Академический Документы

Профессиональный Документы

Культура Документы

Preet Tractors File

Загружено:

Jagjot SinghОригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Preet Tractors File

Загружено:

Jagjot SinghАвторское право:

Доступные форматы

TABLE OF CONTENTS

Contents Page No

1. Abstract 1

2. Introduction 5

2.1 History o t!e ir" 5

2.2 Products 5

2.# Tractors 5

2.$ Present scenario o t!e %&ant 6

2.' Future %&ans 6

#. Pro(ects

#.1 To "a)e Hardness c!art o *arious %arts o tractor so t!at

ease in c!ec)ing t!e inco"ing +ua&ity o *arious co"%onents

7

#.2 Need 7

#.# Beneits 7

#.$ Pur%ose 7

#.' Testing Procedure o t!e co"%onents 8

#., -ua&ity Procedure o t!e co"%onents 10

#.. Hard/are Section

Tab&e #.10 List o instru"ents used into I-C de%art"ent

Tab&e #.2 0 Hardness C!arts o Co"%onents

11

13

17

#.1 Ac!ie*e"ents ti&& date 18

#.2 3e"aining 4or) 18

#.1.1 Ob(ecti*e0 To i"%&e"ent %o/er steering on t!e tractor to

"a)e t!e steering si"%&er and easier

19

#.1.2 3e+uire"ents 19

#.1.# A%%&ications 19

#.1.$ Sc!edu&e 19

#.1.' Layout o %o/er steering 20

#.1., Co"%onents o %o/er steering

Figure 1.10 Steering 4!ee&

21

#.1.. Steering Co&u"n

Figure0 1.20 Steering Co&u"n

22

#.1.1 Steering 5nit

Figure 1.#0 Steering 5nit

23

#.1.2 Ac!ie*e"ents ti&& date 23

#.1.16 3e"aining 4or) 23

$. 3eerences 24

1. ABST3ACT

A tractor is a critical tool in farm mechanization. A 20 HP tractor can replace about 200 laborers.

Tractor is also for material handling in industries and a tractor trailer combination is also used as a

SUSCET, TANGORI 2

passenger / commercial ehicle in rural and semi!urban areas. "tudies done in Pun#ab sho$s that an

aerage farmer runs his tractor for about %&7 hours in a 'ear. (ut of this) 27* hours is spent on

farming $hile the remaining time is diided bet$een mar+eting of produce and purchase of inputs

,-. hours/) customs hiring ,%2 hours/ and other social engagements ,2- hours/.

0ualit' is one of the important factors $hich influences the purchaser of product and helps to

capture mar+et. 1t pla's an important role in customer2s decision and $hich is $h' control of

3ualit' during manufacture of a product is er' necessar'. 0ualit' of product depends upon the

application of materials) men) machines and manufacturing conditions. The 3ualit' control is

needed due to the follo$ing reasons4

a/ Customer5s "atisfaction

b/ 6conom'

c/ 7eduction in "crap

d/ 8easibl' of using arious spare parts

2. INT3O75CTION

2.1 HISTO38 OF THE FI390

SUSCET, TANGORI 3

1n .&*0) $hen the nation needed one t'pe of machine $hich could harest and thresh the crop

simultaneousl') to reduce the losses beared b' the farmers) ". Hari "ingh ,9.:. of Preet Agro Pt.

;td./ $as $or+ing on the pro#ect in his tractor repair $or+shop. After three 'ears of hardship) he

$as able to establish a small scale unit for manufacturing haresting reapers) Threshers) Agriculture

parts. ;ater) his brother ".<urcharan "ingh ,:irector/ #oined him in .&*= and the' $ere able to

ma+e a tractor drien combine in .&*-.

The name Preet $as established in .&*7. The Pro#ect for manufacturing agricultural Tractors $as

the farmer5s agricultural re3uirement. >o$ the 9.: of Preet Tractor is ?".<urpreet "ingh@ s/o ".

Hari "ingh. The deelopment of tractors $hich started in house in 200. $as materialized in

launching manufacturing actiities of tractors hae started in earl' 200%. A batch of 2. tractors hae

been tested ,(n all the farming operation/ through farmers $ho had the ast eAperience in

agriculture.

2.2 P3O75CTS0

Toda') Preet Agro 1ndustries is the largest manufacturer of self!propelled combines) tractors and

haresters in 1ndia. The compan' produces a $ide range of tractors and combines $hich are gien

belo$4

2.# T3ACTO3S0

Preet 7=B&

Preet -0B&!.

Preet -0B&

Preet =0B&

Preet B=B&

Preet B0B&

Preet %=B&

Preet %0B&

2.$ INF3AST35CT53E0

SUSCET, TANGORI 4

P3EET is one of the 1ndiaCs leading manufacturers of agricultural tractors and combine haresters.

P3EET is mar+et leader in self!propelled combine haresters in 1ndia. De are controlling %=E

mar+et share of self!propelled combine haresters.

2.' P3ESENT SCENA3IO OF THE PLANT0 :

The compan' is 1"( &00.4 2000 certified compan'.

Combine haresters are manufactured on organized assembl' production line.

Plant is e3uipped $ith latest C>C turning machines for machining of components and others

computerized machines i.e. shearing machines) bending press) po$er press) lathe) shapers and

radial drill machines etc.

Compan' is haing one another full' computerized Turret punching machine to enhance

production capacit' and to maintain the 3ualit' of product.

2., F5T53E PLANS

Compan' has installed ;aser oscillator machine from 9AFAG Hapan.

De $ill be first to install 7obots for all t'pe of $elding #obs in our plant in neAt financial 'ear.

:ip Painting of sheet metal $ill be install soon.

#.1 P3O;ECT 0

SUSCET, TANGORI 5

To ma+e Hardness chart of arious parts of tractor so that ease in chec+ing the incoming 3ualit' of

arious components.

#.2 NEE74

The 3ualit' control is needed due to the follo$ing reasons4

a. Customer5s "atisfaction

b. 6conom'

c. 7eduction in "crap

#.# BENEFITS

There are man' adantages b' controlling the product 3ualit'. "ome of them are listed belo$4

a/ 1mproement in 3ualit'.

b/ 1ncreased production under same set up.

c/ 7eduction in cost due to lo$er re#ection and re$or+ing.

d/ 7eduction in scrap.

e/ 7eduction in production bottlenec+s.

f/ 7eduction in inspection in terms manpo$er and e3uipment cost.

g/ 6aluation of 3ualit' tolerance $ith an idea of aoiding uncalled for 3ualit' build!up.

h/ 9aintenance of operating efficienc'.

i/ ;ess customer complaints.

#/ 0ualit' consciousness.

#.$ P53POSE0

1ncoming 7a$ 9aterial are inspected in order to

a. 6liminate those material $hich do not meet specification and li+el' to cause trouble during

processing.

b. 6aluate endor5s 3ualit' and abilit' to suppl' acceptable materials.

c. 1nspection of ra$ material ma' inole a isuals chec+ up onl') a dimensional chec+) a test

of ph'sical properties and chemicals composition) etc.

d. 7a$ materials depending upon their characteristics and ma' re3uire a sampling inspection

SUSCET, TANGORI 6

e. After inspection) the right 3ualit' parts are sent either to stoc+ room or Assembl' lines.

#.$.1 -5ALIT8 3ESPONSIBILITIES0:

AS A USER:-

.. Transmit needs to supplier.

2. Proide feedbac+ to supplier

%. (btain feedbac+ from supplier

AS A PROCESSOR:-

.. Plan process to meet customers need.

2. Control process to meet customers need.

%. 1mproe process based on customers feedbac+.

AS A SUPPLIER:-

.. Gno$ $ho are customers

2. Inderstand the needs of customers.

%. Aoid creating problems for customers

B. (btain feedbac+ from customers.

#.' TESTIN< P3OCE753E OF THE CO9PONENTS

The components are tested b' the follo$ing procedure4!

./ Appearance

2/ :imensions

%/ Deight

B/ 8itment

=/ 8unction/Performance

-/ 9aterial

7/ P7(C6""

SUSCET, TANGORI 7

1. APPE3ANCE0 :

1t is the first step to chec+ing appearance of the components means ho$ the component loo+s li+e.

Dhether its surface is smooth or notJ Dhether its sharp edges are chamfered or notJ 1n this step

component $elding) surface treatment and machining is also chec+ed.

2. 7I9ENSIONS0 :

1t is the most important step of the 3ualit' testing of the arious components. The dimensioning

means the chec+ing of the dimensions of the component) $hether these are correct or notJ The

dimensioning is done b' certain instruments li+e the K67>167 CA;;1P67) 91C7(96T67)

L6K6; P7(T6CT(7) H61<HT <AI<6) etc. L' these measuring instruments the measurement

of the dimensions of the component become er' eas'. These dimensions are chec+ed $ith respect

to the dimensions gien in the dra$ing i.e. the re3uired dimensions.

#. 4EI<HT0 :

The material of component is also necessar' because it gies idea of the material re3uired for

manufacture the component. The $eight of the component is measured b' $eighing machine. This

machine can measure the $eight from =00gram to =0000gram. There is scale on the measuring

machine) $hich sho$s the reading of the $eight.

$. FIT9ENT0 :

8itment means fitting of the component actuall' in the ehicle. The component is then chec+ed

$hether it fit properl' in the releant position or not. 1f the component is fitted properl' and then

component get accepted other$ise it re#ected. "o the acceptation or re#ection of the component is

also based upon the fitment of the component.

=. F5NCTIONAL PE3FO39ANCE0 :

The functional performance of the component is measured after the fitment of the component.

8unctional performance means ho$ $ell the component is functioning in the ehicle.

-. 9ATE3IAL0 :

SUSCET, TANGORI 8

The material of the component should be able to absorb the stresses produced in that component.

The material ma' be brittle) hard or tensile as per re3uirement. Hardness of the material is generall'

chec+ed b' 7oc+$ell hardness testing machine) poldi hardness tester and shore hardness tester.

7. P3OCESS0 :

1n this step of the 3ualit' control of the components the processes of the components are chec+ed.

8or ma+ing a certain component there are certain processes b' $hich a component should go

through. These processes are made in serial $ise and the component should follo$ these processes

in serial $ise. 1f the processes are serial $ise then component is made eAactl' according to our

re3uirement. These processes can be chec+ed onl' at the production site i.e. $here the component is

manufactured. "o in case of our industr' the processes can onl' be chec+ed on the endor side

$here the component is manufactured. The processes can be drilling) punching) tapering) lathing)

heat treatment) machining etc.

#., -5ALIT8 I9P3O=E9ENT S8STE9S

.. Component dra$ings

2. Process sheet $ith summer' sheet. ,ref. scd process sheets/.

%. 8irst pc. setting o+ record

B. 7un chart filling b' operator M audit b' 3i on run chart.

=. Chec+list on front side M pdi on the bac+side of the sheet.

-. 1n plant re#ection M there defect anal'sis.

7. Periodic inspection and maintenance of tools/gauges M machines.

*. 9aster sample should be aailable for each sheet.

&. 9aterial should be properl' stac+ed in bins .,no material should be on shop floor/

.0. Tools M gauges should be +ept properl' at their embar+ed place.

... Dor+station should be according to la'out plan.

.2. 9aterial should be transported tin bins.

.%. The responsibilit' of implementing and maintaining the arious records should be clearl'

defined and the name of the person to be intimated to acs and bu'.

.B. "ubmission of self!appraisal form.

SUSCET, TANGORI 9

#.. HA374A3E SECTION

Hard$are is one of the main sections of the 1ncoming 0ualit' Control :epartment. All the hard$are

items $hich are used in the tractor assembl' are chec+ed thoroughl' in this section of 10C

department. There are more than &00 different components $hich are chec+ed on regular basis) for

this purpose 0ualit' 1nspectors are proided $ith the entire measuring 1nstrument re3uired b' them.

8or the conenience these components are further categorized under different groups .>ame of such

groups is as follo$s4!

.. WASHERS:- There are &- t'pes of different DA"H67" $hich are chec+ed under this group.

All these are used in different tractor assemblies.

2. SHIMS: - There are 7= t'pes of different "H19" $hich are chec+ed under this group. All

these are used in different tractor assemblies

%. BOLTS & SCREWS: - There are -0 t'pes of different L(;T" M "C76D" $hich are

chec+ed under this group. All these are used in different tractor assemblies

B. RUBBER ITEMS: - There are *0 t'pes of different 7ILL67 1T69" $hich are chec+ed

under this group. All these are used in different tractor assemblies.

=. SPRINGS: - There are =0 t'pes of different "P71><" $hich are chec+ed under this group.

All these are used in different tractor assemblies.

-. DELIVERY & FUEL PIPES: - There are =B t'pes of different :6;1K67N M 8I6; P1P6"

$hich are chec+ed under this group. All these are used in different tractor assemblies.

7. SUCTION PIPES: - There are =B t'pes of different "ICT1(> P1P6" $hich are chec+ed

under this group. All these are used in different tractor assemblies.

*. KNOBS: - There are 2. t'pes of different G>(L" $hich are chec+ed under this group. All

these are used in different tractor assemblies.

&. PLUGS: - There are 2. t'pes of different P;I<" $hich are chec+ed under this group. All

these are used in different tractor assemblies.

.0. O-RINGS &SEALING RINGS: - There are 20t'pes of different (!71><" M"6A;1><

71><" $hich are chec+ed under this group. All these are used in different tractor

assemblies.

... CLAMPS: - There are 2% t'pes of different C;A9P" $hich are chec+ed under this group.

All these are used in different tractor assemblies.

.2. HOSE PIPES: - There are .* t'pes of different H("6 P1P6" $hich are chec+ed under this

group. All these are used in different tractor assemblies.

SUSCET, TANGORI 10

.%. DUST CAP PTO COVER: - There are20 t'pes of different :I"T CAP PT( C(K67 $hich

are chec+ed under this group. All these are used in different tractor assemblies.

.B. BUSHES: - There are=* t'pes of different LI"H6" $hich are chec+ed under this group. All

these are used in different tractor assemblies.

.=. WIRE & CABLES: - There are 2% t'pes of different D176 M CAL;6" $hich are chec+ed

under this group. All these are used in different tractor assemblies.

.-. PINS: - There are .20t'pes of different P1>" DA"H67" $hich are chec+ed under this

group. All these are used in different tractor assemblies.

.7. NUTS: - There are .B t'pes of different >IT" $hich are chec+ed under this group. All these

are used in different tractor assemblies.

.*. ADOPTERS: - There are .% t'pes of different A:(PT67" $hich are chec+ed under this

group. All these are used in different tractor assemblies.

.&. SPACERS: - There are -= t'pes of different "PAC67" $hich are chec+ed under this group.

All these are used in different tractor assemblies.

20. GASKETS: - There are -- t'pes of different <A"G6T" $hich are chec+ed under this group.

All these are used in different tractor assemblies.

2.. FUEL CUT OFF RODS: - There are - t'pes of different 8I6; CIT (88 7(: $hich are

chec+ed under this group. All these are used in different tractor assemblies.

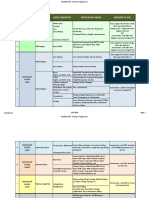

Tab&e #.10 List o instru"ents used into I-C de%art"ent

S.NO. NA9E OF INST359ENT 3AN<E 9A>E -T8.

. K67>167 CA;;1P67 0 ! -00mm 91TIT(N( .

2 K67>167 CA;;1P67 0 ! %00mm 91TIT(N( 2

% K67>167 CA;;1P67 0 ! .=0mm 91TIT(N( .

B :1A; 1>:1CAT(7 0 ! ..mm 91TIT(N( %

= :1A; 1>:1CAT(7 ! 91TIT(N( .

- 91C7(96T67 0 ! 2=mm 91TIT(N( .

7 91C7(96T67 2= ! =0mm 91TIT(N( .

* 91C7(96T67 =0 ! 7=mm 91TIT(N( .

& 91C7(96T67 7= ! .00mm 91TIT(N( .

.0 91C7(96T67 .00 ! .2=mm 91TIT(N( .

.. 91C7(96T67 .2= ! .=0mm 91TIT(N( .

SUSCET, TANGORI 11

.2 91C7(96T67 .=0 ! .7=mm 91TIT(N( .

.% 8;A><6 91C7(96T67 0 ! 2=mm 91TIT(N( .

.B 8;A><6 91C7(96T67 2= ! =0mm 91TIT(N( .

.= 8;A><6 91C7(96T67 =0 ! 7=mm 91TIT(N( .

.- 8;A><6 91C7(96T67 7= ! .00mm 91TIT(N( .

.7 8;A><6 91C7(96T67 .00 ! .2=mm 91TIT(N( .

.* 8;A><6 91C7(96T67 .2= ! .=0mm 91TIT(N( .

.& ";1P <AI<6 L(O *%PC. P6C(CG .

20 7A:1I" <AI<6 . ! 7mm 91TIT(N( .

2. 7A:1I" <AI<6 7.= ! .=mm 91TIT(N( .

22 7A:1I" <AI<6 .= ! 2=mm 91TIT(N( .

2% 866;67 <AI<6 0.0= ! ..00 ATI; .

2B H61<HT <AI<6,:1<1TA;/ 0 ! -00 91TIT(N( .

2=

7(CGD6;; HA7:>6"

T6"T67 ! 81>6 .

2-

"H(76 HA7:>6""

T6"T67 0 ! .00 91TIT(N( .

27 :1A; L(76 <AI<6 .0 ! .*.= 91TIT(N( .

2* :1A; L(76 <AI<6 .* ! %= 91TIT(N( .

2& :1A; L(76 <AI<6 %= ! -0 91TIT(N( .

%0 :1A; L(76 <AI<6 =0 ! .=0 91TIT(N( .

%. 96<>6T1C "TA>: ! ! .

%2 91C7(96T67 "TA>: 9" ! . ! .

%% 9A<>6T1C K ! L;(CG .02O&-O72 "A97T .

%B 9A<>6T1C K ! L;(CG .=2O&*O7B "A97T .

%= TH76A: P1TCH <AI<6 L.".D. 91TIT(N( .

%- "P6C1A; :6A: C6>T76 !

LHA;

6><<. .

%7 "C76D HACG ,L1</ ! ! B

%* "C76D HACG ,"9A;;/ ! ! B

%& L6: C6>T76 .000O2-0 ;ITH7A .

SUSCET, TANGORI 12

B0

"I78AC6 P;AT6

,<7A>1T6/ .000O.000 ;ITH7A .

B. CN;1>:71CA; P1>" P %.. ! =

B2 CN;1>:71CA; P1>" P %.2 ! =

B% CN;1>:71CA; P1>" P B.= ! =

BB CN;1>:71CA; P1>" P =.00 ! =

B= CN;1>:71CA; P1>" P =.=0 ! =

B- CN;1>:71CA; P1>" P -.00 ! =

B7 CN;1>:71CA; P1>" P 7.00 ! =

B* CN;1>:71CA; P1>" P *.00 ! .

B& CN;1>:71CA; P1>" P *..0 ! =

=0 TH76A: 71>< <AI<6 92BO..= H1P .

=. TH76A: 71>< <AI<6 922O..= H1P .

=2 TH76A: 71>< <AI<6 920O..= H1P .

=% TH76A: 71>< <AI<6 9.*O..= H1P .

=B TH76A: 71>< <AI<6 9.-O..= H1P .

== TH76A: 71>< <AI<6 9.-O2 H1P .

=- TH76A: 71>< <AI<6 9.BO..= H1P .

=7 TH76A: 71>< <AI<6 9.2O..7= H1P .

=* TH76A: 71>< <AI<6 9.0O..= H1P .

=& TH76A: 71>< <AI<6 9*O..2= H1P .

-0 TH76A: 71>< <AI<6 9*O. H1P .

-. TH76A: 71>< <AI<6 9-O. H1P .

-2 TH76A: P;I< <AI<6 92BO..= H1P .

-% TH76A: P;I< <AI<6 922O..= H1P .

-B TH76A: P;I< <AI<6 920O..= H1P .

-= TH76A: P;I< <AI<6 9.*O..= H1P .

-- TH76A: P;I< <AI<6 9.-O..= H1P .

-7 TH76A: P;I< <AI<6 9.-O2 H1P .

-* TH76A: P;I< <AI<6 9.BO..= H1P .

SUSCET, TANGORI 13

-& TH76A: P;I< <AI<6 9.2O..7= H1P .

70 TH76A: P;I< <AI<6 9.0O..= H1P .

7. TH76A: P;I< <AI<6 9*O..2= H1P .

72 TH76A: P;I< <AI<6 9*O. H1P .

7% TH76A: P;I< <AI<6 9-O. H1P .

7B CA;CI;T(7 "C16>T181C ! CA"1( .

7= <6A7 P7(81;6 T6AT67 91TIT(N

(

.

Ai"0 ! 9a+ing hardness chart of arious parts of tractor $hich are generall' undergoing to chec+ in

3ualit' control for hardness purposes.

3e+uire"ent o Hardness C!art0:

.. 1f an' component $hich is come under line re#ection in 3ualit' control for mainl' hardness

then there is no need to open the control plan of that components) simpl' see the hardness of

that component from hardness chart and chec+ it again $ith suitable instrument.

2. 1t is eas' to locate the component control plan from the file b' note the component part no.

from the hardness chart.

%. 1t is beneficial for trainee students and for trainee engineers that the' not +no$ hardness of

arious components of tractors.

Contro& P&ans used or "a)ing Hardness c!art0

.. 7ear Coer

2. 8ront AAle

%. :ifferential

B. <ear and "hafts

=. <ear LoA

-. Hard$are

Tab&e #.20 HA37NESS CHA3T o CO9PONENTS

3EA3 CO=E3

SUSCET, TANGORI 14

S.NO. PA3T NO. 7ESC3IPTION HA37NESS

. B0.00B P("1T1(> ACTIAT(7 A""N. =*!-%H7C

2 B0.007 P("1T1(> ;1>G A""N. %0!%=H7C

% B0.0.0 :7A8T ;1>G A""N. %=!B0H7C

B B0.0.. "6>"(7 ;6K67 H1><6 P1> 2=!%0H7C

= B0.0.% "6>"(7 ,;!B2/ B0!B=H7C

- B0.0.7 "6>"(7 7(: %0!%-H7C

7 B0.020 P1> 7(CG67 ;1>G 2=!%0H7C

* B0200* C(>>6CT1>< 7(: B0!B=H7C

& B020.0 ;18T A79 A""N. =*!-2H7C

.0 B0=00& P("1T1(> C7A>G A""N. 20!2BH7C

.. B0=0.- 76TA1>1>< P1> ,L1</ 20!2=H7C

.2 B0%007 76"P(>6 KA;K6 2=!%0H7C

.% B020.* ;1>6A7 =0!-0H7C

.B .0B00= ;1>G P1> 2=!%0H7C

.= B0%00- LA;; "H66T =0!-0H7C

.- .0B00- ;1>CH P1> 2=!%0H7C

.7 B0%002 P;I< 20!2=H7C

.* .0B00B P1> 2=!%0H7C

.& B0.02% P1> 2=!%0H7C

20 B0.0.0- "D1K6; P1> 2=!%0H7C

2. B0202. 1>"67T B0!B=H7C

22 B020.- 7(CG "HA8T =0!==H7C

2% B0=02% :7A8T ;6K67 A""N. %=!B0H7C

2B B0=0.% P("1T1(> ;6K67 A""N. %=!B0H7C

2= B0=007 :78T C7A>G A""N. 20!B0H7C

7IFFE3ENTIAL

S.NO. PA3T NO. 7ESC3IPTION HA37NESS

. P0.0%00= P.T.(. C(K67 P;AT6 , ; / .*0!2%0LH>

2 P0B0-00. P.T.(. C(K67 P;AT6 , 7 / .*0!2%0LH>

% B0.0.& 7(CG67 ;1>G A""N. B0!B=H7C

B B0702% :7AD LA7 2=!%0H7C

= 90*0=007 D1TH:7AD; >IT ,P1>1(>B2O..=/ 2=!%0H7C

- %0.00= P;AT6 A""N. , ; / 2=!2*H7C

7 %0.00- P;AT6 A""N. , 7 / 2=!2*H7C

* B0702= ;(D67 ;1>G L7ACG6T , ; / 2=!%0H7C

& B0702- ;(D67 ;1>G L7ACG6T , 7 / 2=!%0H7C

F3ONT A?LE

S.NO

. PA3T NO. 7EC3IPTION HA37NESS

SUSCET, TANGORI 15

. =020.% "T6671>< A79 , ; / 2.0!2B0LH>

2 =0200& "T6671>< A79 , 7 / 2.0!2B0LH>

% =02007 HIL CAP .%0!.*0LH>

B =0.02. :(D6; ;66K6 20!2=LH>

= =0200* (!71>< H(;:67 20!2=LH>

- =0.00% P1> , T(6 H((G / %=!B2LH>

7 =02002 D6A7 71>< , "TIL AO;6 / B=!=0LH>

* =020.= G1>< P1> B=!=0H7C

& =0.0.0 P1K(T P1> 2=!%=H7C

ACHIE=E9ENTS TILL 7ATE0

.. Hardness Charts of 7ear Coer) 8ront AAle and the :ifferential has been prepared.

3E9AININ< 4O3>

.. Hardness charts of <ear and "hafts) <ear LoA are remaining.

P3O;ECT 2

#.1.1 OB;ECTI=E0 : To implement po$er steering on the tractor to ma+e the steering simpler and

easier.

#.1.2 3E-5I3E9ENT OF THIS P3O;ECT

;arger amount of tor3ue is re3uired to be applied b' the drier for steering of medium and hea'

ehicles

Hea' ehicles such as (ff!road truc+s) for+ lifts) earth moing machines) and tractors demands

high steering forces.

SUSCET, TANGORI 16

9echanical lin+age bet$een the steering $heel and the steered $heels $ould be more difficult

and eApensie in compact design ehicles.

#.1.# APPLICATIONS

Agriculture

Construction

8or+lift truc+s

;a$n and garden

9ini tractors

9unicipal ehicles

#.1.$. SCHE75LE0 STEP 10 9a+ing a la'out of h'drostatic po$er steering.

STEP 20 "izing the correct steering s'stem.

,A/ Calculating the total steering tor3ue.

,L/ Calculating the force re3uired for aAle.

,C/ "electing the steering unit displacement.

,:/ Calculating the re3uired pump flo$.

STEP #0 Troubleshooting the steering column.

#.1.' LA8O5T OF

PO4E3 STEE3IN<

SUSCET, TANGORI 17

STEP 1. TOTAL STEERING TORQUE:-

Total steering torque, T = C.f (B

2

/8 + E

2

) kgmm

Were C = !oa" on te steere" a#le (in kgmm)

E = $ing %in offset (in mm)

B = T&re 'rea"t (in mm)

!()* (+ T,E -TEE.E* )/!E,

C = 0121 (!()* (+ 3.(+T -TEE.4+5)

+2111 (!oa" of te loa"er)

SUSCET, TANGORI 18

C = 3030 kg

E/B = 61/071 = .206

(W,E.E B=071,E=61)

F = 0.4 (from a'o8e gra% )

Were f = 9oeffi9ient of fri9tion("imensionless).Base" on 1.:

)s ma#imum.

T = 2121/1.; (071)

2

/8+(61)

2

kgmm

= 2121/1.;/71.1: kgmm

T = 109164.13 kgmm

#.1., CO9PONENTS OF PO4E3 STEE3IN<

STEE3IN< 4HEEL4 ! its diameter is %=0mm Q.B inch.R) % spo+e steering $heel $ith +nob

standard and optional horn button.

SUSCET, TANGORI 19

8igure ...4 "teering Dheel

#.1.. STEE3IN< COL59N

"teering columns connect the steering $heel to the steering unit.

The steering column must be supported $hen its length eAceeds .=0 mm.

The mounting of the steering column

must be properl' aligned so that the

steering unit can return to neutral

position automaticall' after a steering

action has been completed.

The construction of the steering column

must ensure that no aAial or radial forces

are transferred to the steering unit input

shaft.

8igure4 ..24 "teering Column

SUSCET, TANGORI 20

#.1.1 STEE3IN< 5NIT

8igure ..%4 "teering Init

a/ 1t has four ports) one is connected to tan+ or reseroir) one is connected to pump) and

remaining t$o is connected to steering c'linder.

b/ 1t controls the flo$ of oil in different ports.

c/ 1t is rigidl' fiAed $ith steering column.

#.1.2 ACHIE=E9ENTS TILL 7ATE0

.. "tep . of the pro#ect is complete.

2. "tep 2 of the pro#ect is complete.

#.1.16 3E9AININ< 4O3>

.. "tep 2 ,L/) ,C/ and ,:/ are incomplete.

2. "tep % is incomplete.

%. Conclusion

$. 3EFE3ENCES

SUSCET, TANGORI 21

.. 1nformation Lrochure of the compan'.

2. (fficial Debsites of the compan'

a) $$$.preetagro.com

b) $$$.preetcombines.com

c/ $$$.preettractors.com

SUSCET, TANGORI 22

Вам также может понравиться

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryОт EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryРейтинг: 3.5 из 5 звезд3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)От EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Рейтинг: 4.5 из 5 звезд4.5/5 (120)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaОт EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaРейтинг: 4.5 из 5 звезд4.5/5 (266)

- The Little Book of Hygge: Danish Secrets to Happy LivingОт EverandThe Little Book of Hygge: Danish Secrets to Happy LivingРейтинг: 3.5 из 5 звезд3.5/5 (399)

- Never Split the Difference: Negotiating As If Your Life Depended On ItОт EverandNever Split the Difference: Negotiating As If Your Life Depended On ItРейтинг: 4.5 из 5 звезд4.5/5 (838)

- The Emperor of All Maladies: A Biography of CancerОт EverandThe Emperor of All Maladies: A Biography of CancerРейтинг: 4.5 из 5 звезд4.5/5 (271)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeОт EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeРейтинг: 4 из 5 звезд4/5 (5794)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyОт EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyРейтинг: 3.5 из 5 звезд3.5/5 (2259)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersОт EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersРейтинг: 4.5 из 5 звезд4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnОт EverandTeam of Rivals: The Political Genius of Abraham LincolnРейтинг: 4.5 из 5 звезд4.5/5 (234)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreОт EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreРейтинг: 4 из 5 звезд4/5 (1090)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceОт EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceРейтинг: 4 из 5 звезд4/5 (895)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureОт EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureРейтинг: 4.5 из 5 звезд4.5/5 (474)

- The Unwinding: An Inner History of the New AmericaОт EverandThe Unwinding: An Inner History of the New AmericaРейтинг: 4 из 5 звезд4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)От EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Рейтинг: 4 из 5 звезд4/5 (98)

- Coordinate Geometry Loney SLДокумент452 страницыCoordinate Geometry Loney SLDivyaGoel175% (52)

- Recovery in TrainingДокумент7 страницRecovery in TrainingAnonymous 92hWDcОценок пока нет

- DiffusionДокумент25 страницDiffusionbonginkosi mathunjwa0% (1)

- Chemical BondingДокумент58 страницChemical BondingJagjot SinghОценок пока нет

- Estimation and Costing Textbook by BN Dutta PDFДокумент156 страницEstimation and Costing Textbook by BN Dutta PDFJagjot SinghОценок пока нет

- Digital Clock ReportДокумент12 страницDigital Clock ReportJagjot SinghОценок пока нет

- Fuels Engineering ChemistryДокумент67 страницFuels Engineering ChemistryJagjot SinghОценок пока нет

- 2012 EngДокумент2 страницы2012 EngWalid Mohammad MukuОценок пока нет

- The Future Is NanoДокумент22 страницыThe Future Is NanoJagjot SinghОценок пока нет

- Monument Autocad GateДокумент1 страницаMonument Autocad GateJagjot SinghОценок пока нет

- William ShakespeareДокумент13 страницWilliam ShakespeareJagjot SinghОценок пока нет

- Gud LyfДокумент2 страницыGud LyfNitin PandeyОценок пока нет

- Sikhitothemax User Guide New FeaturesДокумент2 страницыSikhitothemax User Guide New FeaturesJagjot SinghОценок пока нет

- 12th STD FormulaДокумент64 страницы12th STD Formulagowsikh92% (25)

- Gud LyfДокумент2 страницыGud LyfNitin PandeyОценок пока нет

- Dispersion and SpectraДокумент3 страницыDispersion and SpectraDhruv KlerОценок пока нет

- 12th STD FormulaДокумент64 страницы12th STD Formulagowsikh92% (25)

- "Gurbaniakhar" Key Map For Ms Windows: Ansi NumbersДокумент1 страница"Gurbaniakhar" Key Map For Ms Windows: Ansi NumbersJagjot SinghОценок пока нет

- HC Verma SolutionДокумент1 страницаHC Verma SolutionArnavADОценок пока нет

- 22.solutions To ConceptsДокумент2 страницы22.solutions To ConceptsডৰাজবংশীОценок пока нет

- Chapter 19 Optical InstrumentsДокумент7 страницChapter 19 Optical Instrumentsabbh07Оценок пока нет

- Solutions To Concepts: Chapter - 1Документ4 страницыSolutions To Concepts: Chapter - 1Jayanth VgОценок пока нет

- SM Electrical Guidelines: General Notes:: Site HereДокумент1 страницаSM Electrical Guidelines: General Notes:: Site HereNathaniel DreuОценок пока нет

- Ship Captain's Medical Guide - 22nd EdДокумент224 страницыShip Captain's Medical Guide - 22nd EdcelmailenesОценок пока нет

- Sacrament ChartДокумент3 страницыSacrament ChartXam PerezОценок пока нет

- 8DJ - 8DH Katalog en PDFДокумент32 страницы8DJ - 8DH Katalog en PDFJosue Espinoza YachachinОценок пока нет

- 1stweek Intro Quanti Vs QualiДокумент18 страниц1stweek Intro Quanti Vs QualiHael LeighОценок пока нет

- Instructions For UseДокумент14 страницInstructions For UseEddie UnivoОценок пока нет

- Pediatric Medication Dosing GuildelinesДокумент2 страницыPediatric Medication Dosing GuildelinesMuhammad ZeeshanОценок пока нет

- Physical Fitness TestДокумент1 страницаPhysical Fitness TestGiessen Fran RamosОценок пока нет

- Radfet DatasheetДокумент6 страницRadfet DatasheetNicholas EspinozaОценок пока нет

- Dna Recombinant TechnologyДокумент20 страницDna Recombinant TechnologyJuliet Ileto Villaruel - AlmonacidОценок пока нет

- Doka H20 BeamДокумент20 страницDoka H20 Beamshoaib100% (1)

- WAUZZZ8K0BA159120Документ10 страницWAUZZZ8K0BA159120Vedad VedaddОценок пока нет

- Narrative Report On Conduct of Classes-October 2021Документ1 страницаNarrative Report On Conduct of Classes-October 2021Jansen Roy D. JaraboОценок пока нет

- Electrical Rooms Fire FightingДокумент2 страницыElectrical Rooms Fire Fightingashraf saidОценок пока нет

- Fishing Broken Wire: WCP Slickline Europe Learning Centre SchlumbergerДокумент23 страницыFishing Broken Wire: WCP Slickline Europe Learning Centre SchlumbergerAli AliОценок пока нет

- NANOGUARD - Products and ApplicationsДокумент2 страницыNANOGUARD - Products and ApplicationsSunrise VenturesОценок пока нет

- Carapace DigitalДокумент15 страницCarapace DigitalVillain ChatОценок пока нет

- Dowry SystemДокумент10 страницDowry SystemBhoomejaa SKОценок пока нет

- 2457-Article Text-14907-2-10-20120724Документ6 страниц2457-Article Text-14907-2-10-20120724desi meleniaОценок пока нет

- Asking and Showing Rooms in Hospital2Документ17 страницAsking and Showing Rooms in Hospital2Roland DelОценок пока нет

- Review Related LiteratureДокумент3 страницыReview Related LiteratureHanz EspirituОценок пока нет

- Serbia Malta & Bermuda Medical Instructions PDFДокумент3 страницыSerbia Malta & Bermuda Medical Instructions PDFGISI KeyBOarD0% (1)

- What Is Nursing?: What Exactly Do Nurses Do?Документ3 страницыWhat Is Nursing?: What Exactly Do Nurses Do?mabel yapuraОценок пока нет

- Exercise 3 ASC0304 - 2019-1Документ2 страницыExercise 3 ASC0304 - 2019-1Nuraina NabihahОценок пока нет

- TQM Assignment 3Документ8 страницTQM Assignment 3ehte19797177Оценок пока нет

- Yume Beauty Price ListДокумент1 страницаYume Beauty Price ListjessicaelaОценок пока нет

- Pia AlgebraДокумент12 страницPia AlgebraCarvajal EdithОценок пока нет

- UAW-FCA Hourly Contract SummaryДокумент20 страницUAW-FCA Hourly Contract SummaryClickon DetroitОценок пока нет