Академический Документы

Профессиональный Документы

Культура Документы

3.3.12 - Camber Design

Загружено:

Irshad KhanОригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

3.3.12 - Camber Design

Загружено:

Irshad KhanАвторское право:

Доступные форматы

Design Guides 3.3.

12 - Camber Design

Nov. 2006 Page 3.3.12-1

3.3.12 Camber Design for Plate Girders

Typical slab-on-beam bridges have space between the bottom of the slab and the top of the top

flanges of beams. This space, referred to as the fillet or haunch by IDOT, typically consists of

unreinforced concrete that increases the dead load of the section but is not normally considered

to add strength. Excessive fillets are considered problematic and, if greater than 6 in. in depth,

require reinforcing. See Section 3.3.9 of the Bridge Manual. It is common practice to minimize

the depth of fillets by cambering plate girders while rolled beams are only cambered

occasionally. For plate girder structures, cambering is most commonly achieved by cutting the

top and bottom of the web to achieve predetermined curves. This design guide gives the

designer a step-by-step process for determining these curves.

Camber Design Procedure, Equations, and Outline

Determine Necessary Number of Camber Diagrams

Based on the profile grade, determine the theoretical top-of-deck elevations for each beam at

ten ft. intervals along the beam. These elevations are dictated by the profile grade, horizontal

curve data, and crown. If the theoretical top-of-deck elevations have similar vertical curves for

each beam, and all girders in the bridge have similar deflected shapes, only one girder need be

detailed for camber with all others cambered identically. This is typically the case for any bridge

that avoids the following scenarios:

1. Curved girders, where the radius of curvature is less than 1,200 feet

2. Highly skewed structures

3. Structures with non-parallel substructure elements

4. Non-uniform dead loads (large or eccentric median or sidewalk loads, sign structures

or light poles attached to bridge, etc.)

5. Flared girders or partial length girders

6. Large superelevation transition

For cases such as 1 through 6 above, separate camber diagrams are required for all girders

that are not within a in. tolerance of a girder that is already cambered.

Design Guides 3.3.12 - Camber Design

Page 3.3.12-2 Nov. 2006

Determine Number and Location of Camber Definition Points

Girder segments are defined as fabricated girder elements bounded by beam ends, field

splices, and pin/link hangers. Examples of beam segments include (but are not limited to):

abutment to splice, splice to splice, abutment to abutment (no splice), and pin/link hanger to

splice.

Camber shall be defined at a minimum of three points within a girder segment. These points

should be positioned to adequately define the curve, including the maximum distances from

end-to-end chords and any inflection points. The objective is to provide adequate information

for the fabricator to able to construct the correct curve. As such, some engineering judgment is

required when choosing points to report on a camber diagram.

At each camber definition point and at segment ends, the following information is calculated:

1. Theoretical top-of-deck elevations

2. Distance from top-of-slab to top-of-web, which includes slab thickness, in.

minimum fillet, top flange splice plate (if applicable), and top flange thickness

3. Dead Load (DC1) deflections of the non-composite section due to self-weight and

weight of slab and fillet

Determine the Maximum Adjusted Top-of-Web Elevations and Camber

At each camber definition point and at beam ends, the maximum adjusted top-of-web elevations

are calculated as follows:

1. Subtract the top-of-slab to top-of-web distances from the theoretical top-of-deck

elevations. This results in the maximum top-of-web elevations.

2. Add the DC1 deflections to the maximum top-of-web elevations. Downward

deflections are taken as positive, upward deflections as negative. This results in the

maximum adjusted top-of-web elevations.

3. Using the maximum adjusted top-of-web elevations at the ends of each segment,

interpolate linearly to calculate what the elevations would be at each camber

Design Guides 3.3.12 - Camber Design

Nov. 2006 Page 3.3.12-3

definition point. When drawn out, this interpolation should give a straight line from

one segment end to the other.

4. At each camber definition point, subtract the straight line interpolation value

determined above from each maximum adjusted top-of-web elevation. This gives

the required camber at each point. A positive number represents camber in the

upward direction, while a negative number represents camber in the downward

direction.

If the required camber is less than in. for the entire segment, the segment need not be

cambered.

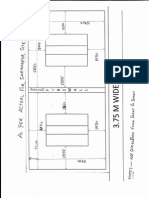

Plot the Camber Diagram

The camber diagram, when plotted, should show the approximate shape of the curve made by

the maximum adjusted top-of-web elevations. It should also show the straight-line interpolation

between segment ends, the locations of the camber definition points, and the camber at each

camber definition point.

It is important that the camber diagram follows a smooth curve. Therefore, if necessary, the

camber at each location may be varied slightly to allow for a smooth curve. See the calculated

and chosen camber diagrams presented in the following example for an illustration of this

concept.

Camber is detailed to a tolerance of in.

Camber Design Example: Two-Span Plate Girder

Bridge Data and Top-of-Slab Elevations

Span Lengths: Two equal spans of 98.75 ft.

Number of Beams: 6

No horizontal curve, normal crown, zero skew, no appurtenances

Design Guides 3.3.12 - Camber Design

Page 3.3.12-4 Nov. 2006

CL Bearing Abutment 1: Station 374+54.25, Elevation 471.00

CL Bearing Pier: Station 375+53.00, Elevation 471.51

CL Bearing Abutment 2: Station 376+51.75, Elevation 471.61

Profile Grade Data

PVC: Station 374+55.00, Elevation 471.01

PVI: Station 375+92.50, Elevation 472.00

PVT: Station 377+30.00, Elevation 471.40

Steel Section Data

Top Flange Thickness: 1 in. for 76.75 ft. from CL Brg. Abut. 1,

1.75 in. for remaining 22 ft. in Span 1,

Span 2 symmetrical about CL Brg. Pier

Splice Location: 76.75 ft. from CL Brg. Abut. 1

Top Flange Splice Plate Thickness: 0.8125 in.

Determine Necessary Number of Camber Diagrams

The bridge does not have any conditions which would cause dissimilar vertical top-of-slab

curves or deflected girder shapes. Consequently, only one camber diagram need be

calculated which is applicable to each girder.

Determine Number and Location of Camber Definition Points

The girder is divided into two segments: CL Brg. Abut. 1 to CL Splice (Segment 1), and CL

Splice to CL Brg. Abut. 2 (Segment 2):

Segment 1 does not contain any changes in section. Therefore, the minimum of three

camber definition points will be used at quarter-points of the segment.

Design Guides 3.3.12 - Camber Design

Nov. 2006 Page 3.3.12-5

Segment 2 does contain a change in section. The top flange transitions from 1.75 in.

flange thickness to 1 in. flange thickness at a distance of 44 ft. along the segment.

Therefore, camber will be defined at the quarter points along each section (44 ft. and

76.75 ft.) and at the location of section change, for a total of seven camber definition

points.

Determine the Maximum Adjusted Top-of-Web Elevations and Exact Camber

Tabular camber calculations for Segment 1 are given below and are followed by calculations

for Segment 2. Calculated and chosen design camber diagrams are presented at the end of

this example.

CL Br. Abut. 1 Pt. 1 Pt. 2 Pt. 3 CL Splice

Camber

Definition

Point Location

(ft.) 0.00 19.19 38.38 57.56 76.75

Theoretical

Top-of-Slab

Elevation (ft.) 470.689 470.821 470.937 471.037 471.122

Slab

Thickness (ft.) 0.667 0.667 0.667 0.667 0.667

Minimum 0.75

in. Fillet (ft) 0.063 0.063 0.063 0.063 0.063

Top Flange

Thickness (ft.) 0.083 0.083 0.083 0.083 0.146

Top Splice

Plate

Thickness (ft.) 0.068

DC1

Deflections

(ft.) 0.000 0.079 0.115 0.093 0.039

Maximum

Adjusted Top-

of-Web

Elevation (ft.) 469.877 470.088 470.240 470.317 470.218

Straight-Line

Interpolation

Elevation (ft.) 469.877 469.962 470.047 470.133 470.218

Exact Camber

(in.) 0.00 1.51 2.30 2.21 0.00

Design Guides 3.3.12 - Camber Design

Page 3.3.12-6 Nov. 2006

C

L

S

p

l

i

c

e

P

t

.

1

P

t

.

2

P

t

.

3

S

e

c

t

i

o

n

T

r

a

n

s

i

t

i

o

n

P

t

.

4

P

t

.

5

P

t

6

.

C

L

A

b

u

t

m

e

n

t

2

C

a

m

b

e

r

D

e

f

i

n

i

t

i

o

n

P

o

i

n

t

L

o

c

a

t

i

o

n

(

f

t

.

)

0

.

0

0

0

1

1

.

0

0

2

2

.

0

0

3

3

.

0

0

4

4

.

0

0

6

3

.

1

9

8

2

.

3

8

1

0

1

.

5

6

1

2

0

.

7

5

T

h

e

o

r

e

t

i

c

a

l

T

o

p

-

o

f

-

S

l

a

b

E

l

e

v

a

t

i

o

n

(

f

t

.

)

4

7

1

.

1

2

2

4

7

1

.

1

6

4

4

7

1

.

2

0

0

4

7

1

.

2

3

2

4

7

1

.

2

5

8

4

7

1

.

2

9

2

4

7

1

.

3

1

1

4

7

1

.

3

1

4

4

7

1

.

3

0

1

S

l

a

b

T

h

i

c

k

n

e

s

s

(

f

t

.

)

0

.

6

6

7

0

.

6

6

7

0

.

6

6

7

0

.

6

6

7

0

.

6

6

7

0

.

6

6

7

0

.

6

6

7

0

.

6

6

7

0

.

6

6

7

M

i

n

i

m

u

m

0

.

7

5

i

n

.

F

i

l

l

e

t

(

f

t

)

0

.

0

6

3

0

.

0

6

3

0

.

0

6

3

0

.

0

6

3

0

.

0

6

3

0

.

0

6

3

0

.

0

6

3

0

.

0

6

3

0

.

0

6

3

T

o

p

F

l

a

n

g

e

T

h

i

c

k

n

e

s

s

(

f

t

.

)

0

.

1

4

6

0

.

1

4

6

0

.

1

4

6

0

.

1

4

6

0

.

1

4

6

0

.

0

8

3

0

.

0

8

3

0

.

0

8

3

0

.

0

8

3

T

o

p

S

p

l

i

c

e

P

l

a

t

e

T

h

i

c

k

n

e

s

s

(

f

t

.

)

0

.

0

6

8

D

C

1

D

e

f

l

e

c

t

i

o

n

s

(

f

t

.

)

0

.

0

3

9

0

.

0

1

3

0

.

0

0

0

0

.

0

1

3

0

.

0

3

9

0

.

0

9

3

0

.

1

1

5

0

.

0

7

9

0

.

0

0

0

M

a

x

i

m

u

m

A

d

j

u

s

t

e

d

T

o

p

-

o

f

-

W

e

b

E

l

e

v

a

t

i

o

n

(

f

t

.

)

4

7

0

.

2

1

8

4

7

0

.

3

0

2

4

7

0

.

3

2

5

4

7

0

.

3

7

0

4

7

0

.

4

2

2

4

7

0

.

5

7

2

4

7

0

.

6

1

4

4

7

0

.

5

8

1

4

7

0

.

4

8

9

S

t

r

a

i

g

h

t

-

L

i

n

e

I

n

t

e

r

p

o

l

a

t

i

o

n

E

l

e

v

a

t

i

o

n

(

f

t

.

)

4

7

0

.

2

1

8

4

7

0

.

2

4

3

4

7

0

.

2

6

8

4

7

0

.

2

9

2

4

7

0

.

3

1

7

4

7

0

.

3

6

0

4

7

0

.

4

0

3

4

7

0

.

4

4

6

4

7

0

.

4

8

9

E

x

a

c

t

C

a

m

b

e

r

(

i

n

.

)

0

.

0

0

0

.

7

0

0

.

6

9

0

.

9

3

1

.

2

6

2

.

5

5

2

.

5

3

1

.

6

2

0

.

0

0

Design Guides 3.3.12 - Camber Design

Nov. 2006 Page 3.3.12-7

Вам также может понравиться

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryОт EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryРейтинг: 3.5 из 5 звезд3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)От EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Рейтинг: 4.5 из 5 звезд4.5/5 (119)

- Never Split the Difference: Negotiating As If Your Life Depended On ItОт EverandNever Split the Difference: Negotiating As If Your Life Depended On ItРейтинг: 4.5 из 5 звезд4.5/5 (838)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaОт EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaРейтинг: 4.5 из 5 звезд4.5/5 (265)

- The Little Book of Hygge: Danish Secrets to Happy LivingОт EverandThe Little Book of Hygge: Danish Secrets to Happy LivingРейтинг: 3.5 из 5 звезд3.5/5 (399)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyОт EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyРейтинг: 3.5 из 5 звезд3.5/5 (2219)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeОт EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeРейтинг: 4 из 5 звезд4/5 (5794)

- Team of Rivals: The Political Genius of Abraham LincolnОт EverandTeam of Rivals: The Political Genius of Abraham LincolnРейтинг: 4.5 из 5 звезд4.5/5 (234)

- The Emperor of All Maladies: A Biography of CancerОт EverandThe Emperor of All Maladies: A Biography of CancerРейтинг: 4.5 из 5 звезд4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreОт EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreРейтинг: 4 из 5 звезд4/5 (1090)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersОт EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersРейтинг: 4.5 из 5 звезд4.5/5 (344)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceОт EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceРейтинг: 4 из 5 звезд4/5 (894)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureОт EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureРейтинг: 4.5 из 5 звезд4.5/5 (474)

- The Unwinding: An Inner History of the New AmericaОт EverandThe Unwinding: An Inner History of the New AmericaРейтинг: 4 из 5 звезд4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)От EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Рейтинг: 4 из 5 звезд4/5 (98)

- Revised Foundation For 315 Mva Transformer. 28-10-09 - ModelДокумент1 страницаRevised Foundation For 315 Mva Transformer. 28-10-09 - ModelIrshad KhanОценок пока нет

- Weather CardДокумент2 страницыWeather Cardmekstone100% (1)

- George Van TasselДокумент2 страницыGeorge Van TasselManea SilviuОценок пока нет

- 6m RTP Design ReportДокумент25 страниц6m RTP Design Reportmanohargud100% (1)

- Liquid Nitrogen Safety TrainingДокумент21 страницаLiquid Nitrogen Safety TrainingSteven James CapuanoОценок пока нет

- Wind Loading of Industrial, Mining and Petrochemical StructuresДокумент16 страницWind Loading of Industrial, Mining and Petrochemical StructuresapirakqОценок пока нет

- AA Holtz & Kovacs - An Introduction To Geotechnical EngineeringДокумент23 страницыAA Holtz & Kovacs - An Introduction To Geotechnical EngineeringfaizanОценок пока нет

- Baseplate t3p 18 07Документ3 страницыBaseplate t3p 18 07Irshad KhanОценок пока нет

- 2D Compressible Viscous-Flow Solver On Unstructured Meshes With Linear and Quadratic Reconstruction of Convective FluxesДокумент77 страниц2D Compressible Viscous-Flow Solver On Unstructured Meshes With Linear and Quadratic Reconstruction of Convective FluxeshityouОценок пока нет

- Civil Specification Vol-IIIДокумент266 страницCivil Specification Vol-IIIIrshad KhanОценок пока нет

- Ref. - No.: 261 - Ruston Gas Turbine Power Generation PackagesДокумент8 страницRef. - No.: 261 - Ruston Gas Turbine Power Generation Packagesscribdkhatn0% (1)

- Prepared By: Ms. Ethel D. Nabor, LPTДокумент29 страницPrepared By: Ms. Ethel D. Nabor, LPTJohn Ralf T. TorrejosОценок пока нет

- Sol 4Документ10 страницSol 4Stian BilekОценок пока нет

- The Code Corner No. 15Документ3 страницыThe Code Corner No. 15Irshad KhanОценок пока нет

- Wasim CVДокумент2 страницыWasim CVIrshad KhanОценок пока нет

- Drawings of GIS, SEC-4, GurgaonДокумент62 страницыDrawings of GIS, SEC-4, GurgaonIrshad Khan100% (1)

- Are 12 PDFДокумент105 страницAre 12 PDFIrshad KhanОценок пока нет

- Typical Plinth Protection DetailДокумент1 страницаTypical Plinth Protection DetailIrshad KhanОценок пока нет

- M.Raje Structural Consultants Pvt. LTDДокумент2 страницыM.Raje Structural Consultants Pvt. LTDIrshad KhanОценок пока нет

- Scanned Docs by CamScanner AppДокумент5 страницScanned Docs by CamScanner AppIrshad KhanОценок пока нет

- 1367 6 PDFДокумент20 страниц1367 6 PDFIrshad Khan100% (1)

- Vendor Contact & Bank Details for Alif Engineers and PlannersДокумент1 страницаVendor Contact & Bank Details for Alif Engineers and PlannersIrshad KhanОценок пока нет

- Is 13920 1993Документ24 страницыIs 13920 1993structuralengineersОценок пока нет

- PortalДокумент1 страницаPortalIrshad KhanОценок пока нет

- Code of Conduct For Intemediaries Including Consultants / Agents / Business Partners / VendorsДокумент2 страницыCode of Conduct For Intemediaries Including Consultants / Agents / Business Partners / VendorsIrshad KhanОценок пока нет

- Steel ConnectionДокумент18 страницSteel ConnectionIrshad KhanОценок пока нет

- D 800 Cover 40 Bar Dia FCK 50 Fy 500 SДокумент2 страницыD 800 Cover 40 Bar Dia FCK 50 Fy 500 SIrshad KhanОценок пока нет

- Retaining Wall ProposalДокумент2 страницыRetaining Wall ProposalIrshad KhanОценок пока нет

- Is 2502 1963Документ31 страницаIs 2502 1963Lokesh SharmaОценок пока нет

- Fire Retardant Paint RequirementsДокумент2 страницыFire Retardant Paint RequirementsIrshad Khan100% (1)

- Car LiftДокумент4 страницыCar LiftIrshad KhanОценок пока нет

- PortalДокумент1 страницаPortalIrshad KhanОценок пока нет

- Typical Plinth Protection DetailДокумент1 страницаTypical Plinth Protection DetailIrshad KhanОценок пока нет

- Axially Loaded ColumnsДокумент33 страницыAxially Loaded Columnsyunuswsa0% (2)

- Bot 0001Документ1 страницаBot 0001Irshad KhanОценок пока нет

- COVER Burnt Oil PitДокумент1 страницаCOVER Burnt Oil PitIrshad KhanОценок пока нет

- Alif Engineers and Planners ProfileДокумент5 страницAlif Engineers and Planners ProfileIrshad KhanОценок пока нет

- Base Plate For Thickness CalculationsДокумент7 страницBase Plate For Thickness CalculationsyunuswsaОценок пока нет

- Mixdesign M25Документ9 страницMixdesign M25Irshad KhanОценок пока нет

- Dimention of TraffoДокумент1 страницаDimention of TraffoIrshad KhanОценок пока нет

- CE - MECH - 2 DYNAMIC OF RIGID BODIES (2nd Semester S.Y. 2020-2021)Документ5 страницCE - MECH - 2 DYNAMIC OF RIGID BODIES (2nd Semester S.Y. 2020-2021)Lyra GurimbaoОценок пока нет

- The Circle and Its Parts: NameДокумент4 страницыThe Circle and Its Parts: NameDaniel DubeОценок пока нет

- Chemistry Project XIIДокумент13 страницChemistry Project XIIKanav MalhotraОценок пока нет

- Oct 2022 P4 Model AnswerДокумент25 страницOct 2022 P4 Model AnswerabiyyaОценок пока нет

- Multistage CompressorДокумент12 страницMultistage CompressorFahmi AliОценок пока нет

- Handbook of Magnetic PDFДокумент572 страницыHandbook of Magnetic PDFQassem MohaidatОценок пока нет

- LYSAGHT Klip Lok Optima Sep 2010Документ12 страницLYSAGHT Klip Lok Optima Sep 2010Ramius HamdaniОценок пока нет

- Aits 2223 FT Vi Jeem OfflineДокумент15 страницAits 2223 FT Vi Jeem OfflineSuvrajyoti TaraphdarОценок пока нет

- Nioec SP 00 89 (R0) (Ed1)Документ8 страницNioec SP 00 89 (R0) (Ed1)aminОценок пока нет

- Photography March 2016Документ32 страницыPhotography March 2016ArtdataОценок пока нет

- Fracture Mechanics Study Compact Tension SpecimenДокумент7 страницFracture Mechanics Study Compact Tension SpecimencsmanienОценок пока нет

- 20220606-03 Bombilla de Referencia - Prueba #1 - Después Del AДокумент11 страниц20220606-03 Bombilla de Referencia - Prueba #1 - Después Del Ajesus sanchezОценок пока нет

- 01 11 20-Cta5Документ36 страниц01 11 20-Cta5Goury ShankarОценок пока нет

- EE593Документ4 страницыEE593hassanОценок пока нет

- Shirokov 2020 IOP Conf. Ser. Mater. Sci. Eng. 775 012148Документ8 страницShirokov 2020 IOP Conf. Ser. Mater. Sci. Eng. 775 012148Tomás de AlmeidaОценок пока нет

- Lm331 AppnoteДокумент8 страницLm331 AppnoteEward KenОценок пока нет

- Statistical and Thermal Physics Fundamentals and ApplicationsДокумент13 страницStatistical and Thermal Physics Fundamentals and Applicationsgul jahanОценок пока нет

- Tetron Spherical Bearing s3'05Документ9 страницTetron Spherical Bearing s3'05nouseph6391Оценок пока нет

- Lesson Plan For Demo Class RumanaДокумент2 страницыLesson Plan For Demo Class RumanaRumana PathanОценок пока нет