-Commissioning & Functional TestingДокумент9 страницSaudi Aramco Test Report: SATR-P-3105 Elect-UPS DC/AC Inverter, Pre-Commissioning & Functional TestingehteshamОценок пока нет

- WI-NG-6460-002-103 Work Instruction For - Ammeter Rev00Документ7 страницWI-NG-6460-002-103 Work Instruction For - Ammeter Rev00Mohamed NasrОценок пока нет

- SAIC & SATR - InstrumentationДокумент8 страницSAIC & SATR - InstrumentationAdel KlkОценок пока нет

- Saudi Aramco Test ReportДокумент5 страницSaudi Aramco Test Reportkarthi51289Оценок пока нет

- CCL 3Документ59 страницCCL 3Srinivasan RamachandranОценок пока нет

- Saudi Aramco Inspection ChecklistДокумент5 страницSaudi Aramco Inspection ChecklistAdel KlkОценок пока нет

- SATR-J-6911Rev 0 PDFДокумент6 страницSATR-J-6911Rev 0 PDFAdel KlkОценок пока нет

- CL-NG-6460-002-048 Checklist For AC Distribution Panels Rev00Документ3 страницыCL-NG-6460-002-048 Checklist For AC Distribution Panels Rev00sachin francisОценок пока нет

- Saudi Aramco Test Report: Elect-LV Controlgear - ATS / MTS Calibration, Setting, and Functional Testing SATR-P-3824Документ6 страницSaudi Aramco Test Report: Elect-LV Controlgear - ATS / MTS Calibration, Setting, and Functional Testing SATR-P-3824Ma.socorro SaballaОценок пока нет

- Ei GSM Ericsson) Bts atДокумент5 страницEi GSM Ericsson) Bts atGayan IndikaОценок пока нет

- Saudi Aramco Test Report: UPS/DC Vented Ni-Cad Wet Cell, Jobsite Acceptance Test SATR-P-3102 ElectДокумент7 страницSaudi Aramco Test Report: UPS/DC Vented Ni-Cad Wet Cell, Jobsite Acceptance Test SATR-P-3102 ElectehteshamОценок пока нет

- BuswayДокумент5 страницBuswayuddinnadeemОценок пока нет

- Cooper Bussman NSC CRДокумент21 страницаCooper Bussman NSC CRrjpatil19Оценок пока нет

- Saudi Aramco Test ReportДокумент5 страницSaudi Aramco Test Reportkarthi51289Оценок пока нет

- Saudi Aramco Test Report: Final Inspection/Re-Instatement Punch ListДокумент17 страницSaudi Aramco Test Report: Final Inspection/Re-Instatement Punch ListnadeemОценок пока нет

- EET 4350 10 FaultsДокумент103 страницыEET 4350 10 FaultsSunny ModiОценок пока нет

- SATR-J-6406 Rev 0 PDFДокумент10 страницSATR-J-6406 Rev 0 PDFAdel KlkОценок пока нет

- Saudi Aramco Test ReportДокумент8 страницSaudi Aramco Test ReportMa.socorro SaballaОценок пока нет

- WI-NG-6460-002-084 Work Instruction For LCC Panel Scheme Check and Function Test Rev00Документ9 страницWI-NG-6460-002-084 Work Instruction For LCC Panel Scheme Check and Function Test Rev00Mohamed NasrОценок пока нет

- SATR-J-6912 Rev 0 PDFДокумент4 страницыSATR-J-6912 Rev 0 PDFAdel KlkОценок пока нет

- Saudi Aramco Test ReportДокумент3 страницыSaudi Aramco Test ReportMa.socorro SaballaОценок пока нет

- Satip-X-600-02 Rev 1 For CP SystemДокумент4 страницыSatip-X-600-02 Rev 1 For CP SystemSaleem MohammedОценок пока нет

- Saudi Aramco Test Report: Final Inspection/Re-Instatement Punch ListДокумент11 страницSaudi Aramco Test Report: Final Inspection/Re-Instatement Punch ListEswari AnandОценок пока нет

- 121114.001 - Specification For - TCN - VCU - Website PDFДокумент32 страницы121114.001 - Specification For - TCN - VCU - Website PDFSunil JadhavОценок пока нет

- WI-NG-6460-002-083 - Work Instruction For Panel Scheme Check and Function Tests Rev00Документ9 страницWI-NG-6460-002-083 - Work Instruction For Panel Scheme Check and Function Tests Rev00Mohamed NasrОценок пока нет

- Saudi Aramco Test ReportДокумент7 страницSaudi Aramco Test Reportkarthi51289Оценок пока нет

- Saudi Aramco Test Report: Overhead T&D - High-Potential Withstand Testing SATR-P-3220 3-Jul-18 ElectДокумент8 страницSaudi Aramco Test Report: Overhead T&D - High-Potential Withstand Testing SATR-P-3220 3-Jul-18 Electkarthi51289Оценок пока нет

- Saudi Aramco Test Report: 30-Apr-13 Elect-DC Switchboard / CB'S, Pre-Commissioning & Functional Testing SATR-P-3116Документ5 страницSaudi Aramco Test Report: 30-Apr-13 Elect-DC Switchboard / CB'S, Pre-Commissioning & Functional Testing SATR-P-3116zhangОценок пока нет

- Saudi Aramco Test Report: Switchyard - HV Mechanical Termination Torque Testing SATR-P-3901 3-Jul-18 ElectДокумент8 страницSaudi Aramco Test Report: Switchyard - HV Mechanical Termination Torque Testing SATR-P-3901 3-Jul-18 Electkarthi51289Оценок пока нет

- SAIC-A-2025 Rev 6 Pre Test Pressure VesselДокумент4 страницыSAIC-A-2025 Rev 6 Pre Test Pressure Vesselpookkoya thangal100% (1)

- Saudi Aramco Inspection ChecklistДокумент6 страницSaudi Aramco Inspection ChecklistMa.socorro SaballaОценок пока нет

- Saudi Aramco Test Report: 3-Jul-18 Elect-DC Switchboard / CB'S, Pre-Commissioning & Functional Testing SATR-P-3116Документ5 страницSaudi Aramco Test Report: 3-Jul-18 Elect-DC Switchboard / CB'S, Pre-Commissioning & Functional Testing SATR-P-3116karthi51289Оценок пока нет

- Saudi Aramco Inspection Checklist: Intrinsically Safe Circuit - Circuit Final Inspection SAIC-J-6906 24-Jul-18 InstДокумент3 страницыSaudi Aramco Inspection Checklist: Intrinsically Safe Circuit - Circuit Final Inspection SAIC-J-6906 24-Jul-18 Instnisha_khanОценок пока нет

- On-Chip Electro-Static Discharge (ESD) Protection for Radio-Frequency Integrated CircuitsОт EverandOn-Chip Electro-Static Discharge (ESD) Protection for Radio-Frequency Integrated CircuitsОценок пока нет

- Inverter Topologies and Control Structure in Photovoltaic Applications: A ReviewДокумент24 страницыInverter Topologies and Control Structure in Photovoltaic Applications: A ReviewKrishna PrasathОценок пока нет

- Low Voltage Ride ThroughДокумент11 страницLow Voltage Ride ThroughAdel KlkОценок пока нет

- Headlines DL - NERC 2013 Annual Report - Final - WebДокумент31 страницаHeadlines DL - NERC 2013 Annual Report - Final - WebAdel KlkОценок пока нет

- PDS in ElectricalДокумент16 страницPDS in ElectricalPepe Garcia EstebezОценок пока нет

- Power Management and Control Strategies For Off-Grid Hybrid Power Systems With Renewable Energies and StorageДокумент7 страницPower Management and Control Strategies For Off-Grid Hybrid Power Systems With Renewable Energies and StorageAdel KlkОценок пока нет

- Kelada, Buire JCGE22Документ7 страницKelada, Buire JCGE22Adel KlkОценок пока нет

- Guide To Protection of Steel Against CorrosionДокумент9 страницGuide To Protection of Steel Against CorrosionAdel KlkОценок пока нет

- Reactive Power and Fuel CalculationДокумент10 страницReactive Power and Fuel CalculationAdel KlkОценок пока нет

- Reactive Energy CompensationДокумент38 страницReactive Energy Compensationcyo3fffОценок пока нет

- Transmission System Performance Analysis For High-Penetration Photovoltaics PDFДокумент77 страницTransmission System Performance Analysis For High-Penetration Photovoltaics PDFkm11kartalОценок пока нет

- Transmission LineДокумент2 страницыTransmission LineAdel KlkОценок пока нет

- Transmission LineДокумент2 страницыTransmission LineAdel KlkОценок пока нет

- Lesson Learned From Int - Wind Integration StudiesДокумент109 страницLesson Learned From Int - Wind Integration StudiesAdel KlkОценок пока нет

- 3 Fulfillment of Grid CodeДокумент21 страница3 Fulfillment of Grid CodeAdel KlkОценок пока нет

- Grid Code China Vs Amerca5Документ50 страницGrid Code China Vs Amerca5Adel KlkОценок пока нет

- 3 2 GIZ17 XXX Presentation Sandip SharmaДокумент49 страниц3 2 GIZ17 XXX Presentation Sandip SharmaAdel KlkОценок пока нет

- Blackout PreventionДокумент8 страницBlackout PreventionAdel KlkОценок пока нет

- 3 3 GIZ17 XXX Presentation J HenkelДокумент28 страниц3 3 GIZ17 XXX Presentation J HenkelAdel KlkОценок пока нет

- 3 4 GIZ17 XXX Presentation Clemens HoffmannДокумент20 страниц3 4 GIZ17 XXX Presentation Clemens HoffmannAdel KlkОценок пока нет

- 3 1 GIZ17 XXX Presentation Ernesto HuberДокумент36 страниц3 1 GIZ17 XXX Presentation Ernesto HuberAdel KlkОценок пока нет

- NERC Balancing and Frequency Control 040520111Документ53 страницыNERC Balancing and Frequency Control 040520111pongpumОценок пока нет

- Using Clcs in Real-Time Applications: Wwwproducts/En/Pic18F47Q10Документ41 страницаUsing Clcs in Real-Time Applications: Wwwproducts/En/Pic18F47Q10Bruno LeppeОценок пока нет

- Group No.: 8 Section Code: B315 Group Leader: Group MembersДокумент21 страницаGroup No.: 8 Section Code: B315 Group Leader: Group MembersAlfie BautistaОценок пока нет

- AIF BizTalk Adapter Configuration For Data Exchange Part IIДокумент46 страницAIF BizTalk Adapter Configuration For Data Exchange Part IIUmbBОценок пока нет

- Ministry of Communications & Informatics: Libyan National Frequency Plan (LNFP)Документ255 страницMinistry of Communications & Informatics: Libyan National Frequency Plan (LNFP)Ali AbushhiwaОценок пока нет

- Gaz Classifieds 220514Документ6 страницGaz Classifieds 220514Digital MediaОценок пока нет

- What Is Test Scenario - Template With ExamplesДокумент3 страницыWhat Is Test Scenario - Template With ExamplesFlorin ConduratОценок пока нет

- IkeGPS 2 Page BrochureДокумент2 страницыIkeGPS 2 Page BrochureShawn FausОценок пока нет

- Thomson THG540Документ36 страницThomson THG540Tibi SloviОценок пока нет

- Datasheet IPM 100RSE120Документ6 страницDatasheet IPM 100RSE120Alif AriyadiОценок пока нет

- Comprehensive ExamДокумент4 страницыComprehensive ExamMonit AgrawalОценок пока нет

- "A Study of Online Trading and Stock Broking": A Project Report OnДокумент85 страниц"A Study of Online Trading and Stock Broking": A Project Report OnShubha DevОценок пока нет

- XDKДокумент584 страницыXDKreksab_16Оценок пока нет

- Lo Datasources: Logistic Cockpit (LC) Is A Technique To Extract Logistics Transaction Data From R/3Документ4 страницыLo Datasources: Logistic Cockpit (LC) Is A Technique To Extract Logistics Transaction Data From R/3Dennis VuОценок пока нет

- 02-Ax 2012 Admin Wkshp-Installation and ConfigurationДокумент59 страниц02-Ax 2012 Admin Wkshp-Installation and Configurationمحمد زكريОценок пока нет

- P780Документ50 страницP780Shailesh BhanushaliОценок пока нет

- Blues Scales PDFДокумент2 страницыBlues Scales PDFWayne OnSaxОценок пока нет

- USBDF01W5 (SMD UD1 Sot323-5l)Документ11 страницUSBDF01W5 (SMD UD1 Sot323-5l)VasyaОценок пока нет

- PROJECTДокумент34 страницыPROJECTBiswajit PaulОценок пока нет

- OpenNebula WorkshopДокумент5 страницOpenNebula WorkshopThangavel MuruganОценок пока нет

- NS2 Lab2Документ11 страницNS2 Lab2Tech Talk Paper PresentationОценок пока нет

- eS383P Supported OS EДокумент2 страницыeS383P Supported OS EEmad SaadОценок пока нет

- Product Description FONST 3000 (Intelligent OTN Equipment)Документ310 страницProduct Description FONST 3000 (Intelligent OTN Equipment)mohd fauzi mohamad yusofОценок пока нет

- 04 Activity 1 - PLATTECHДокумент2 страницы04 Activity 1 - PLATTECHMarc GonzalesОценок пока нет

- Broadband Policy-Draft - EnglishДокумент16 страницBroadband Policy-Draft - EnglishReg BhandariОценок пока нет