Академический Документы

Профессиональный Документы

Культура Документы

Fluid Beds

Загружено:

sujay137800 оценок0% нашли этот документ полезным (0 голосов)

28 просмотров6 страницFluid Beds

Авторское право

© © All Rights Reserved

Доступные форматы

PDF, TXT или читайте онлайн в Scribd

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документFluid Beds

Авторское право:

© All Rights Reserved

Доступные форматы

Скачайте в формате PDF, TXT или читайте онлайн в Scribd

0 оценок0% нашли этот документ полезным (0 голосов)

28 просмотров6 страницFluid Beds

Загружено:

sujay13780Fluid Beds

Авторское право:

© All Rights Reserved

Доступные форматы

Скачайте в формате PDF, TXT или читайте онлайн в Scribd

Вы находитесь на странице: 1из 6

4350 Helton Drive

Florence, Alabama, USA 35630

Phone: 1-256-760-9600

Fax: 1-256-760-9638

Toll Free: 1-800-ACT-3217

e-mail: act@appliedchemical.com

web site: http://www.appliedchemical.com

Large Scale, continuous fluid

bed/baghouse combination,

installed in production plant.

Since 1981, Applied Chemical Tech-

nology has provided high quality, low

cost fluid bed solutions to clients

around the globe. You will find ACT

fluid beds in use at private corpora-

tions, universities, research facili-

ties, government installations, pilot

plants and production plants. Our

fluid beds serve an unlimited range

of industries producing industrial

chemicals, fine chemicals, fertilizers,

food, pharmaceuticals, cosmetics

and more. Without a doubt, Applied

Chemical Technology is the world

leader in fluid bed technology.

Pilot plant scale fluid bed/

cyclone system.

Client Services

ACT welcomes and encourages client involvement in every step of

uid bed design. We consider your input crucial to the development

process. We will provide oce space and support to your personnel at

our own facilities throughout the design, development, testing and

training process. In addition, ACT operates under the strictest con-

dentiality guidelines. Your proprietary information is protected by

signed secrecy agreements provided by ACT.

Ordering Information

To order one of our standard uid beds, or for more information

about ACT services, including complete catalogs of ACT uid beds

and other process equipment, you may contact us by phone, post or

e-mail.

APPLIED CHEMICAL TECHNOLOGY, INC.

APPLI ED CHEMI CAL TECHNOLOGY

T HE WORL D L EADER I N PROCESS EQUI PMENT DESI GN

FLUID BEDS

Two ACT standard large scale continuous fluid beds

preparing to ship. Air plenums in foreground, beds in

background.

4350 Helton Drive

Florence, Alabama, USA 35630

Phone: 1-256-760-9600

Fax: 1-256-760-9638

Toll Free: 1-800-ACT-3217

e-mail: act@appliedchemical.com

web site: http://www.appliedchemical.com

Large Scale, continuous fluid

bed/baghouse combination,

installed in production plant.

Since 1981, Applied Chemical Tech-

nology has provided high quality, low

cost fluid bed solutions to clients

around the globe. You will find ACT

fluid beds in use at private corpora-

tions, universities, research facili-

ties, government installations, pilot

plants and production plants. Our

fluid beds serve an unlimited range

of industries producing industrial

chemicals, fine chemicals, fertilizers,

food, pharmaceuticals, cosmetics

and more. Without a doubt, Applied

Chemical Technology is the world

leader in fluid bed technology.

Pilot plant scale fluid bed/

cyclone system.

Client Services

ACT welcomes and encourages client involvement in every step of

uid bed design. We consider your input crucial to the development

process. We will provide oce space and support to your personnel at

our own facilities throughout the design, development, testing and

training process. In addition, ACT operates under the strictest con-

dentiality guidelines. Your proprietary information is protected by

signed secrecy agreements provided by ACT.

Ordering Information

To order one of our standard uid beds, or for more information

about ACT services, including complete catalogs of ACT uid beds

and other process equipment, you may contact us by phone, post or

e-mail.

APPLIED CHEMICAL TECHNOLOGY, INC.

APPLI ED CHEMI CAL TECHNOLOGY

T HE WORL D L EADER I N PROCESS EQUI PMENT DESI GN

FLUID BEDS

Two ACT standard large scale continuous fluid beds

preparing to ship. Air plenums in foreground, beds in

background.

An ACT uid bed sends a powerful stream of air up through your particulate material, suspend-

ing and circulating the particles like a boiling uid. Tis churning action, or Fluidization,

produces an even distribution of air among the particles, making the uid bed perfect for

heating, cooling or drying processes. Te uidized particles can

also be easily and evenly coated or otherwise treated using a

variety of techniques. Te uid action is achieved using nothing

more than air, thus your material is handled as gently as possible.

Whatever your production needs, ACT uid beds oer a

proven, low cost solution.

Benefits and Applications

Standard Fluid Beds

Specialty Designs and Modifications

ACT Standard Fluid Beds Include the Following:

Technical and

Engineering Support.

ACT Fluid Beds Are Ideal For:

Your Specialty Fluid Bed Could Include:

ACT Engineering and Technical Services Includes:

Heating

Cooling

Drying

Coating

Reacting

Granulating

Special handling

Conveying

Mixing

Impregnating

Dedusting

Classifying

Decontaminating

Scrubbing

ACT Continuous fluid bed/baghouse

combination, unassembled and ready for

shipment. Left to right: Fluid bed, baghouse

top and air plenum (In background).

ACT Laboratory Fluid Bed

Dryer/ Granulator/Coater -

Model 100N. Standard model

includes batch operation,

variable speed blower, full

pressure and temperature

instrumentation, air tempera-

ture up to 250F.

ACT can provide you with a variety of uid bed systems suitable for any applica-

tion. Our uid beds oer batch or continuous operation and are available in

static and vibrating designs. We also build complete process systems to handle

every aspect of your production needs. Many of our models include baghouse

systems, heating and cooling units, or other custom features to save you space

and money. Sizes of our standard models range from our bench top laboratory

uid bed (capable of approximately 2kg/batch, depending on material) to

industrial scale continuous models with operating capacities of 50 tons per hour.

Batch or continuous operation

Static or vibrating designs

Push, pull or combination air ow

Positive, negative or atmospheric pressure

Particle size capacity ranging from 2 inches to 10 microns

1/4 sq. ft. to 1000 sq. ft. bed sizes

2 kg batch to 50 ton/hour continuous production

Optional ACT spray systems and bed inserts

Modular or complete system designs

Scalability

Easy operation and clean up

Full compatibility with all ACT industrial equipment

Fluid bed/baghouse cooler for

continuous operation.

Fully automated ACT 125 lb.

batch fluid bed system with

inert gas recirculation. Features

solvent recovery system,

integral bag filter, explosion

resistance, steam heating and

stainless steel construction.

At ACT we understand that one size does not t all. Tat's why all of our uid beds

can be easily modied to meet your process specications and, whenever necessary,

we can build your uid bed from specialty materials.

We design and build ASME pressure vessels.

Complete custom engineering and design

Custom size and shape

Food/pharmaceutical

Specialty alloys or other specialty materials

High temperature operation

Explosion resistant material

Hazardous chemical systems

Recirculating contained gas design

Specialty inserts, screens and spraying systems

Fully automated operation

ACT oers complete engineering services to take your project

from start to nish. Our engineering and design team will evalu-

ate your process, production and site requirements to develop the

uid bed system that is right for you. Once fabrication is

complete, your uid bed undergoes rigorous performance testing

at our facilities. Our technicians will then install your uid bed at

any site you choose. We'll also oversee your startup operations to

ensure that your uid bed works perfectly for your process and

production needs. We can also train your employees to operate

your new equipment, either on site or at our own complete pilot

plant facilities. Should you wish to make changes later or need

other assistance, our engineering team is readily available to meet

your needs.

Chemical, mechanical, and electrical engineering

Raw materials, process, product and site evaluation

Custom research, development, engineering and design

Automation/computer control

Lab and pilot plant testing

On site installation

Equipment testing at ACT

Startup

Operator training

Test production runs at ACT

Complete technical support

Equipment and process modication

High Temperature (1400F) continuous

fluid bed reactor under construction. Made

of 100% Inconel 600. Custom designed

by Applied Chemical Technology.

Bench scale high temperature

(900F) vibrating fluid bed reactor.

Example of an ACT complete fluid bed system,

including contained gas recirculation, built-in bag

house, explosion protection, optional heating or

cooling, and optional spraying system.

An ACT uid bed sends a powerful stream of air up through your particulate material, suspend-

ing and circulating the particles like a boiling uid. Tis churning action, or Fluidization,

produces an even distribution of air among the particles, making the uid bed perfect for

heating, cooling or drying processes. Te uidized particles can

also be easily and evenly coated or otherwise treated using a

variety of techniques. Te uid action is achieved using nothing

more than air, thus your material is handled as gently as possible.

Whatever your production needs, ACT uid beds oer a

proven, low cost solution.

Benefits and Applications

Standard Fluid Beds

Specialty Designs and Modifications

ACT Standard Fluid Beds Include the Following:

Technical and

Engineering Support.

ACT Fluid Beds Are Ideal For:

Your Specialty Fluid Bed Could Include:

ACT Engineering and Technical Services Includes:

Heating

Cooling

Drying

Coating

Reacting

Granulating

Special handling

Conveying

Mixing

Impregnating

Dedusting

Classifying

Decontaminating

Scrubbing

ACT Continuous fluid bed/baghouse

combination, unassembled and ready for

shipment. Left to right: Fluid bed, baghouse

top and air plenum (In background).

ACT Laboratory Fluid Bed

Dryer/ Granulator/Coater -

Model 100N. Standard model

includes batch operation,

variable speed blower, full

pressure and temperature

instrumentation, air tempera-

ture up to 250F.

ACT can provide you with a variety of uid bed systems suitable for any applica-

tion. Our uid beds oer batch or continuous operation and are available in

static and vibrating designs. We also build complete process systems to handle

every aspect of your production needs. Many of our models include baghouse

systems, heating and cooling units, or other custom features to save you space

and money. Sizes of our standard models range from our bench top laboratory

uid bed (capable of approximately 2kg/batch, depending on material) to

industrial scale continuous models with operating capacities of 50 tons per hour.

Batch or continuous operation

Static or vibrating designs

Push, pull or combination air ow

Positive, negative or atmospheric pressure

Particle size capacity ranging from 2 inches to 10 microns

1/4 sq. ft. to 1000 sq. ft. bed sizes

2 kg batch to 50 ton/hour continuous production

Optional ACT spray systems and bed inserts

Modular or complete system designs

Scalability

Easy operation and clean up

Full compatibility with all ACT industrial equipment

Fluid bed/baghouse cooler for

continuous operation.

Fully automated ACT 125 lb.

batch fluid bed system with

inert gas recirculation. Features

solvent recovery system,

integral bag filter, explosion

resistance, steam heating and

stainless steel construction.

At ACT we understand that one size does not t all. Tat's why all of our uid beds

can be easily modied to meet your process specications and, whenever necessary,

we can build your uid bed from specialty materials.

We design and build ASME pressure vessels.

Complete custom engineering and design

Custom size and shape

Food/pharmaceutical

Specialty alloys or other specialty materials

High temperature operation

Explosion resistant material

Hazardous chemical systems

Recirculating contained gas design

Specialty inserts, screens and spraying systems

Fully automated operation

ACT oers complete engineering services to take your project

from start to nish. Our engineering and design team will evalu-

ate your process, production and site requirements to develop the

uid bed system that is right for you. Once fabrication is

complete, your uid bed undergoes rigorous performance testing

at our facilities. Our technicians will then install your uid bed at

any site you choose. We'll also oversee your startup operations to

ensure that your uid bed works perfectly for your process and

production needs. We can also train your employees to operate

your new equipment, either on site or at our own complete pilot

plant facilities. Should you wish to make changes later or need

other assistance, our engineering team is readily available to meet

your needs.

Chemical, mechanical, and electrical engineering

Raw materials, process, product and site evaluation

Custom research, development, engineering and design

Automation/computer control

Lab and pilot plant testing

On site installation

Equipment testing at ACT

Startup

Operator training

Test production runs at ACT

Complete technical support

Equipment and process modication

High Temperature (1400F) continuous

fluid bed reactor under construction. Made

of 100% Inconel 600. Custom designed

by Applied Chemical Technology.

Bench scale high temperature

(900F) vibrating fluid bed reactor.

Example of an ACT complete fluid bed system,

including contained gas recirculation, built-in bag

house, explosion protection, optional heating or

cooling, and optional spraying system.

An ACT uid bed sends a powerful stream of air up through your particulate material, suspend-

ing and circulating the particles like a boiling uid. Tis churning action, or Fluidization,

produces an even distribution of air among the particles, making the uid bed perfect for

heating, cooling or drying processes. Te uidized particles can

also be easily and evenly coated or otherwise treated using a

variety of techniques. Te uid action is achieved using nothing

more than air, thus your material is handled as gently as possible.

Whatever your production needs, ACT uid beds oer a

proven, low cost solution.

Benefits and Applications

Standard Fluid Beds

Specialty Designs and Modifications

ACT Standard Fluid Beds Include the Following:

Technical and

Engineering Support.

ACT Fluid Beds Are Ideal For:

Your Specialty Fluid Bed Could Include:

ACT Engineering and Technical Services Includes:

Heating

Cooling

Drying

Coating

Reacting

Granulating

Special handling

Conveying

Mixing

Impregnating

Dedusting

Classifying

Decontaminating

Scrubbing

ACT Continuous fluid bed/baghouse

combination, unassembled and ready for

shipment. Left to right: Fluid bed, baghouse

top and air plenum (In background).

ACT Laboratory Fluid Bed

Dryer/ Granulator/Coater -

Model 100N. Standard model

includes batch operation,

variable speed blower, full

pressure and temperature

instrumentation, air tempera-

ture up to 250F.

ACT can provide you with a variety of uid bed systems suitable for any applica-

tion. Our uid beds oer batch or continuous operation and are available in

static and vibrating designs. We also build complete process systems to handle

every aspect of your production needs. Many of our models include baghouse

systems, heating and cooling units, or other custom features to save you space

and money. Sizes of our standard models range from our bench top laboratory

uid bed (capable of approximately 2kg/batch, depending on material) to

industrial scale continuous models with operating capacities of 50 tons per hour.

Batch or continuous operation

Static or vibrating designs

Push, pull or combination air ow

Positive, negative or atmospheric pressure

Particle size capacity ranging from 2 inches to 10 microns

1/4 sq. ft. to 1000 sq. ft. bed sizes

2 kg batch to 50 ton/hour continuous production

Optional ACT spray systems and bed inserts

Modular or complete system designs

Scalability

Easy operation and clean up

Full compatibility with all ACT industrial equipment

Fluid bed/baghouse cooler for

continuous operation.

Fully automated ACT 125 lb.

batch fluid bed system with

inert gas recirculation. Features

solvent recovery system,

integral bag filter, explosion

resistance, steam heating and

stainless steel construction.

At ACT we understand that one size does not t all. Tat's why all of our uid beds

can be easily modied to meet your process specications and, whenever necessary,

we can build your uid bed from specialty materials.

We design and build ASME pressure vessels.

Complete custom engineering and design

Custom size and shape

Food/pharmaceutical

Specialty alloys or other specialty materials

High temperature operation

Explosion resistant material

Hazardous chemical systems

Recirculating contained gas design

Specialty inserts, screens and spraying systems

Fully automated operation

ACT oers complete engineering services to take your project

from start to nish. Our engineering and design team will evalu-

ate your process, production and site requirements to develop the

uid bed system that is right for you. Once fabrication is

complete, your uid bed undergoes rigorous performance testing

at our facilities. Our technicians will then install your uid bed at

any site you choose. We'll also oversee your startup operations to

ensure that your uid bed works perfectly for your process and

production needs. We can also train your employees to operate

your new equipment, either on site or at our own complete pilot

plant facilities. Should you wish to make changes later or need

other assistance, our engineering team is readily available to meet

your needs.

Chemical, mechanical, and electrical engineering

Raw materials, process, product and site evaluation

Custom research, development, engineering and design

Automation/computer control

Lab and pilot plant testing

On site installation

Equipment testing at ACT

Startup

Operator training

Test production runs at ACT

Complete technical support

Equipment and process modication

High Temperature (1400F) continuous

fluid bed reactor under construction. Made

of 100% Inconel 600. Custom designed

by Applied Chemical Technology.

Bench scale high temperature

(900F) vibrating fluid bed reactor.

Example of an ACT complete fluid bed system,

including contained gas recirculation, built-in bag

house, explosion protection, optional heating or

cooling, and optional spraying system.

4350 Helton Drive

Florence, Alabama, USA 35630

Phone: 1-256-760-9600

Fax: 1-256-760-9638

Toll Free: 1-800-ACT-3217

e-mail: act@appliedchemical.com

web site: http://www.appliedchemical.com

Large Scale, continuous fluid

bed/baghouse combination,

installed in production plant.

Since 1981, Applied Chemical Tech-

nology has provided high quality, low

cost fluid bed solutions to clients

around the globe. You will find ACT

fluid beds in use at private corpora-

tions, universities, research facili-

ties, government installations, pilot

plants and production plants. Our

fluid beds serve an unlimited range

of industries producing industrial

chemicals, fine chemicals, fertilizers,

food, pharmaceuticals, cosmetics

and more. Without a doubt, Applied

Chemical Technology is the world

leader in fluid bed technology.

Pilot plant scale fluid bed/

cyclone system.

Client Services

ACT welcomes and encourages client involvement in every step of

uid bed design. We consider your input crucial to the development

process. We will provide oce space and support to your personnel at

our own facilities throughout the design, development, testing and

training process. In addition, ACT operates under the strictest con-

dentiality guidelines. Your proprietary information is protected by

signed secrecy agreements provided by ACT.

Ordering Information

To order one of our standard uid beds, or for more information

about ACT services, including complete catalogs of ACT uid beds

and other process equipment, you may contact us by phone, post or

e-mail.

APPLIED CHEMICAL TECHNOLOGY, INC.

APPLI ED CHEMI CAL TECHNOLOGY

T HE WORL D L EADER I N PROCESS EQUI PMENT DESI GN

FLUID BEDS

Two ACT standard large scale continuous fluid beds

preparing to ship. Air plenums in foreground, beds in

background.

Вам также может понравиться

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryОт EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryРейтинг: 3.5 из 5 звезд3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)От EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Рейтинг: 4.5 из 5 звезд4.5/5 (121)

- Never Split the Difference: Negotiating As If Your Life Depended On ItОт EverandNever Split the Difference: Negotiating As If Your Life Depended On ItРейтинг: 4.5 из 5 звезд4.5/5 (838)

- The Little Book of Hygge: Danish Secrets to Happy LivingОт EverandThe Little Book of Hygge: Danish Secrets to Happy LivingРейтинг: 3.5 из 5 звезд3.5/5 (400)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaОт EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaРейтинг: 4.5 из 5 звезд4.5/5 (266)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeОт EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeРейтинг: 4 из 5 звезд4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreОт EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreРейтинг: 4 из 5 звезд4/5 (1090)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyОт EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyРейтинг: 3.5 из 5 звезд3.5/5 (2259)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersОт EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersРейтинг: 4.5 из 5 звезд4.5/5 (345)

- The Emperor of All Maladies: A Biography of CancerОт EverandThe Emperor of All Maladies: A Biography of CancerРейтинг: 4.5 из 5 звезд4.5/5 (271)

- Team of Rivals: The Political Genius of Abraham LincolnОт EverandTeam of Rivals: The Political Genius of Abraham LincolnРейтинг: 4.5 из 5 звезд4.5/5 (234)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceОт EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceРейтинг: 4 из 5 звезд4/5 (895)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureОт EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureРейтинг: 4.5 из 5 звезд4.5/5 (474)

- Valve Manufacturers in USAДокумент24 страницыValve Manufacturers in USAsujay13780Оценок пока нет

- The Yellow House: A Memoir (2019 National Book Award Winner)От EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Рейтинг: 4 из 5 звезд4/5 (98)

- The Unwinding: An Inner History of the New AmericaОт EverandThe Unwinding: An Inner History of the New AmericaРейтинг: 4 из 5 звезд4/5 (45)

- Solvent Extraction Technology For Used Oil TreatmentДокумент30 страницSolvent Extraction Technology For Used Oil TreatmentGyra LuthmanaОценок пока нет

- Pilotplantscaleuptechniquesusedinpharmaceuticalmanufacturing 131002222820 Phpapp02Документ73 страницыPilotplantscaleuptechniquesusedinpharmaceuticalmanufacturing 131002222820 Phpapp02Gautam SharmaОценок пока нет

- HR ContactsДокумент70 страницHR Contactssujay1378080% (5)

- Scale-Up of Chemical Engineering Process: Prof H R ShahДокумент27 страницScale-Up of Chemical Engineering Process: Prof H R Shahatgtegtrhrh100% (1)

- MVR-mills From PfeifferДокумент24 страницыMVR-mills From PfeifferRollerJonnyОценок пока нет

- Financial Plan For Starting Up The RestaurantДокумент11 страницFinancial Plan For Starting Up The Restaurantsujay13780Оценок пока нет

- ISO 9001 Clauses Simply ExplainedДокумент26 страницISO 9001 Clauses Simply Explainedpooja.dayal3930Оценок пока нет

- Commercializing Process TechnologiesДокумент11 страницCommercializing Process TechnologiesBramJanssen76Оценок пока нет

- Pilot Plant Testing Methods - BPRДокумент17 страницPilot Plant Testing Methods - BPRravibelavadiОценок пока нет

- Best Practice For Pilot Plant LayoutДокумент10 страницBest Practice For Pilot Plant LayoutRashesh ShahОценок пока нет

- Pilot Plant Scale-Up TechniquesДокумент62 страницыPilot Plant Scale-Up TechniquesVaseline Robinson100% (2)

- Pilot Plant Scale Up Techniques SeminarДокумент24 страницыPilot Plant Scale Up Techniques Seminarsakumar5678Оценок пока нет

- CO2 Absorption Simulation PaperДокумент11 страницCO2 Absorption Simulation PaperUmer AzharОценок пока нет

- Considerations For Estimating The Costs of Pilot-Scale FacilitiesДокумент9 страницConsiderations For Estimating The Costs of Pilot-Scale FacilitiesAlexОценок пока нет

- TMG Stressing EquipmentsДокумент15 страницTMG Stressing Equipmentssujay13780Оценок пока нет

- Brochure - For ReferenceДокумент4 страницыBrochure - For Referencesujay13780Оценок пока нет

- F02 Project Status Purchased Parts QR83 2011 Version 1-0-01Документ3 страницыF02 Project Status Purchased Parts QR83 2011 Version 1-0-01sujay13780Оценок пока нет

- Tie Rod CylindersДокумент4 страницыTie Rod Cylinderssujay13780Оценок пока нет

- Equivalent Grades of Gray IronДокумент2 страницыEquivalent Grades of Gray Ironsujay13780100% (1)

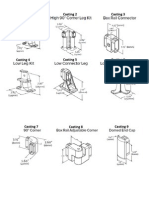

- Casting 1 Casting 2 Casting 3Документ2 страницыCasting 1 Casting 2 Casting 3sujay13780Оценок пока нет

- Hot Dip Galvanizing, A Guide ToДокумент14 страницHot Dip Galvanizing, A Guide Topbharadwaj545Оценок пока нет

- T-6 Heat Treat: T-6 30% Increase in StrengthДокумент2 страницыT-6 Heat Treat: T-6 30% Increase in Strengthsujay13780Оценок пока нет

- Useful Articles: What To Consider When Buying CastingsДокумент5 страницUseful Articles: What To Consider When Buying Castingssujay13780Оценок пока нет

- Hospitalisation Claim FormДокумент2 страницыHospitalisation Claim Formsujay13780Оценок пока нет

- Generate FormsДокумент824 страницыGenerate Formssujay1378050% (2)

- Amarnath Registration FormДокумент1 страницаAmarnath Registration Formsujay13780Оценок пока нет

- Ci and SG Grade ReferenceДокумент4 страницыCi and SG Grade Referencesujay13780Оценок пока нет

- Case Study NIM FinalДокумент12 страницCase Study NIM Finalsujay13780Оценок пока нет

- Ott AppformДокумент2 страницыOtt Appformsujay13780Оценок пока нет

- SB Interest CalculationДокумент3 страницыSB Interest Calculationsujay13780Оценок пока нет

- Pilot PlantДокумент7 страницPilot PlantNaveen Kamat100% (1)

- Pilot Plant Services: Our SolutionsДокумент2 страницыPilot Plant Services: Our SolutionsLia Putri LestariОценок пока нет

- SABIC Lao ResearchДокумент7 страницSABIC Lao Researchswaggeroni yololoОценок пока нет

- Drum DryerДокумент13 страницDrum DryerFAiz100% (1)

- ISO 9001: 2008 CompanyДокумент8 страницISO 9001: 2008 Companymanoj nirgudeОценок пока нет

- JK Presentation MFC Pilot v3Документ11 страницJK Presentation MFC Pilot v3AyОценок пока нет

- Launching An RTD Beverage WhitepaperДокумент5 страницLaunching An RTD Beverage WhitepaperpowerОценок пока нет

- VIETNAM. PROCESSING OF AROMA CHEMICALS AND FRAGRANCE MATERIALS. TECHNICAL REPORT - AROMA CHEMICALS AND PERFUME BLENDING (20598.en) PDFДокумент83 страницыVIETNAM. PROCESSING OF AROMA CHEMICALS AND FRAGRANCE MATERIALS. TECHNICAL REPORT - AROMA CHEMICALS AND PERFUME BLENDING (20598.en) PDFOsamaAliMoussaОценок пока нет

- 2012 - Lab Pilot Plant EngДокумент33 страницы2012 - Lab Pilot Plant EngArquimedes PerezОценок пока нет

- Andritz Drum FlakerДокумент20 страницAndritz Drum Flakerfhormozi1Оценок пока нет

- Bioplastic Pilot Plant - BIДокумент2 страницыBioplastic Pilot Plant - BIMohamad DinОценок пока нет

- ReactorДокумент12 страницReactorDnyaneshwar KarwarОценок пока нет

- Report PDFДокумент5 страницReport PDFShaswat Shovan PandaОценок пока нет

- Chemical Engineering 2017Документ40 страницChemical Engineering 2017mnamkyОценок пока нет

- A Risk-Based Approach To Cleaning Validation Using Visible Residue LimitsДокумент10 страницA Risk-Based Approach To Cleaning Validation Using Visible Residue LimitsPraveenОценок пока нет

- Pilot Plant Review1Документ10 страницPilot Plant Review1raju narayana padalaОценок пока нет

- Industrial Best Practices of Conceptual Process DesignДокумент5 страницIndustrial Best Practices of Conceptual Process DesignAnonymous N3LpAXОценок пока нет

- Curriculam Vitae Gopi Pasupuleti Contact No: +91-7730804128Документ4 страницыCurriculam Vitae Gopi Pasupuleti Contact No: +91-7730804128Ramakrishna SomuОценок пока нет

- Industrial Pharmacy IIДокумент4 страницыIndustrial Pharmacy IIAvinash KumarОценок пока нет