Академический Документы

Профессиональный Документы

Культура Документы

Coal India Machinery

Загружено:

Ashish Kumar0 оценок0% нашли этот документ полезным (0 голосов)

84 просмотров48 страницcoal india machinery

Авторское право

© © All Rights Reserved

Доступные форматы

PDF, TXT или читайте онлайн в Scribd

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документcoal india machinery

Авторское право:

© All Rights Reserved

Доступные форматы

Скачайте в формате PDF, TXT или читайте онлайн в Scribd

0 оценок0% нашли этот документ полезным (0 голосов)

84 просмотров48 страницCoal India Machinery

Загружено:

Ashish Kumarcoal india machinery

Авторское право:

© All Rights Reserved

Доступные форматы

Скачайте в формате PDF, TXT или читайте онлайн в Scribd

Вы находитесь на странице: 1из 48

1

COAL MINING IN INDIA

COAL INDIA LIMITED

PRESENTATION AT IMME 2008

:: KOLKATA :: 5

th

NOVEMBER 2008 ::

3/31/2009 2

Indias Energy Landscape

Abundance of coal resources compared to oil and gas

-- Indian energy supply largely dependent on coal

Coal contributes to about 55% of the commercial energy

consumption as compared to 27 % world average

India is the 3rd largest coal producing country after China

and USA.

More than 65% of electricity generation capacities are

coal based.

Surging oil and international coal prices compels coal

Industry to play key role for energy security of the country

3

COAL INDIA LTD (CIL) PROFILE

Contributes around 85% of coal production in India.

Meets 46% of commercial energy needs of the country

Single largest coal producing company in the World

Employs over 420 thousand persons and is the largest

corporate employer in the country.

One of the largest Companies in the country, turnover

being 9.69 billion US $ in 2007-08

Paid 1.09 billion US $ to Govt. exchequer by way of Tax in

2007-08

Paid highest ever Dividend of 426 million US $ to the Govt.

of India in 2007-08

In India, CIL offers coal at much lesser price than the

International prices.

4

COAL INDIAS OPERATION

Spreads over Eight States in India (Jharkhand, West

Bengal, Orissa, Chattisgarh, M.P, U.P, Maharashtra &

Assam)

Operates 473 Mines (UG Mines:283, OC Mines:155, Mixed

Mines:35) through 7 coal producing Subsidiary companies

(ECL, BCCL, CCL, SECL, WCL, NCL, MCL) and one

consultancy company (CMPDIL)

Operates 17 Washeries

( Coking Coal - 11, Non Coking coal - 6 )

Has Over 200 Other Establishments Like Workshops,

Hospitals, Captive Power Plants Etc.

5

1

2

3

4

5

6

7

9

8

10

COAL

LIGNITE

A. CIL :COAL PRODUCING SUBSIDIARIES

EASTERN COALFIELDS LTD.(ECL) (1)

BHARAT COKING COAL LTD.(BCCL) (2)

CENTRAL COALFIELDS LTD.(CCL) (3)

NORTHERN COALFIELDS LTD.(NCL) (4)

WESTERN COALFIELDS LTD.(WCL) (5)

SOUTH EASTERN COALFIELDS LTD.(SECL) (6)

MAHANADI COALFIELDS LTD.(MCL) (7)

NORTH EASTERN COALFIELDS.(NEC) (8)

( A UNIT UNDER CIL(HQ) )

PLANNING & DESIGN INSTITUTE

CENTRAL MINE PLANNING & DESIGN

INSTITUTE (CMPDIL)

B. SINGARENI COLLIERIES CO. LTD. (9)

(SCCL)

C. NEYVELI LIGNITE CORPORATION (10)

(NLC)

6

CONSUMER PROFILE (2007-08 )

POWER

74.68%

OTHERS*

9.75%

SPONGE IRON

3.25%

CPP

6.76%

CEMENT

2.54%

FERTILIZER

0.68%

STEEL

2.35%

OTHERS(Non core): SSF (Special Smokeless Fuel) units, Briquette manufacturing

units, Chemical, Glass & Potteries, Leather units, coke oven etc.

7

1956 Setting up of NCDC a Govt. UT

1972 Nationalisation of coking

coal mines

1973 Nationalisation of

non-Coking coal mines

456.40mts .

The Growth of

Indian Coal Industry

.

80.93mts

C

o

a

l

P

r

o

d

u

c

t

i

o

n

Systematic Mining

2007-08

1774 Start of Coal Mining in India

1900 Coal Production 6.12 mts.

1920 Coal Production 18 mts.

1942 Coal Production 29 mts.

1946 Coal Production 30 mts.

1947 Advent of Independence

.

1956 Takeover of SCCL mines by Govt.

6.12mts

C

o

a

l

P

r

o

d

u

c

t

i

o

n

8

YEAR WISE INCREASE IN PROFITABILITY

(PROFIT BEFORE TAX)

M

I

L

L

I

O

N

U

S

$

-

1

3

-

3

5

-

2

4

2

-

6

1

-

1

0

1

-

5

6

2

0

4

2

1

0

0

1

5

3

4

5

1

1

7

4

7

1

6

1

2

2

2

1

2

0

1

2

1

6

9

2

1

3

0

2

1

6

4

-1000

-600

-200

200

600

1000

1400

1800

2200

75-76 79-80 83-84 87-88 91-92 95-96 99-00 '03-04 '05-06 '07-08

9

Coal Production in India 2007-08

Coal India

Limited

IISCO

NEC

Private

34.38mt

Govt Companies 422.12mt

Singareni

Collieries Ltd

TISCO Others

ECL

NCL

MCL

BCCL CCL WCL

SECL NCL

CMPDI

24.06mt 25.22mt 44.17mt 43.51mt

93.79mt 59.62mt

88.01mt Expl, Plng

40.60mt 1.1mt 1.02mt

7.21mt 27.17mt

379.49mt

10

DEMAND SUPPLY PROJECTION

Mill T

70 40.85 COKING

Shortfall - 10.25 NON-COKING

1020.00 662.60 NON-COKING

1125.00 731.10 TOTAL

1020.00 652.35 NON-COKING

35.00 27.65 COKING

PRODUCTION

1055.00 680.00 TOTAL

DEMAND

Year 2016-17 2011-12

70 51.10 TOTAL

105.00 68.50 COKING

11

Investment Opportunities /

New Avenues in Coal India

Limited

12

UNDERGROUND MINE

13

Development and Operation of High capacity

Underground Mines

17 Expression of Interests (EoI) have been received for

Construction, Development and Operation of 2 to 5 million tonne

annual Capacity 7 Underground Mines

The EoIs are under scrutiny. Limited tender will be floated

amongst short listed parties after pre-NIT meeting

The bidding will be opened for Contractual Operation by

successful bidder in each project

Scope Includes Exploration, Mine Planning, Mine Construction,

Mine Development, Mine Operation on Long-term basis

14

Extraction of Residual Coal from Closed /

Abandoned Mines

A large number of Underground Mines are Closed/ Abandoned

for reasons of

Depletion of Reserves having residual Coal as Protective

Pillars

Mine Fire in the Working Seam/ Neighboring Seam(s)

Presence of Waterlogged Old Working in and around the

Mine

Poor Economic Returns due to obsolete technology

15

Coal India Intends to Re-open such Mines for

Extraction of Residual Coal

For the First Phase of Re-opening/ Operation 18 Mines

having Cumulative Reserves of 1647 million tonne are

being Considered

These Mines are Open for Joint Venture Participation

by Internationally Reputed Mining Companies

Detailed Notice for Inviting Expression of Interest

formulated and floated on 6.8.08. Revised last date of

submission is 12.11.08

Details are available in www.coalindia.nic.in

16

UNDER GROUND MINING EQUIPMENT

6

5

264

774

Existing

1

6

42

138

09-10

1

12

25

47

10-11

6

16

23

43

11-12 08-09

Proposed Future Requirement Equipment

Side Discharge

Loader

126

Load Haul

Dump

49

Continuous

Miner

4

Power Support

Longwall

1

17

OPENCAST MINE

18

Opportunities in opencast mining

From the present level of 335 Mt, the production in OC

mines is expected to reach a level of 465 Mt in 2011-12

and 606 Mt in 2016-17

Introduction of higher capacity/size equipment to

support the growth parameters like:

Rope shovel with bucket capacity up to 42 cum

10-15 cum hydraulic shovel

Rear dumper up to 240 t

Dozers up to 850 hp

Long term Maintenance And Repair Contract

( MARC) with OEM.

19

In-pit crushing & conveying technology as an alternative

for large volume handling

Use of Mobile crushing unit

Drilling and Exploration

Airborne laser Terrain mapping (ALTM) technology for

regular monitoring of excavation and land restoration

status in respect of Opencast Mines

Use of GPS based TDS system in mining operation.

20

Future Requirement - DRAGLINE

15

2

24

-

Existing

1

09-10

1

10-11

0

11-12 12-13 08-09

Proposed Future Requirement Size

42 M

3

20-30 M

3

10-15 M

3

2 0

5-10 M

3

21

Future Requirement - ROPE SHOVEL

111

6

9

Existing

12

0

2

09-10

5

2

0

10-11

6

1

0

11-12 12-13 08-09

Proposed Future Requirement Size

42 M

3

1 1

20 M

3

0 2

12.5 M

3

10 M

3

11 3

22

Future Requirement - HYDRAULIC EXCAVATOR

99

224

29

4

Existing

18

20

27

3

09-10

14

16

16

4

10-11

5

17

10

4

11-12 12-13 08-09

Proposed Future Requirement Size

More than

10 M

3

3 0

5-10 M

3

23 9

2.2-5 M

3

44 12

2.2 M

3

&

below

29 12

23

Future Requirement - REAR DUMPER

675

678

260

35

Existing

267

110

14

10

14

09-10

206

96

12

15

4

10-11

141

106

51

5

4

11-12 12-13 08-09

Proposed Future Requirement Size

240 T 8 7

170 T 26 1

120/150 T 35 15

85/100 T 240 55

50/60 T 153 153

24

Future Requirement - DOZER (High Capacity)

21

42

520

406

9

Existing

1

8

77

49

1

09-10

0

9

40

29

10

10-11

0

9

77

50

6

11-12 12-13 08-09

Proposed Future Requirement Size

Crawler

More than

700 HP

11 2

410 HP 122 37

320 HP 66 32

Wheel

400 HP 2 5

300 HP 1 3

25

Future Requirement - DRILL

410

245

15

Existing

89

20

2

09-10

67

20

0

10-11

43

11

0

11-12 12-13 08-09

Proposed Future Requirement Size

311 MM &

above

1 1

250 MM 47 14

160 MM 84 32

26

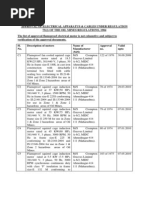

TENTATIVE REQUIREMENT OF OTR TYRES

UPTO 2011-12

TYRE SIZE

EXISTING

08-09 09-10 10-11 11-12 TOTAL

UPTO

11-12

40.00 X 57

(240T)

- 24 62 74 160

36.00 X 51

(170T)

64 161 192 230 647

30.00 X 51

(120T)

473 766 914 1093 3246

24.00 X 49

(85T)

1586 2686 2915 3168 10355

27

COAL RESOURCES -

OPPORTUNITIES IN EXPLORATION &

DRILLING

28

INDIAN COAL RESERVES

As on 1.4.2008

(Bill Tonnes)

33.34

231.2

Coking Non-Coking

TOTAL RESOURCE 264.54 Bt

29

GEOLOGICAL RESOURCES OF INDIAN COAL

CATEGORYWISE AND DEPTHWISE (AS ON 01.04.2008)

Depth (M) Proved Indicated Inferred Total %

0-300 79.34 66.84 14.34 160.52 60.7

300-600 7.11 45.22 18.10 70.43 26.6

0-600 (For

Jharia)

137.1 0.50 - 14.21 5.4

600-1200 1.67 11.66 6.05 19.37 7.3

Total 101.83 124.22 38.49 264.54 100

% 38.49 46.96 14.55 100 -

(In Billion Tonnes)

30

Targets of Drilling for CMPDIL (2007-08 to 11-12)

2.34 million metre exploratory drilling has to be achieved by

departmental resources and outsourcing.

In 2007-08, 0.209 million metre of drilling has been achieved.

Departmental capacity to be increased from 0.20 million

metre to 0.4 million metre by 2011-12. Outsourcing will

continue during this period to achieve XI plan targets.

Action initiated to enhance drilling capacity to 1.00 million

metre/annum through departmental resources and

outsourcing.

31

Projected Phasing of Exploration Program of CMPDIL in XI Plan

Projected Phasing of Exploration Program of CMPDIL in XI Plan

(in thousand m) (in thousand m)

Block- types 2007-08

Actual

2008-09

Program

2009-10

Projected

2010-11

Projected

2011-12

Projected

XI Plan

Total

CIL Command 161 149 207 194 199 910

Outside CIL

Command

045 174 265 423 443 1350

Regional/Promo

tional

003 004 017 021 023 68

St.Govt. - 013 003 - - 16

Total 209 340 492 638 665 2344*

Through

outsourcing

- - 508 362 335 1205

Total 209 340 1000 1000 1000 3549

*Action initiated to enhance drilling capacity to 1.0 million metre/annum through departmental

resources and outsourcing.

32

Outsourcing to Augment Exploration Capacity

9 blocks for 0.359 million metre Work Order issued

4 blocks for 0.028 million metre through National

tenders LOI issued.

8 blocks involving 0.65 million metre Global tender

floated. (Last date extended ,details and documents

available at web site : www.cmpdi.co.in ,

www.cmpdi.gov.in )

Expression of Interest invited and received from

National/International parties for undertaking

detailed exploration of Indian coal blocks involving

1.0 million metre/annum of drilling. EOI is under

evaluation.

33

COAL BENEFICIATION

34

Setting up of Coal Beneficiation Plants

WASHED COAL SUPPLY POLICY

Coal India has taken a policy decision to supply washed non-

coking coal to all consumers by 2011-12 except pit head

consumers.

Coal India is going to set up Coal Washeries within next four

years for a total capacity of 100.6 MTY (Primarily for non-coking

coal)

These Washeries will be built up, commissioned, operated and

maintained by Private Operators selected by Global Bidding

process.

Coal India will provide Fund and infrastructure like land, power,

water, Railway siding.

35

WASHERIES TO BE SET UP IN DIFFERENT

SUBSIDIARY COMPANIES IN 1ST PHASE

SL.NO. NAME OF

COMPANY

CAPACITY

(MTY)

No. OF

WASHERY

1. ECL 7.50 2

2. BCCL 18.60 6

3. CCL 19.50 4

4. SECL 10.00 2

5. MCL 40.00 4

6. WCL 5.00 1

Total 100.60 19

36

COAL VIDESH

37

COAL VIDESH GOING GLOBAL

Widening of Demand-Supply Gap and Growing Imports

Imports -> 2005-06 : 38 Mt 2006-07 : 45 Mt

2011-12 : 51 Mt 2024-25 : 180 Mt

Constraint of Indian coal reserves :

Limited coking and low ash non-coking reserves

Leveraging Core Competence Abroad :

Core competence in coal business value chain can be gainfully leveraged in the

international market.

Transnational Business Competence :

Develop transnational business competence to venture into strategic

opportunities abroad for yielding higher ROI and as well add value by inheriting

global best practices

38

Supplementing production from mines abroad

CIL is pursuing the initiatives of acquiring coal resources abroad

through two alternative routes :

Participation in JV of PSUs for formation of an SPV to secure coal

resources abroad

SPV was accorded approval of the Cabinet on 8th Nov 2007

SPV proposed to be formally registered as Coal Ventures International

CIL a major stakeholder with contribution of Rs 1000 Crs in equity of

Rs 3500 Crs

Acquisition of coal mines/blocks by CIL

Pursued through Coal Videsh Division functioning at CIL(HQ)

CIL Board approved several proposals to operationalize the venture;

Govt. approval is awaited

39

PROCUREMENT

BY COAL INDIA LIMITED

40

HEMM PROCUREMENT

Heavy Earth Moving Machinery (HEMM)

Draglines( 15-55 Cu mtrs)

Electric shovels (5-42 cu mtrs)

Hydraulic Shovels( 2-10 Cu mtrs)

Dump Trucks ( 50-240 Tons)

Blast Hole drills(160mm 380mm)

Crawler Dozers (320- 850 HP)

Wheel Dozers (320-410 HP)

Front end loaders (2-10 cu mtrs)

Tyre handlers

Motor Graders(145-280 HP)

CONTD.

41

UG MACHINERY PROCUREMENT

Underground Mining Machinery

At Face (Continuous Miner, Side Discharge

Loaders,Load Haul Dumpers,Belt conveyors,

Coal drills, Long Wall equipment)

For transport (Haulages, Shuttle cars,

Conveyors, Winding engines, Cages and skips)

For ventilation ( Ventilation Fans,Auxiliary fans)

Pumps and compressors

For Crushing ( Coal crushers, Vibratory screens)

Electrical equipments ( Transformers,ACB, OCB,

Switch gears)

Safety items ( Cap lamps,Breathing apparatus,

Self rescuers)

42

CILs Annual Volume of Purchase

Maintenance Repair Operation (MRO),

spare parts and consumables : Rs 3000

crores (US $ 650 millions ) ( 1 $= Rs 45)

Plant, machinery, capital equipments Rs

4000 crores (US $ 880 millions )

Services ( Transportation,Contract mining,

consultancy, IT ) :Rs 3000 crores (US $ 650

millions )

Total Rs 10,000 crore every year (> US $ 2

billions )

43

Eligible Products

Provenness criteria : Your products

offered must have been supplied in the

past to any corporate customer and

performed satisfactorily for at least 1

year. Documentary evidences required to

be submitted with your bid.

44

Maintenance and Repair

Contract (MARC)

Concluded at the time of supply of equipment for

certain high capacity HEMM.

Bids are evaluated at total price Price of

equipment, price of spare parts and consumables,

cost of supervision and overhead during the entire

MARC period.

MARC period is fixed at a 70% of economic life of

equipment.

Guaranteed Availability of equipment.

45

Integrity Pact

For tenders above certain threshold value, Bidders will have to sign

an Integrity Pact (IP) with CIL.

The Integrity Pact (IP) is a tool developed in the 1990s by

Transparency International to help governments, businesses and

civil society to fight corruption in the field of public contracting.

IP establishes mutual contractual rights and obligations of both

buyer and supplier.

Integrity Pact : CILs Responsibility

CIL commits that:-no official will demand or accept any illicit

gratification to give any of the parties an advantage at any stage of

the project.

All necessary and appropriate technical, legal and administrative

information related to the contract will be made public.

46

Integrity Pact : Bidders Responsibility

They will not offer any illicit gratification to

obtain unfair advantage.

They will not collude with other parties to impair

transparency and fairness.

They will not accept any advantage in exchange

for unprofessional behavior.

They will disclose all payments made to agents

and intermediaries of all descriptions.

Penalties for breach.

IEMs

47

Procurement Responsibility

By Coal India Limited(HQ)

High capacity HEMM, OTR tyres New

technology, Joint Ventures, Turn-key

projects for Mine development etc.

By Subsidiaries

Lower Sized equipments, All

Consumables, services, Spare parts:

Subsidiary companies

48

THANK YOU

Вам также может понравиться

- A 0145021112Документ6 страницA 0145021112Ashish KumarОценок пока нет

- Ps6530b Ess ManualДокумент9 страницPs6530b Ess ManualAshish KumarОценок пока нет

- Approved Vendor List for Mahavitaran Infrastructure Plan WorksДокумент33 страницыApproved Vendor List for Mahavitaran Infrastructure Plan Workssunilgvora86% (7)

- BV WECC TransCostReport FinalДокумент40 страницBV WECC TransCostReport FinalAshish KumarОценок пока нет

- Decomposition of Energy Consumption and Intensity in Indian ManufacturingДокумент33 страницыDecomposition of Energy Consumption and Intensity in Indian ManufacturingAshish KumarОценок пока нет

- Active Harmonic Filter Reduces THD to Less Than 5Документ4 страницыActive Harmonic Filter Reduces THD to Less Than 5Gurdev SainiОценок пока нет

- Compact Unitized Sub Station Product OverviewДокумент2 страницыCompact Unitized Sub Station Product OverviewAshish KumarОценок пока нет

- Coal India MachineryДокумент48 страницCoal India MachineryAshish KumarОценок пока нет

- Hazardous MinigДокумент5 страницHazardous MinigAshish KumarОценок пока нет

- Custom PDF SignerДокумент24 страницыCustom PDF SignerAshish KumarОценок пока нет

- Different MiningДокумент2 страницыDifferent MiningAshish KumarОценок пока нет

- Study of Equipment Prices in The Power SectorДокумент121 страницаStudy of Equipment Prices in The Power Sector이주성100% (1)

- MotorsДокумент11 страницMotorsAshish KumarОценок пока нет

- Switchgears MiningДокумент10 страницSwitchgears MiningAshish KumarОценок пока нет

- Break Even Analysis of Mining ProjectsДокумент60 страницBreak Even Analysis of Mining ProjectsAnil Kumar100% (1)

- Mining EqipmentДокумент4 страницыMining EqipmentAshish KumarОценок пока нет

- 9460 Colombia Fact Sheet Mining Equipment and Technology PrintДокумент3 страницы9460 Colombia Fact Sheet Mining Equipment and Technology PrintAshish KumarОценок пока нет

- Study of Equipment Prices in The Power SectorДокумент121 страницаStudy of Equipment Prices in The Power Sector이주성100% (1)

- MMCP Paper 5 - 0Документ28 страницMMCP Paper 5 - 0Ashish KumarОценок пока нет

- Schneider MRKT ShareДокумент16 страницSchneider MRKT ShareAshish KumarОценок пока нет

- ISM Dhandab SyallabusДокумент36 страницISM Dhandab SyallabusAshish KumarОценок пока нет

- Mining ABBДокумент8 страницMining ABBAshish KumarОценок пока нет

- Mining GEДокумент28 страницMining GEAshish KumarОценок пока нет

- Estimating Total Cost For OB RemovalДокумент12 страницEstimating Total Cost For OB RemovalKuldeep SinghОценок пока нет

- Estimating Total Cost For OB RemovalДокумент12 страницEstimating Total Cost For OB RemovalKuldeep SinghОценок пока нет

- CSS AmericaДокумент48 страницCSS AmericaAshish KumarОценок пока нет

- Coal India MachineryДокумент48 страницCoal India MachineryAshish KumarОценок пока нет

- Strategic Plan Mnre 2011 17Документ85 страницStrategic Plan Mnre 2011 17Umasankar ChilumuriОценок пока нет

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeОт EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeРейтинг: 4 из 5 звезд4/5 (5784)

- The Little Book of Hygge: Danish Secrets to Happy LivingОт EverandThe Little Book of Hygge: Danish Secrets to Happy LivingРейтинг: 3.5 из 5 звезд3.5/5 (399)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceОт EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceРейтинг: 4 из 5 звезд4/5 (890)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureОт EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureРейтинг: 4.5 из 5 звезд4.5/5 (474)

- The Yellow House: A Memoir (2019 National Book Award Winner)От EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Рейтинг: 4 из 5 звезд4/5 (98)

- Team of Rivals: The Political Genius of Abraham LincolnОт EverandTeam of Rivals: The Political Genius of Abraham LincolnРейтинг: 4.5 из 5 звезд4.5/5 (234)

- Never Split the Difference: Negotiating As If Your Life Depended On ItОт EverandNever Split the Difference: Negotiating As If Your Life Depended On ItРейтинг: 4.5 из 5 звезд4.5/5 (838)

- The Emperor of All Maladies: A Biography of CancerОт EverandThe Emperor of All Maladies: A Biography of CancerРейтинг: 4.5 из 5 звезд4.5/5 (271)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryОт EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryРейтинг: 3.5 из 5 звезд3.5/5 (231)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaОт EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaРейтинг: 4.5 из 5 звезд4.5/5 (265)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersОт EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersРейтинг: 4.5 из 5 звезд4.5/5 (344)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyОт EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyРейтинг: 3.5 из 5 звезд3.5/5 (2219)

- The Unwinding: An Inner History of the New AmericaОт EverandThe Unwinding: An Inner History of the New AmericaРейтинг: 4 из 5 звезд4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreОт EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreРейтинг: 4 из 5 звезд4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)От EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Рейтинг: 4.5 из 5 звезд4.5/5 (119)

- Deposit TypesДокумент13 страницDeposit TypesMartin HaryadiОценок пока нет

- HDS-6 River EngineeringДокумент646 страницHDS-6 River EngineeringAnthony AlvaradoОценок пока нет

- Narrative Report: Anapog Integrated SchoolДокумент8 страницNarrative Report: Anapog Integrated SchoolArgie Corbo BrigolaОценок пока нет

- PDF 11-0078 Camg (Co3) 2 Dolomite PDF 05-0586 Caco3 Calcite, Syn 11.9% MajorДокумент3 страницыPDF 11-0078 Camg (Co3) 2 Dolomite PDF 05-0586 Caco3 Calcite, Syn 11.9% MajorsonficyusОценок пока нет

- Aleltu Engineering & Geology Study Final Report (Edited)Документ110 страницAleltu Engineering & Geology Study Final Report (Edited)Hechalu MeseretОценок пока нет

- AASHTO GeoTechnical Design of PileДокумент6 страницAASHTO GeoTechnical Design of PileTee Bun PinОценок пока нет

- Earthquake PPT - Dhanush RaghavДокумент32 страницыEarthquake PPT - Dhanush Raghav19C401-Dhanush RaghavОценок пока нет

- Relationship between Mw and ML for small earthquakesДокумент8 страницRelationship between Mw and ML for small earthquakesQuangNguyenVanОценок пока нет

- MPLT logging by SDI: Analyze fluid flow profilesДокумент25 страницMPLT logging by SDI: Analyze fluid flow profilesISPОценок пока нет

- ArticoloXIIIAEGCongress Torino2014Документ5 страницArticoloXIIIAEGCongress Torino2014jmhs31Оценок пока нет

- Sicest Soil CreepДокумент20 страницSicest Soil CreepAhmad Fuad SalamОценок пока нет

- Methods of Geochemical AnalysisДокумент411 страницMethods of Geochemical Analysisalvaro M100% (1)

- Volcano Presentation Comic Strip.Документ2 страницыVolcano Presentation Comic Strip.Ahyamae DumagatОценок пока нет

- InventoryДокумент36 страницInventoryBernadette BuladacoОценок пока нет

- SPE Geomechanics PresentationДокумент54 страницыSPE Geomechanics PresentationAhmed AbdelnabyОценок пока нет

- EARTHQUAKE ENGINEERING PPT 1Документ41 страницаEARTHQUAKE ENGINEERING PPT 1jessa aranesОценок пока нет

- ME Sci 9 Q3 1201 PS 1Документ50 страницME Sci 9 Q3 1201 PS 1osimp3095Оценок пока нет

- Durability of ConcreteДокумент31 страницаDurability of ConcreteTabish IzharОценок пока нет

- Final CAG Report On COAL SCAM - Full Report in Single FileДокумент65 страницFinal CAG Report On COAL SCAM - Full Report in Single FileSuresh NakhuaОценок пока нет

- Test Bank For Earth Science 14th Edition by Tarbuck and Lutgens Test BankДокумент108 страницTest Bank For Earth Science 14th Edition by Tarbuck and Lutgens Test BankKavita KrishnamorthiОценок пока нет

- AttachmentДокумент99 страницAttachmentBill Sandoval SantacruzОценок пока нет

- 24-Fracturing Horizontal Wells PDFДокумент37 страниц24-Fracturing Horizontal Wells PDFmorcaronte08Оценок пока нет

- Résumés Des Articles de La Conférence Internationale Sur Las Argiles PDFДокумент862 страницыRésumés Des Articles de La Conférence Internationale Sur Las Argiles PDFyassine selmaniОценок пока нет

- Basic Subsurface Flow Chapter 4Документ3 страницыBasic Subsurface Flow Chapter 4Mark lord bongat100% (2)

- Bgi Pertemuan 4Документ26 страницBgi Pertemuan 4tilda 1701Оценок пока нет

- Cement Process OverviewДокумент162 страницыCement Process OverviewRamachandra Rao Maddali50% (2)

- Nickel Laterite Ore Deposits: Weathered Serpentinites: Charles R. M. Butt and Dominique CluzelДокумент6 страницNickel Laterite Ore Deposits: Weathered Serpentinites: Charles R. M. Butt and Dominique Cluzelalan sapoetraОценок пока нет

- Historical - Geography - Armenia - Hewson PDFДокумент42 страницыHistorical - Geography - Armenia - Hewson PDFAnonymous WpMUZCb935Оценок пока нет

- Cable Route Survey DictionaryДокумент18 страницCable Route Survey DictionaryginziroОценок пока нет

- Tunnelling Its EffectsДокумент13 страницTunnelling Its Effectsqu1627Оценок пока нет