Академический Документы

Профессиональный Документы

Культура Документы

CDEtbe Technology Profile

Загружено:

dharmayogaАвторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

CDEtbe Technology Profile

Загружено:

dharmayogaАвторское право:

Доступные форматы

Ca t a l y t i c

Di s t i l l a t i on

Te c hnol ogi e s

ETBE From Steam Cracker and Dehydro C

4

Feeds

T e c h n o l o g y P r o f i l e

Overvi ew The CDEtbe catalytic

distillation technology processes C

4

streams from steam cracker and isobu-

tane dehydrogenation units to produce

ETBE. CDEtbe is one of a family of

process technologies developed and

commercialized by Catalytic Distillation

Technologies (CDTECH) for license to

the petroleum refining and petrochemi-

cal industries. CDTECH is a partnership

between ABB Lummus Crest Inc. and

Chemical Research & Licensing, a Nova

Company.

ETBE Synthesis ETBE is formed by the catalytic etherification of isobutylene with

ethanol. The patented CDEtbe process is based on a two-step reactor design, consisting

of a boiling point fixed bed reactor followed by final conversion in a catalytic distillation

column. The process utilizes an acidic ion exchange resin catalyst in both its fixed bed

reactor and proprietary catalytic distillation structures.

The boiling point reactor is designed so that the liquid is allowed to reach its boiling

point by absorbing the heat of reaction, after which a limited amount of vaporization

takes place thereby maintaining precise temperature control. The amount of vaporization

is fixed by recycling cooled reactor effluent. The maximum temperature is adjusted by

setting the total system pressure. Since the reacting liquid mixture temperature cannot

exceed the boiling temperature, control is far superior to those systems in which heat

must be transferred by convection or conduction. This design retains the heat of reaction

as latent heat, reducing heat input requirements for the ensuing fractionation. Reactor

effluent is cooled by condensation rather than by convection, resulting in the use of smaller-

sized equipment.

The unique catalytic distillation column combines reaction and fractionation in a single

unit operation. It allows a high conversion of isobutylene (exceeding fixed bed equilib-

rium limitations) to be achieved simply and economically. By using distillation to separate

the product from the reactants, the equilibrium limitation is exceeded and higher conver-

sion of isobutylene is achieved. Catalytic distillation also takes advantage of the improved

kinetics through increased temperature without penalizing equilibrium conversion.

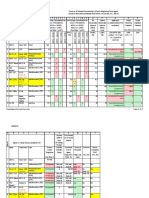

CDEtbe Process Flow Diagram

Boiling Point Catalytic Ethanol Ethanol

Reactor Distillation Extraction Recovery

Fresh Ethanol

Recycle Ethanol

Water

Mixed C4s

Ethanol

and C4s

ETBE

C4 Raffinate

Typical Overall Material Balance Isobutylene conversion percent: 95+

Feeds LB/HR

C

4

s (Isobutylene 27.0 wt. %) 20,900

Ethanol (95 vol %) 4,700

Products

C

4

Raffinate 15,400

ETBE product 10,200

ETBE Product Composition (excluding C

5

+)

Wt.%

C

4

s <0.1

Ethanol <1.0

Di-isobutylene 0.5

TBA 0.4

DEE 0.2

ETBE 97.8

Total 100.0

Ca t a l y t i c

Di s t i l l a t i on

Te c hnol ogi e s

Process Chemistry

C

2

H

5

OH CH

3

COC

2

H

5

CH

3

C

=

CH

2

CH

3

Isobutylene Ethanol ETBE

CH

3

CH

3

Advantages

CDTECHs Boiling Point

reactor offers:

Simple and effective control

Elimination of hot spots

Long catalyst life

High flexibility

Low capital cost

Elimination of catalyst attrition

Most effective heat removal technique

CDTECHs catalytic

distillation offers:

Improved kinetics

High conversion

(beyond fixed bed equilibrium limit)

Low capital cost

Low utilities

Long catalyst life with

sustained high conversion

Reduced plot area

CDEtbe process offers:

Low ethanol content in ETBE product

without additional processing

Etherification

ETBE From Steam Cracker

and Dehydro C

4

Feeds

CDTECH

3010 Briarpark Drive

Houston, TX 77042 USA

Tel: 713-821-4734

Fax: 713-821-3587

Вам также может понравиться

- CDMTBE Tech Profile Flysheet Rev1Документ2 страницыCDMTBE Tech Profile Flysheet Rev1Đức Long TrầnОценок пока нет

- D27/D36 Marine Diesel Engines Technical SpecificationsДокумент4 страницыD27/D36 Marine Diesel Engines Technical SpecificationsMermaid TanajibОценок пока нет

- Distillation Curve of Fuel SamplesДокумент4 страницыDistillation Curve of Fuel SamplesRais Alfiansyah TaufiqОценок пока нет

- Unit IV - Air Compressors: Classification and Working of Reciprocating CompressorsДокумент10 страницUnit IV - Air Compressors: Classification and Working of Reciprocating CompressorsKONDERU RAJKUMARОценок пока нет

- Questions Bank Summary Crude Oil Pumping StationsДокумент31 страницаQuestions Bank Summary Crude Oil Pumping StationsAkol AganyОценок пока нет

- AUTOMДокумент9 страницAUTOMMadhavi VaidОценок пока нет

- Performance Analysis of Reciprocating Refrigerant CompressorДокумент6 страницPerformance Analysis of Reciprocating Refrigerant CompressorIjsrnet EditorialОценок пока нет

- Hydrotreating: P A R T 8Документ24 страницыHydrotreating: P A R T 8Bharavi K SОценок пока нет

- Full Cream Milk Powder SDS enДокумент6 страницFull Cream Milk Powder SDS enNguyễn Thị Diễm MiОценок пока нет

- Divinylbenzene Storage, Handling and SafetyДокумент19 страницDivinylbenzene Storage, Handling and SafetyMehul DeshpandeОценок пока нет

- Compatibility With Plastics and Elastomers: TitleДокумент2 страницыCompatibility With Plastics and Elastomers: TitleashrafОценок пока нет

- M.F. Menoufy, H.S. Ahmed, M.A. Betiha, M.A. Sayed: Highlights GraphicalДокумент5 страницM.F. Menoufy, H.S. Ahmed, M.A. Betiha, M.A. Sayed: Highlights GraphicalTya ArisandiОценок пока нет

- Main Engine Starting ProcedureДокумент5 страницMain Engine Starting ProcedureAbishek AbiОценок пока нет

- Autoclave Test SystemsДокумент7 страницAutoclave Test SystemsKen's CornerОценок пока нет

- Distillation Exp.Документ5 страницDistillation Exp.Ibrahim DewaliОценок пока нет

- Sample: Please Do Not Write On TestДокумент9 страницSample: Please Do Not Write On TestPrimelift Safety Resources Limited0% (1)

- Resolving Process Distillation Equipment OpportunitiesДокумент13 страницResolving Process Distillation Equipment Opportunitiesrvkumar61Оценок пока нет

- Training Report HeritageДокумент65 страницTraining Report HeritageSurya Kanta SenОценок пока нет

- Quiz Mohd Rafiq Mohd ZubirДокумент11 страницQuiz Mohd Rafiq Mohd ZubirMohd RafiqОценок пока нет

- Boiler Operator Need To Know TermsДокумент2 страницыBoiler Operator Need To Know TermsRafaqat Ali100% (1)

- Transportation: EGEE 102 - Energy Conservation and Environmental ProtectionДокумент45 страницTransportation: EGEE 102 - Energy Conservation and Environmental ProtectionTanweer SalahОценок пока нет

- JamnagarДокумент4 страницыJamnagarkatariamanojОценок пока нет

- DCB31 Eng.Документ15 страницDCB31 Eng.Aimad ChamsaouiОценок пока нет

- STCW Standards for Engine Room Watch KeepingДокумент6 страницSTCW Standards for Engine Room Watch KeepingJoresol AlorroОценок пока нет

- Synthesis of Biomass-Derived Gasoline Fuel Oxygenates by Microwave IrradiationДокумент18 страницSynthesis of Biomass-Derived Gasoline Fuel Oxygenates by Microwave IrradiationDevesh Pratap ChandОценок пока нет

- EnnnДокумент9 страницEnnnSajid AliОценок пока нет

- DR For Methyl AcetateДокумент12 страницDR For Methyl AcetateProbablyсвдсОценок пока нет

- 04pa Je 2 2 PDFДокумент7 страниц04pa Je 2 2 PDFMarcelo Varejão CasarinОценок пока нет

- MTBE Unit Expansion-ConversionДокумент13 страницMTBE Unit Expansion-Conversiontunganh1110100% (1)

- Acetylene Reactor PerformanceДокумент19 страницAcetylene Reactor Performancevenkateshs_g5420Оценок пока нет

- Petrochemical ProcessДокумент20 страницPetrochemical Processsanjeevs01Оценок пока нет

- Petroleum Technology: Presented By: Mohd Tauqeer Alam CSJMA14001390208 Chemical Engineering. B. Tech. (Final Year)Документ27 страницPetroleum Technology: Presented By: Mohd Tauqeer Alam CSJMA14001390208 Chemical Engineering. B. Tech. (Final Year)PAUL KingatОценок пока нет

- Hydrodealkylation 12Документ2 страницыHydrodealkylation 12khanh11h100% (1)

- Crude Oil Processing and Production of Hydrocarbon IntermediatesДокумент20 страницCrude Oil Processing and Production of Hydrocarbon Intermediatessanjeevs01Оценок пока нет

- Hydrocarbon Processing Refining Processing 2004Документ293 страницыHydrocarbon Processing Refining Processing 2004Anonymous I29NP3c100% (1)

- Catalytic Reforming: 2011 Refining Processes HandbookДокумент3 страницыCatalytic Reforming: 2011 Refining Processes HandbookGaspar BlaserОценок пока нет

- Mini Project StyereneДокумент25 страницMini Project StyereneMard Apik100% (1)

- MANUFACTURING TOLUENE PROCESSESДокумент4 страницыMANUFACTURING TOLUENE PROCESSESMiko Yee Teng100% (1)

- Lecture 6 Catalytic Reforming ProcessДокумент18 страницLecture 6 Catalytic Reforming ProcessGAMERS OF KUWAITОценок пока нет

- UZ Petroleum Engineering Catalytic CrackingДокумент9 страницUZ Petroleum Engineering Catalytic CrackingSaMiHRОценок пока нет

- Chapter 4Документ26 страницChapter 4indumathijayakaranОценок пока нет

- Self-heat Recuperation Cuts Bioethanol Distillation Energy by 80Документ6 страницSelf-heat Recuperation Cuts Bioethanol Distillation Energy by 80hmossОценок пока нет

- Che MaturДокумент4 страницыChe MaturTralalaОценок пока нет

- Chapter 2 Oil Refinery Plant - Conversion and TreatmentДокумент52 страницыChapter 2 Oil Refinery Plant - Conversion and Treatmenthafizulhakim02Оценок пока нет

- Petroleum Refining ProcessДокумент26 страницPetroleum Refining Processdana mohammedОценок пока нет

- Recycle Structure and Design Decisions for Flowsheet SynthesisДокумент19 страницRecycle Structure and Design Decisions for Flowsheet SynthesisSanyog GhoshОценок пока нет

- Uop Catalytic Dewaxing Process: Hemant GalaДокумент6 страницUop Catalytic Dewaxing Process: Hemant GalaBharavi K SОценок пока нет

- Isobutylene by MTBE Decomposition-CD TECHДокумент2 страницыIsobutylene by MTBE Decomposition-CD TECHDrVedprakash Mishra100% (1)

- Synthesis and Distillation1Документ31 страницаSynthesis and Distillation1AgathiyanОценок пока нет

- Isomerization TechniqueДокумент14 страницIsomerization TechniqueharisОценок пока нет

- Steam ReformingДокумент5 страницSteam ReformingAshok S. PathakОценок пока нет

- Alkylation and Polymerization ProcessДокумент61 страницаAlkylation and Polymerization ProcessWan Afiff100% (2)

- RFCC Process Characteristics and Numerical StudiesДокумент3 страницыRFCC Process Characteristics and Numerical StudiesMinh Tuấn PhạmОценок пока нет

- CrackingДокумент20 страницCrackingNiaz Ali KhanОценок пока нет

- FCC - LummusДокумент2 страницыFCC - LummusIam BallОценок пока нет

- Inf Ufc 85Документ13 страницInf Ufc 85Luciano Montellano Abasto100% (2)

- Jan May 2017 - CH4250 - Group18 - Final Project ReportДокумент184 страницыJan May 2017 - CH4250 - Group18 - Final Project ReportPalak SinghОценок пока нет

- Separation ChainДокумент2 страницыSeparation ChainKaleem UllahОценок пока нет

- Fluid Catalytic Craking Unit (Fccu)Документ6 страницFluid Catalytic Craking Unit (Fccu)Nitin VarshneyОценок пока нет

- Refinery TerminologyДокумент46 страницRefinery TerminologyGunturXie100% (1)

- 5S Lean Manufacturing Work Station Design in Silver Line PDFДокумент20 страниц5S Lean Manufacturing Work Station Design in Silver Line PDFdharmayogaОценок пока нет

- Neuralnet PDFДокумент13 страницNeuralnet PDFdharmayogaОценок пока нет

- Production System Design and Evaluation For Increased System RobustnessДокумент30 страницProduction System Design and Evaluation For Increased System RobustnessdharmayogaОценок пока нет

- CDEtbe Technology ProfileДокумент2 страницыCDEtbe Technology ProfiledharmayogaОценок пока нет

- Design For System SuccessДокумент6 страницDesign For System SuccessdharmayogaОценок пока нет

- R Guide For Multivariate AnalysisДокумент51 страницаR Guide For Multivariate AnalysisdharmayogaОценок пока нет

- Lean ProductionДокумент7 страницLean ProductiondharmayogaОценок пока нет

- Overview of Quality Gurus Deming, Juran, Crosby, Imai, Feigenbaum & Their ContributionsДокумент11 страницOverview of Quality Gurus Deming, Juran, Crosby, Imai, Feigenbaum & Their ContributionsVenkatesh RadhakrishnanОценок пока нет

- WassiДокумент12 страницWassiwaseem0808Оценок пока нет

- TransistorДокумент1 страницаTransistorXhaОценок пока нет

- Reservoir Rock TypingДокумент56 страницReservoir Rock TypingAffan HasanОценок пока нет

- Robocon 2010 ReportДокумент46 страницRobocon 2010 ReportDebal Saha100% (1)

- Instagram Dan Buli Siber Dalam Kalangan Remaja Di Malaysia: Jasmyn Tan YuxuanДокумент13 страницInstagram Dan Buli Siber Dalam Kalangan Remaja Di Malaysia: Jasmyn Tan YuxuanXiu Jiuan SimОценок пока нет

- Brain, Behavior, and Immunity: Alok Kumar, David J. LoaneДокумент11 страницBrain, Behavior, and Immunity: Alok Kumar, David J. LoaneRinaldy TejaОценок пока нет

- 13 Fashion Studies Textbook XIДокумент158 страниц13 Fashion Studies Textbook XIMeeta GawriОценок пока нет

- School Quality Improvement System PowerpointДокумент95 страницSchool Quality Improvement System PowerpointLong Beach PostОценок пока нет

- Common Size Analys3esДокумент5 страницCommon Size Analys3esSaw Mee LowОценок пока нет

- IP68 Rating ExplainedДокумент12 страницIP68 Rating ExplainedAdhi ErlanggaОценок пока нет

- Clean Agent ComparisonДокумент9 страницClean Agent ComparisonJohn AОценок пока нет

- Afu 08504 - International Capital Bdgeting - Tutorial QuestionsДокумент4 страницыAfu 08504 - International Capital Bdgeting - Tutorial QuestionsHashim SaidОценок пока нет

- Creatures Since Possible Tanks Regarding Dengue Transmission A Planned Out ReviewjnspeДокумент1 страницаCreatures Since Possible Tanks Regarding Dengue Transmission A Planned Out Reviewjnspeclientsunday82Оценок пока нет

- Numerical Methods: Jeffrey R. ChasnovДокумент60 страницNumerical Methods: Jeffrey R. Chasnov2120 sanika GaikwadОценок пока нет

- Course Tutorial ASP - Net TrainingДокумент67 страницCourse Tutorial ASP - Net Traininglanka.rkОценок пока нет

- Henny Penny 500-561-600 TM - FINAL-FM06-009 9-08Документ228 страницHenny Penny 500-561-600 TM - FINAL-FM06-009 9-08Discman2100% (2)

- Test Bank For Core Concepts of Accounting Information Systems 14th by SimkinДокумент36 страницTest Bank For Core Concepts of Accounting Information Systems 14th by Simkinpufffalcated25x9ld100% (46)

- Chapter 1: The Critical Role of Classroom Management DescriptionДокумент2 страницыChapter 1: The Critical Role of Classroom Management DescriptionJoyce Ann May BautistaОценок пока нет

- April 2017 Jacksonville ReviewДокумент40 страницApril 2017 Jacksonville ReviewThe Jacksonville ReviewОценок пока нет

- PCSE_WorkbookДокумент70 страницPCSE_WorkbookWilliam Ribeiro da SilvaОценок пока нет

- Corn MillingДокумент4 страницыCorn Millingonetwoone s50% (1)

- Advantages and Disadvantages of The DronesДокумент43 страницыAdvantages and Disadvantages of The DronesVysual ScapeОценок пока нет

- WhatsoldДокумент141 страницаWhatsoldLuciana KarajalloОценок пока нет

- Impact of Bap and Iaa in Various Media Concentrations and Growth Analysis of Eucalyptus CamaldulensisДокумент5 страницImpact of Bap and Iaa in Various Media Concentrations and Growth Analysis of Eucalyptus CamaldulensisInternational Journal of Innovative Science and Research TechnologyОценок пока нет

- Laws of MotionДокумент64 страницыLaws of MotionArnel A. JulatonОценок пока нет

- Conceptual FrameworkДокумент24 страницыConceptual Frameworkmarons inigoОценок пока нет

- APC Smart-UPS 1500VA LCD 230V: Part Number: SMT1500IДокумент3 страницыAPC Smart-UPS 1500VA LCD 230V: Part Number: SMT1500IDesigan SannasyОценок пока нет

- PW CДокумент4 страницыPW CAnonymous DduElf20OОценок пока нет

- Liber Chao (Final - Eng)Документ27 страницLiber Chao (Final - Eng)solgrae8409100% (2)