Академический Документы

Профессиональный Документы

Культура Документы

PAK Suzuki Case Study

Загружено:

zahranqv10 оценок0% нашли этот документ полезным (0 голосов)

492 просмотров15 страницcase

Авторское право

© © All Rights Reserved

Доступные форматы

DOCX, PDF, TXT или читайте онлайн в Scribd

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документcase

Авторское право:

© All Rights Reserved

Доступные форматы

Скачайте в формате DOCX, PDF, TXT или читайте онлайн в Scribd

0 оценок0% нашли этот документ полезным (0 голосов)

492 просмотров15 страницPAK Suzuki Case Study

Загружено:

zahranqv1case

Авторское право:

© All Rights Reserved

Доступные форматы

Скачайте в формате DOCX, PDF, TXT или читайте онлайн в Scribd

Вы находитесь на странице: 1из 15

Page 1 of 15

Pak Suzuki Motor Company Limited

The war of high segment cars.

1. Abstract:

Suzuki Company needs to focus more positively on higher segment of the automobile

industry which is 1300CC to 1800CC cars. The company is doing well in low segment

(800cc to 1000cc) cars in which they have got the highest market share. Suzuki has

got the highest market share (62 percent market share), needs to think about high

segment seriously. One of the foreseeable events, the third phase is Global Era for

Pakistan automobile industry, this era starting from 2012 onwards in which the auto

industry will transform itself for the purpose of becoming a global player by

maximizing their value added production, in that specific area Pak Suzuki has no

specialties. With the start of Global Era Phase due to mass production level the

industry experts are anticipating to accomplish the huge scales which is supported by

the size of GDP of $210 Billion by 2012 and Per capita income reaching to $ 1,300.

Globalization and dynamic environment leads the auto industry towards the

development of skilled people, acquisitions, technological development,

advancement of Infrastructure and living conditions, all these things push the auto

industry to Produce fuel efficient, high standard and environment friendly vehicles,

and at the same time meeting or exceeding customer expectations. The consumer

still have a lot of concerns about quality, safety and after sale service along with

relatively less fuel efficient engine technologies and features of the cars are still the

growing challenges for the Pak Suzuki Motor Company Limited.

The major problem that the Suzuki Company currently facing is in the form of Suzuki

LIANA, which does not fulfill the customers needs and not able to sustain the market

it was made for. Although the company has continued its journey in higher segment,

recently company launched a new model Suzuki SWIFT in the market, and it looks

like an attractive move of the company in the 1300cc class. But still company has

done nothing to compete with HONDA and TOYOTA.

Key words: Pak Suzuki Motor Company (PSMC), Auto Industry Development Program

(AIDP), higher segment (1300cc to 2000cc cars), low segment (800cc to 1000cc cars),

EDB (engineering development board), PAMA (Pakistan Automotive Manufacturers

Association).

Page 2 of 15

2. History:

Pak Suzuki Motor Company Limited is a joint venture between Pakistan Automobile

Corporation and Suzuki Motor Corporation (SMC) - Japan. The Company was

incorporated as a public limited company in August 1983 and started commercial

operations in January 1984. Initially SMC got the market share of 12.5% and with the

passage of time increased to 73.09%. Pak Suzuki has annual production capacity of

150,000 and with largest manufacturing facilities, PSMC is considered to be the

biggest player in automobile business. The company has a huge product line which

includes cars, small vans, Cargo vans and Motorcycle. PSMC followed the aggressive

policy of Indigenization, The capability to manufacture a product independently

within a country instead of relying on foreign manufactures or suppliers. Suzuki

vehicles have a healthy local content up to 72%. It is because of strong support of

vendors.

PSMC has the Dealers network on a large scale consisting of 3S (Sales, Service and

Spare Parts) facilities across Pakistan. PSMC also involved in social responsibility in

which caring for the Environment Pak Suzuki was the first to introduce Factory fitted

CNG vehicles. PSMC always attempted to achieve a goal aggressively for the purpose

of developing a society by increasing industrialization and improving the quality of

life and living standard by creating job opportunities and with the combined efforts

of all the dealers, vendors and Pak Suzuki employees. The major automobile

companies in Pakistan have been set up as joint venture with foreign multinational

companies. Joint Ventures for Automotive Vehicles (See Exhibit: 1)

(Exhibit: 1)

Joint Ventures for Automotive Vehicles:

Company Joint Venture Product

Indus Motor Company Toyota, Japan and Daihatsu,

Japan

Toyota and Daihatsu Cuore

cars

Atlas Honda Ltd. Honda, Japan Honda Cars, Honda

Motorcycles

Pak Suzuki Suzuki, Japan Suzuki cars

Suzuki Motorcycle Pakistan

Ltd.

Suzuki, Japan Suzuki Motorcycles

Ghandara Nissan Nissan, Japan Cars and Truck

Dewan Farooq Motors Ltd. Kia and Hyundai, Korea Cars and LCVs

Raja Motor Co. Fiat, Italy Cars

Source: PAMA

Page 3 of 15

3. Suzukis product line;

SWIFT (1300cc), LIANA (1300 & 1600 cc), CULTUS (1000cc), ALTO (1000cc), MEHRAN

(800cc), APV (1500cc).

4. Suzukis Vision and Mission;

4.1 VISION:

Excellence in all respects.

4.2 MISSION:

Our mission to realize this vision is, to provide automobile of international quality at

competitive price, to improve skills of valued employees by imparting training and

inculcating in them a sense of participation, to achieve maximum indigenization and

promote Pakistan`s automobile vending industry. To make valuable contribution to

social development of Pakistan through development of industry in general and

automobile industry in particular.

5. Industry analysis;

Pakistan auto industry faces a Preparation Phase 1985-05 which was also called

deletion programs. In these programs formulation and implementation of

compulsory local content conditions was adopted. Functions of these programs were

on the basis of Industry Specific Deletion Programs (ISDPs) and Product Specific

Deletion Programs (PSDP). Under these programs assembler had an option to choose

components from a basket based on their individual values. The EDB had the

responsibility to check whether the targets are achieved by conducting audit and also

check the shortfalls of deletion targets.

The auto industry is going to face the Development Phase 2005-12 that phase

consist of developing different strategies to transform the industry into a new

competitive environment. In this phase the main focus of the government was to

facilitate the environment for the auto industry to enhance their production capacity

to achieve mass production. In this phase more focus was on the issues of human

resource development, R&D, technology acquisition, competitiveness, innovation,

creativity and investment rather than tariff management, although it remains one of

the valuable tools for policy makers. During the preparation phase, major role for the

assemblers was to transfer technologies, provide help and assistance for developing

the vendors, enhancing the management skills to fulfill market and consumer needs.

The import of reconditioned cars remained low because of high import duties. High

Page 4 of 15

import of used cars in the last 2 to 3 years was however, to bridge temporary

demand-supply gap. In 2006 was indeed a Systematic shift in the business

environment in the form of tariff rates. Assemblers was not forced to implement

local content conditions, they have got the choice of buying the vehicles components

at most competitive price, quality and improved supply chain. (See exhibit: 2)

(Exhibit: 2)

Import of Vehicles Tax Slabs:

Type of vehicle

(meant for

transport of

passengers)

Customs

Duty on Value

Assessed

(See Para

13below)

Sales

Income

Tax on Sales

Tax paid

value

Special Federal

Excise Duty on duty

paid value

Used vehicles (Not covered under

special regime)

From 1601 CC to 1800 CC (Other than Asian makes)

15.00% 5.00% 1.00% From 1601 CC to 1800 CC (Jeeps)

15.00% 5.00% 1.00% From 1801 CC and above

15.00% 5.00% 1.00%

New Cars (Regular import or under

aforesaid three schemes)

Up to 800 CC

50.00% 15.00% 5.00% 1.00%

From 801 CC to

1000 CC

55.00% 15.00% 5.00% 1.00%

From 1001 CC to

1300 CC

60.00% 15.00% 5.00% 1.00%

From 1301 CC to

1500 CC

60.00% 15.00% 5.00% 1.00%

Source: Import of Vehicles Taxpayers Facilitation Guide (FBR) table 3.

Page 5 of 15

One of the foreseeable events, the third phase is Global Era for Pakistan

automobile industry, this era starting from 2012 onwards in which the auto industry

will transform itself for the purpose of becoming a global player by maximizing their

value added production. The most important benefit auto industry has in the form of

established vendors, huge number of vendors; they have developed themselves

during the second phase. Now they are in a position to recognize the design and

technicalities require for manufacturing components in house or through other

vendors. As auto industry is going to become a global player, so the role of vendors is

very much important in the global supply chain, because industry experts are

expecting that many of the overseas assemblers outsource manufacturing of

components to them. With the start of Global Era Phase due to mass production

level the industry experts are anticipating to accomplish the huge scales which is

supported by the size of GDP of $210 Billion by 2012 and Per capita income reaching

to $ 1,300. Globalization and dynamic environment leads the auto industry towards

the development of skilled people, acquisitions, technological development,

advancement of Infrastructure and living conditions, all these things push the auto

industry to produce fuel efficient, high standard and environment friendly vehicles,

and at the same time meeting or exceeding customer expectations. The overseas

companies are now looking to export and manufacturing cars by using Pakistani

market as a regional hub. The consumers still have a lot of concerns about quality,

safety and after sale service along with relatively less fuel efficient engine

technologies and features of the cars are still the growing challenges for the local

automobile industry.

Pakistan auto sector operates on a large scale and they have got the investment of Rs

98 billion, and this sector contributed about Rs. 63 billion as indirect taxes. Auto

sector also creates lot employment opportunities as it employs about 192,000

people directly and around 1.2 million indirectly. Pakistan auto industry also playing

an important role in the development of an economy, as the sector paying

approximately Rs. 08 billion per year in the form of taxes and contributed more than

Rs 30 billion to countries GDP. Although the industry is going slowly but it has got the

high potential in the coming years. Pakistans total share of car and commercial

vehicles remains 0.37% of the world production during the year 2006-07. (See

exhibit: 3)

(Exhibit: 3)

Page 6 of 15

Installed Capacity of Cars and Light Commercial Vehicles (LCVs):

Organization Capacity Unit/Annum

Pak Suzuki Motor Co. Ltd, Karachi

Public Limited Company with 72.82%

shares and management held by

Suzuki Motor Corporation, Japan.

150,000

Indus Motor Co. Ltd, Karachi

Joint venture between Habib Group,

Pakistan,

Toyota Tsusho Corporation, Japan

(Toyota and Cuore

50,000

Honda Atlas Cars (Pak) Ltd, Lahore

Joint venture between Atlas Group

Pakistan and

Honda Motor Co. Japan.

20,000

Ghandhara Nissan Ltd

Technical cooperation agreement

with Nissan Motors, Japan.

6,000

Dewan Farooq Motors Ltd

Technical cooperation agreement

with Hyundai

Corporation, South Korea.

25,000

251,000

Source: PAMA (Updated to FY. 2007-2008)

6. Recent Developments in Automotive Industry;

Pak automotive industry has recently created system enhancement, technological

development and skills improvement on the basis of forward and backward

integration, and all these things provide help to the rest of technical and engineering

sector as well. Because local material is used in manufacturing, so industrys

backward integration for materials and toolings such as steel, aluminum, copper,

plastics & chemicals, rubber & glass and its forward linkages in the form of retail &

wholesale, dealerships & logistics, workshops & maintenance, filling stations, finance

& insurance, marketing, advertising and consultancy services and trade, it stand to

reason that all these things plays a vital role for the development of auto industry in

future as well. If we look at the other side of the picture, material prices are declining

in overseas market so companies can reduce per unit cost and increase profits.

Page 7 of 15

7. Government Reforms for Automotive Industry;

Now automotive industry is becoming a global thespian by achieving

competitiveness, critical mass production and contribution to Pakistan s GDP 5.6%

by 2012 through attracting domestic and foreign investment in the auto industry and

development of human resource through a well-constructed policy framework and

for the development of new innovative technology. Over next five years which are

offering many challenges and obstacles, important is being continuing the high

growth, achieving competitiveness, investment in compliance to safety and quality

management standards. The goals set by the government and automotive industry

together can only be achieved by inclusive policy development through which cross

sectional issues can be addressed. The government of Pakistan has initiated the

Automotive Industry development Program (AIDP) for the sake of address issues

including the predictability of auto production and stable tariff for the next five

years. The (AIDP) undertaken by the government for the development of the

automotive industry. The Engineer Development Board (EBD) has the authority for

the implementation of this program to boost car production capacity to half a million

units as well as attract the investment of US$ 3 Billion and reach the auto export

target of US$ 650 Million.

The low cost production issues to compete in international market, adopting new

global emerging trends and dynamics of fuel efficient and environment friendly

vehicles, and the contribution in GDP remain dominant in the policy environment. As

fuel prices increasing rapidly, demand to produce fuel efficient and hybrid cars are

also under the consideration. The role of foreign investors and their interest in the

automotive industry speaks about a lot of potential and growth opportunities for

production and export. Pakistan Automotive industry has positioned to become a

global choice for outsourcing and becoming the part of global supply chain.

Government of Pakistan had undertaken major initiatives in the form of National

Trade Corridor Improvement Program (NTCIP) that reduces inefficiencies like

reduction the cost of doing business, increasing economic growth and increasing

export competitions.

Page 8 of 15

8. Competition;

8.1 Indus Motors company Pakistan:

Indus Motors Company Pakistan production facilities are located at Port Bin Qasim

Industrial Zone near Karachi in an area of over 105 acres. Indus Motor Company s

plant is the only manufacturing site in the world where both Toyota and Daihatsu

brands manufactured. Huge investments are made to build its production facilities

based on state of art technology. To ensure high degree of productivity, Toyota

production systems are implemented. Indus Motors Company Toyota production line

includes six variants of the newly introduced Toyota Corolla, Toyota Hilux Single

Cabin 4x2 and versions of Daihatsu Cuore.

8.2 Toyota Corolla:

The Toyota Corolla has been achieving success as a strong brand science 1970 in

Pakistan when Toyota Corolla was not manufactured in Pakistan but at the import

basis this brand tremendously took place in the Pakistan automotive market. The

most famous series of Corolla are 1976, 1978, 1986 and the list of early series of the

models is still considered as powerful and memorable brands. Toyota Corolla

assembling progressive manufacturing and marketing in Pakistan since July 01, 1990.

Corolla brand has already established in Pakistan auto market. So there was no hard

struggle made to establish the brand.

Toyota Corolla is well standardizing product in the market and its current series is

1300cc XLI, GLI Cruisetronic in each of the product they provide state of the art

features, reliability and serviceability to make more loyal customers.

8.3 Honda:

Honda Cars Pakistan Limited is a joint venture between Honda Motor Company

Limited Japan and the Atlas Group of Companies Pakistan. The joint venture was

initiated on November 1992 and joint venture agreement was signed on August

1993. Science the commencement of production in 1994, the company has produced

and sold more than 150,000 cars until October 2008. The company also regularly

conducts service campaigns to facilitate customer s need for service. This has given

to customers absolute confidence in the product evident from the increasing sales

volume. It is the constant endeavor of the Honda Atlas Cars (Pakistan) Limited to

achieve No.1 customer satisfaction. Honda Atlas Cars (Pakistan) Limited is committed

to meet customer satisfaction and to provide good value of money.

Page 9 of 15

0

20,000

40,000

60,000

80,000

100,000

120,000

140,000

160,000

180,000

200,000

U

n

i

t

s

i

n

T

h

o

u

s

a

n

d

production of cars:1300cc, 1000cc, 800cc

Units in Thousand

9. Increasing trends in higher segments;

After the disaster of September 11, 2001 increased in the home remittances has

resulted in increased liquidity in the market therefore, people started to invest in

cars. At that time growth in high capacity car s segment increases. It becomes easy

to purchase new cars due to cars loans provided by banks. In order to fulfill rising

demand the automotive production capacity increased. Because of that mass

production the domestic car engine technology lags years behind the world markets

and people were unable to get the benefits of new technology. (See exhibit: 4).

(Exhibit: 4)

Production of Cars:

Source: PAMA

Page 10 of 15

10. Problems of Suzuki in Higher Segment Cars;

Suzuki has more focused on price competitiveness in higher segment of cars rather

than quality and innovation. Suzuki has more than 50% share in low segment vehicles

but lacking far behind in higher segment cars. The development of highly skilled

human resource and partnership with venders, acquisition of technology and

infrastructure, incorporating the environment changes will drive the automotive

industry to produce high standard, fuel efficient and environment friendly vehicles in

the better price range along with satisfying the customer requirements and

expectations. The consumers concern on quality, safety and after sale services along

with relatively less sophisticated engine technologies and features are still the

growing challenges for the automotive industry of Pakistan, especially for Pak Suzuki

Motors Company Limited.

Major setbacks to Pak Suzuki Motors Company Limited (PSMC) was in the shape of

Suzuki LIANA and BALINO, which was not able to compete neck to neck competition

with its competitors, Honda city, Honda civic and Toyota corolla because of unable to

meet the customers expectations and could not grasp the market. But PSMC didnt

stop its journey there, and now Suzuki SWIFT has recently been launched in the

market, which seems to be an attractive offer for the auto market in 1300cc

segment, but still PSMC has nothing to compete with HONDA and TOYOTA. The

gaining advantages of loyal customers before starting production of Toyota Corolla

brand in Pakistan, they didnt need to much hard struggle to give awareness and

make customers because of strong brand loyalty perception. So if we are talking

about higher segment (1300cc to 2000cc) cars Toyota Corolla is the leader in Pakistan

followed by Honda and then Suzuki.

Now Suzuki is focusing upon production to meet the market demand in small 800cc

and 1000cc cars segment. The reason was deletion program is replaced by tariff

based program from year 2006 to encourage local automobile part manufacturers to

enhance their productivity and decrease in the price as there are incentives in term

of using local parts. As far as this is helpful in declining the price of cars but on the

other hand it cause serious problems in quality and innovation. Pak Suzuki has

greater advantage then Honda in this policy because the Suzuki has a perception of

low cost normal quality car by using local manufacturing auto parts. Suzuki has not

serious decline in its perception if it uses the local manufactured auto parts if Honda

uses local parts their perception of high quality could decline. So decline in

technology will destroy the customer s confidence on brands and consumer will shift

focus on imported vehicles.

Page 11 of 15

The concept of CNG (compressed natural gas) in Pakistan also raises the demand of

automobiles in the country because CNG is cheaper than petrol. Pakistan now

becomes the first country in the world who consumes the CNG in automobiles.

Suzuki lays its focus by serving the low segments by introducing CNG kits in cars but

on the other side now people became very conscious to buy the car even invest in

the car market and rapid growth in the consumer financing from banks and other

companies provide the opportunity to buy latest models having more innovative

features compare to international top brands as they also reflect the status symbol.

(See exhibit: 5)

(Exhibit: 5)

CARS (Number of units sold)

CARS: Number of units

sold

2005-

06

2006-

07

2007-

08

2008-

09

2009-

10

2010-

11

2011-

12

1300-1600cc (2000cc Diesel)

July'11-

Jun'12

Honda

Honda (civic) 11,998 6,513 5,762 4,662 5,908 6,365 4,977

Honda (city) 16,136 11,848 8,439 6,482 8,212 9,121 7,142

Honda Total: No. of units

sold

28,134 18,361 14,201 11,144 14,120 15,486 12,119

Toyota

Toyota Corolla (No. of units

sold)

30,527 35,762 33,640 26,760 43,510 41,111 46,207

Suzuki

Suzuki (Baleno) 3,173 0 0 0 0 0 0

Suzuki (Liana) 4,571 6,067 8,439 851 1,025 470 450

Suzuki (Swift) ~ ~ ~ ~ 2,353 4,080 7,040

Suzuki Total (No. of units

sold)

7,744 6,067 8,439 851 3,378 4,550 7,490

Grand Total 46,015 47,896 50,518 28,462 50,266 50,211 61,187

Source: PAMA

Page 12 of 15

(Exhibit: 6)

Source: PAMA

Pakistan automotive industry is not equipped to undertake research and

development due to relatively weak technical base and risk evasiveness of producers.

Technology acquisition costs vary with the type and extend of sophistication. Cutting

edge technology transfers are difficult and may be the major factor.

Toyota transfer technology directly to local venders for manufacturing parts.

Manufacturing facility is audited first to judge the potential of a local vendor before

permitting him to produce sample of the part for testing approval. Japan is ready to

provide technical assistance up to certain level, but still no adequate infrastructure

and skilled human resource has been developed to meet the desired standard. An

average of only 45% parts of various models has been permitted to be developing

locally by Toyota after their extensive test trail in Japan. Due to non-availability of

expensive quality control equipment, all safety components are imported. Highly

trained engineers and technicians are also sending to Toyota Behren Training Center

for further skills enhancement. Manufacturing knowhow is transferred directly to

local vendors as per their qualification and skills, whereas assembly and operational

knowhow is provided to Indus Motors Company.

Due to the increasing demand of automobile rapidly and non-availability of strong

competitors in local market, the company remains unable to meet the technological

assistance requirements of local vendors to the desired level. Still no adequate

0

5,000

10,000

15,000

20,000

25,000

30,000

35,000

40,000

45,000

50,000

1300cc (No.of units sold)

Honda Total (no.of units sold)

Toyota (Corolla no.of units sold)

Suzuki Total (no of units sold)

Page 13 of 15

quality control standards are emphasizing to meet the required standards of the

automobiles. This has result in consistently deteriorated quality of the finish products

especially in Mehran, Bolan and Alto vehicles. The benefits achieved by Suzuki

include saving of foreign exchange through development of 65% parts locally. Local

industry is promoted and develops resulting in employment benefits and economic

boost as per Pakistan government policy but it results in lack of innovation and major

quality initiatives the Suzuki s product line that cause the failure of the cars in higher

segments.

Honda Motors Company Japan is getting only 5% parts manufactured locally, due to

non-implementation of government policy (AIDP) forcefully and avoid giving any

design and manufacturing knowhow to local vendor industry. They are opinion that

due to non-availability of research and development infrastructure, it is extremely

default for Honda to provide any manufacturing technology to Pakistan. Instead of

relying on local vendors, Honda has continued to improve their vehicle parts. It can

be a short term advantage for them but in the long run they are losing credibility in

local market through increased production cost, depreciation of currency value and

non-availability of local vendors for manufacturing their vehicle parts.

By the start of Global Era Phase the automotive industry is expected to achieve the

high scale of production level and supported by the size of GDP of US$ 210 Billion by

2012. Global flattening, information systems and development of technologies,

improvement of infrastructure and living conditions will drive the automotive

industry to produce high standard, fuel efficient and environment friendly vehicles in

a better price range and satisfying consumers expectations. It is a major challenge

for the local car assemblers to achieve the acceptability of vehicles in the global

market. They need to be more concern about these challenges. (See Exhibit: 7)

Page 14 of 15

Sales of Cars (Exhibit: 7)

CAR 2005-06 2006-07 2007-08 2008-09 2009-10 2010-11 2011-12

1300-1600cc (2000cc Diesel) July'11-

Jun'12

Honda (Civic) 11,998 6,513 5,762 4,662 5,908 6,365 4,977

Honda (City) 16,136 11,848 8,439 6,482 8,212 9,121 7,142

Suzuki (Baleno) 3,173 0 0 0 0 0 0

Suzuki (Liana) 4,571 6,067 8,439 851 1,025 470 450

Suzuki (Swift) ~ ~ ~ ~ 2,353 4,080 7,040

Toyota (Corolla) 30,527 35,762 33,640 26,760 43,510 41,111 46,207

1000cc

Suzuki (Khyber/ Cultus) 21,390 29,837 27,563 9,198 12,658 11,428 13,693

Suzuki (Alto) 16,823 21,988 19,097 6,550 10,794 11,932 16,288

Hyundai (Santro Plus) 7,031 3,470 2,227 404 244 0 0

800c

Daihatsu (Cuore) 7,883 12,776 12,204 5,852 5,301 6,007 3,857

Suzuki (Mehran) 35,982 37,007 35,526 13,421 22,513 24,119 35,131

Suzuki (Bolan) 10,451 15,566 17,209 8,664 11,439 13,311 22,540

TOTAL CARS: 165,965 180,834 164,650 82,844 123,957 127,944 157,325

Source: PAMA

Market Shares for FY-Year 2011-2012 (Exhibit: 8);

CARS Units Sold (nos.) Market Share (%)

Suzuki 95,142 62%

Toyota 46,207 30%

Honda 12,119 8%

Hyundai 0 0%

Nissan 0 0%

Kia 0 0%

Total 153,468 100

Source: PAMA

Cars

Suzuki

Toyota

Honda

Hyundai

Nissan

Kia

Page 15 of 15

11. In future;

One of the foreseeable events, the third phase is Global Era for Pakistan

automobile industry, this era starting from 2012 onwards in which the auto industry

will transform itself for the purpose of becoming a global player by maximizing their

value added production. . With the start of Global Era Phase due to mass

production level the industry experts are anticipating to accomplish the huge scales

which is supported by the size of GDP of $210 Billion by 2012 and Per capita income

reaching to $ 1,300. Globalization and dynamic environment leads the auto industry

towards the development of skilled people, acquisitions, technological development,

advancement of Infrastructure and living conditions, all these things push the auto

industry to Produce fuel efficient, high standard and environment friendly vehicles,

and at the same time meeting or exceeding customer expectation. To fulfill the

above stated requirements it means more focus on product development,

technology, R&D, and innovations, Pak Suzuki lacks the expertise in all these areas,

so in order to earn huge profits in higher segments and to remain in competition

with Toyota and Honda, strategically Pak Suzuki has to think about it seriously.

Вам также может понравиться

- Toyota Indus Vs Honda AtlasДокумент4 страницыToyota Indus Vs Honda Atlasareel bhattiОценок пока нет

- Ratio Analysis of Indus and Pak SuzukiДокумент44 страницыRatio Analysis of Indus and Pak SuzukiImran Zulfiqar0% (2)

- Pak Suzuki MotorsДокумент31 страницаPak Suzuki Motorshammy86100% (2)

- Pak Suzuki Motor Company Limited Success StoryДокумент2 страницыPak Suzuki Motor Company Limited Success StoryArslan ZubariОценок пока нет

- Analysis of Financial StatementsДокумент49 страницAnalysis of Financial Statementsnimra farooq0% (1)

- Enviornmental Analysis of Pak Suzuki Motor CompanyДокумент55 страницEnviornmental Analysis of Pak Suzuki Motor Companybilal asifОценок пока нет

- Honda Atlas CarsДокумент100 страницHonda Atlas CarsShery AwanОценок пока нет

- Introduction To Pak SuzukiДокумент3 страницыIntroduction To Pak Suzukiishraqshah095154100% (1)

- Pak Suzuki Motor Company Limited: Internship ReportДокумент29 страницPak Suzuki Motor Company Limited: Internship ReportMuhammad Hassan Ahmad Madni100% (1)

- Pak Suzuki MotorДокумент13 страницPak Suzuki MotorShariq Khan100% (1)

- PAK Suzuki Motors Company Limited: Operations Management: Teacher: Sir Khurram AminДокумент3 страницыPAK Suzuki Motors Company Limited: Operations Management: Teacher: Sir Khurram AminWarda TariqОценок пока нет

- Indus Motor Co. Final Project-2Документ65 страницIndus Motor Co. Final Project-2Nida Akram0% (2)

- OB - Atlas HondaДокумент22 страницыOB - Atlas Hondaatique092828886% (7)

- Atlas HondaДокумент4 страницыAtlas Hondaحبا عرفانОценок пока нет

- Automobile Industry AssignmentДокумент9 страницAutomobile Industry AssignmentNeelam KhanОценок пока нет

- Pak Suzuki Motors Case StudyДокумент10 страницPak Suzuki Motors Case StudyAsif Javaid50% (2)

- Suzuki Motors ReportДокумент12 страницSuzuki Motors ReportAfza MasoodОценок пока нет

- Ashok LeylandДокумент13 страницAshok LeylandDiptiОценок пока нет

- Indus Motor Report BBA-35Документ23 страницыIndus Motor Report BBA-35Zeeshan MazharОценок пока нет

- EFE of Pak SuzukiДокумент4 страницыEFE of Pak SuzukishahmeerbilalОценок пока нет

- Internship ReportДокумент66 страницInternship Reportusman_mughall100% (7)

- BCG Analysis of Pak Suzuki Motor Company LTD.: Manufacturing Strategies & TechnologiesДокумент5 страницBCG Analysis of Pak Suzuki Motor Company LTD.: Manufacturing Strategies & TechnologieskiranОценок пока нет

- Suzuki Motor Corporation Change AnalysisДокумент21 страницаSuzuki Motor Corporation Change Analysismclawson1Оценок пока нет

- Swot Ananlysisi SuzukiДокумент4 страницыSwot Ananlysisi SuzukijohnymascularОценок пока нет

- Sajid Final Zong ReportДокумент37 страницSajid Final Zong ReportKhurram Warriach0% (1)

- Operations Honda Atlas CarsДокумент29 страницOperations Honda Atlas Carsyasaramir60% (5)

- FFC vs. EngroДокумент36 страницFFC vs. EngroAnsaria100% (1)

- Honda Atlas MotorsДокумент132 страницыHonda Atlas MotorsIgnorant Human0% (1)

- Hum Network SM Final Report PDFДокумент32 страницыHum Network SM Final Report PDFfatima100% (1)

- PAk Suzuki Motor (Sundus Shehzadi)Документ38 страницPAk Suzuki Motor (Sundus Shehzadi)Sûñdûs ShêhzãdîОценок пока нет

- Strategic Analysis Pak Suzuki MotorsДокумент27 страницStrategic Analysis Pak Suzuki Motorsnasirenam0% (1)

- Suzuki Annual Report 2020Документ85 страницSuzuki Annual Report 2020Zeeshan MeharОценок пока нет

- Executive Summary Atlas HondaДокумент1 страницаExecutive Summary Atlas Hondaحبا عرفانОценок пока нет

- Introduction To ZongДокумент5 страницIntroduction To ZongSaad Ijaz Khan100% (1)

- HISTORY of AUTOMOBILE INDUSTRY in PAKISTAN The Pakistan Automobile Industry Is A Crucial Part of Our Growing EconomyДокумент4 страницыHISTORY of AUTOMOBILE INDUSTRY in PAKISTAN The Pakistan Automobile Industry Is A Crucial Part of Our Growing EconomyKhizar FarooqОценок пока нет

- Atlas HondaДокумент17 страницAtlas Hondaanum fatimaОценок пока нет

- Toyota Pom Project ReportДокумент22 страницыToyota Pom Project ReportALI SHER HaidriОценок пока нет

- EngroДокумент73 страницыEngrogoldenguy90100% (3)

- ORIXДокумент42 страницыORIXAmin Farooq100% (1)

- Ashok LeylandДокумент33 страницыAshok Leylandpg1875% (4)

- Pak Suzuki Motors Company Limited: Operations Management: Teacher: Sir Khurram AminДокумент4 страницыPak Suzuki Motors Company Limited: Operations Management: Teacher: Sir Khurram AminWarda TariqОценок пока нет

- Ashok Leyland Report 2011-2012Документ76 страницAshok Leyland Report 2011-2012Mukesh Kumar Rajpurohit100% (1)

- Engro Food STG MNGT (1) ..Документ43 страницыEngro Food STG MNGT (1) ..naseeb58% (12)

- Js - Camels AnalysisДокумент7 страницJs - Camels AnalysisTammy DavisОценок пока нет

- Bajaj Individual AssignmentДокумент15 страницBajaj Individual AssignmentPriyanka Katkar100% (1)

- ZAHOOR Internship ReportДокумент38 страницZAHOOR Internship Reportaashir chОценок пока нет

- Supply Chain Activities of Atlas Honda Motorcycles PakistanДокумент31 страницаSupply Chain Activities of Atlas Honda Motorcycles PakistanJaved MalikОценок пока нет

- Toyota Pakistan...... Research Report On Sales ManagementДокумент22 страницыToyota Pakistan...... Research Report On Sales ManagementAkbar Syed100% (1)

- Atlas Honda (LTD)Документ70 страницAtlas Honda (LTD)Abdul Manan0% (1)

- Maruti SuzukiДокумент30 страницMaruti SuzukiChaitanya KulkarniОценок пока нет

- Final Project: International Islamic University IslamabadДокумент24 страницыFinal Project: International Islamic University IslamabadSohaibDanishОценок пока нет

- Ratio Analysis - Ashok LeylandДокумент18 страницRatio Analysis - Ashok Leylandgunjan02060% (1)

- Project Atlas Honda Limited PakistanДокумент16 страницProject Atlas Honda Limited PakistanAmjad Iqbal100% (3)

- Pest Analysis of Pak SuzukiДокумент10 страницPest Analysis of Pak SuzukiTehman Ahmed WarraichОценок пока нет

- University of Education Lower Mall Campus, LahoreДокумент27 страницUniversity of Education Lower Mall Campus, LahoreSeemab Sheikh QurashiОценок пока нет

- Slogan: "The Power of Dreams"Документ38 страницSlogan: "The Power of Dreams"asimsquareОценок пока нет

- SM-Final ProjectДокумент40 страницSM-Final Projectmaliha fatimaОценок пока нет

- Market Adaptation of Volkswagen PoloДокумент36 страницMarket Adaptation of Volkswagen PoloRohit Sopori100% (1)

- Indus Motor CompnayДокумент4 страницыIndus Motor CompnayAsif KhanОценок пока нет

- Atlas Honda CasestudyДокумент20 страницAtlas Honda CasestudyDrMunir Hussain Siddiqui0% (1)

- Class ProjectДокумент6 страницClass Projectzahranqv1Оценок пока нет

- Chapter 8Документ11 страницChapter 8zahranqv1Оценок пока нет

- Chapter 9Документ9 страницChapter 9zahranqv1Оценок пока нет

- Business Policy and StrategyДокумент38 страницBusiness Policy and Strategyzahranqv1Оценок пока нет

- IEДокумент10 страницIEzahranqv1Оценок пока нет

- SwotДокумент5 страницSwotzahranqv1Оценок пока нет

- Class ProjectДокумент6 страницClass Projectzahranqv1Оценок пока нет

- BCG MATRIX of Bank Alfalah:: Banking Industry Growth in 2013 Is 9%Документ3 страницыBCG MATRIX of Bank Alfalah:: Banking Industry Growth in 2013 Is 9%zahranqv1Оценок пока нет

- SWOT Analysis of DepositsДокумент3 страницыSWOT Analysis of Depositszahranqv1Оценок пока нет

- IFE Matrix of Bank Alfalah Deposits: Weights Rates Weighted Scores StrengthsДокумент4 страницыIFE Matrix of Bank Alfalah Deposits: Weights Rates Weighted Scores Strengthszahranqv1Оценок пока нет

- Internal Factor Evaluation Matrix 2Документ4 страницыInternal Factor Evaluation Matrix 2zahranqv1100% (1)

- IEДокумент10 страницIEzahranqv1Оценок пока нет

- IFE Matrix of Bank Alfalah Deposits: Weights Rates Weighted Scores StrengthsДокумент4 страницыIFE Matrix of Bank Alfalah Deposits: Weights Rates Weighted Scores Strengthszahranqv1Оценок пока нет

- The Nap Tracker 2016Документ162 страницыThe Nap Tracker 2016Zain IqbalОценок пока нет

- United Front.1954pptДокумент14 страницUnited Front.1954pptSourav Ghosh100% (2)

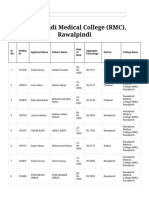

- Rawalpindi Medical College (RMC) by MDCATIOLOGYДокумент28 страницRawalpindi Medical College (RMC) by MDCATIOLOGYzinniashakilОценок пока нет

- Strategic Analysis of United Bank LimitedДокумент75 страницStrategic Analysis of United Bank Limitedshahid_pak1_2611436480% (5)

- Press Note Chemistry (F)Документ2 страницыPress Note Chemistry (F)Sohail NadeemОценок пока нет

- Balloting List of Category - Iii (35' X 70' or 272 Sq. Yds) : File No Name of Allottee Plot No Street No SectorДокумент43 страницыBalloting List of Category - Iii (35' X 70' or 272 Sq. Yds) : File No Name of Allottee Plot No Street No SectorNasir RajputОценок пока нет

- Elections 2024: List of PTI Candidates - Punjab AssemblyДокумент9 страницElections 2024: List of PTI Candidates - Punjab AssemblyWasif Shakil100% (1)

- Pak Bulwark Against CommunismДокумент2 страницыPak Bulwark Against CommunismMominaQureshiОценок пока нет

- Ability Test Syllabus KPK Public Service CommisionДокумент25 страницAbility Test Syllabus KPK Public Service CommisionEngr Asad SufyanОценок пока нет

- Solved Objectives of Indo-Pak Past Papers (1985-2011) - Page 2 - CSS ForumsДокумент22 страницыSolved Objectives of Indo-Pak Past Papers (1985-2011) - Page 2 - CSS Forumsmahamnadirminhas0% (1)

- CV - Aqeel Ahmed Qazi Updated - Rev - CompressedДокумент4 страницыCV - Aqeel Ahmed Qazi Updated - Rev - Compressedsidiq7Оценок пока нет

- State Military and Democracy by Akbar Zaidi PDFДокумент10 страницState Military and Democracy by Akbar Zaidi PDFAsjad HussainОценок пока нет

- Details of Oil Marketing Companies' Licenses: S. # Company Name Address Phone & Fax NoДокумент2 страницыDetails of Oil Marketing Companies' Licenses: S. # Company Name Address Phone & Fax Noasad raza100% (1)

- Rajiv Malhotra - The Root of India-Pakistan ConflictsДокумент18 страницRajiv Malhotra - The Root of India-Pakistan Conflictsganesh_iyergОценок пока нет

- Trade Association Updated PDFДокумент12 страницTrade Association Updated PDFMariam AkhtarОценок пока нет

- Circular DebtДокумент14 страницCircular DebtNaina MukhtarОценок пока нет

- NTS - National Testing Service PDFДокумент4 страницыNTS - National Testing Service PDFAamir AhmedОценок пока нет

- Abbottabad Chamber of CommerceДокумент28 страницAbbottabad Chamber of CommerceMansoor Ul Hassan SiddiquiОценок пока нет

- HistoryДокумент14 страницHistoryPrajwal DongareОценок пока нет

- Forests in Beautiful PakistanДокумент8 страницForests in Beautiful PakistanS Lakhte Haider ZaidiОценок пока нет

- 2 OFFICE NOTE For OvertimeДокумент7 страниц2 OFFICE NOTE For OvertimeSana UllahОценок пока нет

- Facts and Figures For CSS Exam 2023Документ10 страницFacts and Figures For CSS Exam 2023Mr MalikОценок пока нет

- (South Asia in World Affairs) Haroon K. Ullah-Vying For Allah's Vote - Understanding Islamic Parties, Political Violence, and Extremism in Pakistan-Georgetown University Press (2013)Документ266 страниц(South Asia in World Affairs) Haroon K. Ullah-Vying For Allah's Vote - Understanding Islamic Parties, Political Violence, and Extremism in Pakistan-Georgetown University Press (2013)hareemОценок пока нет

- Geography Notes Part 5Документ10 страницGeography Notes Part 5Airfa MОценок пока нет

- How Is Policy Making in Pakistan Influenced by Its Indigenous Classes?Документ7 страницHow Is Policy Making in Pakistan Influenced by Its Indigenous Classes?Tabish HamidОценок пока нет

- General Knowledge (G.K) MCQSДокумент47 страницGeneral Knowledge (G.K) MCQSMeena KhanОценок пока нет

- Multani Punjabis of IndiaДокумент2 страницыMultani Punjabis of IndiaTonynasir100% (3)

- December ReportsДокумент47 страницDecember ReportsjunaidahmadmalikОценок пока нет

- Telephone DirectoryДокумент4 страницыTelephone Directorysaqib hashmiОценок пока нет

- 1970 Education PolicyДокумент2 страницы1970 Education Policyabdul bari92% (12)